Professional Documents

Culture Documents

Tutorial 7 HT PDF

Tutorial 7 HT PDF

Uploaded by

Ardila Hayu TiwikramaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tutorial 7 HT PDF

Tutorial 7 HT PDF

Uploaded by

Ardila Hayu TiwikramaCopyright:

Available Formats

THAPAR INSTITUTE UNIVERSITY, PATIALA

(Department of Chemical Engineering)

Tutorial Sheet – 7 (Unsteady State Heat transfer)

Subject: Heat Transfer Semester: II

Course No.: UCH 402 Session: 2011 - 2012

Course-Coordinator: Dr. D. Gangacharyulu Date: February 13, 2012

1. A cylindrical ingot 10 cm diameter and 30 cm long passes through a heat treatment furnace,

which is 6 m in length. The ingot must reach 800 oC before it comes out of the furnace. The

furnace gas is at 1250 oC and ingot initial temperature is 90 oC. What is the maximum speed

with which the ingot should move in the furnace to attain the required temperature? The

combined convective and radiative heat transfer coefficient is 100 W/(m2-K). The thermal

conductivity and the thermal diffusivity of the ingot steel are 40 W/(m-K) and 1.16x10-5

m2/sec.

2. A 100 cm 100 cm copper slab of 10 cm thick has a uniform temperature of 400 oC. Its

temperature is suddenly lowered to 100 oC and maintained. Calculate the time required for the

plate to reach the temperature of 200 oC. Take copper slab properties as, = 9000 kg/m3; Cp =

0.38 kJ/(kg-K); k = 370 W/(m-K); and ‘h’ = 100 W/(m-K).

3. A vessel is filled with 0.0283m3 of water initially at 288.8 K. The vessel, which is well stirred,

is suddenly immersed in a steam bath held at 377.6 K. The overall heat-transfer coefficient U

between the steam and water is 1136W/(m2-K) and the area is 0.372m2. Neglecting the heat

capacity of the walls and agitator, calculate the time in hours to heat the water to 338.7 K.

[Hint: Since the water is well stirred, its temperature is uniform.]

You might also like

- Solutions Manual to accompany Engineering Materials ScienceFrom EverandSolutions Manual to accompany Engineering Materials ScienceRating: 4 out of 5 stars4/5 (1)

- Additional Tutorial 3 Heat TransfeDocument6 pagesAdditional Tutorial 3 Heat TransfeTeeWenSengNo ratings yet

- Heat and Mass TransferDocument1 pageHeat and Mass TransferlibbissujessyNo ratings yet

- Assignment Unsteady StateDocument2 pagesAssignment Unsteady StateChirag JainNo ratings yet

- Transient ConductionDocument3 pagesTransient ConductionSanith RenjalNo ratings yet

- HT Mod 3 and 4 Solved ProbsDocument46 pagesHT Mod 3 and 4 Solved ProbsVishnu Prada A RNo ratings yet

- Sheet 5Document5 pagesSheet 5Mohamed AbdulazimNo ratings yet

- MEL301 2014 Tutorial4 Draft Version 01 PDFDocument2 pagesMEL301 2014 Tutorial4 Draft Version 01 PDFAkhil NekkantiNo ratings yet

- HT Homework 1Document2 pagesHT Homework 1Nirmal PanghalNo ratings yet

- Heat Exchangers: Tutorial Sheet - 8Document2 pagesHeat Exchangers: Tutorial Sheet - 8Mohammed MaazNo ratings yet

- Example 4.10-1. Radiation To A Metal TubeDocument7 pagesExample 4.10-1. Radiation To A Metal TubeShane Patulot0% (2)

- Sheet 7Document1 pageSheet 7mkkNo ratings yet

- Assignment - Process Heat Transfer (CDB2023)Document4 pagesAssignment - Process Heat Transfer (CDB2023)qrunchyNo ratings yet

- Assignment2 of HMT ME 6003-1Document2 pagesAssignment2 of HMT ME 6003-1Faraz KhanNo ratings yet

- Practice Problems For Quiz 2Document6 pagesPractice Problems For Quiz 2divyanshuNo ratings yet

- Final HMT AssignmentsDocument7 pagesFinal HMT Assignments544 vishwavijay PatilNo ratings yet

- Tutorial SheetsDocument5 pagesTutorial SheetsDhiraj DhimanNo ratings yet

- Rr310803 Heat TransferDocument8 pagesRr310803 Heat TransferSaravanan MathiNo ratings yet

- 8S 2105 Mepc22 1Document2 pages8S 2105 Mepc22 1Challa YachendraNo ratings yet

- Tutorial 2 Temperature & Heat - Part 2Document4 pagesTutorial 2 Temperature & Heat - Part 2Yixiang TanNo ratings yet

- HEAT TRANSFER 2011 JNTUH Question PaperDocument8 pagesHEAT TRANSFER 2011 JNTUH Question PaperAnil Frivolous AbstemiousNo ratings yet

- 9A03505 Heat TransferDocument4 pages9A03505 Heat TransfersivabharathamurthyNo ratings yet

- HTDocument13 pagesHTJhon MalabagNo ratings yet

- HW-7. Transient Heat Conduction PDFDocument1 pageHW-7. Transient Heat Conduction PDFSafaa Hameed Al NaseryNo ratings yet

- Group Assignment DDocument1 pageGroup Assignment DALAMEL MANZGHAI A/P GANESONNo ratings yet

- Heat Transfer - 012110043920 - 1Document8 pagesHeat Transfer - 012110043920 - 1shweta_770587No ratings yet

- Heat Transfer AssignmentDocument2 pagesHeat Transfer Assignmentdodo123dodo0% (1)

- Second AssignmentDocument2 pagesSecond AssignmentNitish NehraNo ratings yet

- HT Notes For ESEDocument25 pagesHT Notes For ESEM BhurleNo ratings yet

- Heat and Mass Transfer Practice Questions 1Document2 pagesHeat and Mass Transfer Practice Questions 1Lucky 230503No ratings yet

- HeatDocument7 pagesHeatkevinjorgeramosNo ratings yet

- UNIT-1: Question BankDocument3 pagesUNIT-1: Question Bankdoddi.ajith2003No ratings yet

- Soal KONDUKTIVITASDocument2 pagesSoal KONDUKTIVITASSupriyantiNo ratings yet

- Tutorial - Transient ConductionDocument2 pagesTutorial - Transient Conduction219016536No ratings yet

- SUB: Heat & Mass Transfer (EME 504) : Assignment-IDocument2 pagesSUB: Heat & Mass Transfer (EME 504) : Assignment-IdearsaswatNo ratings yet

- To UploadDocument2 pagesTo Uploadsmg26thmayNo ratings yet

- Assignment 2Document3 pagesAssignment 2Arjun AgarwalNo ratings yet

- Phy103 Tutorial QuestionsDocument30 pagesPhy103 Tutorial QuestionsGeorge nwatarali100% (1)

- 4.tutorial HMTDocument5 pages4.tutorial HMTdearsaswatNo ratings yet

- Test-IV (Spring, 2015) ME 308 (Heat and Mass Transfer) : o o o o o 2 oDocument2 pagesTest-IV (Spring, 2015) ME 308 (Heat and Mass Transfer) : o o o o o 2 oKrishnaJaiswal0% (1)

- 13 HT Assignment 01 2023 24 IisemDocument2 pages13 HT Assignment 01 2023 24 IisemrakiravaishuNo ratings yet

- 20ME111, Heat Transfer-Unit I II-Question BankDocument7 pages20ME111, Heat Transfer-Unit I II-Question BankR.MANIKANTHANo ratings yet

- Tutorial SheetDocument5 pagesTutorial Sheetpradeep.kumarNo ratings yet

- Prob. Sheet Basic ConceptsDocument3 pagesProb. Sheet Basic ConceptsAnonymous mXicTi8hBNo ratings yet

- Heat Transfer Lectures Chemical Engineering Department University of Technology, IraqDocument1 pageHeat Transfer Lectures Chemical Engineering Department University of Technology, IraqChemical EngineeringNo ratings yet

- Heat TransferDocument4 pagesHeat TransferR B Yarasu100% (1)

- Thermodynamics Assignment SheetDocument3 pagesThermodynamics Assignment SheetSatwikMohantyNo ratings yet

- Heat TransferDocument6 pagesHeat Transferkevinjorgeramos100% (1)

- (An Autonomous Institute Under VTU) Manandavadi Road, Mysore-570008, Karnataka, IndiaDocument2 pages(An Autonomous Institute Under VTU) Manandavadi Road, Mysore-570008, Karnataka, IndiaMohammed Maaz100% (1)

- 4th Sem.-ME 1251-HMTDocument18 pages4th Sem.-ME 1251-HMTPon ShanmugakumarNo ratings yet

- Tutorial 3 HeatDocument1 pageTutorial 3 HeatBriana PalmerNo ratings yet

- Prob Set Heat and MassDocument15 pagesProb Set Heat and MassCheng PasionNo ratings yet

- Heat Transfer Review ProblemsDocument1 pageHeat Transfer Review ProblemssayanNo ratings yet

- Advances in Heat Pipe Technology: Proceedings of the IVth International Heat Pipe Conference, 7-10 September 1981, London, UKFrom EverandAdvances in Heat Pipe Technology: Proceedings of the IVth International Heat Pipe Conference, 7-10 September 1981, London, UKNo ratings yet

- NCF 2005 Cdnotes 1674307913Document2 pagesNCF 2005 Cdnotes 1674307913Sahil GoyalNo ratings yet

- Pay Fixation 1-1-06Document37 pagesPay Fixation 1-1-06Sahil GoyalNo ratings yet

- Samsung-Thapar - SL - Chem & CivilDocument2 pagesSamsung-Thapar - SL - Chem & CivilSahil GoyalNo ratings yet

- Index: © Fluent Inc., Mar-06 Index-1Document10 pagesIndex: © Fluent Inc., Mar-06 Index-1Sahil GoyalNo ratings yet

- Gambit Turbo File FormatDocument22 pagesGambit Turbo File FormatSahil GoyalNo ratings yet

- Step 2Document1 pageStep 2Sahil GoyalNo ratings yet

- Food Processing 5Document19 pagesFood Processing 5Sahil GoyalNo ratings yet

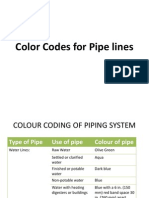

- Color Codes For Pipe LinesDocument24 pagesColor Codes For Pipe Linesamantania12386% (14)