Professional Documents

Culture Documents

Mechanics Formulas

Uploaded by

Marvin Dale WongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanics Formulas

Uploaded by

Marvin Dale WongCopyright:

Available Formats

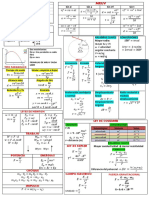

ECE 2115 General Engineering Cognate

Formula Sheet & Conversion Factors

STATICS Friction

𝑓 = 𝜇𝑁

Forces and Components 𝑓

Θ = tan-1 𝑁

Fx = Fcosθ

Fy = Fsinθ

Belt Friction

F = √(𝐹𝑥)2 + (𝐹𝑦)2 𝑇1

𝐹𝑦 = 𝑒 𝜇β

Θ= tan-1 (𝐹𝑥 ) 𝑇2

By coordinate dimensions: DYNAMICS

𝐹𝑥 𝐹𝑦 𝐹𝑧 𝐹

= = = Rectilinear Motion

𝑥 𝑦 𝑧 𝑑

𝑑𝑆

d = √𝑥 2 + 𝑦 2 + 𝑧 2 𝑣=

𝑑𝑡

𝑑𝑉

By direction angles: 𝑎=

𝑑𝑡

𝐹𝑥 𝐹𝑦 𝐹𝑧 𝐹

= = =

𝑐𝑜𝑠Θx 𝑐𝑜𝑠Θ𝑦 𝑐𝑜𝑠Θ𝑧 1 𝑉 2 = 𝑉𝑜2 + 2𝑎𝑠

𝑉 = 𝑉𝑜 + 𝑎𝑡

Resultant of Forces in Space: 1

𝑠 = 𝑉𝑜𝑡 + 𝑎𝑡 2

R = √(𝑅𝑥)2 + (𝑅𝑦)2 + (𝑅𝑧)2 2

Moment Analysis Free-Falling Bodies

Moment of a Force 𝑉 2 = 𝑉𝑜2 − 2𝑔𝑦

M = Fd 𝑉 = 𝑉𝑜 − 𝑔𝑡

1

𝑠 = 𝑉𝑜𝑡 − 𝑔𝑡 2

Couple 2

| C | = Fd

Curvilinear Motion

𝑑𝑣

Equilibrium 𝑎𝑇 =

𝑑𝑡

Loading Principles

𝑣2

Square: R = ωL 𝑎𝑁 =

𝑟

Triangle: R = (½) ωL

𝑎 = √(𝑎𝑁 ) + (𝑎 𝑇 )2

2

Projectile Motion Banking of Highway Curves

x-axis; ax = 0 V = V-rated

𝑥 = (𝑉𝑜 cos 𝜃)(𝑡) 𝑉𝑟𝑎𝑡𝑒𝑑 2

tan 𝜃 =

𝑉𝑥 2 = (𝑉𝑜 cos 𝜃)2 𝑟𝑔

𝑉𝑥 = 𝑉𝑜 cos 𝜃 𝜃 = 𝑎𝑛𝑔𝑙𝑒 𝑜𝑓 𝑒𝑙𝑒𝑣𝑎𝑡𝑖𝑜𝑛

y-axis; ay =-g V > V-rated

1 𝛽 =𝜃+∅

𝑦 = (𝑉𝑜 sin 𝜃𝑡) − 𝑔𝑡 2

2 ∅ = 𝑎𝑛𝑔𝑙𝑒 𝑜𝑓 𝑓𝑟𝑖𝑐𝑡𝑖𝑜𝑛

2 2

𝑉𝑦 = (𝑉𝑜 sin 𝜃) − 2𝑔𝑦

𝑉𝑦 = 𝑉𝑜 sin 𝜃 − 𝑔𝑡 V < V-rated

𝛼 = 𝜃−∅

𝑉𝑜2 sin 2𝜃

𝑅=

𝑔 Impulse and Momentum

Coefficient of Restitution

(𝑉𝑜 sin 𝜃)2 𝑢2 − 𝑢1

ℎ= 𝑒=

2𝑔 𝑣1 − 𝑣2

General Equation of a Projectile Impulse Equation

𝑔𝑥 2 𝑤

𝑦 = 𝑥 tan 𝜃 − 𝛴𝐹 • 𝑡 = (𝑉 − 𝑉𝑜)

2𝑉𝑜2 𝑐𝑜𝑠 2 𝜃 𝑔

Rotational Motion Momentum

𝜔 = 𝜔𝑜 + 𝛼𝑡 𝑤

𝑀𝑂𝑀 = (𝑣) = 𝑚𝑣

𝜔 = 𝜔𝑜 2 + 2𝛼𝜃

2 𝑔

1

𝜃 = 𝜔𝑜 𝑡 + 𝛼𝑡 2 STRENGTH OF MATERIALS

2

Stress

Mass Moment of Inertia 𝑃

𝜎=

𝑤 𝐴

𝐼 = 𝑚𝑘 2 = ( )𝑘 2

𝑔

Tensile Stress (Solid Cylinder)

Force-Inertia Method 𝑃

𝜎𝑡 = 𝜋

𝑤 (4 𝐷2 )

𝑅 = 𝛴𝐹 = 𝑚𝑎 = ( ) 𝑎

𝑔

g = 32 fps2 = 9.8 m/s2

Tensile Stress (Hollow Cylinder)

𝑃

Dynamic Equilibrium 𝜎𝑡 = 𝜋

𝑤

(4 𝐷2 − 𝑑2 )

REF = ( 𝑔 ) 𝑎

Compressive Stress Static Indeterminancy

𝑃 Case 1

𝜎𝑐 = 𝜋

( 𝐷2 ) 𝛿𝑠 = 𝛿𝑐

4

𝑃

𝜎𝑐 = 𝜋 Case 2

(4 𝐷2 − 𝑑2 )

𝛿𝑠 = 𝛿𝑠 + 𝑒

Stress on Riveted Plate

Case 3

𝑃

𝜎𝑠 = 𝜋 𝛿𝑠 𝛿𝑎 𝑑𝑄

(4 𝑑2) tan 𝜃 = = =

𝑎 𝑎+𝑏 𝑎+𝑏+𝑐

𝑃

𝜎𝑏 =

𝑑𝑡 𝛴𝑀𝐴 = 0]

𝑃𝑠 (𝑎) + 𝑃𝑎 (𝑎 + 𝑏) − 𝑄(𝑎 + 𝑏 + 𝑐) = 0

Stress on a Plate

𝑃 Thermal Deformation

𝜎𝑐 = 𝜋

(4 𝑑2) 𝛿𝑡ℎ = 𝛼𝐿∆𝑇

𝑃

𝜎𝑠 =

𝜋𝑑𝑡 Torsional Shearing Stress

𝑇𝜌

𝜏=

Stresses in Bolts 𝐽

𝑃 T = Torque; 𝜌 = radial distance;

𝜎𝑐 = 𝜋

(4 𝐷2 − 𝑑2 ) J = polar moment of inertia

𝑃 𝑇𝑟

𝜎𝑡 = 𝜋 𝜏𝑚𝑎𝑥 =

𝐽

( 𝑑2 )

4

𝑃

𝜎𝑠 = Polar Moment of Inertia

𝜋𝑑ℎ 𝜋

𝐽𝑠𝑜𝑙𝑖𝑑 = (𝐷)4

32

Strain 𝜋

𝐽ℎ𝑜𝑙𝑙𝑜𝑤 = (𝐷4 − 𝑑 4 )

𝛿 32

𝜀=

𝐿

Angle of Twist

Hooke’s Law 𝑇𝐿

𝜃=

𝜎 = 𝐸𝜀 𝐽𝐺

E = modulus of elasticity

Modulus of Rigidity

𝑃𝐿 𝜏

𝛿= 𝐺=

𝐴𝐸 𝛾

Deformation Power Transmission

𝜌𝑔𝐿2 𝑃 = 2𝜋𝑓𝑇

𝛿=

2𝐸 𝜔 = 2𝜋𝑓

𝑃𝐿 𝜌𝑔𝐿2 T = twisting moment/torque

𝛿𝑇𝐹 = +

𝐴𝐸 2𝐸

Flanged Bolt Coupling Spring Index

Torque Capacity 𝐷𝑚

𝑚=

For any number of bolts, n 𝑑

𝜋

𝑇 = 𝑃𝑅𝑛 = 𝜏( 𝑑2 )(𝑅𝑛 )

4 Wahl’s Factor

4𝑚 − 1 0.615

𝑊𝐹 = ( + )

Two concentric rows of bolts 4𝑚 − 4 𝑚

𝑇 = 𝑃1 𝑅1 𝑛1 + 𝑃2 𝑅2 𝑛2

Bar Elongation

Shear Strain 64𝑃𝑅 3 𝑛

𝛾1 𝛾2 𝛿=

𝐺𝑑 4

=

𝑅1 𝑅2

Spring Constant

Hooke’s Law 𝑃 𝐺𝑑 4

𝑃1⁄ 𝑃2 𝑘= =

𝛿 64𝑅 3 𝑛

𝐴1 = ⁄𝐴2

𝐺1𝑅1 𝐺2𝑅2 Springs in series: inverse

Springs in parallel: additive

Bolts on the two circles have the same area, bolts

are made of the same material Thin-Walled Pressure Vessel

𝑃1 𝑃2 1

= 𝑡 ≤ 𝑟

𝑅1 𝑅2 10

Stress in Helical Springs Circumferential Stress

𝜏 = 𝜏1 + 𝜏2 𝜌𝑑

𝜎𝑐 =

2𝑡

Direct Shear Stress

𝑃 Longitudinal / Circumferential Stress

𝜏1 = 𝜋 𝜌𝑑

(4 𝑑2 ) 𝜎𝑙 =

4𝑡

Torsional Shearing Stress

16𝑃𝑅 Factor of Safety

𝜏2 =

𝜋𝑑 3 𝜎𝑦

𝑆𝐹 =

𝜎𝑤

Total Stress (Light Spring)

16𝑃𝑅 𝑑 Thermodynamics

𝜏= (1 + )

𝜋𝑑3 4𝑅 𝑘𝐹

R = mean radius (coil radius) 𝑎=

𝑚

𝐹 = 𝑚𝑎

Total Stress (Heavy Spring)

16𝑃𝑅 4𝑚 − 1 0.615

𝜏= ( + )

𝜋𝑑 3 4𝑚 − 4 𝑚

Pressure

Vacuum

P = Po – Pg

Not Vacuum

P = Po + Pg

Absolute Temperature, T

T°R = t°F + 460 (degree Rankine)

T°K = t°C + 273 (Kelvin)

180 F° = 100 C°

5

1 F° = 9 C°

9

1 C° = 5 F°

1𝑔𝑓 =980.66 dyne 1 F° = 1 R°

1𝑘𝑔𝑓 =9.8066 N 1 C° = 1 K°

1𝑙𝑏𝑓 = 4.448 𝑁

1 slug = 32.174 𝑙𝑏𝑚

1𝑙𝑏𝑚 = 453.51 𝑔𝑚 Conservation of Mass

𝑚 𝐹 𝐹𝑔 Quantity of fluid passing thru a given section:

= = 𝑉̇ = 𝐴𝜐

𝑘 𝑎 𝑔

𝑉̇ 𝐴𝜐

𝑚̇ = = = 𝐴𝜐𝜌

Specific Volume 𝑣 𝑣

𝑉 1

𝑣= =

𝑚 𝜌

Specific Weight

𝐹𝑔

𝛾=

𝑉

Relationship

𝜌𝑔

𝛾=

𝑘

You might also like

- Dynamics FULL Equation SheetDocument2 pagesDynamics FULL Equation SheetZachNo ratings yet

- Orbital Mechanics Cheat SheetDocument3 pagesOrbital Mechanics Cheat SheetRodolfo SotoNo ratings yet

- Grade 11 Pre Calculus Formula SheetDocument1 pageGrade 11 Pre Calculus Formula SheetNantaNo ratings yet

- Module Iii - Elastic Design of PrestressedDocument28 pagesModule Iii - Elastic Design of PrestressedJonas Fernandez100% (2)

- Lectures On Building PhysicsDocument145 pagesLectures On Building PhysicsKarolina DróżdżNo ratings yet

- Seismic Response Spectrum: A Tool for Seismic Analysis and DesignDocument53 pagesSeismic Response Spectrum: A Tool for Seismic Analysis and Designbalamech91No ratings yet

- Midas - Nonlinear Analysis Using General Link ElementsDocument20 pagesMidas - Nonlinear Analysis Using General Link ElementsSampathNarayananNo ratings yet

- Sph4ue - Formula Sheet 2023Document2 pagesSph4ue - Formula Sheet 2023speedyz3377No ratings yet

- General Physics 1 First Quarter Important FormulasDocument1 pageGeneral Physics 1 First Quarter Important FormulasWarren PagsuyuinNo ratings yet

- Physics 1301 Equation SheetDocument2 pagesPhysics 1301 Equation Sheeth.krijestoracNo ratings yet

- MIE100H1 - 20195 - 631572298320MIE 100 CheatsheetDocument2 pagesMIE100H1 - 20195 - 631572298320MIE 100 CheatsheetSCR PpelusaNo ratings yet

- 1 L2 Basic Interference (Step by Step) v.2Document7 pages1 L2 Basic Interference (Step by Step) v.2Vincent TionoNo ratings yet

- Formulario FisicaDocument1 pageFormulario Fisicanayely merchanNo ratings yet

- Formulario Matter and Energy IDocument3 pagesFormulario Matter and Energy IHever AranaNo ratings yet

- Physics 1 Formula SheetDocument2 pagesPhysics 1 Formula SheetMichaelNo ratings yet

- قوانينDocument1 pageقوانينMajd OsamaNo ratings yet

- Formulario Física 2Document2 pagesFormulario Física 2carlos camposNo ratings yet

- 1301-formula-sheetDocument2 pages1301-formula-sheetdivitimaniteja999786No ratings yet

- Laplace and Z-TransformsDocument23 pagesLaplace and Z-TransformsHussam AliraqiNo ratings yet

- Physics Class 11 DerivationDocument4 pagesPhysics Class 11 Derivation1234raoshabNo ratings yet

- AERODYN2 Part 5 Fundamentals of Flight Mechanics For Steady FlightDocument25 pagesAERODYN2 Part 5 Fundamentals of Flight Mechanics For Steady FlightSecretNo ratings yet

- Formula Rio PotenciaDocument2 pagesFormula Rio PotenciaKELY PILCONo ratings yet

- Center: Pre-Calculus GuideDocument7 pagesCenter: Pre-Calculus GuideLovEegnia BalbuenaNo ratings yet

- Physics 12 Data SheetDocument3 pagesPhysics 12 Data SheetfesNo ratings yet

- Electric PotentialDocument10 pagesElectric PotentialSrishti PathakNo ratings yet

- Physics 141 Equation Sheet for Motion, Forces & EnergyDocument1 pagePhysics 141 Equation Sheet for Motion, Forces & EnergySimon SituNo ratings yet

- 1.0 Atomic StructureDocument37 pages1.0 Atomic StructureRustin PurplemanNo ratings yet

- PRECALCDocument2 pagesPRECALCItachi ItachiNo ratings yet

- Formulas - MathDocument49 pagesFormulas - MathReuben Madera DabaNo ratings yet

- Physics EquationsDocument2 pagesPhysics Equationsapi-641245937No ratings yet

- General Physics Summary of FormulasDocument8 pagesGeneral Physics Summary of FormulasJemimah FVNo ratings yet

- Electric Potential New SylabusDocument11 pagesElectric Potential New SylabusNilesh ku. BeheraNo ratings yet

- Physics 25.1 Chapter OverviewDocument4 pagesPhysics 25.1 Chapter Overviewjulianne sanchezNo ratings yet

- PHY108-Spring22-EquationSheet4Document3 pagesPHY108-Spring22-EquationSheet4yasiv29532No ratings yet

- PDFsam_mergeDocument4 pagesPDFsam_mergeyasiv29532No ratings yet

- Act Math Formulas Interactive 1Document2 pagesAct Math Formulas Interactive 1Isley Quintine YutucNo ratings yet

- EDC Unit-I RectifiersDocument12 pagesEDC Unit-I Rectifiersneha yarrapothuNo ratings yet

- ALGEBRAIC CURVES AND TRIGONOMETRIC FUNCTIONSDocument4 pagesALGEBRAIC CURVES AND TRIGONOMETRIC FUNCTIONSblueberrytimeNo ratings yet

- Techniques To Solve: - WorkDocument9 pagesTechniques To Solve: - Workarianne denice100% (1)

- Kinematics Formulas and Motion EquationsDocument6 pagesKinematics Formulas and Motion EquationsMarvin LabiNo ratings yet

- Advance Mathematical Physics in Cylindrical CoordinatesDocument6 pagesAdvance Mathematical Physics in Cylindrical CoordinatesRaufAhmedNo ratings yet

- Hagen Poisuille EquationDocument4 pagesHagen Poisuille EquationRochakNo ratings yet

- CaseDocument3 pagesCaseZeeshan MahmoodNo ratings yet

- MECH380 - Take Home Quiz - 1 - SolutionDocument7 pagesMECH380 - Take Home Quiz - 1 - SolutionvjscricNo ratings yet

- Rumus FisikaDocument2 pagesRumus FisikaJatiurNo ratings yet

- Physics 1 Formula SheetDocument4 pagesPhysics 1 Formula Sheetk kNo ratings yet

- Axisymmetric consolidation equation in polar coordinatesDocument113 pagesAxisymmetric consolidation equation in polar coordinatespiyush anandNo ratings yet

- List of FormulasDocument1 pageList of FormulasKevin ElevenNo ratings yet

- Formulae, Tables and Guidance Notes For Examination PDFDocument31 pagesFormulae, Tables and Guidance Notes For Examination PDF123No ratings yet

- Geometry Formula SheetDocument1 pageGeometry Formula Sheetclara.hyun.baeNo ratings yet

- 1714methods Unit 1 Exam NotesDocument2 pages1714methods Unit 1 Exam NotesIsaiah KimNo ratings yet

- Formula Sheet For Free VibrationDocument5 pagesFormula Sheet For Free VibrationCesar MolinaNo ratings yet

- Design & Control of Excitation System For Sync Generator: Mid Project PresentationDocument33 pagesDesign & Control of Excitation System For Sync Generator: Mid Project PresentationMuhammad Raheel TariqNo ratings yet

- Chapterwise Formula-1Document3 pagesChapterwise Formula-1tunio.bscsf21No ratings yet

- Constant velocity formula sheet for physics formulasDocument2 pagesConstant velocity formula sheet for physics formulassharon100% (2)

- Formula StatistikDocument2 pagesFormula StatistikIkmal FaizienNo ratings yet

- Formula Sheet: Olutions To A Quadratic Equation NtegralsDocument2 pagesFormula Sheet: Olutions To A Quadratic Equation Ntegralssamantha davidsonNo ratings yet

- MA20226 Statistics 2A CourseworkDocument3 pagesMA20226 Statistics 2A CourseworkVlad BrebeanuNo ratings yet

- Diodo Emisor de Luz (LED) : Fibra ÓpticaDocument1 pageDiodo Emisor de Luz (LED) : Fibra ÓpticaDario Vasco MeleroNo ratings yet

- Statics 2Document5 pagesStatics 2Byron Lorenzo YumolNo ratings yet

- Machine Design Tutorials - Week 1Document24 pagesMachine Design Tutorials - Week 1Yunsu LeeNo ratings yet

- A-level Maths Revision: Cheeky Revision ShortcutsFrom EverandA-level Maths Revision: Cheeky Revision ShortcutsRating: 3.5 out of 5 stars3.5/5 (8)

- Fransson Jocker Bolcs Ott Igti490 98Document11 pagesFransson Jocker Bolcs Ott Igti490 98HomeNo ratings yet

- Cluny Public School Model Exam ChemistryDocument2 pagesCluny Public School Model Exam ChemistryAine Ann BabuNo ratings yet

- Physical Modelling of Porous Plug Stirred LadleDocument17 pagesPhysical Modelling of Porous Plug Stirred LadleSonali ChourasiaNo ratings yet

- Rotameter ExperimentDocument5 pagesRotameter ExperimentMeet Mac PatelNo ratings yet

- VBA Hysys User Unit Operation - DehumidifierDocument3 pagesVBA Hysys User Unit Operation - DehumidifierEnrique RuedaNo ratings yet

- Hec Ras Training Day 2 PDFDocument147 pagesHec Ras Training Day 2 PDFHendrickNo ratings yet

- Dr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsDocument37 pagesDr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsVikram BorkhediyaNo ratings yet

- Magnetic RefrigerationDocument21 pagesMagnetic RefrigerationVishnu RajuNo ratings yet

- Introduction About Distillation ColumnDocument24 pagesIntroduction About Distillation ColumneliasNo ratings yet

- Cpp-Liquid Solution-Pkd - VKTDocument6 pagesCpp-Liquid Solution-Pkd - VKTVIVEK KUMARNo ratings yet

- Odometer Reading (Mi)Document4 pagesOdometer Reading (Mi)Terra DrakeNo ratings yet

- Iso 3555 1977Document13 pagesIso 3555 1977KRUNALNo ratings yet

- Capitulo 9 Incropera 4 EdDocument16 pagesCapitulo 9 Incropera 4 EdDaxon RodriguezNo ratings yet

- An Empirical Equation For Thermodynamic Properties of Light Hydrocarbons and Their Mixtures Ii. Mixtures of Methane, Ethane, Propane, and NbutaneDocument13 pagesAn Empirical Equation For Thermodynamic Properties of Light Hydrocarbons and Their Mixtures Ii. Mixtures of Methane, Ethane, Propane, and NbutanelucasNo ratings yet

- Vol.1 - 41 - How Is A Truss Element and A Cable Element Considered in Midas CivilDocument1 pageVol.1 - 41 - How Is A Truss Element and A Cable Element Considered in Midas CivilafdhalNo ratings yet

- HSEB Question Collection Series - Physics, New Course 2069 XI - HSEB NOTESDocument1 pageHSEB Question Collection Series - Physics, New Course 2069 XI - HSEB NOTESHSEB Notes100% (10)

- Coiled Tubing Calculation: Sws - Career Development System (Phase - I) Coiled Tubing Service Class Room TrainingDocument16 pagesCoiled Tubing Calculation: Sws - Career Development System (Phase - I) Coiled Tubing Service Class Room TrainingNardo AvalosNo ratings yet

- Dual Counterbalance: A-VBSO-DE-30-PI 08.48.11 - X - Y - ZDocument2 pagesDual Counterbalance: A-VBSO-DE-30-PI 08.48.11 - X - Y - ZcoelhoclaudiosNo ratings yet

- Coupled Fluid Structure Interaction Simulation Using Abaqus CELDocument8 pagesCoupled Fluid Structure Interaction Simulation Using Abaqus CELbadaboyNo ratings yet

- Dynamic Simulation of Sub-Scale ITER CS/STR Cooling LoopDocument4 pagesDynamic Simulation of Sub-Scale ITER CS/STR Cooling LoopgopalkrishnaNo ratings yet

- Chapter - Vii Reservoirs and Distribution SystemDocument50 pagesChapter - Vii Reservoirs and Distribution SystemMadan GorathokiNo ratings yet

- ICFD10 Conference ProgramDocument46 pagesICFD10 Conference ProgramSamy El-BeheryNo ratings yet

- Demonstration1415-1i DontevenDocument7 pagesDemonstration1415-1i DontevenLaura WigginsNo ratings yet

- Mitsui Wall Type Series On-Off MVE - Technical SpecificationDocument1 pageMitsui Wall Type Series On-Off MVE - Technical SpecificationBruno Faria CotaNo ratings yet

- PPT On Fracture MechanicsDocument81 pagesPPT On Fracture Mechanicskamel touilebNo ratings yet

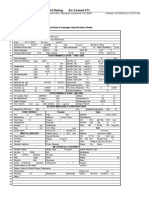

- Aspen Exchanger Design and Rating Sheet for Forced Draft Air Cooled Heat ExchangerDocument1 pageAspen Exchanger Design and Rating Sheet for Forced Draft Air Cooled Heat ExchangerHafidzAliyufaNo ratings yet