Professional Documents

Culture Documents

An Experimental Study of Alternative Materials For Dense Bituminous Macadam Surface

Uploaded by

sudarshan vOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Experimental Study of Alternative Materials For Dense Bituminous Macadam Surface

Uploaded by

sudarshan vCopyright:

Available Formats

ISSN: 1748-0345 (Online) www.tagajournal.

com

An experimental study of alternate materials for

dense bituminous macadam surface

Sankarlal.K.R

Research Scholar, Anna University, Chennai

Assistant Divisional Engineer

Highways Department, Coimbatore, India

krsankarlal@gmail.com

Ravi.E

Professor & Head

Department of Civil Engineering

Velalar College of Engineering and Technology, India

soilravi@gmail.com

Abstract— In this paper, an experimental work is carried through the replacement of fine aggregates by copper slag (CS), fly ash

(FA) and waste shredded plastics (WSP) in dense bituminous macadam surface. The copper slag is used as a fine aggregate in varying

proportion of 20%, 30% and 40%. The fly ash is used as substitute for filler material. Waste shredded plastic is added to enhance the

binding characteristics of the bitumen. The various properties were studied viz., stability, bulk density, flow value, air voids, void filled

in mineral aggregate (VMA), void filled in bitumen (VFB) for controlled mix compared with proportion of copper slag, flyash and waste

shredded plastic. The result demonstrated that the use of copper slag in additional percentage of 30% is favorable because the flow

value increase and the stability value decreases. The stability aspect in the above materials may be useful to replace the aggregate since

the bulk density of mix has been increased by addition of alternate material and the life time of surface may be increased.

Keywords— copper slag, Marshall stability, flow value, waste shredded plastic

I. INTRODUCTION

In India, the demand for aggregate is increasing drastically towards civil engineering industry especially for highway and

concrete constructions. The addition of copper slag as aggregate replacement in hot asphalt mixes containing the reclaimed

asphalt pavement and it shows the presence of the copper slag in all addition percentage increases the density of mixes upto 16%

due to iron content that exists in these materials. The use of copper slag reduces the Marshall Stability values for additions

exceeding 25% reaching similar levels to the control mixture values [1]. Copper slag and zinc slag may be used as a partial

replacement of the fine aggregate for the construction of sub base, base and bituminous layers. The specific gravity of copper

slag, zinc slag and steel slag ranges from 2.75-3.6. The Marshall stability value ranges from 8.7kN to 14.7kN. The amount of

replacement various from 10-25% in the bituminous mix [2].

The copper slag (CS) was used as a fine aggregate upto 30% in the design of bituminous mix like dense bituminous macadam

and bituminous concrete. Addition of CS as fine aggregate in various bituminous mixes provides good interlocking and

eventually improves volumetric and mechanical properties of bituminous mix [3]. When CS is used as an aggregate replacement in

an asphalt mixture, the leaching that copper slag could generate is controlled, as each of the slag particle is coated by asphalt

binder and sealed of all voids. Some projects with copper slag as a fine aggregate replacement in the manufacture of asphalt

pavement has been developed with successful results for additions ranging from 5% to 30% [4, 5].

The feasibility of copper slag – fly ash mix for use in sub base course of the flexible pavements has been studied, the 30%

flyash with 70% copper slag mix was found to be optimum and suitable for use in sub base layers of the flexible pavements [6].

© 2018 SWANSEA PRINTING TECHNOLOGY LTD 546 TAGA JOURNAL VOL. 14

ISSN: 1748-0345 (Online) www.tagajournal.com

II. MATERIAL AND METHODOLOGY

A. Materials

The hard broken granite metal corresponding gradation for dense bituminous macadam grade II was selected. The copper

slag obtained from M/s. Sterlite Industry, Tuticorin. The flyash has been obtained from Neyveli Lignite Corporation, Neyveli,

Tamilnadu. The waste shredded plastics were collected from Coimbatore, Tamilnadu. Viscosity Grade bitumen VG 30 has been

used as binder content. All physical properties of above materials are tabulated in table I and table II.

B. Methodology

Aggregate gradation is one of the most important properties in bituminous mixture, which affects almost all the important

properties like stability, durability, workability and resistance to moisture damage. Therefore, gradation is primary consideration

of bituminous mix design. The typical aggregate gradation taken for the design of dense bituminous macadam (DBM) are as per

the Ministry of Road Transport and Highways (MoRTH) specification for mid-point gradation so as to explore the potential use

of fine aggregates in optimum level which enhances the property of the mixes to get the final grading. The Marshall’s method of

mix design as per ASTM D-1559 was adopted for this study. The Marshall Stability test specimens were prepared by adding 4.5,

5.0, 5.5, and 6.0 percent of bitumen by weight of aggregates. Three set of samples according to alternate materials used can be

distinguished in this research which is shown in table III.

C. Optimum Binder Content

For each proposed grading, Marshall Samples were prepared by varying the percentage of binder content and tested to infer its

volumetric properties. To obtain the optimum binder content (OBC), the values of Bulk density, Stability, Flow value and air

voids are plotted against the binder contents.

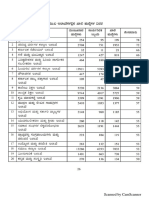

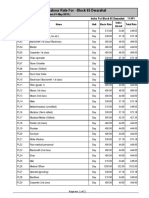

TABLE I. PROPERTIES OF MATERIALS

Properties Test value

Properties of Coarse aggregates

Bulk specific gravity 2.70

Apparent specific gravity 2.72

Impact Value 18%

Flakiness and Elongation

28%

(Combined ) Index

Water absorption 0.5 %

Properties of Fine aggregates

Bulk specific gravity 2.68

Apparent specific gravity 2.72

Properties of Copper Slag

Particle size Angular

Surface texture Granular

Colour Blackish grey

Unit weight 2800 – 3800 kg/m3

Absorption 0.13 %

Crushing Value 10.0 - 26.4

Specific gravity 3.395

Properties of flyash

Specific gravity 2.21

Fineness of Fly ash 4500cm2/kg

© 2018 SWANSEA PRINTING TECHNOLOGY LTD 547 TAGA JOURNAL VOL. 14

ISSN: 1748-0345 (Online) www.tagajournal.com

TABLE II. PROPERTIES OF VG 30 GRADE BITUMEN

Properties Test value

Softening Point, R & B 67o C

Ductility at 25 oC 75+ cm

Water content 0.2 % wt

Viscosity at 60 oC 2600 poise

o

Viscosity at 135 C 410 cst

Flash point, COC 230oC

Specific gravity at 27 oC 0.99

TABLE III. AGGREGATES (AG), COPPER SLAG (CS), FLY ASH (FA) AND WASTE SHREDDED PLASTIC (WSP) COMBINATION

Volume dosage by Percentage

WSP

Combination Samples

( % in

AG CS FA

binder)

Control Mix Control Mix 100

20 CS 80 20

Set -I 30 CS 70 30

40 CS 60 40

20 CS + FA 73 20 7

Set -II 30 CS + FA 63 30 7

40 CS + FA 53 40 7

20 CS + FA+ WSP 73 20 7 8

Set -III 30 CS + FA+ WSP 63 30 7 8

40 CS + FA+ WSP 53 40 7 8

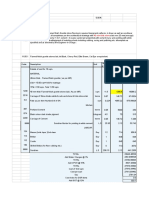

TABLE IV. RESULTS OF BITUMINOUS MIXES FOR THE COMBINATION

Binder content ( By

Bulk density, g/cc

weight of mix)

Air voids, %

Stability , kg

Flow, mm

VMA, %

VFB, %

Combination

Control Mix 4.51 2.409 4.208 14.866 72 1428 2.43

20 CS 4.76 2.452 4.084 15.543 73 1421 2.70

30 CS 5.00 2.527 4.170 16.586 74 1341 2.98

40 CS 5.57 2.639 4.119 18.551 78 1020 3.67

20 CS + FA 4.60 2.421 4.203 15.134 73 1284 2.88

30 CS + FA 4.94 2.481 4.097 16.132 75 1187 3.13

40 CS + FA 5.53 2.605 4.16 18.289 77 980 4.22

© 2018 SWANSEA PRINTING TECHNOLOGY LTD 548 TAGA JOURNAL VOL. 14

ISSN: 1748-0345 (Online) www.tagajournal.com

20 CS + FA+ WSP 4.58 2.425 4.089 14.993 73 1327 2.81

30 CS + FA+ WSP 4.85 2.485 4.091 15.924 74 1290 3.02

40 CS + FA+ WSP 5.35 2.617 4.029 17.764 78 981 3.69

III. RESULTS AND DISCUSSSION

It has been seen that from fig 1. 40% copper slag with fly ash, waste shredded plastics gives the low stability value and

controlled mix without any alternate materials produces good stability values. The increasing order of stability values

corresponding to the binder content as follows: 40CS+FA<40CS+FA+WSP<40CS<30CS+FA<30CS+FA+

WSP<20CS+FA<30CS<20CS+FA+WSP<20CS<controlled mix. As per the MoRTH in India, standard the optimum binder ratio

has to produce the stability value of 9 kN. Based on the above standard value, the binder content with 40% of copper slag may

produce the strength of dense bituminous macadam surface. Raposeiras et al., (2016), the addition of 35% of copper slag gives

favorable stability value. All the provision including the controlled mix and the initial portion of curve shows more stability than

the optimum of more binder content. It is evident that beyond the optimum particles are separated by which the load is applied on

the marshal stability test.

Fig. 1.Binder Content Vs Stability

From fig.2. binder content with bulk density the marshal results show maximum, increasing of binder content is directly

proportional to the bulk density for 40 CS, 40CS+FA and 40CS+FA+WSP. Whereas other proportion gives the optimum up to

5.5% of binder content, beyond the bulk density has decreased. It has been found that the gradual increasing and decreasing trends

taken place all proportion of material except 40CS, 40CS+FA and 40CS+FA+WSP.

Fig. 2. Binder Content Vs Bulk density

The binder content with air voids curves shown in fig.3 that the binder content for 40CS, 40 CS+FA and 40 CS+FA+WSP is

indirectly proportional to air voids. The remaining proportion, no increase in air voids beyond the 5.50% binder content. This

result shows that upto 30 CS in addition with FA and WSP may be adoptable for preparing the DBM larger. Many researchers

proceed that the addition of binder content beyond 5.5% has not influenced in the air voids.

© 2018 SWANSEA PRINTING TECHNOLOGY LTD 549 TAGA JOURNAL VOL. 14

ISSN: 1748-0345 (Online) www.tagajournal.com

Fig. 3. Binder Content Vs Air Voids

The flow value for the binder content is directly proportional to the alternate material. The curve shown in fig. 4. between

binder and flow value in mm deals that beyond 5.5% and binder another drastically increases the value. It has been observed that

40CS with FA and WSP not suited. Since the flow value leads to bleeding effect during summer period.

Fig. 4. Binder Content Vs Flow value

IV. CONCLUSIONS

Based on the experimental and analysis of results on the effect carried by the replacement of copper slag, fly ash and waste

shredded plastic for the fine aggregate in hard broken granite metal as follows,

1. The optimum binder content with the marshal stability shows the higher value for controlled mix, where as the alternate

material replaces upto 30% of copper slag with fly ash and waste shredded plastic gives the requirements based on ministry of

road transport and highways (MORTH).

2. Regarding with density consideration higher percent of CS, CS+FA and CS+FA+WSP shows the abnormal value.

Hence, the binder content of 5.5% for replacement of other alternate material like CS,FA and WSP may consider to form DBM

layer.

3. The binder content with flow value graph may considered that the higher flow for 40% CS with FA and WSP produced

more and not suitable .The controlled mix will show the low flow value and the 30CS, 30CS+FA and 30CS+FA+WSP, shows

moderate flow value.

4. The binder content with air void curve shows that beyond the optimum, there is no change of air voids except 40CS,

40CS+FA,40CS+FA+WSP. Hence, the 20% replacement and 30% replacement may be well suited to make DBM surface.

© 2018 SWANSEA PRINTING TECHNOLOGY LTD 550 TAGA JOURNAL VOL. 14

ISSN: 1748-0345 (Online) www.tagajournal.com

References

[1] A.C.Raposeiras, A.Vargas-ceron, D.Mavilla-Quesada,“Effect of copper slag addition on mechanical behaviour of asphalt mixes containing reclaimed asphalt

pavement”, Construction and Building materials,119,PP.268-276, 2016.

[2] Havanagi V G , Sinha A K , Arora V K and Mathur S, “Waste materials for construction of road embankment and pavement layers ”, international journal of

environmental engineering research, volume 1, issue 2,pp. 51-59, 2012.

[3] Pundhir N K S, Kamaraj C and Nanda P K, “Use of copper slag as construction material in bituminous pavements”, Journal of scientific and Industrial

Research, Volume 64, PP 997-1002,2005.

[4] B.Gorai, R.K.Jana, charactersiitcs and utilization of copper slag – a review, Resour, Conserv. Recyl. 39 (4),PP299-313, 2003

[5] V.G.Havanagi, A.K.Sinha, P.Prasad, “Copper slag as an alternative material for Road constrcution”, 25 th international conference on solid waste technology

and management, Philadelphia, USA, March 2009.

[6] Patel S, Shahu J T, Senapati A, “ Feasibility of Copper Slag - Fly Ash Mix as a Road Construction Material” ACEE Int. J. on Transportation and Urban

Development, Vol. 2, No. 1, April 2012.

[7] Kajial, Pundhir N K S, Sangita, and Chandra A , “Use of waste plastics and copper slag for low cost bituminous road”, Journal of scientific and Industrial

Research, Volume 66, PP 997-1002, 2007.

[8] Lavanya C ,Sreerama Rao A, and Darga Kumar N , “Review on utilization of copper slag in geotechnical applications Proceedings of Indian Geotechnical

Conference”, December 15-12, Kochi (Paper No.H-212),2011.

[9] Nitish K. K, Harish N, Muttana S.B and Swamy C B, “ Utilization of Copper ore tailings and fly ash mix as road sub grade/embankment material”

Proceedings of Indian Geotechnical Conference December 22-24, 2013, Roorkee.

[10] Debashish Kar, Mahabir Panda and Jyoti Prakash Giri , “Influence of fly-ash as a filler in bituminous mixes”, ARPN Journal of Engineering and Applied

Sciences, Vol.9, no. 6, issn 1819-6608,2014.

[11] Rahman.M.N and Sobhan. M.A, “ Use of Non-Conventional Fillers on Asphalt-Concrete Mixture”, International Journal of Innovation and Applied Studies

ISSN 2028-9324, Volume 3, pp. 1101-1109,2013.

[12] Katara S.D, Modhiya C.S, Raval N.G, “Influence of Modify Bituminous Mix with Fly Ash” International Journal of Engineering and Technical Research

(IJETR) ISSN: 2321-0869, Volume-2, Issue-4, April 2014.

[13] S. Bose, M. C. Harit, C. Kamaraj and M. Singh, Development of Mix Design Procedures for Bituminous Macadam Mixes for Roads and Highways,

Highway Research Bulletin, Indian Roads Congress, 65, Dec 2001, Special Research Presentation at Annual Session of IRC, Kochi, Jan 2002.

[14] P. B. Queneau, L. D. May and D. E. Cregar, Application of Slag Technology to Recycling of Solid Wastes, Incineration Conference, Knoxwille, TN, May

1991.

© 2018 SWANSEA PRINTING TECHNOLOGY LTD 551 TAGA JOURNAL VOL. 14

You might also like

- 6 Aa 0Document7 pages6 Aa 0jose nicolas hidalgoNo ratings yet

- Ba 3 PDFDocument5 pagesBa 3 PDFhakNo ratings yet

- Utilization of Bagasse Ash As A Partial Replacement of Fine Aggregate in ConcreteDocument5 pagesUtilization of Bagasse Ash As A Partial Replacement of Fine Aggregate in ConcreteManasa MadugulaNo ratings yet

- IJASTDocument9 pagesIJASTgopierode4No ratings yet

- M0509083087 PDFDocument5 pagesM0509083087 PDFMr PolashNo ratings yet

- Experimental Study On Flexural Behaviour of RC Beams With Graphene Oxide and Bottom AshDocument35 pagesExperimental Study On Flexural Behaviour of RC Beams With Graphene Oxide and Bottom AshPraveen RajNo ratings yet

- Application of Waste Materials As Fillers in Bituminous MixesDocument9 pagesApplication of Waste Materials As Fillers in Bituminous MixesDipendra AwasthiNo ratings yet

- Improving The Performance of Bituminous Concrete Mix by Waste PlasticDocument6 pagesImproving The Performance of Bituminous Concrete Mix by Waste PlasticAfi KhanNo ratings yet

- IJCRT1892221Document6 pagesIJCRT1892221Niva R ChandraNo ratings yet

- Strength of Concrete Structure Partial Replacement of Sand by Copper SlagDocument6 pagesStrength of Concrete Structure Partial Replacement of Sand by Copper SlagEditor IJTSRDNo ratings yet

- Experimental Study On Heavy Weight Concrete Using Hematite and Laterite As Coarse AggregateDocument5 pagesExperimental Study On Heavy Weight Concrete Using Hematite and Laterite As Coarse Aggregatesampath karriNo ratings yet

- Ground Granulated Blast Furnace Slag (GGBS) : Effect of Particle Size and Dosage On Compressive Strength With Microstructural Analysis of ConcreteDocument8 pagesGround Granulated Blast Furnace Slag (GGBS) : Effect of Particle Size and Dosage On Compressive Strength With Microstructural Analysis of ConcreteIJRASETPublicationsNo ratings yet

- A Study On Properties of Glass Fiber Reinforced Self Compacting Concrete (GFRSCC) Using Fly AshDocument5 pagesA Study On Properties of Glass Fiber Reinforced Self Compacting Concrete (GFRSCC) Using Fly AshFyroz DadapeerNo ratings yet

- Study On Partial Replacement of Cement WDocument6 pagesStudy On Partial Replacement of Cement Wpastor.flores111No ratings yet

- 1218 2818 1 PBDocument8 pages1218 2818 1 PBmahparaNo ratings yet

- Bitumen VG 30 & VG 40 Mix DesignDocument5 pagesBitumen VG 30 & VG 40 Mix DesignPoirei Zildjian0% (1)

- 03 Liteature ReviewDocument3 pages03 Liteature Reviewmohammed shamsuddinNo ratings yet

- Study On Utilization of Iron Ore Tailings As Fine Aggregates and Ggbs As Partial Substitute in Concrete IJERTV6IS060445Document4 pagesStudy On Utilization of Iron Ore Tailings As Fine Aggregates and Ggbs As Partial Substitute in Concrete IJERTV6IS060445Mahima ANo ratings yet

- 543 373 1 PBDocument12 pages543 373 1 PBsuba vNo ratings yet

- Effect of Water Cement Ratio On The Work PDFDocument8 pagesEffect of Water Cement Ratio On The Work PDFMohamed HamdyNo ratings yet

- Comparing Properties of Bituminous Concrete Mixes Prepared Using Morth and Superpave GradationsDocument8 pagesComparing Properties of Bituminous Concrete Mixes Prepared Using Morth and Superpave Gradationsmots02No ratings yet

- Study of Plastic WasteDocument15 pagesStudy of Plastic WasteJogeswari SamantarayNo ratings yet

- Fly Ash As A Fine Aggregate Replacement in Concrete Building BlocksDocument5 pagesFly Ash As A Fine Aggregate Replacement in Concrete Building BlockserpublicationNo ratings yet

- Flexural Behaviour of Fly Ash Based Geopolymer ConcreteDocument3 pagesFlexural Behaviour of Fly Ash Based Geopolymer ConcreteKarthik MANo ratings yet

- Foundry Sand Utilisation As A Partial Re PDFDocument4 pagesFoundry Sand Utilisation As A Partial Re PDFHarshit KumarNo ratings yet

- Experimental Investigation On The Use of Sugarcane Bagasse Ash Granite Waste As Fine Aggregate in ConcreteDocument11 pagesExperimental Investigation On The Use of Sugarcane Bagasse Ash Granite Waste As Fine Aggregate in ConcreteIJRASETPublicationsNo ratings yet

- Experimental Investigation On Partially Replacement of Cement, Coarse Aggregate by Corn Cob Ash and Steel SlagDocument6 pagesExperimental Investigation On Partially Replacement of Cement, Coarse Aggregate by Corn Cob Ash and Steel SlagIJIRSTNo ratings yet

- IJETR033435Document6 pagesIJETR033435erpublicationNo ratings yet

- Review On The Industrial Waste As A Building Material. Jaya RathoreDocument9 pagesReview On The Industrial Waste As A Building Material. Jaya RathoreJaya RathoreNo ratings yet

- Evaluation of Mechanical Properties of High Strength Banana Fibre Concrete (HSBFC) IncorporatingDocument17 pagesEvaluation of Mechanical Properties of High Strength Banana Fibre Concrete (HSBFC) IncorporatingIJRASETPublicationsNo ratings yet

- Durabilidad y Caracteristicas de Union de Un Concreto Con Agregado PlasticoDocument8 pagesDurabilidad y Caracteristicas de Union de Un Concreto Con Agregado PlasticoNicolas Perez VillarragaNo ratings yet

- Experimental Investigation of Silica Fume Based Concrete of M25 GradeDocument7 pagesExperimental Investigation of Silica Fume Based Concrete of M25 GradeIJRASETPublicationsNo ratings yet

- Ijsetr Vol 3 Issue 6 1877 1880Document4 pagesIjsetr Vol 3 Issue 6 1877 1880Ramya DeepthiNo ratings yet

- Experimental Investigation On Concrete With Partial Replacement of Fine Aggregate by Marble Dust PowderDocument7 pagesExperimental Investigation On Concrete With Partial Replacement of Fine Aggregate by Marble Dust PowderDas TadankiNo ratings yet

- Mechanical Properties of Self Compacting Concrete Containing Crushed Sand and Sisal FiberDocument13 pagesMechanical Properties of Self Compacting Concrete Containing Crushed Sand and Sisal FiberKevin ChumánNo ratings yet

- F8861088619Document12 pagesF8861088619jitendraNo ratings yet

- Effect of Waste Foundry Sand As PartialDocument4 pagesEffect of Waste Foundry Sand As Partialshivanand hippargaNo ratings yet

- Experimental Investigation On Partial Replacement of Fine Aggregate With Sabbath (Cuddapah Stone) StoneDocument8 pagesExperimental Investigation On Partial Replacement of Fine Aggregate With Sabbath (Cuddapah Stone) StoneAnonymous kw8Yrp0R5rNo ratings yet

- Paper862782 27861 PDFDocument5 pagesPaper862782 27861 PDFHarshali BhatNo ratings yet

- An Experimental Investigation On Steel Fiber Reinforced Concrete With Partial Replacement of Natural Sand by M-SandDocument7 pagesAn Experimental Investigation On Steel Fiber Reinforced Concrete With Partial Replacement of Natural Sand by M-SandAnonymous kw8Yrp0R5rNo ratings yet

- Experimental Study On Paver Block Production Using Construction and Demolition WasteDocument6 pagesExperimental Study On Paver Block Production Using Construction and Demolition WasteIJRASETPublicationsNo ratings yet

- Laboratory Investigation On Use of Fly Ash Plastic Waste Composite in Stone Matrix AsphaltDocument11 pagesLaboratory Investigation On Use of Fly Ash Plastic Waste Composite in Stone Matrix AsphaltMan ManNo ratings yet

- Durability Behavior of Nano-Silica and OMMT Nano-Clay in High Performance ConcreteDocument11 pagesDurability Behavior of Nano-Silica and OMMT Nano-Clay in High Performance ConcreteIJRASETPublicationsNo ratings yet

- Irjet V4i7178 PDFDocument4 pagesIrjet V4i7178 PDFAalaya Housing Private LimitedNo ratings yet

- Mechanical Behavior of Graphite/Granite Particles Reinforced Al-Si Alloy Based Composites by Stir Casting RouteDocument10 pagesMechanical Behavior of Graphite/Granite Particles Reinforced Al-Si Alloy Based Composites by Stir Casting RouteTJPRC PublicationsNo ratings yet

- Durability Study of Concrete Using Foundry Waste SandDocument4 pagesDurability Study of Concrete Using Foundry Waste SandEditor IJTSRDNo ratings yet

- Partial Replacement of Aggregates by Burnt Brick Bats and Lateritic Fines in Concrete - An Experimental InvestigationDocument10 pagesPartial Replacement of Aggregates by Burnt Brick Bats and Lateritic Fines in Concrete - An Experimental InvestigationIRJMETS JOURNALNo ratings yet

- Effect of Nano-Silica and Metakaolin On Properties of Recycled Coarse Aggregate Concrete-Ijaerdv04i0133706Document7 pagesEffect of Nano-Silica and Metakaolin On Properties of Recycled Coarse Aggregate Concrete-Ijaerdv04i0133706Editor IJAERDNo ratings yet

- Investigation On Sustainable Concrete Using M-Sand and Rice Husk AshDocument4 pagesInvestigation On Sustainable Concrete Using M-Sand and Rice Husk AshjyothiNo ratings yet

- The Behaviour of Concrete by Partial Replacement of Fine Aggregate With Copper Slag and Cement With GGBS - An Experimental StudyDocument6 pagesThe Behaviour of Concrete by Partial Replacement of Fine Aggregate With Copper Slag and Cement With GGBS - An Experimental StudyBijay Krishna DasNo ratings yet

- Analysis On Compressive Strength of Concrete Using Different Sources of Fine AggregatesDocument6 pagesAnalysis On Compressive Strength of Concrete Using Different Sources of Fine AggregatesAbhishekNo ratings yet

- Experimental Investigation of Self Compacting Concrete by Partially Replacing Fine Aggregate With Quartz Sand With Use of Recron FibreDocument6 pagesExperimental Investigation of Self Compacting Concrete by Partially Replacing Fine Aggregate With Quartz Sand With Use of Recron Fibreshivanand hippargaNo ratings yet

- Effects of Using Rice Straw and Cotton Stalk Ashes On The Properties of Lightweight Self-Compacting ConcreteDocument12 pagesEffects of Using Rice Straw and Cotton Stalk Ashes On The Properties of Lightweight Self-Compacting Concreteprincessxena.sta.rosaNo ratings yet

- Comparative Study On Replacement of Cement by Rice Husk Ash in Conventional Concrete and M Sand Concrete 1Document3 pagesComparative Study On Replacement of Cement by Rice Husk Ash in Conventional Concrete and M Sand Concrete 1International Journal of Innovative Science and Research TechnologyNo ratings yet

- 93 May2020Document6 pages93 May2020free netNo ratings yet

- Stabilization of Concrete Using Rubber Tyre Waste: January 2018Document8 pagesStabilization of Concrete Using Rubber Tyre Waste: January 2018Suno AliNo ratings yet

- Publication 5Document3 pagesPublication 5Nagaraj K CNo ratings yet

- G0709084055Document16 pagesG0709084055phanendra kumarNo ratings yet

- Experimental Study On Waste Glass As A Partial Replacing Material in Concrete For Fine AggregateDocument6 pagesExperimental Study On Waste Glass As A Partial Replacing Material in Concrete For Fine AggregateSruthi100% (1)

- KSRP SI Question Paper-2 PDFDocument30 pagesKSRP SI Question Paper-2 PDFsudarshan vNo ratings yet

- IITK Thesis Prepration GuideDocument12 pagesIITK Thesis Prepration GuideTGrey027No ratings yet

- Dissertation Phase-I GuidelinesDocument1 pageDissertation Phase-I GuidelinesnileshvranaNo ratings yet

- READDocument56 pagesREADsudarshan vNo ratings yet

- An Experimental Study of Alternative Materials For Dense Bituminous Macadam SurfaceDocument6 pagesAn Experimental Study of Alternative Materials For Dense Bituminous Macadam Surfacesudarshan vNo ratings yet

- 07 Chapter 2Document22 pages07 Chapter 2mirzaNo ratings yet

- A Partial Replacement of Fine Aggregate by Copper Slag in ConcreteDocument4 pagesA Partial Replacement of Fine Aggregate by Copper Slag in Concretesudarshan vNo ratings yet

- ReadDocument1 pageReadsudarshan vNo ratings yet

- 07 Chapter 2Document22 pages07 Chapter 2mirzaNo ratings yet

- Karnataka VacancyDocument3 pagesKarnataka Vacancysudarshan vNo ratings yet

- Sample BOQDocument2 pagesSample BOQJose Wilberto CarreteroNo ratings yet

- L-1-Classification & Various Types of BridgesDocument6 pagesL-1-Classification & Various Types of Bridgesaryan aryanNo ratings yet

- Cement Industries DataDocument66 pagesCement Industries DataChaitanya Agarwal100% (1)

- Rencana Penugasan PersonilDocument1 pageRencana Penugasan PersonilKONSULTAN RELOKASI RTGNo ratings yet

- VIJAYDocument61 pagesVIJAYYOGESH CHAUHANNo ratings yet

- Pump Hose Machine Foundation DesignDocument11 pagesPump Hose Machine Foundation DesignARSENo ratings yet

- CONTACTDocument8 pagesCONTACTJhessa Dy PerezNo ratings yet

- Basic Thumb Rules Used in Construction by Civil EngineersDocument7 pagesBasic Thumb Rules Used in Construction by Civil Engineersearth one100% (1)

- Profile Geogabinfra PDFDocument19 pagesProfile Geogabinfra PDFदेवराज सिंह गहरवारNo ratings yet

- M32-8 Statically IndeterminateMembersDocument8 pagesM32-8 Statically IndeterminateMembersRyan Jhay YangNo ratings yet

- XPS and Foam BoardDocument6 pagesXPS and Foam BoarddantranzNo ratings yet

- Granite RateDocument1 pageGranite RateBamila EliezarNo ratings yet

- Construction Methods and Project Management (C.E. 511) : Quiz No.1 and Prelim Exam Date: September 30,2021Document2 pagesConstruction Methods and Project Management (C.E. 511) : Quiz No.1 and Prelim Exam Date: September 30,2021Mary Grace PinlacNo ratings yet

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Document2 pagesET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- Base EstabilizadaDocument36 pagesBase EstabilizadaReox OneNo ratings yet

- Presentation ON Pile Foundation: Presentation By: Sangita Sutar Civil 4 Year Roll No: 1721215082Document22 pagesPresentation ON Pile Foundation: Presentation By: Sangita Sutar Civil 4 Year Roll No: 1721215082Ramakrishna PradhanNo ratings yet

- THE FEASIBILITY OF COCONUT HUSK ASH (Cocos Nucifera), SAND, AND WASTE PAPER MATERIALS AS COMPONENTS IN CEMENT-MAKINGDocument6 pagesTHE FEASIBILITY OF COCONUT HUSK ASH (Cocos Nucifera), SAND, AND WASTE PAPER MATERIALS AS COMPONENTS IN CEMENT-MAKINGJoevan Capote100% (1)

- KSB Facts Figures Addresses, Property FileDocument12 pagesKSB Facts Figures Addresses, Property FilevicknNo ratings yet

- High Strength Concrete - Material For High Rise BuldingsDocument11 pagesHigh Strength Concrete - Material For High Rise BuldingsMentorM.DervodeliNo ratings yet

- Study of Siesmic Analysis of Multistorey Building With or Without Floating ColumnsDocument18 pagesStudy of Siesmic Analysis of Multistorey Building With or Without Floating ColumnsAnkita PalNo ratings yet

- Plastering, Pointing PaintingDocument78 pagesPlastering, Pointing PaintingjashndeepNo ratings yet

- PIANC Seminar Henry WardDocument24 pagesPIANC Seminar Henry WardAl-Razzaq Al-WahhabNo ratings yet

- Block 65 Dwarahat - ResourceRate - LabourDocument2 pagesBlock 65 Dwarahat - ResourceRate - LabourManojNo ratings yet

- Design of Retaining WallsDocument69 pagesDesign of Retaining WallsJaber KnowlesNo ratings yet

- ACFrOgBVJ4gmGEUbkDmXI2Fd cgxPpERav mRXeXUraJkAW0kzvgAgSOI U1Bmmq2 YT-SmsVmpVL 1EAcXbjdOI3es VEVkEUUHHEOjbF5upb5m0tBtpmMlDQ4y VoDocument4 pagesACFrOgBVJ4gmGEUbkDmXI2Fd cgxPpERav mRXeXUraJkAW0kzvgAgSOI U1Bmmq2 YT-SmsVmpVL 1EAcXbjdOI3es VEVkEUUHHEOjbF5upb5m0tBtpmMlDQ4y VoAriel Dela CruzNo ratings yet

- Butt Weld Cap Dimension - Penn MachineDocument1 pageButt Weld Cap Dimension - Penn MachineEHT pipeNo ratings yet

- For Construction: LegendDocument1 pageFor Construction: LegendFran LuqueNo ratings yet

- Design DrawingsDocument26 pagesDesign DrawingsSuhas ZoreNo ratings yet

- OMCM ArquitectosDocument4 pagesOMCM ArquitectosGowshikaNo ratings yet

- TRCS 2 PDFDocument2 pagesTRCS 2 PDFshivaji.sarvadeNo ratings yet