Professional Documents

Culture Documents

Fabrication Norms

Uploaded by

Renny Devassy0 ratings0% found this document useful (0 votes)

104 views8 pagesnorms

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentnorms

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

104 views8 pagesFabrication Norms

Uploaded by

Renny Devassynorms

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 8

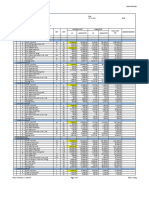

1.

1 PRESSURE VESSELS (CS)

Fabrication Welding Logistics Overall

Weight

Sr. (MH/Ton) (MH/Ton) (MH/Ton) (MH/Ton)

Material

No.

(Tons)

(A) (B) (C) D = A+B+C

Carbon

1 1–5

Steel

Carbon

2 6 – 10

Steel

Carbon

3 11 – 20

Steel

Carbon

4 21 – 40

Steel

Carbon

5 41 – 60

Steel

Carbon

6 61 – 80

Steel

Carbon

7 81 – 100

Steel

Carbon

8 101 - 150

Steel

Carbon

9 151 - 200

Steel

Carbon

10 > 200

Steel

1.2 PRESSURE VESSELS (SS / DUPLEX)

Overall

Fabrication Welding Logistics

Weight (MH/Ton)

Sr. (MH/Ton) (MH/Ton) (MH/Ton)

Material

No.

(Tons) D=

(A) (B) (C)

A+B+C

Stainless

1 1–5

Steel

Stainless

2 6 – 10

Steel

Stainless

3 11 – 20

Steel

Stainless

4 21 – 40

Steel

Stainless

5 41 – 60

Steel

Stainless

6 61 – 80

Steel

Stainless

7 81 – 100

Steel

Stainless

8 101 - 150

Steel

Stainless

9 151 - 200

Steel

Stainless

10 > 200

Steel

1.3 PRESSURE VESSELS (ALLOY STEEL)

Overall

Fabrication Welding Logistics

Weight (MH/Ton)

Sr. (MH/Ton) (MH/Ton) (MH/Ton)

Material

No.

(Tons) D=

(A) (B) (C)

A+B+C

Alloy

1 1–5

Steel

Alloy

2 6 – 10

Steel

Alloy

3 11 – 20

Steel

Alloy

4 21 – 40

Steel

Alloy

5 41 – 60

Steel

Alloy

6 61 – 80

Steel

Alloy

7 81 – 100

Steel

Alloy

8 101 - 150

Steel

Alloy

9 151 - 200

Steel

Alloy

10 > 200

Steel

1.4 SHOP FABRICATED TANKS (CS)

Fabrication Welding Logistics Overall

Weight

Sr. (MH/Ton) (MH/Ton) (MH/Ton) (MH/Ton)

Material

No.

(Tons)

(A) (B) (C) D = A+B+C

Carbon

1 1–5

Steel

Carbon

2 6 – 10

Steel

Carbon

3 11 – 15

Steel

1.5 SHOP FABRICATED TANKS (SS)

Fabrication Welding Logistics Overall

Weight

Sr. (MH/Ton) (MH/Ton) (MH/Ton) (MH/Ton)

Material

No.

(Tons)

(A) (B) (C) D = A+B+C

Stainless

1 1–5

Steel

Stainless

2 6 – 10

Steel

Stainless

3 11 – 15

Steel

1.6 SHOP FABRICATED TANKS (ALLOY)

Fabrication Welding Logistics Overall

Weight

Sr. (MH/Ton) (MH/Ton) (MH/Ton) (MH/Ton)

Material

No.

(Tons)

(A) (B) (C) D = A+B+C

Alloy

1 1–5

Steel

Alloy

2 6 – 10

Steel

Alloy

3 11 – 15

Steel

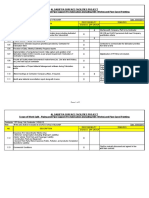

1.7 SITE ERECTED TANKS (CS)

Pre-

Pre-

fabrication Site Overall

fabrication

Weight of Nozzles Erection (MH/Ton)

Sr. of Tanks

Material (MH/Ton)

No. (MH/Ton)

(Tons) (MH/Ton) D=

(C) A+B+C

(A)

(B)

Carbon

1 15 – 30

Steel

Carbon

2 31 – 50

Steel

Carbon

3 51 – 75

Steel

Carbon

4 76 – 100

Steel

Carbon

5 101 – 150

Steel

Carbon

6 151 – 200

Steel

Carbon

7 201 – 250

Steel

Carbon

8 251 – 300

Steel

Carbon

9 > 300

Steel

1.8 SITE ERECTED TANKS (SS)

Pre-

Pre-

fabrication Site

fabrication Overall

Weight of Nozzles Erection

Sr. of Tanks (MH/Ton)

Material (MH/Ton)

No. (MH/Ton)

(Tons) (MH/Ton)

D = A+B+C

(C)

(A)

(B)

Stainless

1 15 – 30

Steel

Stainless

2 31 – 50

Steel

Stainless

3 51 – 75

Steel

Stainless

4 76 – 100

Steel

Stainless

5 101 – 150

Steel

Stainless

6 151 – 200

Steel

Stainless

7 201 – 250

Steel

Stainless

8 251 – 300

Steel

Stainless

9 > 300

Steel

1.9 SITE ERECTED TANKS (ALLOY)

Pre-

Pre-

fabrication Site

fabrication Overall

Weight of Nozzles Erection

Sr. of Tanks (MH/Ton)

Material (MH/Ton)

No. (MH/Ton)

(Tons) (MH/Ton)

D = A+B+C

(C)

(A)

(B)

Alloy

1 15 – 30

Steel

Alloy

2 31 – 50

Steel

Alloy

3 51 – 75

Steel

Alloy

4 76 – 100

Steel

Alloy

5 101 – 150

Steel

Alloy

6 151 – 200

Steel

Alloy

7 201 – 250

Steel

Alloy

8 251 – 300

Steel

Alloy

9 > 300

Steel

1.10 STEEL STRUCTURE

Overall

Fabrication Welding Logistics

(MH/Ton)

Sr. (MH/Ton) (MH/Ton) (MH/Ton)

Material Category

No.

D=

(A) (B) (C)

A+B+C

Carbon

1 Light

Steel

Carbon

2 Medium

Steel

Carbon

3 Heavy

Steel

You might also like

- Progress Piping GCC CaCo3Document66 pagesProgress Piping GCC CaCo3Alif Rahmat FebriantoNo ratings yet

- 1.1 Welder Test 86,350,000: PackageDocument2 pages1.1 Welder Test 86,350,000: PackageAhmad Dzulfiqar RahmanNo ratings yet

- Welding and Fabrication NoteDocument54 pagesWelding and Fabrication NoteluminiousNo ratings yet

- Proposed Warehouse Cost EstimateDocument2 pagesProposed Warehouse Cost EstimateAlvin Dela CruzNo ratings yet

- Drawing Atap WP 7Document1 pageDrawing Atap WP 7Fresly PatriaNo ratings yet

- MTO For StructureDocument2 pagesMTO For StructureRajnath Rajbhar PanchamNo ratings yet

- Quotation Comparing AbhishekDocument50 pagesQuotation Comparing AbhishekAbhishek KumarNo ratings yet

- Piping Line List: Ventech Engineers, Inc. Pasadena, Texas, P.O.Box 4261Document3 pagesPiping Line List: Ventech Engineers, Inc. Pasadena, Texas, P.O.Box 4261samer8saifNo ratings yet

- Crew Mix RatiosDocument2 pagesCrew Mix RatioskamlNo ratings yet

- Manhour StandardsDocument6 pagesManhour StandardsErick EnriquezNo ratings yet

- Piping Material EquivalentsDocument1 pagePiping Material EquivalentspejnorozyNo ratings yet

- CV Mechanical Engineer Project Manager 11 Years ExperienceDocument2 pagesCV Mechanical Engineer Project Manager 11 Years ExperienceDARA SINGHNo ratings yet

- Project price list for painting worksDocument67 pagesProject price list for painting worksRenny DevassyNo ratings yet

- 2-Year 2014 BaseDocument25 pages2-Year 2014 BaseMohamed MolhamNo ratings yet

- Hilti Core CuttingDocument5 pagesHilti Core CuttingSarinNo ratings yet

- CV Sample - 2Document20 pagesCV Sample - 2Lateef Ur REhmanNo ratings yet

- Pipes PoolsDocument3 pagesPipes PoolsjorgemachigueNo ratings yet

- Plan of Piping 3 Week Plan PDFDocument1 pagePlan of Piping 3 Week Plan PDFebsmsartNo ratings yet

- Rate Analysis-Norms 1Document10 pagesRate Analysis-Norms 1yamanta_rajNo ratings yet

- Man HoursDocument2 pagesMan Hourserastus_petersNo ratings yet

- Progress Update For Pre Fabrication WorksDocument4 pagesProgress Update For Pre Fabrication WorksAlagu ThirunavirkarasuNo ratings yet

- Structural Estimate BasisDocument8 pagesStructural Estimate BasisKaloyNo ratings yet

- Smart Glass ProcedureDocument117 pagesSmart Glass ProcedureFrancis DhanarajNo ratings yet

- Supply of Pipe and Fittings BlankDocument7 pagesSupply of Pipe and Fittings BlankMiko AbiNo ratings yet

- Level IV Plan 41 - Area WiseDocument11 pagesLevel IV Plan 41 - Area WisederwaishjeeNo ratings yet

- Consumption Calculation PDFDocument1 pageConsumption Calculation PDFzniperxNo ratings yet

- Nalco Idler-S409/1 - 37870/8200004980/IDLERS&ROLLERSDocument2 pagesNalco Idler-S409/1 - 37870/8200004980/IDLERS&ROLLERSAlok NayakNo ratings yet

- 12 5 2 Schedule of Fab EreDocument1 page12 5 2 Schedule of Fab EreGlobaltoyoNo ratings yet

- BORL Feedback: Workshop On Project Execution StrategiesDocument24 pagesBORL Feedback: Workshop On Project Execution StrategiesVinothrajaNo ratings yet

- Boq Working JharkhandDocument36 pagesBoq Working JharkhandsmithNo ratings yet

- Progress Review Meeting-FormatDocument14 pagesProgress Review Meeting-FormatImalka KariyawasamNo ratings yet

- Conversion of MT To Inch DiaDocument4 pagesConversion of MT To Inch DianikunjNo ratings yet

- Hydro Test ProcedureDocument11 pagesHydro Test ProcedureRohit SharmaNo ratings yet

- Rate Analysis For Pergola at 8th Floor SL - No Description Unit Qty Rate AmountDocument3 pagesRate Analysis For Pergola at 8th Floor SL - No Description Unit Qty Rate AmountvinothNo ratings yet

- P6 Piping Tank FarmDocument6 pagesP6 Piping Tank FarmIvan Sanzana RodríguezNo ratings yet

- ASME Piping Standards and Material Selection GuideDocument36 pagesASME Piping Standards and Material Selection Guideتدریس زبان ESLNo ratings yet

- ROXUL Process Manual 082714 - Compliance To CINIDocument191 pagesROXUL Process Manual 082714 - Compliance To CINIMichael TayactacNo ratings yet

- DESCON Engineering Limited: Cost Centers List Civil WorksDocument11 pagesDESCON Engineering Limited: Cost Centers List Civil Worksasif iqbalNo ratings yet

- Dia Inch PipingDocument77 pagesDia Inch PipingmyDJAPA myDJAPANo ratings yet

- Team Leader - Senior Checker For Structural Steel Detailing - Delhi - Delhi - Simsona Technology Pvt. Ltd. - 3 To 6 Years of Experience PDFDocument3 pagesTeam Leader - Senior Checker For Structural Steel Detailing - Delhi - Delhi - Simsona Technology Pvt. Ltd. - 3 To 6 Years of Experience PDFDeepankar ChoudhuryNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Overall Welding Progress: Nidoco Phase #3 Project Welding SummaryDocument9 pagesOverall Welding Progress: Nidoco Phase #3 Project Welding SummaryKareem ZidanNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument7 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Piping Cost BreakdownDocument2 pagesPiping Cost BreakdownMarie100% (1)

- Crane Painting SystemDocument1 pageCrane Painting SystemdbpatNo ratings yet

- Proposal For Structural Steel WorksDocument1 pageProposal For Structural Steel Worksshabban4uNo ratings yet

- Estimate of Duct For OFCDocument12 pagesEstimate of Duct For OFCrajinder kutaalNo ratings yet

- (RDMP) BQ Piping Smp3 170601 Iti Rev0Document365 pages(RDMP) BQ Piping Smp3 170601 Iti Rev0Fahmy FlipNo ratings yet

- PEB-Fabrication Details: DurationDocument4 pagesPEB-Fabrication Details: DurationaravindNo ratings yet

- Steel Pipe Weight CalculatorDocument1 pageSteel Pipe Weight Calculatorbejay bermudezNo ratings yet

- WCC.11031MM (Rolled Pipe)Document7 pagesWCC.11031MM (Rolled Pipe)keymal9195No ratings yet

- Qa/Qc Lab Origination Chart: SK .ImamulDocument1 pageQa/Qc Lab Origination Chart: SK .ImamulkanagarajodishaNo ratings yet

- DPR - Product Storage Tank 07.06.2023Document6 pagesDPR - Product Storage Tank 07.06.2023ashfaque khanNo ratings yet

- Block Calculator V 1.0 - EnglishDocument4 pagesBlock Calculator V 1.0 - EnglishJinishEGNo ratings yet

- Structural Steel ProgressDocument1 pageStructural Steel ProgressghilesNo ratings yet

- RC Col FTNG (F-4)Document2 pagesRC Col FTNG (F-4)Ken AlcorizaNo ratings yet

- Furnace Area & VolumeDocument22 pagesFurnace Area & VolumeRajnath Rajbhar PanchamNo ratings yet

- Total Project Cost For 2nos. 25KL Tanks and One 40 KL TankDocument2 pagesTotal Project Cost For 2nos. 25KL Tanks and One 40 KL Tankarajamani78No ratings yet

- HardnessDocument5 pagesHardnessAmin Ali AminNo ratings yet

- Weldingguide ENGDocument518 pagesWeldingguide ENGBoris Kozjan0% (1)

- Responsibility Matrix For Shop Piping WorksDocument5 pagesResponsibility Matrix For Shop Piping WorksRenny DevassyNo ratings yet

- OGASCO - ENOC Jabel Ali Refinery Expansi Technical Specification 2017-06-21Document14 pagesOGASCO - ENOC Jabel Ali Refinery Expansi Technical Specification 2017-06-21Renny DevassyNo ratings yet

- Project price list for painting worksDocument67 pagesProject price list for painting worksRenny DevassyNo ratings yet

- WPS Alloy 625 Strip With Flux EST 236Document1 pageWPS Alloy 625 Strip With Flux EST 236Renny DevassyNo ratings yet

- Lincoln Electric ESW Strip Cladding GuideDocument26 pagesLincoln Electric ESW Strip Cladding GuideRenny DevassyNo ratings yet

- Tubular Products From Special MetalsDocument26 pagesTubular Products From Special Metalskaveh-bahiraeeNo ratings yet

- Cummins C350D5 Diesel Generator Data SheetDocument3 pagesCummins C350D5 Diesel Generator Data SheetasdthuNo ratings yet

- Soudokay Strip Cladding - PrincipesDocument31 pagesSoudokay Strip Cladding - PrincipesRenny DevassyNo ratings yet

- Cummins C900D5 Diesel Generator Data Sheet PDFDocument3 pagesCummins C900D5 Diesel Generator Data Sheet PDFpurushmicroNo ratings yet

- 0400GF Amerlock 400 GF PDS PDFDocument4 pages0400GF Amerlock 400 GF PDS PDFRenny DevassyNo ratings yet

- 1250 kVA Generator Specs and Performance DataDocument8 pages1250 kVA Generator Specs and Performance DataRenny DevassyNo ratings yet

- Ratnamani - Manufacturing RangeDocument2 pagesRatnamani - Manufacturing RangeRenny DevassyNo ratings yet

- Garnet IDocument3 pagesGarnet IRenny DevassyNo ratings yet

- Tubular Products From Special MetalsDocument26 pagesTubular Products From Special Metalskaveh-bahiraeeNo ratings yet

- Tubular Products From Special MetalsDocument26 pagesTubular Products From Special Metalskaveh-bahiraeeNo ratings yet

- Cummins C350D5 Diesel Generator Data SheetDocument3 pagesCummins C350D5 Diesel Generator Data SheetasdthuNo ratings yet

- 0400GF Amerlock 400 GF PDSDocument4 pages0400GF Amerlock 400 GF PDSRenny DevassyNo ratings yet

- 888DFHD - 1000kva. Fuel ConsumptionDocument3 pages888DFHD - 1000kva. Fuel ConsumptionRenny DevassyNo ratings yet

- Cummins C350D5 Diesel Generator Data SheetDocument3 pagesCummins C350D5 Diesel Generator Data SheetasdthuNo ratings yet

- HEMI Cryo Brochure 6 PageDocument6 pagesHEMI Cryo Brochure 6 PageRenny DevassyNo ratings yet

- FILTRACIONDocument14 pagesFILTRACIONantoniojaviermaciasNo ratings yet

- Cummins C350D5 Diesel Generator Data SheetDocument3 pagesCummins C350D5 Diesel Generator Data SheetasdthuNo ratings yet

- Cummins C900D5 Diesel Generator Data Sheet PDFDocument3 pagesCummins C900D5 Diesel Generator Data Sheet PDFpurushmicroNo ratings yet

- T 71 UDocument1 pageT 71 URenny DevassyNo ratings yet

- Cummins C350D5 Diesel Generator Data SheetDocument3 pagesCummins C350D5 Diesel Generator Data SheetasdthuNo ratings yet

- 1250 kVA Genset SpecificationsDocument8 pages1250 kVA Genset SpecificationsRenny DevassyNo ratings yet

- Compressible Cake Constant Pressure ProfileDocument9 pagesCompressible Cake Constant Pressure ProfileClarence AG YueNo ratings yet

- Friction Factor Formulas For CheresourcesDocument4 pagesFriction Factor Formulas For CheresourcesHarjasa AdhiNo ratings yet

- Inspection Certificate EN 10204 PDFDocument0 pagesInspection Certificate EN 10204 PDFkronos39zeusNo ratings yet

- D C450 Firestop Technical Data Sheet C450 TDC450Document2 pagesD C450 Firestop Technical Data Sheet C450 TDC450Samir SalihovicNo ratings yet

- Column Spec Data Sheets - CoulsonDocument1 pageColumn Spec Data Sheets - CoulsonAhmed YounisNo ratings yet

- Laboratory Basket Granulator: Technical BulletinDocument1 pageLaboratory Basket Granulator: Technical BulletinMacaroon BeanNo ratings yet

- Paint Master Plaster Primer - TDSDocument2 pagesPaint Master Plaster Primer - TDSMichael JoudalNo ratings yet

- NC-CNC 1Document155 pagesNC-CNC 1mukul vermaNo ratings yet

- Nanotechnology PPT R22Document35 pagesNanotechnology PPT R22keerthi goratiNo ratings yet

- Yale - Hoist - Global - King - 5 - To - 15 - Ton - Manual V2 PDFDocument56 pagesYale - Hoist - Global - King - 5 - To - 15 - Ton - Manual V2 PDFJulValdiNo ratings yet

- Zinc Oxide Surge Arrester PEXLIM Q-Y GuideDocument7 pagesZinc Oxide Surge Arrester PEXLIM Q-Y GuidewiznuvNo ratings yet

- Section 14 (Water Distribution Systems)Document88 pagesSection 14 (Water Distribution Systems)badrul79No ratings yet

- 02 - WORLDBRIDGE - Aluminum Dome RoofDocument50 pages02 - WORLDBRIDGE - Aluminum Dome RoofALONSO GOMEZNo ratings yet

- 01-SAMSS-042 - RTR Pipe and Fittings in Water and Hydrocarbon ServicesDocument4 pages01-SAMSS-042 - RTR Pipe and Fittings in Water and Hydrocarbon ServicesZahidRafiqueNo ratings yet

- Product Data: Hexply 916Document2 pagesProduct Data: Hexply 916McLemiNo ratings yet

- Bearing FitsDocument7 pagesBearing FitsBurak KoyuncuogluNo ratings yet

- Group Codes and Rates for Agricultural ProductsDocument260 pagesGroup Codes and Rates for Agricultural ProductsSK Business groupNo ratings yet

- 04-06 T1 VW Touareg HID Conversion DIYDocument4 pages04-06 T1 VW Touareg HID Conversion DIYMiriam Zahir100% (1)

- Engineering Chemistry 2Document12 pagesEngineering Chemistry 2Anirudhan GuruNo ratings yet

- Tool WearDocument11 pagesTool WearRam27092003 GermanNo ratings yet

- CONTROL TECHNICIAN TUBING INSTALLATIONDocument19 pagesCONTROL TECHNICIAN TUBING INSTALLATIONsomucdm6023No ratings yet

- Application of Plasma MIG Hybrid Welding To Dissimilar Joints Between Copper and SteelDocument6 pagesApplication of Plasma MIG Hybrid Welding To Dissimilar Joints Between Copper and SteelKaushik SenguptaNo ratings yet

- Carboguard 190HB: Selection & Specification DataDocument2 pagesCarboguard 190HB: Selection & Specification DataAchraf BoudayaNo ratings yet

- RBFBBEDocument66 pagesRBFBBELauro RdzNo ratings yet

- Andritz Decanter For Soyamilk Processing - Loic LebegueDocument30 pagesAndritz Decanter For Soyamilk Processing - Loic LebeguebanerjeeamlanNo ratings yet

- 8.1 O&M-KAT B 1310 EKN Edition2 en 11 09.unlockedDocument16 pages8.1 O&M-KAT B 1310 EKN Edition2 en 11 09.unlockeddarinnavilNo ratings yet

- 1l7410a e 4 - Exaxa2 1PBDocument44 pages1l7410a e 4 - Exaxa2 1PBEduardo Muñiz67% (3)

- Kurita Recommnedation On Boiler Chemical TreatmentDocument12 pagesKurita Recommnedation On Boiler Chemical TreatmentSibabrata Choudhury100% (1)

- NCERT Solutions For Class 10 Science Chapter 1 Chemical Reactions & EquationsDocument1 pageNCERT Solutions For Class 10 Science Chapter 1 Chemical Reactions & Equationscaptain6233No ratings yet

- Thermocouple and RTD Measurements Experiment ReportDocument10 pagesThermocouple and RTD Measurements Experiment Reporthellothere100% (1)

- General Bearing Requirements and Design CriteriaDocument6 pagesGeneral Bearing Requirements and Design Criteriaapi-3701567100% (2)

- Sikalastic®-560 GCC Eco-friendly Liquid Roof WaterproofingDocument7 pagesSikalastic®-560 GCC Eco-friendly Liquid Roof WaterproofingDarwin SagiNo ratings yet

- Gledhill Stainless ES Issue 7 1Document32 pagesGledhill Stainless ES Issue 7 1anthonycmartin76No ratings yet