Professional Documents

Culture Documents

HPP 2504 002R0

Uploaded by

Yerania SalinasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HPP 2504 002R0

Uploaded by

Yerania SalinasCopyright:

Available Formats

Holtec Proprietary Intellectual Property - Unauthorized Dissemination Unlawful

MANUFACTURING AND INSPECTION PLAN FOR THE

MPC-89 and Basket

T

AF

R

D

Seller: Holtec International

Seller’s Address: Holtec Center, One Holtec Drive, Marlton, NJ 08053, USA

Holtec Procedure HPP-2504-002 Holtec Project 2504

Holtec Proprietary Intellectual Property - Unauthorized Dissemination Unlawful

Revision Log

Rev. 0: Initial Issue.

T

AF

R

D

HPP-2504-002 Page 1 of 18 Project 2504

Holtec Proprietary Intellectual Property - Unauthorized Dissemination Unlawful

1.0 PURPOSE

To provide the essential framework of the Manufacturing, Inspection for the MPC-89 and

Basket. The document defines the manufacturing sequence and hold/witness points.

2.0 DEFINITIONS

None

3.0 REFERENCE

None

4.0 DISCUSSION

T

This Manufacturing, Inspection and Test Plan outlines the major fabrication and

examination steps along with other essential requirements to ensure that the MPC 89

containment shells and baseplate are manufactured to comply with the certificate of

compliance issued by the applicable licensing body (NRC ).

AF

5.0 RESPONSIBILITIES

The Holtec Program/Project Manager shall champion the Manufacturing, Inspection and

Test Plan and furnish it to the buyer and applicable licensing body (as required).

6.0 PROCEDURE

The Manufacturing, Inspection and Test Plan details are provided in Exhibits 7.1, 7.2,

R

7.3, 7.4. Review and approval by the Buyer, shall be obtained before start of fabrication

by the Seller, Holtec International.

7.0 EXHIBITS

7.1 MPC-89 Basket Assembly Views

D

7.2 Manufacturing and Inspection Plan for the MPC-89 Basket

7.3 MPC-89 Assembly View

7.4 Manufacturing and Inspection Plan for the MPC-89

HPP-2504-002 Page 2 of 18 Project 2504

Holtec Proprietary Intellectual Property - Unauthorized Dissemination Unlawful

7.1 MPC-89 BASKET VIEWS

T

AF

R

D

BASKET COMPLETE ASSEMBLY

HPP-2504-002 Page 3 of 18 Project 2504

Holtec Proprietary Intellectual Property - Unauthorized Dissemination Unlawful

T

AF

R

D

HPP-2504-002 Page 4 of 18 Project 2504

Holtec Proprietary Intellectual Property - Unauthorized Dissemination Unlawful

T

AF

R

D

HPP-2504-002 Page 5 of 18 Project 2504

Holtec Proprietary Intellectual Property - Unauthorized Dissemination Unlawful

T

AF

R

D

HPP-2504-002 Page 6 of 18 Project 2504

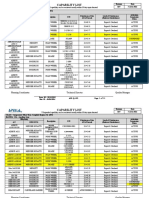

Exhibit 7.2: Manufacturing, Inspection and Test Plan for the MPC-89 Basket

Component Identifier

Operation Activity Activity Type Applicable Rev. Verification Inspection Points Comments

# Document Document

Holtec CLIENT OTHER

1. Load Panel Stock with lot Manufacturing DWG 8689

HSP-635

numbers facing up.

Identify basket custom

height and enter into

T

program.

Run Waterjet Program.

Complete panel sets for all

required panel from

AF

8689.(ITEMS 1-42)

2. Verify panel dimensions Manufacturing HSP-214 W

Random

and custom height matches

drawing.

Mark components for

traceability per HSP

3. Process panels through Manufacturing HSP-639

washer.

4.

R

QC Perform Dimensional

inspection and complete

Inspection 8689

QCP 10.5H

Inspection

Report

W

Random

IRDS.

5. Complete MPC-89 Top Manufacturing DWG 8689

HSP 214

D

Half Assembly. HSP-638

Using 10 middle sections

and 1 top section.

6. Production Verify Fit-up of Top Manufacturing 8689

Half Assembly. HSP-214

HSP-638

HPP-2504-002 Page 7 of 18 Project 2504

Exhibit 7.2: Manufacturing, Inspection and Test Plan for the MPC-89 Basket

Component Identifier

Operation Activity Activity Type Applicable Rev. Verification Inspection Points Comments

# Document Document

Holtec CLIENT OTHER

7. Fixture Basket and Manufacturing 8689 W

HSP-214

Complete Appropriate HSP-638

Checklist.

Verify dimensions

T

8. Complete welds #1-4 Manufacturing 8689 W

WPS-344

HSP-638

9. QC VT Inspect Weld #1-4 Inspection 8689 W

AF

WPS-344

HSP-638

10. Complete welds #5-8 Manufacturing 8689

WPS-344

HSP-638

11. QC VT Inspect Weld #5-8 Inspection 8689 W

WPS-344

HSP-638

12. Production Verify all Manufacturing 8969 W

dimensions for Top Half HSP-104

13.

R

Assembly

Complete MPC-89 Basket Manufacturing

HSP-701

DWG 8689

HSP 214

Full Assembly.

HSP-638

Using 9 middle sections

D

and 1 bottom section.

14. Fixture Basket and Manufacturing 8689 W

HSP-214

Complete Appropriate

HSP-638

Checklist.

Verify dimensions

HPP-2504-002 Page 8 of 18 Project 2504

Exhibit 7.2: Manufacturing, Inspection and Test Plan for the MPC-89 Basket

Component Identifier

Operation Activity Activity Type Applicable Rev. Verification Inspection Points Comments

# Document Document

Holtec CLIENT OTHER

15. Complete welds #1-4 Manufacturing 8689 W

WPS-344

HSP-638

16. QC VT Inspect Weld #1-4 Inspection 8689 W

WPS-344

T

HSP-638

17. Complete welds #5-8 Manufacturing 8689

WPS-344

HSP-638

AF

18. QC VT Inspect Weld #5-8 Inspection 8689 W

WPS-344

HSP-638

19. QC Perform inspection of Inspection 8689 Inspection H H

all Final Dimensions HSP-104 Report

HSP-701

IRDS

20. Prepare Basket for Manufacturing HSP-314

Shipping.

R

Note: H/W – Hold Point for the first Cask, Witness Point for the other casks.

D

HPP-2504-002 Page 9 of 18 Project 2504

Exhibit 7.3 MPC ASSEMBLY VIEWS

T

AF

R

D

MPC SHELL ISO SECTION

HPP-2504-002 Page 10 of 18 Project 2504

Exhibit 7.3: Manufacturing and Inspection Plan for the MPC

Component Identifier

Operation Activity Activity Type Applicable Rev. Verification Inspection Points Comments

# Document Document Holtec CLIENT OTHER

T

1. Cut/Burn Item 8728-02, Manufacturing DWG 8728

HSP 214

Verify Dimension and

mark for traceability.

2. Machine 8728-02 to Manufacturing DWG 8728

AF

drawing requirements and

verify dimensions.

3. QC Dimensionally Inspect Inspection 8728

HSP 10.0

IRDS

4. Cut/Burn Item 8728-03, Manufacturing DWG 8728

Verify Dimension and HSP 214

mark for traceability.

5.

R

Extrude Shim Set 8728-

05,06,07,08,13,14

4 each BWR Fuel

Manufacturing 8728

6. QC Complete Inspection Inspection 8728

D

IRDS

7. Saw Cut Shims to Length Manufacturing 8728

HSP 639

HSP 214

PS-211

HPP-2504-002 Page 11 of 18 Project 2504

Exhibit 7.3: Manufacturing and Inspection Plan for the MPC

Component Identifier

Operation Activity Activity Type Applicable Rev. Verification Inspection Points Comments

# Document Document Holtec CLIENT OTHER

8. Machine Shims per Manufacturing 8728

Drawing, install helicoils PS-211

Grind Away Surface

T

defects.

9. QC Visually Inspect Shims Inspection

for Surface Defects

10. Ship Shims to Anodizer. Manufacturing 8728

AF

PS-211

11. Cleans Shims. Manufacturing 8728

HSP-639

12. QC Perform Inspection of Manufacturing 8728

Anodizing coating color PS-211

and thickness. HQP 7.0

13. Prepare Shims for Final Manufacturing

14.

R

MPC Assembly

Cut/Burn Bottom Shell Manufacturing 8728

Segment 8728-01 HSP-214

Mark Component for

Traceability.

D

15. Bevel 8728-01 per drawing Manufacturing 8728 Inspection

specifications. Report

16. QC Perform Inspection Inspection HQP 10.0

IRDS

HPP-2504-002 Page 12 of 18 Project 2504

Exhibit 7.3: Manufacturing and Inspection Plan for the MPC

Component Identifier

Operation Activity Activity Type Applicable Rev. Verification Inspection Points Comments

# Document Document Holtec CLIENT OTHER

17. Roll Segment Per Drawing Manufacturing 8728

Fit-Tack and Weld Root Manufacturing

T

18. 8728

Pass Only Weld #3 WPS47HC

WPS76HC

WPS77HC

WPS227HC

AF

19. Re-Roll Segment Per Manufacturing 8728

Drawing

20. QC VT inspect Weld 3 Manufacturing 8728 Inspection

Root and segment OD. QCP 10.5 Report

Perform Final Inspection HQP 10.0

per drawing IRDS

21. Cut/Burn Top Shell Manufacturing 8728

R

Segment 8728-01

Mark Component for

Traceability.

HSP-214

22. Bevel 8728-01 per drawing Manufacturing 8728 Inspection

specifications. Report

D

23. QC Perform Inspection Inspection HQP 10.0

IRDS

24. Roll Segment Per Drawing Manufacturing 8728

HPP-2504-002 Page 13 of 18 Project 2504

Exhibit 7.3: Manufacturing and Inspection Plan for the MPC

Component Identifier

Operation Activity Activity Type Applicable Rev. Verification Inspection Points Comments

# Document Document Holtec CLIENT OTHER

25. Fit-Tack and Weld Root Manufacturing 8728

Pass Only Weld #2 WPS47HC

WPS76HC

T

WPS77HC

WPS227HC

26. Re-Roll Segment Per Manufacturing 8728

Drawing

AF

27. QC VT inspect Weld 2 Manufacturing 8728 Inspection

Root and segment OD. QCP 10.5 Report

Perform Final Inspection HQP 10.0

per drawing IRDS

28. Cut Burn Baseplate per Manufacturing 8798

Burn File

29.

R

Machine Baseplate per Manufacturing 8798

drawing Requirements

Press if Required to meet

Flatness.

D

30. QC Perform Inspection of Inspection HQP 10.0 Inspection

Baseplate 8798 Report

IRDS

HPP-2504-002 Page 14 of 18 Project 2504

Exhibit 7.3: Manufacturing and Inspection Plan for the MPC

Component Identifier

Operation Activity Activity Type Applicable Rev. Verification Inspection Points Comments

# Document Document Holtec CLIENT OTHER

31. Complete MPC Shell Sub- Manufacturing DWG

Assembly HSP-214

Perform weld1,2 and 3 WPS 47 HC

T

WPS 76HC

Mark welds for

Inspectability WPS 227 HC

WPS 314 HC

Verify Shell OD with Pi

Tape.

AF

32. Fit, tack bottom Shell Manufacturing 8728 W

8798

Assembly to Baseplate

WPS 47 HC

WPS 76HC

WPS 227 HC

WPS 314 HC

33. Perform Weld 4 Manufacturing 8728 W

8798

WPS 47 HC

R WPS 76HC

WPS 227 HC

WPS 314 HC

34. QC VT and PT Weld Inspection 8728 W

1.2.3.4 HSP-108

D

QCP 10.5H

QCP 9.6AH

35. QC verify material Inspection HSP-108

thickness in areas where 8728

weld is ground.

HPP-2504-002 Page 15 of 18 Project 2504

Exhibit 7.3: Manufacturing and Inspection Plan for the MPC

Component Identifier

Operation Activity Activity Type Applicable Rev. Verification Inspection Points Comments

# Document Document Holtec CLIENT OTHER

36. QC Verify Diameter Inspection HQP 10.0 Inspection W

8798 Report

8728

T

PS-301

HSP-701

IRDS

37. QC RT Welds 1-4. Inspection 8728 W

AF

8798

SC-111

38. Move assembly to Manufacturing 8728

Machine. Verify and

machine to Length.

39. QC Inspect Shell Final Inspection HQP 10.0 Inspection W

Height 8798 Report

IRDS

40.

R

Perform Helium Leak Test

on Shell

Manufacturing 8728

ITLS 849

HSP-314

41. Downend MPC in Wash Manufacturing 8728

Bay

D

42. Stamp Baseplate with Manufacturing 8728

Serial and 0 degree mark

on top of Shell

43. QC Perform Inspection of Inspection 8728

All Assembly and IRDS

Complete HSP-701

HPP-2504-002 Page 16 of 18 Project 2504

Exhibit 7.3: Manufacturing and Inspection Plan for the MPC

Component Identifier

Operation Activity Activity Type Applicable Rev. Verification Inspection Points Comments

# Document Document Holtec CLIENT OTHER

PS-301

T

44. Production Dry / Clean Manufacturing HSP-314

Shell.

45. QC Verify Shell Inspection HSP-314 W

Cleanliness.

AF

46. Machine Lid to Drawing Manufacturing

Dimensions

47. Assembly Lid and Manufacturing 8728

components Per Drawing

and Traveler

48. QC Perform Inspection on Inspection 8728 W W/H

Lid and Components

49.

R

Cut/Burn Closure

Ring8798-03 per Burn File

Manufacturing 8798

50. Machine Closure Ring Manufacturing 8798

8798-03 per drawing

D

Requirements

Press if Required to meet

Flatness.

51. QC Inspect Closure Ring Inspection HQP 10.0 Inspection

8798 Report

IRDS

HPP-2504-002 Page 17 of 18 Project 2504

Exhibit 7.3: Manufacturing and Inspection Plan for the MPC

Component Identifier

Operation Activity Activity Type Applicable Rev. Verification Inspection Points Comments

# Document Document Holtec CLIENT OTHER

52. Cut/Burn Closure Manufacturing 8798

Ring8798-11 per Burn File

T

53. Machine 8798-11 per Manufacturing 8798

drawing Requirements

Press if Required to meet

Flatness.

AF

54. QC Inspect Port Cover Inspection HQP 10.0 Inspection

Plate 8798 Report

IRDS

55. Assembly MPC Shell and Manufacturing H H

Basket, Shims

56. Prepare MPC, Basket, Lid

and Components For

Shipping.

R

D

HPP-2504-002 Page 18 of 18 Project 2504

You might also like

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- H1006400MKF51 Sa12qt 01Document4 pagesH1006400MKF51 Sa12qt 01MarcoNo ratings yet

- Eds Lan S03Document69 pagesEds Lan S03boy leeNo ratings yet

- 14B. 2082-PM-ITP-7015 Rev.0 - SITE ITP TankageDocument10 pages14B. 2082-PM-ITP-7015 Rev.0 - SITE ITP TankageAmarKumarNo ratings yet

- SPP Book 2 PDFDocument612 pagesSPP Book 2 PDFBagadi AvinashNo ratings yet

- Inspection & Test Plan FOR Concrete Work: Equipment Description: NADocument40 pagesInspection & Test Plan FOR Concrete Work: Equipment Description: NAYuvaraj PonrajNo ratings yet

- 3-ITP - Sample - Mechanical Installation of Compressors, Generators, PumpsDocument10 pages3-ITP - Sample - Mechanical Installation of Compressors, Generators, Pumpsumitkakca04No ratings yet

- PID Level Description Rev 2Document9 pagesPID Level Description Rev 2smithworkNo ratings yet

- Check ListDocument6 pagesCheck ListosersNo ratings yet

- 8188-MD-FEA-RFQ-001 Rev-0Document24 pages8188-MD-FEA-RFQ-001 Rev-0sridharNo ratings yet

- 408 TGMDocument3 pages408 TGMNizamuddien syedNo ratings yet

- DXH900 Installation IQOQPQDocument32 pagesDXH900 Installation IQOQPQMohammed FaizanNo ratings yet

- Annexure IV - QCP - Electrical - and - C&I 2021 07 05 02 - 57 - 28 201 300Document100 pagesAnnexure IV - QCP - Electrical - and - C&I 2021 07 05 02 - 57 - 28 201 300mrherp153No ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282Document14 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282ZaidiNo ratings yet

- Royal Commission For Jubail and Yanbu 021-C19: Document No: Rev. I C - 0 3 3 0 - F - 1 0 2Document12 pagesRoyal Commission For Jubail and Yanbu 021-C19: Document No: Rev. I C - 0 3 3 0 - F - 1 0 2arshad iqbalNo ratings yet

- Receiving Inspection ProcedureDocument12 pagesReceiving Inspection ProcedureDindo QuintanNo ratings yet

- 14C. 2082-PM-ITP-7017 Rev.0 - SITE ITP PaintingDocument6 pages14C. 2082-PM-ITP-7017 Rev.0 - SITE ITP PaintingAmarKumarNo ratings yet

- 60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingDocument109 pages60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingTauqeer SalimNo ratings yet

- MS For Fire Fighting SystemDocument52 pagesMS For Fire Fighting SystemsadiqNo ratings yet

- PHEONWJ-G-SPE-0101 0 - Structural and Piping Fabrication Quality ControlDocument11 pagesPHEONWJ-G-SPE-0101 0 - Structural and Piping Fabrication Quality ControlIksan Adityo Mulyo100% (1)

- Nmif-pip-Ado-cl-itp-p-001 Rev. 0 - (16 Inches Ado Cargoline Repair)Document8 pagesNmif-pip-Ado-cl-itp-p-001 Rev. 0 - (16 Inches Ado Cargoline Repair)parangkilalakitaNo ratings yet

- Technical Bulletin: ACP 5 2.00.0 Version ReleaseDocument8 pagesTechnical Bulletin: ACP 5 2.00.0 Version ReleasedanielNo ratings yet

- FQP Format Cqa-IV-r2 DT 200510Document2 pagesFQP Format Cqa-IV-r2 DT 200510sheb20040% (1)

- Versant 80 - 180 - 280 ACA and HFSI v7Document2 pagesVersant 80 - 180 - 280 ACA and HFSI v7XcopyNo ratings yet

- Pickit 3Document32 pagesPickit 3Sergiu EneNo ratings yet

- PAGE NO: 1 of 3: SWGFD Pumps (1440-PA-62-001 A/B) For HBHDocument3 pagesPAGE NO: 1 of 3: SWGFD Pumps (1440-PA-62-001 A/B) For HBHthakuryaNo ratings yet

- Bin Quraya Holding Co. ةضباقلا هعيرق نب ةكرش: QCP-45 Quality Control Procedure Field Engineering Change Control ProcedureDocument5 pagesBin Quraya Holding Co. ةضباقلا هعيرق نب ةكرش: QCP-45 Quality Control Procedure Field Engineering Change Control ProcedureRAMAKRISHNANo ratings yet

- Fieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Document4 pagesFieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Sam100% (1)

- Installation ChecklistDocument42 pagesInstallation ChecklistBudiyantoNo ratings yet

- DG Spec Final ApprovalDocument41 pagesDG Spec Final Approvalapi-3854942100% (7)

- Field Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-006Document7 pagesField Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-006bernardNo ratings yet

- Index of Revisions: Material RequisitionDocument23 pagesIndex of Revisions: Material RequisitionLANKAPALLISURINo ratings yet

- Catalogues: Rabigh II Project Interconnecting Package (UO1)Document206 pagesCatalogues: Rabigh II Project Interconnecting Package (UO1)dodonggNo ratings yet

- 1500 120 WKP 8464Document19 pages1500 120 WKP 8464Chuck AnsphilNo ratings yet

- Yanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationDocument5 pagesYanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationAmair Cool88% (8)

- Performance Qualification For Rotary PressDocument51 pagesPerformance Qualification For Rotary Pressua2848580No ratings yet

- Performance Testing Procedure Rev 0 PDFDocument36 pagesPerformance Testing Procedure Rev 0 PDFIsaalexNo ratings yet

- SOMC FHR 6 - Manejo Del Proceso de ProducciónDocument4 pagesSOMC FHR 6 - Manejo Del Proceso de ProducciónErgonomic WayNo ratings yet

- QAQC Procedure For Fabrication - Flare KOD Rev ADocument9 pagesQAQC Procedure For Fabrication - Flare KOD Rev ARajesh K Pillai100% (1)

- TGT PVCMS Q XXX PR 0012 - Dimensional Procedure B0Document18 pagesTGT PVCMS Q XXX PR 0012 - Dimensional Procedure B0ngtchungNo ratings yet

- Cathodic Protection ItpDocument9 pagesCathodic Protection ItpHarmalNo ratings yet

- G 000 Za e 09633 QCP For Painting Rev1Document16 pagesG 000 Za e 09633 QCP For Painting Rev1Vinayak VagheNo ratings yet

- C-188-22 R2 Rail Station Cairo-BenisuifDocument36 pagesC-188-22 R2 Rail Station Cairo-BenisuifAhmdNagiNo ratings yet

- Annexure-1H - I&C Scope MatrixDocument2 pagesAnnexure-1H - I&C Scope MatrixSridhar VedulaNo ratings yet

- Technical Proposal For Retrofit of Batch Centrifugal Machines AutomationDocument6 pagesTechnical Proposal For Retrofit of Batch Centrifugal Machines AutomationmichaelNo ratings yet

- 84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsDocument7 pages84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsPeni M. SaptoargoNo ratings yet

- HFY 3800 0000 CIV ITP 0002 - 0 Inspection and Test Plan For Piling Works - Code - ADocument17 pagesHFY 3800 0000 CIV ITP 0002 - 0 Inspection and Test Plan For Piling Works - Code - ANashaat DhyaaNo ratings yet

- MS For Wrapping & CoatingDocument13 pagesMS For Wrapping & CoatingSivaraman SelvarajNo ratings yet

- 25045-A1000-18-ITP-E-004r004 - ITP For Underfloor RacewayDocument8 pages25045-A1000-18-ITP-E-004r004 - ITP For Underfloor RacewaymsmkhanNo ratings yet

- Khwahish - Tec CertificateDocument6 pagesKhwahish - Tec CertificateVIJAY PATELNo ratings yet

- 00000-Hx-0001 - Pressure Vessels General SpecificationsDocument8 pages00000-Hx-0001 - Pressure Vessels General SpecificationsFernando SpinolaNo ratings yet

- 200 20 Pi DTS 00008Document72 pages200 20 Pi DTS 00008ritesh142No ratings yet

- Punch List ProcedureDocument18 pagesPunch List ProcedureAnu Jose0% (1)

- FA - PA Works Wo Revised BoqDocument15 pagesFA - PA Works Wo Revised BoqKamran AliNo ratings yet

- Abbreviations & Definitions:: 2. General InformationDocument7 pagesAbbreviations & Definitions:: 2. General InformationHamza ShujaNo ratings yet

- ITP Instrument-Cover EXAMPLEDocument6 pagesITP Instrument-Cover EXAMPLECharles RobiansyahNo ratings yet

- Instrumentation Switch ChecklistDocument5 pagesInstrumentation Switch Checklistrenjithv_4No ratings yet

- CI-G08-DP-0304 Rev 00Document23 pagesCI-G08-DP-0304 Rev 00Bashir AlamNo ratings yet

- Mil PRF 46108CDocument11 pagesMil PRF 46108COrlando PérezNo ratings yet

- CRD 5 (1a-7) - PICAII CP-81 Inspectors Instruction ManualDocument12 pagesCRD 5 (1a-7) - PICAII CP-81 Inspectors Instruction ManualProfessor Puppies100% (1)

- Api 653Document3 pagesApi 653Mohammed Al-Odat0% (1)

- Dangerous Goods Guidance Note 10 PDFDocument3 pagesDangerous Goods Guidance Note 10 PDFDan DumbravescuNo ratings yet

- SCDL 2009 Assignments - POMDocument114 pagesSCDL 2009 Assignments - POMdNo ratings yet

- European Technical Approval ETA-13/0029Document17 pagesEuropean Technical Approval ETA-13/0029Alex CartesNo ratings yet

- 29 HFY-FC-PM-PD-0029 - Cathodic Protection System Installation Procedure Rev 1 PDFDocument54 pages29 HFY-FC-PM-PD-0029 - Cathodic Protection System Installation Procedure Rev 1 PDFSalam Alkataluni100% (2)

- Lessons From Crane Runway Inspections - 98Document18 pagesLessons From Crane Runway Inspections - 98Emanuel RomagnosiNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerFayez Al-ahmadiNo ratings yet

- Establish Quality StandardsDocument143 pagesEstablish Quality StandardsInfo tech100% (1)

- Lean in Action: 5S System: Techniques For Efficient Workplace OrganizationDocument34 pagesLean in Action: 5S System: Techniques For Efficient Workplace OrganizationIron Man-tcpNo ratings yet

- Capability List Rev. 37Document14 pagesCapability List Rev. 37Vadim RiabovNo ratings yet

- AGS 1 Automated General Purpose ScannerDocument2 pagesAGS 1 Automated General Purpose Scannerkiki270977No ratings yet

- GMP+FSA Ts-1-1-Prerequisite-ProgrammeDocument18 pagesGMP+FSA Ts-1-1-Prerequisite-ProgrammeAri arsiyantiNo ratings yet

- Soft or Annealed Copper Wire: Standard Specification ForDocument5 pagesSoft or Annealed Copper Wire: Standard Specification Fororlando acevedoNo ratings yet

- Satip M 100 07Document10 pagesSatip M 100 07munnaNo ratings yet

- 3532 I 67 Rev 0 ENDocument14 pages3532 I 67 Rev 0 ENIbrahim AsifNo ratings yet

- Flipkart Inventory Management Approach of FlipkartDocument2 pagesFlipkart Inventory Management Approach of FlipkartSanya BansalNo ratings yet

- Inspection and Testing: Assignment of QC Inspections and MonitoringDocument2 pagesInspection and Testing: Assignment of QC Inspections and MonitoringMith MithunNo ratings yet

- 11.01.00 Calibration of Inspection Measuring and Test EquipmentDocument11 pages11.01.00 Calibration of Inspection Measuring and Test EquipmentSanjeev Reddy Kasula100% (1)

- Self Inspection Check ListDocument73 pagesSelf Inspection Check ListOsama Mahmoud100% (2)

- CV of Muhammad Ashfaq HussainDocument5 pagesCV of Muhammad Ashfaq HussainIshfaq UrrehmanNo ratings yet

- Fire Alarm Equipment Register FPADocument139 pagesFire Alarm Equipment Register FPArojas6omar9No ratings yet

- 8071 V 1Document193 pages8071 V 1standapNo ratings yet

- Track Presentation Type Asme Paper Nupaper Title Author First Nam Author Last NamcompanyDocument7 pagesTrack Presentation Type Asme Paper Nupaper Title Author First Nam Author Last NamcompanyYvesfNo ratings yet

- New Forms For Taking Over Process of Water Supply System by Tuan Haji Sanusi SuliemanDocument20 pagesNew Forms For Taking Over Process of Water Supply System by Tuan Haji Sanusi SuliemansharifahNo ratings yet

- IN2205423-2 Container Cleanliness Certificate - 25% - DraftDocument2 pagesIN2205423-2 Container Cleanliness Certificate - 25% - DraftSuraj Kapse100% (1)

- PEC-QU-GDE-X-10866 Rev 3, QCP-E-0003Document7 pagesPEC-QU-GDE-X-10866 Rev 3, QCP-E-0003Muralimohan PandianNo ratings yet

- Sample SWPPPDocument74 pagesSample SWPPPBrandon BaxterNo ratings yet

- Palm SugarDocument27 pagesPalm Sugarsandeepdir100% (2)