Professional Documents

Culture Documents

Wps For Aluminium Welding PDF

Wps For Aluminium Welding PDF

Uploaded by

saifullah629Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wps For Aluminium Welding PDF

Wps For Aluminium Welding PDF

Uploaded by

saifullah629Copyright:

Available Formats

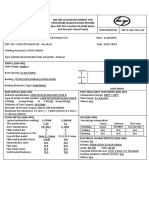

CR ASIA 802, Windfall,Sahar Plaza,J.B.

Nagar,

(India)

CO.,LTD. Andheri(east),Mumbai-400 059

Tel : (91-22) 65701556-57

Fax : (91-22) 26821317

www.crasia.net

WELDING PROCEDURE SPECIFICATION (WPS)

WPS No. : WPS-P15-H-01 (Page 1 of 2)

WRITTEN BY : VISHAL DATE : 12/2/2016

SUPPORTING P.Q.R.(

PQR-P15-H-01

WPS REVISION No. 0 DATE :

WELDING PROCESSGTAW TYPE : Manual

ALL WELDING SHALL BE IN ACCORDANCE WITH, ASME IX & ASME/ ANSI B31.3

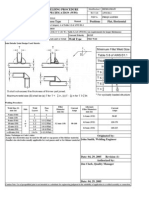

JOINT (QW-402)

JOINT DESIGN As Per Drawing

BACKING : NA

BACKING MATERIAL( NA

(REFER TO BOTH BACKING AND RETAINERS)

BASE METAL (QW-403)

P.No. : 25 GROUP No. : NA TO P #N## GROUP No. :

OR

SPECIFICATION AND TYPE / SB 241 A95083

TO

SPECIFICATION AND TYPE / SB 241 A95083

THICKNESS RANGE : 6

BASE METAL GROOVE11.08 FILLET All

PIPE DIA. RANGE GROOVE

1' to Unlimited FILLET All

OTHER joint design is non-essential varbiale so any change in it do not require to prepare pqr separatly

FILLER METAL (QW-404)

WELD PASS(ES) GTAW SMAW

SPEC. No. (SFA) 5.1 5.1

AWS No.(CLASS) ER5183 ER5183

F-No. F22 F22

A-No. NA NA

TRADE NAME Esab, D&Esab,

H D& H

SIZE OF FILLER METALS 1.6 mm 1.6 mm

Deposited weld metal :

Electrode Flux (Class) bare solidcoated

wire electrode

Flux Trade Name

Consumable Insert

WELD METAL THICKNESS R GROOVE 4.12mm max

7 max

FILLET all all

Other :

PREPARED BY : WITHNESSED & CERTIFIEDAPPROVED BY :

CRAI QA/QC CLIENT

F-QC-33 Rev.00 Issue date : June 19, 2006

SIGNATURE : SIGNATURE : SIGNATURE :

NAME : NAME : NAME :

DATE : DATE : DATE :

F-QC-33 Rev.00 Issue date : June 19, 2006

CR ASIA 802, Windfall,Sahar Plaza,J.B. Nagar,

(India) Andheri(east),Mumbai-400 059

CO.,LTD. Tel : (91-22) 65701556-57

Fax : (91-22) 26821317

www.crasia.net

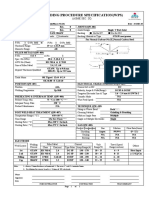

WELDING PROCEDURE SPECIFICATION (WPS)

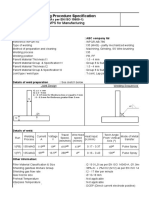

WPS No. : WPS-P15-H-01 (Page 2 of 2)

POSITION (QW-405) POST WELD HEAT TREATMENT (QW-407

POSITION(S) GROOVE 6 G TEMPERATURE RANG NA

WELDING PROGRESSIOUPHILL/ forehand HEATING CYCLE NA

POSITION(S) FILLET All SOAK PERIOD NA

PREHEAT (QW-406) GAS (QW-408)

PREHEAT TEMP.MIN. ambient (26 c) SHIELDING GAS(ES) Argon

INTERPASS TEMP. MAXNA COMPOSITION 99.99%

PREHEAT MAINTENANNA FLOW RATE 9.4-11.8 Ltr/ Min

GAS BACKING NA

ELECTRICAL CHARACTERISTIC (QW-409)

CURRENT(AC OR DC) AC POLARITY Straight & Reverse

AMPS (RANGE) 60-450 VOLTS (RANGE) 10-20

Electrode Wire Feed Speed Rate :

TUNGSTEN ELECTRODE (SIZE AND2.4 mm Tugstan 2% Throated or EW Th2

Mode Of Metal Transfer :

WELD FILLER METAL CURRENT VOLT TRAVE

LAYER PROCESS CLASS DIA POLARITY RANGE heat inputSPEED(mm

AMP RANGE

Root GTAW ER5183 1.6 AC 60-80 10-15 50-55

Hot GTAW ER5183 1.6 AC 60-80 10-15 50-55

Fill up GTAW ER5183 2.4 AC 125-160 15-20 50-55

Final GTAW ER5183 2.4 AC 125-160 15-20 50-55

TECHNIQUE (QW-410)

STRING OR WEAVE BERoot Pass stringer , Fill Up & Final weave bead

ORIFICE OR GAS CUP S6.5mm/13mm

Multiple or Single electrode

Travel Speed (ran: mm/min

Peening

Method Of Back Gouging

Oscillation :

Initial or interpass cleaning :

Other :

PREPARED BY : APPROVED BY :

CRAT QA/QC CLIENT

F-QC-33 Rev.00 Issue date : June 19, 2006

SIGNATURE : SIGNATURE :

NAME : NAME :

DATE : DATE :

F-QC-33 Rev.00 Issue date : June 19, 2006

RE SPECIFICATION (WPS)

-P15-H-01 (Page 1 of 2)

ACCORDANCE WITH, ASME IX & ASME/ ANSI B31.3

T (QW-402)

TAL (QW-403)

NA

ETAL (QW-404)

F-QC-33 Rev.00 Issue date : June 19, 2006

F-QC-33 Rev.00 Issue date : June 19, 2006

RE SPECIFICATION (WPS)

-P15-H-01 (Page 2 of 2)

OST WELD HEAT TREATMENT (QW-407)

GAS (QW-408)

RACTERISTIC (QW-409)

TRAVEL

SPEED(mm/mm)

50-55

50-55

50-55

50-55

QUE (QW-410)

F-QC-33 Rev.00 Issue date : June 19, 2006

F-QC-33 Rev.00 Issue date : June 19, 2006

You might also like

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium Weldingvishal bailur50% (2)

- Hand ToolsDocument4 pagesHand Toolsayessa evangelistaNo ratings yet

- Certified International Welding Engineer PDFDocument2 pagesCertified International Welding Engineer PDFSridharan Chandran100% (1)

- Welding Process NumbersDocument1 pageWelding Process Numbersthho84No ratings yet

- WPS For Smaw06-001 (Pipe 6G CS)Document10 pagesWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- Welding Processes and EquipmentDocument167 pagesWelding Processes and EquipmentTAF150850No ratings yet

- WPS 136 FWDocument1 pageWPS 136 FWsocaugusto100% (1)

- Smaw Fillet Aws d1.1Document1 pageSmaw Fillet Aws d1.1fallalovaldes100% (1)

- Metrode WPS SuperduplexDocument4 pagesMetrode WPS SuperduplexClaudia Mms100% (3)

- Asme B107.1-2002Document26 pagesAsme B107.1-2002PunkR0ckz100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Joint Detail (Qw-402)Document2 pagesJoint Detail (Qw-402)Nitesh Patel100% (3)

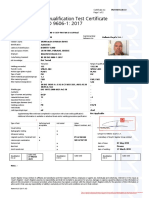

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 pagesWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- IWE SubjectsDocument2 pagesIWE SubjectsAdnan Rana100% (4)

- P-WPS 135 - Mag (S355JR)Document9 pagesP-WPS 135 - Mag (S355JR)Tarun Patel100% (1)

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline SungahidNo ratings yet

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelNo ratings yet

- WPS, PQR 041Document21 pagesWPS, PQR 041swamykommula100% (1)

- Asme Ix - WPS - Gtaw Fcaw Gmaw PDFDocument1 pageAsme Ix - WPS - Gtaw Fcaw Gmaw PDFThe Welding Inspections CommunityNo ratings yet

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingaamirtec301100% (2)

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Mabel Engineers Pvt. LTD Priliminary Welding Procedure Specification (PWPS) EN ISO 15609-1 2004Document2 pagesMabel Engineers Pvt. LTD Priliminary Welding Procedure Specification (PWPS) EN ISO 15609-1 2004dayalram100% (1)

- Welding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)Document2 pagesWelding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)saioman100% (7)

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Weld Test Checklist: Welder (S) DetailsDocument2 pagesWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- Specification Type or Grade AWS Group No. Thickness Size (NPS) Schedule DiameterDocument3 pagesSpecification Type or Grade AWS Group No. Thickness Size (NPS) Schedule Diametercentaury2013No ratings yet

- Shielding Gases ACM Vs CO2Document34 pagesShielding Gases ACM Vs CO2ukavathekar100% (2)

- WPSDocument5 pagesWPSParshottam Brahmxatriya100% (1)

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- Aluminim WPSDocument2 pagesAluminim WPSKarthikeyan ShanmugavelNo ratings yet

- En Iso 9606 1 ADocument2 pagesEn Iso 9606 1 AvitharvanNo ratings yet

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2017Document2 pagesWelder Qualification Test Certificate BS EN ISO 9606-1: 2017idthdrayahbdnhauniNo ratings yet

- Macro Examination StandardDocument4 pagesMacro Examination StandardMohd Akmal Shafie100% (1)

- Submerged Arc Welding: by L D PoyyaraDocument29 pagesSubmerged Arc Welding: by L D PoyyaraSapan KansaraNo ratings yet

- WPS GmawDocument2 pagesWPS Gmawasikur100% (6)

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Document2 pagesWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialNo ratings yet

- B31.3 Table 330.1.1 Preheat TempDocument1 pageB31.3 Table 330.1.1 Preheat TempHusam Ahmed100% (1)

- Old Questions IWEDocument7 pagesOld Questions IWErohit mathankerNo ratings yet

- Wps Magi Tig ExempleDocument6 pagesWps Magi Tig ExempleDanem HalasNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Unitor Maintenance and Repair Welding: The Solutions GuideDocument1 pageUnitor Maintenance and Repair Welding: The Solutions GuideNuzhat Ali100% (1)

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Wps SmawDocument1 pageWps SmawFedericoC67% (3)

- Weld Rod SelectionDocument2 pagesWeld Rod SelectionRads53100% (1)

- WPS-PQR Gmaw LtiDocument2 pagesWPS-PQR Gmaw Ltibgonzalez198150% (2)

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- WPS&PQR For PipeDocument5 pagesWPS&PQR For PipeKAMALNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- 16 2013 Taps and Dies EbookDocument46 pages16 2013 Taps and Dies Ebookwhitelizard2001No ratings yet

- Aluminium 2014 T6 Sheet SuppliersDocument13 pagesAluminium 2014 T6 Sheet Supplierssanghvi overseas incNo ratings yet

- Tap Proses PDFDocument5 pagesTap Proses PDFSyaldiles PutriNo ratings yet

- Plastic Mould SteelDocument20 pagesPlastic Mould SteeldocumentosvaltierraNo ratings yet

- Next Exam 8: 5 Semester (Mechanical Engineering) Advanced Manufacturing Process Unit-4 (Special Purpose Machines)Document2 pagesNext Exam 8: 5 Semester (Mechanical Engineering) Advanced Manufacturing Process Unit-4 (Special Purpose Machines)Kamendra KumarNo ratings yet

- Machined Components: S E C T I O N 4Document10 pagesMachined Components: S E C T I O N 4solquihaNo ratings yet

- Sheet Metal Box - Step by StepDocument5 pagesSheet Metal Box - Step by Stepapi-639942719No ratings yet

- Shapers, Planner and SlottersDocument121 pagesShapers, Planner and SlottersReyven ReconNo ratings yet

- Ts 010Document69 pagesTs 010Satheesh Gopindaran100% (1)

- 980 TDocument6 pages980 TDiego Fernando Cadena ArangoNo ratings yet

- Mhse23040029b ObdDocument2 pagesMhse23040029b ObdhennrycaspersNo ratings yet

- Advanced Manufacturing Processes (ALL SLIDES Gaurav Arora)Document259 pagesAdvanced Manufacturing Processes (ALL SLIDES Gaurav Arora)faizNo ratings yet

- Tap - Drill and Clearance Hole - ChartDocument5 pagesTap - Drill and Clearance Hole - Chartbman0051401No ratings yet

- 1-Metal Forming Week1 - 2Document17 pages1-Metal Forming Week1 - 2Abdelrahman AshrafNo ratings yet

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryDocument1 pageMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalNo ratings yet

- Sandvik Drilling Tools Care and MaintenanceDocument25 pagesSandvik Drilling Tools Care and Maintenancekukuh atmanto100% (1)

- European Steel and Alloy Grades: 36nicrmo16 (1.6773)Document2 pagesEuropean Steel and Alloy Grades: 36nicrmo16 (1.6773)farshid Karpasand100% (1)

- Polytechnic Classes: Civil Engineering DepartmentDocument18 pagesPolytechnic Classes: Civil Engineering Departmentmohd tariqueNo ratings yet

- Weller LT-series PDFDocument13 pagesWeller LT-series PDFsandrorrrNo ratings yet

- Forging Die of SpannerDocument16 pagesForging Die of Spannervirendra pawarNo ratings yet

- ASME B18.2.1 Hex Flange ScrewsDocument1 pageASME B18.2.1 Hex Flange ScrewsMohakumar MaranNo ratings yet

- Mbe3119 Part2 Lect5 PDFDocument35 pagesMbe3119 Part2 Lect5 PDFChoi TomNo ratings yet

- Chapter 5 WeldingDocument16 pagesChapter 5 Weldingchoriya007No ratings yet

- T 1844 F Abrasive WheelsDocument26 pagesT 1844 F Abrasive WheelsrubelNo ratings yet

- Built in - SP - Bi B (E) 07cDocument4 pagesBuilt in - SP - Bi B (E) 07cpc100xohmNo ratings yet

- Technical Datasheet: DIN 84 DIN 963 DIN 965 DIN 7985Document21 pagesTechnical Datasheet: DIN 84 DIN 963 DIN 965 DIN 7985justine lopezNo ratings yet

- Hardinge 5-C Tooling CatalogDocument12 pagesHardinge 5-C Tooling CatalogPedro VianaNo ratings yet

- Catalogo de Bornes ElectricosDocument53 pagesCatalogo de Bornes ElectricosWalter ChavezNo ratings yet