Professional Documents

Culture Documents

Procedure Bit Sharpener Machine

Uploaded by

Anthony ObaraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure Bit Sharpener Machine

Uploaded by

Anthony ObaraCopyright:

Available Formats

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 1 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

DOCUMENT CONTROL

TITLE GRINDING ATLAS COPCO SECOROC BQ3

FILENAME ATLAS COPCO SECOROC BQ3

DEPARTMENT HSE

DOCUMENT TYPE PROCEDURE

AUTHOR ARIS ANTHONY

CERTIFICATE OF ACCEPTANCE

PREPARED BY / RELEASED BY POSITION SIGNATURE DATE

Aris Anthony HSE Supervisor

REVIEW BY / ACCEPTED BY SIGNATURE DATE

I Gusti Nyoman PJO PSI - PT.TTN

Aris Anthony PJO PSI - PT.MSM

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 2 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

CONTENTS PAGE

1. PURPOSE / TUJUAN ................................................................................................ 4

2. SCOPE / TUJUAN ..................................................................................................... 4

3. RESPONSINILITY / PENANGGUNG JAWAB .................................................... 4

4. SEPECIAL REQUIREMENT / PERSYARATAN KHUSUS ………… ………. 4

5. PERSONNEL PROTECTIVE EQUIPMENT / PPE ………........... …………….. 4

6. SAFETY INSTRUCTION / INSTRUKSI KESELAMATAN ............................... 4

7. TECHNICAL DATA / DATA TEKNIS ................................................................... 4

8. TECHNICAL DESCRIPTION / DESKRIPSI TEKNIS ........................................ 4

9. CONTROL LEVER / TUAS KONTROL ................................................................ 4

10. GRINDING ACTIVITY / AKTIVITAS PENGGERINDAAN ............................ 4

A. GENERAL RULE / PERATURAN UMUM ...................................................... 4

B. SETTING GRINDING PRESSURE ..................................................................... 5

C. GRINDING HINTS ................................................................................................ 7

D. GRINDING INSTRUCTION ................................................................................ 9

1. AUTOMATIC FEEDING WITH PRE SET BIT GRINDING TIME ...... 10

2. AUTOMATIC FEEDING ONLY ................................................................. 11

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 3 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

1. PURPOSE / TUJUAN

This procedure describes for operate grinding machine atlas copco secoroc BQ3.

Prosedur ini menjelaskan mengenai pengoperasian mesin pengasah atlas copco secoroc BQ3

2. SCOPE / RUANG LINGKUP

This procedure is the minimum standart that is to be a adopted

Prosedur ini merupakan standar minimum yang dapat dipakai pada lokasi area kerja

3. RESPONSIBILITY / PENANGGUNG JAWAB

Supervisor responsibly to make sure bit grinder based on this procedure.

Pengawas bertanggung jawab untuk memastikan pengasahan bit sesuai dengan prosedur

4. SPECIAL REQUIREMENT

Bit grinder must has attended training to operate grinding machine.

Pengasah bit harus mengikuti pelatihan untuk mengoperasikan mesin grinding.

5. PERSONEL PROTECTIVE EQUIPMENT / PERALATAN PELINDUNG DIRI

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 4 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

6. SAFETY INSTRUCTION / INSTRUKSI KESELAMATAN KERJA

It can be dangerous to use the machine if the care and maintenance

instructions are not followed carefully

Sangat berbahaya menggunakan mesin Jika instruksi perawatan dan

perbaikan tidak diikuti

Before using the machine, read the operator’s instructions carefully and

then put them in a safe place for future reference

Sebelum menggunakan mesin, bacalah buku petunjuk operator dan

tempatkan pada kondisi yang aman

Emergency STOP

Tombol berhenti dalam keadaan darurat

Always replace damaged or illegible signs

Selalu ganti jika sticker / rambu keselamatan rusak

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 5 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

Before using the machine, read through these instruc-tions carefully

Sebelum menggunakan mesin, bacalah instruksinya dengan secara seksama

Important safety information is given at various points in these instructions

Informasi keselamatan penting diberikan diberbagai titik dalam petunjuk ini

Special attention must be paid to the safety information contained in frames and accompanied by

a warning symbol (triangle) and a “signal word“, as shown below

Perhatian khusus harus diberikan

DANGER ; Indicates an immediate risk that WILL result in serious injury or death if the

warning is not observed.

BAHAYA : Menunjukan resiko langsung AKAN menyebabkan cedera serius atau kematian jika

peringatan tersebut tidak diperhatikan

WARNING : Indicates hazards or hazardous procedures which COULD result in serious

injury or death if the warning is not ob-served.

PERINGATAN: Menunjukan bahaya atau prosedur berbahaya yang dapat mengakibatkan

cedera serius atau kematian jika peringatan tersebut tidak diperhatikan

CAUTION : Indicates hazards or hazardous procedures which COULD result in injury or

damage to equipment if the caution is not observed

PERHATIAN: Menunjukan bahaya atau prosedur berbahaya yang dapat mengakibatkan

cedera atau kerusakan pada peralatan jika peringatan tersebut tidak

diperhatikan

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 6 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

Observe the following general safety in-structions / Hal – hal keselamatn yang perlu

diperhatikan:

Make sure that there are no other personnel close to the grinding machine while grinding is in

progress

Pastikan bahwa tidak ada orang di dekat mesin gerinda ketika mesin gerinda sedang bekerja

Always wear goggles, protective clothing, gloves and ear protectors during grinding. Any local

regulations must also be observed

Selalu gunakan pelindung mata, pakaian pelindung, sarung tangan dan pelindung pendengara

selama pekerjaan menggerinda berlangsung. Dan perhatikan juga terhadap peraturan setempat

yang berlaku

Wear an approved dust mask or arrange an effective dust-extraction system. This is especially

important when grinding indoors

Pakailah masker debu yang disetujui atau masker debu yang efektif. Ini sangat penting ketika

melakukan pekerjaan menggerinda di dalam ruangan

The machine must not be used for any purpose other than that for which it is intended.

Mesin gerinda tidak boleh digunakan untuk tujuan lain selain tujuan yang dimaksudkan untuk

menggerinda bit

The machine must not be modified without the permis-sion of the manufacturer. Modifications

not approved by Atlas Copco Secoroc can incur the risk of serious injury to yourself and others

Mesin tidak boleh dimodifikasi tanpa izin dari pabrik. Modifikasi yang tidak disetujui oleh Atlas

Copco dapat menimbulkan resiko serius pada diri anda dan orang lain

Before intervening in the air or electrical systems, make sure there is no pressure in the air

system and that the elec-trical system is dead

Sebelum melakukan intervensi udara atau sistem kelistrikan, pastikan tidak ada tekanan pada

sistem udara dan sistem elektrik sudah mati

Beware of the risk of fire and explosion that could be initiated by sparks from the grinding work

Berhati – hati terhadap resiko potensi kebakaran atau ledakan yang dapat ditimbulkan oleh

percikan api saat melakukan penggerindaan

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 7 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

7. TECHNICAL DATA / DATA TEKNIK

DESCRIPTION REMARK

Maximum height of drill bit 650 mm

Maximum diameter of drill bit 178 mm

Minimum distance between buttons 3.5 mm

Output, spindle motor 3.00 kW

Output, table drive motor 0.25 kW

Output, cooling-fluid pump motor 0.44 kW

Voltage, working lights (40 W E27) 24 V

Air pressure, minimum 80 psi / 5,5 bar

Air pressure, maximum 101 psi / 7 bar

Air consumption 40 L/min

Speed, spindle (50 Hz) 14,900 r/min

Speed, spindle (60 Hz) 14,900 r/min

Speed, table (50 Hz) 22 r/min

Speed, table (60 Hz) 26 r/min

Capacity of cooling-fluid tank 22 L

Weight, exclusive of packaging 345 Kg

Noise level during grinding** 96,5 dB(A)

Sound power level during grinding*** 101 dB(A)

Vibration level during grinding**** < 2.5 m/s2

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 8 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

8. TECHNICAL DESCRIPTION / DESKRIPSI TEKNIKAL

A driving plate that is rotated by an electric motor via a worm gear

Sebuah pelat penggerak yang diputar oleh motor listrik melalui gigi cacing

A grinding plate that is placed on the driving plate. When the centring button on the feed lever is

pressed, an air cushion is created under the grinding plate to facilitate centring of the button that

is to be ground. When the centring button is released, the grinding plate is locked in position by a

vacuum

Plat penggiling yang diletakkan dipelat penggerak. Saat tombil pemusat pada tuas umpan

ditekan, bantalan udara digoreskan dibawah pelat gerinda untuk memudahkan pemusatan

tombol yang harus digiling. Saat tombol pemancar dilepas, pelat penggiling terkunci diposisinya

oleh vacuum

An indexing ring with grooves that correspond to the button configuration in the drill bit

Cincin pengindeksan dengan alur yang sesuai dengan konfigurasi pada bit pengeboran

A main holder, with a bit holder in accordance with the used shank size

Pemegang dudukan utama dengan dudukan bit (mata bor) sesuai dengan ukuran batang bit

A centring device that adopts the centre position automatically when the centring button is

pressed. The centring device is in its lower position when centering the button

Perangkat pemancar yang mengadopsi posisi tengah secara otomatis saat tombol pemantulan

ditekan.

A spindle that is rotated by an electric motor via a drive belt

Sebuah kumparan yang diputar oleh motor listrik melalui sabuk pengaman

A coolant tank with pump to circulate the flushing fluid used to cool the cemented-carbide

buttons and the grinding wheel. Flushing starts automatically when table rotation starts

Tangki pendingin dengan pompa untuk mengedarkan cairan pembilasan yang digunakan untuk

mendinginkan tombol karbida disemen dan roda gerinda. Pembilasan dimulai secara otomatis

saat rotasi table dimulai

The button to be ground must first be centred directly under the grinding wheel. Table rotation is

then started and the profiled grinding wheel fed down to the rotating drill bit. The centred

cemented-carbide button rotates inside the profiled groove in the grinding wheel and is quickly

restored to its spherical or ballistic shape

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 9 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

Tombol yang harus digiling terlebih dulu harus dipusatkan langsung dibawah roda gerinda.

Rotasi meja kemudian dimulai dan roda gerinda yang diumpankan ke bor yang berputar.

Tombol terpusat karbida berputar didalam alur yang diprofikan di roda gerinda dan dengan

cepat dipulihkan ke bentuk bola atau bentuk blasitik.

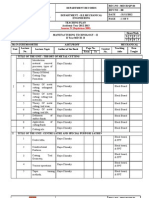

9. CONTROL LEVER / TUAS PENGENDALIAN

13. Filter / Regulator

Filter / Regulator

14. Pressure Gauge

Pengukur Tekanan

15. ON/OFF valve for air

ON/OFF untuk valve

udara

1. Feed Pressure Gauge

Pengukur Kecepatan Tekanan

2. Potentiometer /Potensiometer

3.Table Rotation & Coolant Pump

Tabel Rotasi & Pompa

Pendingin

4. Grinding Spindle /Pompa

Pendingin

5. Manual / Automatic /

Manual / Otomatis

6. Feed Movemenet Manual /

Pemindahan Kecepatan Manual

7. Feed Movemenet Automatic

Pemindahan Kecepatan

Automatis

8. Feed Pressure Regulator

Regulator Tekanan Kecepatan

9. Emergency Stop / Tombol

Darurat

10. Work Lights/ Lampu Kerja

11. Stoke Limiter / Pompa

Pendingin

12. Coolant pump

Pompa Pendingin

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 10 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

10. GRINDING AKTIVITY / AKTIVITAS PENGERINDAAN

Always check that there are no traces of explosive in the flushing holes of the drill bit

Selalu periksa apakah tidak ada bahan / material sisa dilubang pembilasan bor

To clean out the flushing holes, ONLY a wooden stick, a length of copper wire or flushing water

may be used

Untuk membersihkan lubang pembilasan, HANYA gunakan tongkat kayu, kawat tembaga panjang

atau dapat dilakukan pembilasan menggunakan air

Beware of the risks of fire or explosion that might be initiated by sparks from the grinding work

Waspadai dari resiko kebakaran yang mungkin terjadi dimulai dengan percikan api dari pekerjaan

penggilingan

Never remove the grinding guard from the machine

Jangan pernah melepas pengaman keselamatan pada mesin

Make sure that the grinding station or place of work is well ventilated

Pastikan bahwa lokasi area pekerjaan penggerindaan memiliki ventilasi udara yang baik

Always wear goggles, protective clothing, gloves, dust mask and hearing protection during

grinding

Selalu gunakan pelindung wajah, pakaian pelindung, sarung tangan, masker debu dan pelindung

pendengaran selama melakukan pekerjaan penggerindaan

Before removing or fitting a grinding wheel and before changing the drill bit, always switch OFF

the electricity supply

Sebelum memindahkan atau memasang batu gerinda, dan mengganti mata bit, selalu pastikan

kondisi sumber listrik di matikan (Swicth OFF)

The grinding wheel is hot immediately after grind-ing. Take care not to burn your fingers when

changing the grinding wheel

Roda / batu gerinda panas setelah penggerindaan. Berhati – hatilah agar tidak membakar tangan /

jari anda ketika mengganti roda/batu gerinda

To prevent injuries caused by crushing, avoid moving parts when the machine is running

Untuk mencegah cedera tangan, hindari bagian mesin yang bergerak saat mesin gerinda bekerja

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 11 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

A. General Rule

Adequate cooling is crucial to the service life of the grinding wheel, and also to the

grinding result. Poor cooling can result in heat stresses being “ground into“ the

cemented-carbide buttons, with button fracture as a result. The service life of the grinding

wheel falls dramatically if cooling is poor.

Pendinginan yang memadai sangat penting untuk masa kerja roda gerinda dan juga

hasil penggerindaan. Pendingian yang buruk dapat mengakibatkan tekanan panas ke

tombol karbida disemen dengan tombol frktur sebagai akibatnya. Masa kerja roda

penggiling akan rusak dengan cepat jia system pendinginan buruk

Pressing the grinding wheel too hard on to the cemented-carbide button will reduce the

service life of the wheel. Both the grinding wheel and the cemented-carbide button can

be damaged by excessive heat generation.

Menekan roda gerinda terlalu keras ke tombol semen karbida akan mengurangi masa

pakau roda. Baik toda penggiling dan tombol semen karbida dapat rusak oleh panas

yang berlebihan.

B. Setting the Grinding Pressure

To get the most out of your grinding machine, make sure that the operating pressure is set

to a level that provides an optimal grinding force of 150 N. This can be done by easy

means

Untuk mendapatka hasil maksimal dari mesin penggiling. Anda pastikan tekanan operasi

disetel ke tingkat yang memberikan kekuatan penggilingan optimal 150N. Ini dapat

dilakukan denagan mudah

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 12 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

Measure the distance between the grinding disc and the top button that is about to be

ground

Ukur jarak antara cakram penggiling dan tombol atas yang akan digiling

Search for the closest distance in the table

Cari jarak terdekat dengan tabel

Adjust the pressure settings accordingly

Sesuaikan pengaturan tekanan

C. Grinding Hints

The rate of bit wear depends on the rock formation, and is highest in rocks with a high

quartz content. A suitable grinding interval should be determined according to the rate of

bit wear. It is more economical to regrind too early rather than to suffer poor penetration

rates and risk damaging the drill bit through overdrilling. A few hints about the care of

drill bits:

When to regrind

Button bits should be reground when the penetration rate drops, or if any of the

cemented-carbide buttons are damaged (fractured buttons should be ground flat). It is

both practical and economical to redress the buttons when the wear flat reaches about 1/3

of the diameter of the button

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 13 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

Look out for “snake skin“

If microscopic fatigue cracks – so-called “snake skin“ – begin to appear on the cemented

carbide buttons, the cracks must be ground away. In any event, bits should be reground

after 300 metres of drilling at the most.

This should be done even if there are no visible signs of wear and the penetration rate

continues to be good. If snake-skin is not removed, the cracks will deepen and ultimately

result in button fracture

Always grind broken buttons flat

A drill bit can remain in service as long as the gauge buttons maintain the diameter of the

bit. Fractured buttons must always be ground flat to prevent chips of cemented carbide

from damaging the other buttons.

Avoid grinding the perimeter

Gauge button anti-taper has to be removed by grinding, although excessive reduction of

the bit diameter should be avoided. Leave about 2 mm of the wear flat.

If necessary, remove some of the bit-body steel below the gauge buttons, so that a

clearance (taper) of 0.5 mm is maintained.

Make sure that the flushing holes are open

D. Grinding Instruction

1. Automatic Feeding with pre set bit Grinding Time

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 14 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

Before grinding, make the following adjustments / Sebelum menggerinda

lakukan penyesuaian berikut:

1) Adjust the grinding pressure by means of the regulator and table

Sesuaikan tekanan gerinda dengan regulator dan meja

2) Adjust feed speed on the regulator, so that the grinding spindle does not go down

so fast that the grinding wheel strikes the button in the bit

Sesuaikan kecepatan dengan regulator, sehingga spindle penggerindaan tidak

turun secara cepat yang dapat menyebabkan roda/mata gerinda mengantam

tombol pada bit

3) Adjust the needle valve for the feed cylinder, so that the grinding wheel is

initially applied to the button with low pressure. This will help to prevent any

sharp edges on the button from breaking through the wheel’s diamond coating

(which would shorten its service life considerably)

Sesuaikan katup jarum untuk kecepatan cylinder, sehingga roda gerinda saat

awal pekerjaan dimulai pada tombol dengan tekanan rendah. Ini akan membantu

untuk mencegah setiap sisi tajam pada tombol untuk menembus lapisan berlian

roda (yang dapat mempersingkat masa pakai roda gerinda)

4) Attach the indexing ring (if used) to the drill bit and turn it so that the pin on the

ring lines up with one of the front flushing holes, and then tighten the screws.

Now fit the assembly into the main holder.

Pasang cincin penunjuk (jika digunakan) ke mata bor dan putar sehingga pin

pada garis cincin naik dengan salah satu lubang pembilasan depan dan

kemudian kencangkan skrup. Sekarang paskan rakitan / seting ke dudukan utama

5) Tilt the main holder to make it easier to fit the drill bit into the bit holder. Now tilt

back the main holder and make sure that it is locked on to the grinding plate

Miringkan dudukan utama agar lebih mudah disesuakan dengan mata bor di

dudukan. Kemudian miringkan kembali dudukan utama dan pastikan terkunci

pada pelat penggerindaan

6) Note that the gauge buttons should be ground first. Adjust therefore the angle of

the main holder to match the angle of the gauge buttons in the drill bit, so that the

centre-line of a gauge button is always vertical during grinding

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 15 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

Perhatikan bahwa tombol pengukur harus digerinda terlebih dahulu. Sesuaikan

karena itu merupakan sudut pemegang utama untuk mencocokan sudut tombol

pengukur dalam mata bor, sehingga garis tengah dari tombol pengukur selalu

vertical selama penggerindaan

7) Press and hold the centring button on the feed lever. The centring arm moves to

the centring position and an air cushion is formed under the grinding plate,

causing it to float.

Tekan dan tahan tombol pemusatan pada tuas. centering arm bergerak ke posisi

tengah dan bantalan udara terbentuk dibawah pelat penggerindaan,

menyebabkannya mengapung / melayang.

8) Align the grinding plate and press down the feed lever so that the button to be

ground locates exactly in the middle of the centring cup. (Make sure that the size

of the centring cup agrees with the size of the button)

Sejajarkan pelat penggerindaan dan tekan tuas pengumpan sehingga tombol

yang berada di tanah diletakkan tepat di tengah – tengah cangkir pemusatan.

(pastikan ukuran pada cangkir pemusatan sesuai dengan ukuran tombolnya)

9) Release the centring button, whereupon the grinding plate is locked into position

on the driver plate by a vacuum, and the centring arm retreats. Note that there is a

built-in delay in the system to ensure that the centring arm stays in the centring

position while the vacuum is being formed, in order to prevent the bit from

moving. The delay time can be adjusted by means of the time relay.

Lepaskan tombol pemusat, dimana piring penggiling terkunci pada posisi diatas

pelat dengan ruang hampa udara dan bantalan lengan.

Perhatikan bahwa ada penundaan dalam sistem untuk memastikan bahwa

centring arm tetap berada diposisi tengah ketika vacuum sedang terbentuk, untuk

mencegah agar mata bor tidak bergerak. Waktu tunda dapa disesuaikan.

10) Set the desired grinding time by turning the graduated wheel on the

potentiometer. Make sure that the light for AUTO is on

Atur waktu penggerindaan yang diinginkan denga memutar roda pada

potensiometer. Pastikan bahwa lampu AUTO menyala

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 16 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

11) Start the grinding spindle by pressing the button on the control panel.

Mulai penggerindaan spindle dengan menekan tombol pada kontrol panel

12) By means of the feed lever, lower the grinding wheel carefully toward the button

Dengan menggunakan tuas, turunkan roda gerinda secara dengan hati – hati

kearah tombol

13) When the grinding wheel is about 15 mm above the button, switch on the

automatic feed. Bit rotation starts, coolant begins to flow through the nozzle and

the feed cylinder is activated

Saat roda gerinda skitar 15 mm diatas tombol, aktifkan feed otomatis. Bit akan

berputar, pendingin mulai mengalir melalui nosel dan feed cylinder diaktifkan

14) Put the stroke limiter switch into ON position to lock the stroke position. Leave

the switch in this position until the last gauge button has been ground

Pasang saklat pembatas pukulan pada posisi ON untuk mengunci posisi pukulan.

Biarkan saklar dalam posisi ini sampai tombol terakhir telah di gerinda

15) When the pre-set grinding time expires, the feed cylinder releases, the flow of

coolant stops and table rotation stops. The grinding spindle rises to about 10 mm

above the button. If the button has not been ground enough, set the potentiometer

to a longer interval. If the button has been ground too much, a shorter grinding

interval should be set. As a rule, buttons are ground more quickly when the

grinding wheel is new

Ketika waktu penggerindaan yang ditentukan sebelumnya berakhir, feed cylinder

akan terbuka/terlepas, aliran pendingin berhenti dan rota table juga berhenti.

Spindel penggerindaan naik menjadi sekitar 10 mm diatas tombol. Jika tombol

belum cukup rata, atur potensiometer ke interval yang lebih panjang. Jika

tombolnya terlalu banyak, interval penggerindaan yang lebih pendek harus

diatur. Sebagai aturan, tombol – tombol akan digerinda lebih cepat ketika

roda/mata gerinda masih baru

16) Check the grinding result and adjust the potentiometer as necessary. Make sure

that full dome height is obtained, but always leave a 1-2 mm wear flat on top of

the button to avoid grinding away too much of the cemented carbide

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 17 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

Periksa hasil penggerindaan dan sesuaikan dengan potensiometer sesuai

kebutuhan. Pastikan tinggi lengkungan puncak diperoleh, tepi selalu biarkan 1-2

mm rata diatas tombol untuk menghindari penggilingan terlalu banyak karbida

semen

17) Index the next button by turning the drill bit

Pilih tombol berikutnya dengan sambil memutar drill bit

18) Switch on the automatic feed

Hidupkan kecepatan otomatis

19) Repeat steps 13–14 until all gauge buttons have been ground

Ulangi langkah 13 – 14 sampai semua tombol sudah digerinda

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 18 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

2. Automatic Feeding Only

1) See points 1–5 under “Automatic feeding with pre-set grinding time”

Lihat poin 1 – 5 pada langkah “ Pengumpan otomatis dengan waktu

pengerindaan pre set”

2) Start the grinding spindle and table rotation by pressing the respective buttons on

the control panel

Mulai poros penggerindaan dan meja putaran dengan menekan masing – masing

tombol pada control panel

3) By means of the feed lever, lower the grinding wheel carefully toward the button

Dengan menggunakan tuas pengumpan, turunkan roda gerinda secara hati – hati

kearah tombol

4) When the grinding wheel touches the button, activate and hold the switch until the

desired grinding result has been obtained

Ketika roda gerinda menyentuh tombol, aktifkan dan tahan saklar sampai hasil

pengerindaan yang diinginkan diperoleh

5) Check the grinding result. Make sure that full dome height is obtained, but always

leave a 1-2 mm wear flat on top of the button to avoid grinding away too much of

the cemented carbide

Periksa hasil penggerindaan, pastikan tinggi lengkungan puncak telah terpenuhi,

tetapi selalu tinggalkan 1 – 2 mm rata diatas tombol untuk menghindari

penggerindaan terlalu banyak karbida semen

6) Stop the table rotation

Hentikan putaran tabel

7) Index the next button by turning the drill bit

Tekan tombol berikutnya dengan memutar bit

8) Repeat steps 3–7 until all gauge buttons have been ground

Ikuti langkah 3 – 7 sampai semua tombol pengukur telah di gerinda

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 19 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

For best grinding results and wheel life:

Centralize the buttons precisely

Pusatkan / tempatkan tombol secara tepat

Make sure there is a generous flow of coolant at the point of contact

Pastikan ada aliran pendingin yang banyak pada titik kontak

Gind carefully and do not rush

Genggam dengan hati – hati dan jangan terburu - buru

Let the machine do the work

Biarkan mesin melakukan pekerjaan

Do not try to speed up grinding by adding hand pressure to the feed lever

Jangan mencoba untuk mempercepat grinding dengan menambahkan tekanan

tangan kel tuas

Use original grinding wheels only

Gunakan hanya spare part roda gerinda yang asli

Do not use higher than recommended pressures

Jangan gunakan tekanan yang lebih tinggi dari yang direkomendasikan

E. Grinding Wheel

Diamond grinding wheels are sensitive to impact, vibration and heat

Roda penggiling (mata gerinda) sensitive terhadap benturan, getaran dan panas

The grinding wheel must therefore work without vibration and with generous cooling

Roda gerinda harus bekerja tanpa getaran dan dengan pendingin

The grinding wheel must be mounted with the marking on the wheel facing away

from the grinding machine. Use original wheels only

Roda gerinda harus dipasang dengan tanda pada roda yang menhadap jauh dari

mesin penggiling. Gunakan roda asli saja

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 20 dari 21

Document : PSI-SOP-008

STANDARD OPERATING PROCEDURES

Revision : 01

GRINDING ATLAS COPCO SECOROC BQ3

MESIN GERINDA ATLAS COPCO SECOROC BQ3 Date issued : 01 March 2018

F. Steel Removal

In the case of heavy bit wear, one should remove the steel around the button to obtain

maximum service life of the diamond grinding wheel. This is done in the simplest way by

means of using the grinding wheel for removing body steel, alternatively by using a

straight silicon-carbide grinding wheel or by sand-blasting.

Dalam kasus penggunaan bit yang berat, sesorang harus melepaskan baja disekitar

tombol untuk mendapatkan masa kerja maksimal dari mata gerinda (grinding wheel

diamond).

Hal ini dilakukan dengan cara yang paling sederhana dengan menggunakan roda

gerinda (mata gerinda) untuk melepaskan baja atau dengan cara kita menggiling roda

gerinda seilikon – karbida lurus atau dengan kertas amplas

Prepared by : Aris Anthony

Rev Date : Expired Date :

Revisi : 01

01 Feb 2018 01 Feb 2021

Departemen : HSE Document : Procedure Operational Page : 21 dari 21

You might also like

- Annex 1 0331-ESP-UDS-00-00-046 Technical - SpecificationDocument33 pagesAnnex 1 0331-ESP-UDS-00-00-046 Technical - SpecificationOfer GardenNo ratings yet

- 10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitDocument15 pages10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitsithulibraNo ratings yet

- Piping Cleaning ProcedureDocument13 pagesPiping Cleaning ProcedureKandang SawanganNo ratings yet

- Coslstrike: Hse CaseDocument33 pagesCoslstrike: Hse CaseafsartalaNo ratings yet

- Personal Protective Equipment of Iii Category Procedure: Doc. N.: 508-SZV-17 Rev. 01 Date: 08-Jun-2016Document29 pagesPersonal Protective Equipment of Iii Category Procedure: Doc. N.: 508-SZV-17 Rev. 01 Date: 08-Jun-2016arnauld batchiNo ratings yet

- HyNet CCUS Pre-FEED KKD WP5 HYN01-03 Rev 03 Flow Assurance ReportDocument88 pagesHyNet CCUS Pre-FEED KKD WP5 HYN01-03 Rev 03 Flow Assurance ReportSEGUNNo ratings yet

- BBS - Working Procedure For Gathering Line PrecommissioningDocument34 pagesBBS - Working Procedure For Gathering Line PrecommissioningDarmawanNo ratings yet

- 06 Liquefaction Plant Bact AnalysisDocument137 pages06 Liquefaction Plant Bact AnalysisSergio PereiraNo ratings yet

- ANG-RGN-OSS-QMS-PRO-0052 Rev A1 Angola Regional Anomaly Management ProcedureDocument25 pagesANG-RGN-OSS-QMS-PRO-0052 Rev A1 Angola Regional Anomaly Management ProcedureKaoutar KaddouriNo ratings yet

- Suban Compression Project: Document Title: Equipment Protection and Preservation Procedure at SiteDocument23 pagesSuban Compression Project: Document Title: Equipment Protection and Preservation Procedure at SiteMikiRoniWijayaNo ratings yet

- 1602041044-MD-04-MT-RSANA-PD-076 Rev.00 Maintenance Procedure For TOC-COD Analyzer PDFDocument20 pages1602041044-MD-04-MT-RSANA-PD-076 Rev.00 Maintenance Procedure For TOC-COD Analyzer PDFKy Nguyen TrongNo ratings yet

- HAV-EXT-HS-PRO-0144: Hot Work Safety ProcedureDocument14 pagesHAV-EXT-HS-PRO-0144: Hot Work Safety Procedureum erNo ratings yet

- KAK-ANA-CFS-CMS-0005 Demolition of Concrete Pavement Rev.a00Document8 pagesKAK-ANA-CFS-CMS-0005 Demolition of Concrete Pavement Rev.a00rickie7809No ratings yet

- Riwayat Revisis/: Revision HistoryDocument31 pagesRiwayat Revisis/: Revision HistoryVenom Ary BayuNo ratings yet

- CMAS Training Plan: BP Tangguh LNGDocument17 pagesCMAS Training Plan: BP Tangguh LNGAenur RofiiqNo ratings yet

- Inspection and Test Plan (ITP)Document7 pagesInspection and Test Plan (ITP)Zulfokar FahdawiNo ratings yet

- Procedure System of Flange Management Procedure (Site)Document14 pagesProcedure System of Flange Management Procedure (Site)Imtiyaz Akhtar94% (16)

- HSE Plan For Construction ?Document53 pagesHSE Plan For Construction ?BRENDANo ratings yet

- BAP-00-80-PE-0103-R R.2 Physical Progress Measurement Procedure - ASF - A 18.05.05Document37 pagesBAP-00-80-PE-0103-R R.2 Physical Progress Measurement Procedure - ASF - A 18.05.05Jan Richardo Gultom100% (1)

- BESA SAT Procedure Rev 0 YokogawaDocument61 pagesBESA SAT Procedure Rev 0 YokogawaWan Mohd Fauzan bin Wan NawiNo ratings yet

- VPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Floating Ball ValvesDocument21 pagesVPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Floating Ball ValvesXmanyeyNo ratings yet

- Contractor Monthly Report ProcedureDocument8 pagesContractor Monthly Report ProcedureAl Hamra Ayashofiya100% (1)

- KAK-ANA-CFS-CMS-0002 Concrete Works Rev.a02Document10 pagesKAK-ANA-CFS-CMS-0002 Concrete Works Rev.a02rickie7809No ratings yet

- 6.4 Procedure For InsulationDocument11 pages6.4 Procedure For Insulationrendra syamNo ratings yet

- UntitledDocument65 pagesUntitledamal benothmenNo ratings yet

- 5691 Gen Sa RPT 0016 0Document8 pages5691 Gen Sa RPT 0016 0ĐiệnBiênNhâmNo ratings yet

- Hydrocarbon Pipelines - Hydrostatic Testing of Pipelines: Company SpecificationDocument34 pagesHydrocarbon Pipelines - Hydrostatic Testing of Pipelines: Company SpecificationPhilip OjugohNo ratings yet

- IMP206 PipelinesDocument11 pagesIMP206 PipelinesMurali KumaraguruNo ratings yet

- Laporan Hazop SoekantoDocument15 pagesLaporan Hazop SoekantolydiaNo ratings yet

- Instr Procedure - 1y - PM - 28-K - 3112Document33 pagesInstr Procedure - 1y - PM - 28-K - 3112ofon OML102No ratings yet

- CAS1969-2P01-05-176-001 - A - Functional Description-Bauxite StockyardDocument5 pagesCAS1969-2P01-05-176-001 - A - Functional Description-Bauxite StockyardAnindya ananda putriNo ratings yet

- SOP For Condenser Rubber Ball Cleaning System HBSDocument8 pagesSOP For Condenser Rubber Ball Cleaning System HBSAbeer arifNo ratings yet

- Pressure Hydrostatic Test: Technical Procedure 03Document5 pagesPressure Hydrostatic Test: Technical Procedure 03INSTRUCAL CALIBRATION SERVICESNo ratings yet

- Primary Reformer Bact 8-9-19Document13 pagesPrimary Reformer Bact 8-9-19ginga716No ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document17 pagesRas Markaz Crude Oil Park Project (Phase1)anil pkNo ratings yet

- Reharping Tube ProcedureDocument15 pagesReharping Tube ProcedureerfanNo ratings yet

- Advanced Technical Service Company: Calibration Laboratory Single Gas Detector (BW Clip Real Time)Document9 pagesAdvanced Technical Service Company: Calibration Laboratory Single Gas Detector (BW Clip Real Time)MANIVASAGANNo ratings yet

- MZ-000-CCX-HS-PRO-00008 Barriers, Signs and Signals Rev 0Document15 pagesMZ-000-CCX-HS-PRO-00008 Barriers, Signs and Signals Rev 0Abílio Júnior MubaiNo ratings yet

- Executive SummaryDocument38 pagesExecutive Summaryimpexcoscopharmacist100% (1)

- Sop Opet 043Document4 pagesSop Opet 043lets createNo ratings yet

- BEMS-MP-18 SHEQ Emergency Response PlanDocument131 pagesBEMS-MP-18 SHEQ Emergency Response Planremember100% (2)

- EHK-IKPP-IS-CAL-002 Pressure Safety Valve Sizing Calculation Rev. 2Document15 pagesEHK-IKPP-IS-CAL-002 Pressure Safety Valve Sizing Calculation Rev. 2nathaNo ratings yet

- 033 BOD IncubatorDocument4 pages033 BOD Incubatorbhavna sharmaNo ratings yet

- Flange Management Procedure IFUDocument32 pagesFlange Management Procedure IFUMarvan Audy Buriko100% (1)

- AzSPU SSOW Procedure For AuthorisationDocument18 pagesAzSPU SSOW Procedure For AuthorisationAmir M. ShaikhNo ratings yet

- 001.17033.000230 - Da001 - Rev 01 - CDocument70 pages001.17033.000230 - Da001 - Rev 01 - CSérgio RibeiroNo ratings yet

- 1.13 - Hot Tapping Rev A0Document19 pages1.13 - Hot Tapping Rev A0UmarNo ratings yet

- SULBAGUT-1 Document Comment Response Sheet (CRS) : SBG1-00-0H-3-MST-0029Document31 pagesSULBAGUT-1 Document Comment Response Sheet (CRS) : SBG1-00-0H-3-MST-0029zainudin simonNo ratings yet

- GTC Installation Method Rev Rev.0B30.03Document26 pagesGTC Installation Method Rev Rev.0B30.03Yery Awan Susanto100% (1)

- PA Site Process Safety ConceptDocument49 pagesPA Site Process Safety Conceptmehul10941100% (1)

- Lifting Operation ProcedureDocument25 pagesLifting Operation ProcedureImtiyaz Akhtar100% (6)

- Provision of Engineering, Procurement, Construction, Installation & Commissioning (Epcic) For Yetagun Acid Gas Removal Unit (Agru) ProjectDocument15 pagesProvision of Engineering, Procurement, Construction, Installation & Commissioning (Epcic) For Yetagun Acid Gas Removal Unit (Agru) Projectmohsin moin100% (1)

- Air Jet Leak Test ProcedureDocument9 pagesAir Jet Leak Test ProceduredanangNo ratings yet

- Safe Use of Compressed Gases.Document18 pagesSafe Use of Compressed Gases.QHSE BTGNo ratings yet

- 160B Highrange Toyota: Sti HeadlampDocument20 pages160B Highrange Toyota: Sti HeadlampmarcoNo ratings yet

- Pump Centrifugal Pre Commissioning ITPDocument10 pagesPump Centrifugal Pre Commissioning ITPMohamad IbrahimNo ratings yet

- SPCC C SH PR 0004 Environmental Management Procedures F1Document26 pagesSPCC C SH PR 0004 Environmental Management Procedures F1ismayil AdishovNo ratings yet

- Hse Plan For Construction, Commissioning and Pre-CommissioningDocument53 pagesHse Plan For Construction, Commissioning and Pre-Commissioningthinkpad75% (12)

- LTJ-PGAS-GTLG-HSE-PR-005 - Prosedur Investigasi Dan Pelaporan Insiden KecelakaanDocument20 pagesLTJ-PGAS-GTLG-HSE-PR-005 - Prosedur Investigasi Dan Pelaporan Insiden KecelakaanAulia AkbarNo ratings yet

- Terex 5022 Service Manual Global ENDocument1,040 pagesTerex 5022 Service Manual Global ENWere Wolf88% (17)

- ME Manual AppendixDocument641 pagesME Manual AppendixAnonymous uTO1WI0% (1)

- Amp Micro Project 2-Converted EditDocument18 pagesAmp Micro Project 2-Converted Editaryan patilNo ratings yet

- Technical Proposal: Inquiry No.: Proposal No.: 9089873-TECH Revision: 0Document13 pagesTechnical Proposal: Inquiry No.: Proposal No.: 9089873-TECH Revision: 0Martin DanzeNo ratings yet

- Qualichem Straight OilDocument8 pagesQualichem Straight OiltribolasNo ratings yet

- Railtech Aluminothermic Welding ManualDocument35 pagesRailtech Aluminothermic Welding ManualIrwan Joe100% (2)

- Mrs. Mbadugha Augustina O. (Instututionn Based Supervisor)Document31 pagesMrs. Mbadugha Augustina O. (Instututionn Based Supervisor)Michael Chris50% (2)

- Oscm ReportDocument18 pagesOscm Reportavinashdeshmukh216No ratings yet

- Visual Inspection of CrankshaftsDocument40 pagesVisual Inspection of Crankshaftsbetoven8437No ratings yet

- Summary AttendanceDocument37 pagesSummary AttendancedwfajarNo ratings yet

- Product Information Flyer: CIMSTAR® 10-570-HFP With FACT™Document2 pagesProduct Information Flyer: CIMSTAR® 10-570-HFP With FACT™sobheysaidNo ratings yet

- Manufacturing - Engg Lab Vendor Details For Limited TenderingDocument9 pagesManufacturing - Engg Lab Vendor Details For Limited TenderingÐrSúÿôg JhavarNo ratings yet

- Plane and Profile With The Unimat - 100% Quality at A Great PriceDocument20 pagesPlane and Profile With The Unimat - 100% Quality at A Great PricePrince NeroNo ratings yet

- Tool Wear and Cutting Fluid LatheDocument17 pagesTool Wear and Cutting Fluid LatheGnanakumar GanesanNo ratings yet

- Mt-II Lesson PlanDocument5 pagesMt-II Lesson PlanK Nallathambi K NallathambiNo ratings yet

- Bhel Block 3Document35 pagesBhel Block 3Aditya Aggarwal62% (13)

- IEC 60417 ISO 7000 - Graphical Symbols For Use On EquipmentDocument48 pagesIEC 60417 ISO 7000 - Graphical Symbols For Use On EquipmentJNo ratings yet

- Design of Mini Abrasive Vertical Belt Grinding Machine: September 2020Document6 pagesDesign of Mini Abrasive Vertical Belt Grinding Machine: September 2020Venkatesh ChallaNo ratings yet

- Centralized Employment Notice (Cen) No.03/2018: Declaration For Scribe Annexure-V (D)Document9 pagesCentralized Employment Notice (Cen) No.03/2018: Declaration For Scribe Annexure-V (D)NISHANT bhuNo ratings yet

- IAB 089r4 12 PartII International Welders Guideline January 2012 PDFDocument119 pagesIAB 089r4 12 PartII International Welders Guideline January 2012 PDFIgor GrujićNo ratings yet

- PGA PFA: Punch Former Punch GrinderDocument8 pagesPGA PFA: Punch Former Punch Grindersomkiat kongprasiatNo ratings yet

- Machine ToolDocument2 pagesMachine ToolMARIA JULIANA PENA MENDEZNo ratings yet

- Catalog330 NORTONDocument68 pagesCatalog330 NORTONPeter JoselitoNo ratings yet

- 22.service Machines For Flat CardsDocument24 pages22.service Machines For Flat CardsCraig MartinNo ratings yet

- 2013 - PUT - Catalog End Mill DescriptionsDocument52 pages2013 - PUT - Catalog End Mill DescriptionsfgrefeNo ratings yet

- Assignment 1 BMFS 4613Document12 pagesAssignment 1 BMFS 4613Shafi AbdullahNo ratings yet

- Hunger VKM3.1 Valve Griding Machine PDFDocument2 pagesHunger VKM3.1 Valve Griding Machine PDFOrlando GalvanNo ratings yet

- Aurelian Vlase Tehnologia Constructiilor de Masini PDFDocument509 pagesAurelian Vlase Tehnologia Constructiilor de Masini PDFCristea Bogdan100% (5)

- NC-CNC 1Document155 pagesNC-CNC 1mukul vermaNo ratings yet

- Ethiopian Engine Shop PDFDocument28 pagesEthiopian Engine Shop PDFslam12125No ratings yet