Professional Documents

Culture Documents

CXVB Selection 20110404

Uploaded by

jesus casas garayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CXVB Selection 20110404

Uploaded by

jesus casas garayCopyright:

Available Formats

Selection

Two methods of unit selection are provided on the following pages. The heat rejection method is always recommended

and the selection can be made via BAC’s free product selection software, or manually as described below.

Note: Consult your local BAC Representative for evaporative condenser selections for systems utilizing the following:

99Hydrocarbon refrigerants such as propane, butane, or propylene

99Centrifugal compressors

99Rotary screw compressors with water cooled oil coolers

99Ammonia evaporative condensers with desuperheaters

99Halocarbon evaporative condensers with subcooling

Download free selection software at www.BaltimoreAircoil.com

››Heat Rejection Method

In a mechanical refrigeration system, the function of an evaporative condenser is to reject heat to the environment. The

heat to be rejected is the sum of the heat input at the evaporator and the energy input at the compressor. For a given

set of operating conditions, the energy input through the compression process can vary. Therefore, in order to accurately

determine the proper evaporative condenser required, it is necessary to establish the compressor energy input as well as

the heat absorbed in the evaporator.

››Selection Procedure

The Base Heat Rejection of the CXVB and CXV-T Evaporative Condensers are shown in Table 1. Tables 2 and 3 present

capacity factors to be applied to the system heat rejection for various condensing temperatures, entering wet-bulbs, and

refrigerants.

99Establish total heat rejection required in thousands of BTU per hour (MBH): 9

Total heat rejection = compressor evaporator capacity (MBH) + compressor BHP x 2,545.

99Determine the refrigerant and design conditions for condensing temperature and entering wet-bulb temperature.

99Using the appropriate table for the system refrigerant and model (Tables 2 or 3), determine the capacity factor for the

design condensing temperature and entering wet-bulb temperature.

99Multiply the total heat rejection by the capacity factor determined in the previous step.

99From Table 1, select the evaporative condenser whose Base Heat Rejection equals or exceeds the corrected heat

rejection calculated in the previous step.

PRODUCT CATALOG: CXVB AND CXV-T EVAPORATVE CONDENSERS 15

CXVB SELECTION CONTINUED »

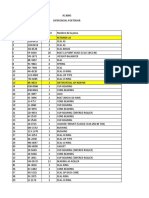

T able 1 : B ase H eat R ejection

Base Heat Base Heat Base Heat Base Heat Base Heat

Rejection Rejection Rejection Rejection Rejection

Model Number (MBH) Model Number (MBH) Model Number (MBH) Model Number1 (MBH) Model Number1 (MBH)

CXVB-75-0806-3 1,097 CXVB-221-0812-7.5 3,245 CXVB-345-0818-30 5,068 CXVB-598-1224-20 8,791 CXVB-1134-1236-75 16,670

CXVB-87-0806-3 1,276 CXVB-226-0812-7.5 3,323 CXVB-355-1212-25 5,225 CXVB-601-1218-45 8,834 CXVB-1161-1236-75 17,068

CXVB-94-0806-3 1,379 CXVB-227-0812-20 3,339 CXVB-357-0818-22.5 5,251 CXVB-604-1224-40 8,879 CXVB-1202-1236-90 17,670

CXVB-95-0806-5 1,398 CXVB-237-1212-10 3,480 CXVB-360-1218-15 5,287 CXVB-612-1224-20 8,996 CXVB-1257-1236-120 18,479

CXVB-102-0806-7.5 1,495 CXVB-237-0812-10 3,488 CXVB-370-1212-25 5,433 CXVB-628-1218-60 9,237 CXVB-1287-1236-120 18,920

CXVB-106-0806-3 1,554 CXVB-238-0812-15 3,494 CXVB-373-0818-30 5,488 CXVB-629-1224-30 9,246 CXV-T645 13,369

CXVB-111-0806-10 1,630 CXVB-241-0812-10 3,542 CXVB-381-1212-30 5,601 CXVB-630-1224-20 9,261 CXV-T686 14,219

CXVB-113-0809-3 1,657 CXVB-248-0818-15 3,651 CXVB-387-0818-30 5,688 CXVB-643-1218-60 9,457 CXV-T717 14,861

CXVB-117-0806-5 1,715 CXVB-259-0812-20 3,808 CXVB-393-1212-30 5,775 CXVB-655-1224-30 9,629 CXV-T729 15,110

CXVB-123-0806-10 1,808 CXVB-264-1212-10 3,881 CXVB-403-1218-15 5,924 CXVB-682-1224-30 10,026 CXV-T763 15,815

CXVB-124-0809-5 1,828 CXVB-268-0818-15 3,938 CXVB-409-0818-45 6,017 CXVB-682-1224-40 10,026 CXV-T792 16,416

CXVB-126-0809-3 1,849 CXVB-270-0812-25 3,969 CXVB-411-1212-40 6,037 CXVB-711-1224-50 10,452 CXV-T791 16,395

CXVB-134-0809-7.5 1,969 CXVB-281-0818-15 4,126 CXVB-437-1218-22.5 6,431 CXVB-719-1236-30 10,570 CXV-T827 17,141

CXVB-137-0806-15 2,016 CXVB-284-0812-30 4,177 CXVB-444-1218-15 6,527 CXVB-739-1224-50 10,864 CXV-T857 17,763

CXVB-138-0809-3 2,026 CXVB-285-1212-15 4,196 CXVB-457-1218-15 6,715 CXVB-762-1224-60 11,201 CXV-T876 18,157

CXVB-138-0809-5 2,032 CXVB-297-1212-10 4,370 CXVB-459-1218-15 6,747 CXVB-786-1224-60 11,555 CXV-T906 18,779

CXVB-141-0809-3 2,073 CXVB-299-1212-10 4,396 CXVB-467-1218-15 6,858 CXVB-806-1236-30 11,849 CXV-T944 19,566

CXVB-144-0809-7.5 2,109 CXVB-302-1212-20 4,439 CXVB-473-1224-20 6,954 CXVB-821-1224-80 12,069 CXV-T1290 26,738

CXVB-152-0809-5 2,232 CXVB-306-1212-10 4,495 CXVB-482-1218-22.5 7,085 CXVB-875-1236-45 12,863 CXV-T1372 28,437

CXVB-158-0809-5 2,328 CXVB-310-0818-15 4,552 CXVB-483-1218-15 7,101 CXVB-888-1236-30 13,054 CXV-T1434 29,723

CXVB-163-0809-7.5 2,398 CXVB-314-1212-15 4,620 CXVB-513-1218-22.5 7,548 CXVB-914-1236-30 13,436 CXV-T1458 30,220

CXVB-172-0812-7.5 2,526 CXVB-315-1212-10 4,631 CXVB-525-1218-22.5 7,711 CXVB-918-1236-30 13,495 CXV-T1526 31,629

CXVB-190-0809-15 2,792 CXVB-321-0818-15 4,724 CXVB-525-1218-30 7,711 CXVB-933-1236-30 13,715 CXV-T1584 32,832

CXVB-195-0812-10 2,860 CXVB-327-0818-15 4,813 CXVB-528-1224-20 7,762 CXVB-964-1236-45 14,171 CXV-T1582 32,790

CXVB-204-0812-7.5 3,003 CXVB-327-1212-15 4,813 CXVB-545-1218-30 8,006 CXVB-966-1236-30 14,201 CXV-T1654 34,282

CXVB-207-0809-20 3,036 CXVB-329-0818-22.5 4,830 CXVB-567-1218-37.5 8,339 CXVB-1027-1236-45 15,098 CXV-T1714 35,526

CXVB-207-0812-15 3,048 CXVB-341-1212-20 5,011 CXVB-571-1224-30 8,394 CXVB-1049-1236-45 15,421 CXV-T1752 36,314

CXVB-216-0812-7.5 3,171 CXVB-341-1212-15 5,016 CXVB-581-1218-37.5 8,535 CXVB-1049-1236-60 15,421 CXV-T1812 37,557

CXVB-217-0812-15 3,188 CXVB-342-0818-15 5,021 CXVB-595-1224-20 8,746 CXVB-1089-1236-60 16,009 CXV-T1888 39,133

16 Q uestions ? C all 4 1 0 . 7 9 9 . 6 2 0 0 or visit W W W . B A L T I M O R E A I R C O I L . C O M

T able 2 : H eat rejection C apacity F actors – R - 7 1 7 ( A mmonia )

Condensing

Pressure (psig) Entering Wet-Bulb Temperature (°F)

Condensing

R-717 Temp (°F) 50 52 54 56 58 60 62 64 66 68 70 72 74 76 78 80 82

151.3 85 0.97 1.01 1.06 1.11 1.17 1.25 1.33 1.43 1.55 1.70 1.89 2.14 2.47 2.97 3.73 — —

154.1 86 0.94 0.98 1.02 1.07 1.13 1.19 1.27 1.36 1.46 1.60 1.76 1.97 2.26 2.66 3.26 4.25 —

156.9 87 0.91 0.95 0.99 1.03 1.08 1.14 1.21 1.29 1.39 1.51 1.65 1.83 2.08 2.40 2.88 3.63 —

159.8 88 0.88 0.91 0.95 0.99 1.04 1.10 1.16 1.23 1.32 1.42 1.55 1.71 1.92 2.20 2.58 3.16 4.13

162.6 89 0.85 0.89 0.92 0.96 1.00 1.05 1.11 1.18 1.26 1.35 1.46 1.60 1.78 2.02 2.34 2.80 3.53

165.5 90 0.83 0.86 0.89 0.93 0.97 1.01 1.07 1.13 1.20 1.28 1.38 1.51 1.67 1.87 2.13 2.51 3.08

168.5 91 0.80 0.83 0.86 0.90 0.93 0.98 1.02 1.08 1.14 1.22 1.31 1.42 1.56 1.73 1.96 2.27 2.72

171.5 92 0.78 0.81 0.83 0.87 0.90 0.94 0.99 1.04 1.10 1.17 1.25 1.35 1.47 1.62 1.82 2.08 2.44

174.5 93 0.76 0.78 0.81 0.84 0.87 0.91 0.95 1.00 1.05 1.11 1.19 1.28 1.38 1.52 1.69 1.91 2.21

177.6 94 0.74 0.76 0.79 0.81 0.84 0.88 0.92 0.96 1.01 1.07 1.13 1.21 1.31 1.43 1.58 1.77 2.02

180.7 95 0.72 0.74 0.76 0.79 0.82 0.85 0.88 0.92 0.97 1.02 1.08 1.16 1.24 1.35 1.48 1.64 1.86

185.0 96.3 0.69 0.71 0.73 0.76 0.78 0.81 0.84 0.88 0.92 0.97 1.02 1.09 1.16 1.25 1.36 1.51 1.68

187.0 97 0.68 0.70 0.72 0.74 0.77 0.79 0.83 0.86 0.90 0.94 0.99 1.05 1.13 1.21 1.31 1.44 1.60

190.2 98 0.66 0.68 0.70 0.72 0.74 0.77 0.80 0.83 0.87 0.91 0.96 1.01 1.07 1.15 1.24 1.35 1.49

193.4 99 0.65 0.66 0.68 0.70 0.72 0.75 0.77 0.80 0.84 0.87 0.92 0.97 1.03 1.10 1.18 1.28 1.40

196.7 100 0.63 0.65 0.66 0.68 0.70 0.72 0.75 0.78 0.81 0.84 0.88 0.93 0.98 1.05 1.12 1.21 1.32

231.7 105 0.56 0.57 0.58 0.60 0.61 0.63 0.65 0.67 0.69 0.71 0.74 0.77 0.81 0.85 0.89 0.95 1.01

231.8 110 0.50 0.51 0.52 0.53 0.54 0.55 0.57 0.58 0.60 0.62 0.64 0.66 0.68 0.71 0.74 0.78 0.82

T able 3 : H eat rejection C apacity F actors – R - 2 2 , R 1 3 4 a

Condensing

Pressure (psig) Entering Wet-Bulb Temperature (°F)

Condensing

R-22 R-134a Temp (°F) 50 52 54 56 58 60 62 64 66 68 70 72 74 76 78 80 82

155.7 95.2 85 1.16 1.21 1.27 1.33 1.41 1.50 1.60 1.72 1.87 2.05 2.29 2.59 3.01 2.29 4.56 — —

158.2 97.1 86 1.13 1.17 1.23 1.29 1.36 1.44 1.53 1.64 1.77 1.94 2.14 2.40 2.75 2.14 3.98 5.21 —

160.7 98.9 87 1.09 1.14 1.19 1.24 1.31 1.38 1.46 1.56 1.68 1.83 2.01 2.23 2.53 2.01 3.53 4.46 —

163.2 100.7 88 1.06 1.10 1.15 1.20 1.26 1.32 1.40 1.49 1.14 1.23 1.89 2.09 2.34 1.89 3.17 3.89 5.09

165.8 102.6 89 1.03 1.07 1.11 1.16 1.21 1.27 1.34 1.43 1.53 1.64 1.78 1.96 2.18 1.78 2.87 3.45 4.35

168.4 104.3 90 0.99 1.03 1.07 1.12 1.16 1.22 1.29 1.36 1.45 1.56 1.68 1.84 2.03 1.68 2.62 3.09 3.79

171.0 106.2 91 0.97 1.00 1.04 1.08 1.13 1.18 1.24 1.31 1.39 1.49 1.60 1.74 1.91 1.60 2.41 2.80 3.36

173.7 108.1 92 0.94 0.97 1.01 1.04 1.09 1.14 1.19 1.26 1.33 1.42 1.52 1.65 1.80 1.52 2.23 2.56 3.02

176.4 110.0 93 0.91 0.94 0.98 1.01 1.05 1.10 1.15 1.21 1.28 1.36 1.45 1.56 1.70 1.45 2.08 2.35 2.73

179.1 111.9 94 0.89 0.92 0.95 0.98 1.02 1.06 1.11 1.17 1.23 1.30 1.39 1.49 1.61 1.39 1.94 2.18 2.50

181.8 113.9 95 0.87 0.89 0.92 0.95 0.99 1.03 1.07 1.12 1.18 1.25 1.33 1.42 1.53 1.33 1.82 2.03 2.30

184.6 115.9 96 0.84 0.87 0.90 0.93 0.96 1.00 1.04 1.09 1.14 1.20 1.27 1.35 1.45 1.27 1.71 1.90 2.13

187.4 117.5 97 0.82 0.85 0.87 0.90 0.93 0.97 1.01 1.05 1.10 1.15 1.22 1.30 1.38 1.22 1.62 1.78 1.98

190.2 119.9 98 0.80 0.82 0.85 0.88 0.91 0.94 0.97 1.01 1.06 1.11 1.17 1.24 1.32 1.17 1.53 1.68 1.85

193.0 122.1 99 0.78 0.80 0.83 0.85 0.88 0.91 0.94 0.98 1.03 1.07 1.13 1.19 1.27 1.13 1.46 1.58 1.74

195.9 124.1 100 0.76 0.78 0.81 0.83 0.86 0.88 0.92 0.95 0.99 1.04 1.09 1.14 1.21 1.09 1.39 1.50 1.64

210.7 149.6 105 0.68 0.70 0.71 0.73 0.75 0.77 0.80 0.82 0.85 0.88 0.92 0.96 1.00 0.92 1.11 1.18 1.26

226.4 146.4 110 0.61 0.62 0.64 0.65 0.67 0.68 0.70 0.72 0.74 0.76 0.79 0.82 0.85 0.79 0.93 0.97 1.03

PRODUCT CATALOG: CXVB AND CXV-T EVAPORATVE CONDENSERS 17

CXVB SELECTION CONTINUED »

››Selection Example ››Evaporator Ton Method

This selection method is based on estimated horsepower

Given:

requirements for open reciprocating compressors only, and

R-717 refrigerant cannot be considered to be precise. Critical selection of this

Compressor evaporator capacity = 550 tons type should be checked by the heat rejection method.

››Selection Procedure

Compressor BHP = 600

Condensing temperature = 95°F

Entering wet-bulb temperature = 76°F

99Determine the evaporator capacity in Refrigeration Tons

››Solution

(one Refrigeration Ton = 12,000 BTUH)

99Determine refrigerant and design conditions of condensing

temperature, suction temperature, and entering wet-bulb

99Determine the total heat rejection: temperature.

• Compressor evaporator capacity =9

550 TR x 12,000 BTUH/TR = 6,600,000 BTUH

99Using tables appropriate for the system refrigerant,

determine two correction factors: the Evaporator Capacity

• Compressor BHP input =9 Factor (Tables 5 and 6) and the Suction Temperature

600 BHP x 2,545 BTUH/BHP = 1,527,000 BTUH Factor (Tables 7 and 8).

• Total heat rejection = 8,127,000 BTUH = 8,127

MBH

99Multiply the evaporator capacity in tons by the two

correction factors determined above.

99From Table 2, the heat rejection capacity factor for

R-717 at 95°F condensing temperature and 76°F 99From Table 4, select an evaporative condenser whose

entering wet-bulb temperature is 1.35. model number equals or exceeds the product (factors x

tons) calculated above.9

99Multiply: 8,127 MBH x 1.35 = 10,972 MBH 9

99From Table 1 select a unit with a Base Heat Rejection 9

equal to or greater than 10,972 MBH: 9 9

Model CXVB-762-1224-60 9

9 Note:

9 Consult your BAC Representative for evaporative condenser

9 selections for systems utilizing refrigerants other than R-717,

9 R-22, or R-134a and systems requiring special considerations,

9

such as screw compressors with water cooled oil coolers,

9

evaporative condensers with ammonia desuperheaters or

halocarbon subcooling.

Contact your local BAC Representative for assistance with alternate refrigerant selections.

18 Q uestions ? C all 4 1 0 . 7 9 9 . 6 2 0 0 or visit W W W . B A L T I M O R E A I R C O I L . C O M

››Selction Example

Open Recip. Compressor

Solution:

99From Table 6, the capacity factor for R-22

at 105°F condensing temperature and 80°F

entering wet-bulb is 0.84.

Given: R-22 refrigerant

Evaporator capacity = 695 tons9 99From Table 8, the capacity factor for R-22 at

Condensing temperature = 105°F9 30°F suction temperature is 1.03.

Suction temperature = 30°F9 99Multiply 695 x 0.84 x 1.03 = 601 corrected

Entering wet-bulb temperature = 80°F tons.

99From Table 4, select a unit with Corrected

Evaporator Tons equal or greater to 601:

Model CXVB-601-1218-45.

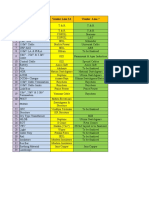

T able 4 : B ase C orrected E vaporator T ons

Corrected Corrected Corrected Corrected Corrected

Evaporator Evaporator Evaporator Evaporator Evaporator

Model Number Tons Model Number Tons Model Number Tons Model Number1 Tons Model Number1 Tons

CXVB-75-0806-3 75 CXVB-221-0812-7.5 221 CXVB-314-1212-15 314 CXVB-528-1224-20 528 CXVB-1134-1236-75 1,134

CXVB-87-0806-3 87 CXVB-226-0812-7.5 226 CXVB-315-1212-10 315 CXVB-571-1224-30 571 CXVB-1161-1236-75 1,161

CXVB-94-0806-3 94 CXVB-227-0812-20 227 CXVB-327-1212-15 327 CXVB-595-1224-20 595 CXVB-1202-1236-90 1,202

CXVB-95-0806-5 95 CXVB-237-0812-10 237 CXVB-341-1212-20 341 CXVB-598-1224-20 598 CXVB-1257-1236-120 1,,257

CXVB-102-0806-7.5 102 CXVB-238-0812-15 238 CXVB-341-1212-15 341 CXVB-604-1224-40 604 CXVB-1287-1236-120 1,287

CXVB-106-0806-3 106 CXVB-241-0812-10 241 CXVB-355-1212-25 355 CXVB-612-1224-20 612 CXV-T645 645

CXVB-111-0806-10 111 CXVB-259-0812-20 259 CXVB-370-1212-25 370 CXVB-629-1224-30 629 CXV-T686 686

CXVB-117-0806-5 117 CXVB-270-0812-25 270 CXVB-381-1212-30 381 CXVB-630-1224-20 630 CXV-T717 717

CXVB-123-0806-10 123 CXVB-284-0812-30 284 CXVB-393-1212-30 393 CXVB-655-1224-30 655 CXV-T729 729

CXVB-137-0806-15 137 CXVB-248-0818-15 248 CXVB-411-1212-40 411 CXVB-682-1224-30 682 CXV-T763 763

CXVB-113-0809-3 113 CXVB-268-0818-15 268 CXVB-360-1218-15 360 CXVB-682-1224-40 682 CXV-T792 792

CXVB-124-0809-5 124 CXVB-281-0818-15 281 CXVB-403-1218-15 403 CXVB-711-1224-50 711 CXV-T791 791

CXVB-126-0809-3 126 CXVB-310-0818-15 310 CXVB-437-1218-22.5 437 CXVB-739-1224-50 739 CXV-T827 827

CXVB-134-0809-7.5 134 CXVB-321-0818-15 321 CXVB-444-1218-15 444 CXVB-762-1224-60 762 CXV-T857 857

CXVB-138-0809-3 138 CXVB-327-0818-15 327 CXVB-457-1218-15 457 CXVB-786-1224-60 786 CXV-T876 876

CXVB-138-0809-5 138 CXVB-329-0818-22.5 329 CXVB-459-1218-15 459 CXVB-821-1224-80 821 CXV-T906 906

CXVB-141-0809-3 141 CXVB-342-0818-15 342 CXVB-467-1218-15 467 CXVB-719-1236-30 719 CXV-T944 944

CXVB-144-0809-7.5 144 CXVB-345-0818-30 345 CXVB-482-1218-22.5 482 CXVB-806-1236-30 806 CXV-T1290 1,290

CXVB-152-0809-5 152 CXVB-357-0818-22.5 357 CXVB-483-1218-15 483 CXVB-875-1236-45 875 CXV-T1372 1,372

CXVB-158-0809-5 158 CXVB-373-0818-30 373 CXVB-513-1218-22.5 513 CXVB-888-1236-30 888 CXV-T1434 1,434

CXVB-163-0809-7.5 163 CXVB-387-0818-30 387 CXVB-525-1218-22.5 525 CXVB-914-1236-30 914 CXV-T1458 1,458

CXVB-190-0809-15 190 CXVB-409-0818-45 409 CXVB-525-1218-30 525 CXVB-918-1236-30 918 CXV-T1526 1,526

CXVB-207-0809-20 207 CXVB-237-1212-10 237 CXVB-545-1218-30 545 CXVB-933-1236-30 933 CXV-T1584 1,584

CXVB-172-0812-7.5 172 CXVB-264-1212-10 264 CXVB-567-1218-37.5 567 CXVB-964-1236-45 964 CXV-T1582 1,582

CXVB-195-0812-10 195 CXVB-285-1212-15 285 CXVB-581-1218-37.5 581 CXVB-966-1236-30 966 CXV-T1654 1,654

CXVB-204-0812-7.5 204 CXVB-297-1212-10 297 CXVB-601-1218-45 601 CXVB-1027-1236-45 1,027 CXV-T1714 1,714

CXVB-207-0812-15 207 CXVB-299-1212-10 299 CXVB-628-1218-60 628 CXVB-1049-1236-45 1049 CXV-T1752 1,752

CXVB-216-0812-7.5 216 CXVB-302-1212-20 302 CXVB-643-1218-60 643 CXVB-1049-1236-60 1,049 CXV-T1812 1,812

CXVB-217-0812-15 217 CXVB-306-1212-10 306 CXVB-473-1224-20 473 CXVB-1089-1236-60 1,089 CXV-T1888 1,888

PRODUCT CATALOG: CXVB AND CXV-T EVAPORATVE CONDENSERS 19

CXVB SELECTION CONTINUED »

T able 5 : E vaporator C apacity F actors – R - 7 1 7 ( A mmonia )

Condensing

Pressure (psig) Entering Wet-Bulb Temperature (°F)

Condensing

R-717 Temp (°F) 50 52 54 56 58 60 62 64 66 68 70 72 74 76 78 80 82

151.7 85 0.70 0.73 0.76 0.80 0.84 0.89 0.95 1.02 1.11 1.22 1.35 1.53 1.77 2.12 2.67 — —

154.1 86 0.68 0.70 0.73 0.77 0.81 0.86 0.91 0.97 1.05 1.15 1.26 1.42 1.62 1.91 2.33 3.05 —

156.9 87 0.66 0.68 0.71 0.74 0.78 0.82 0.87 0.93 1.00 1.08 1.19 1.32 1.49 1.73 2.07 2.61 —

159.8 88 0.64 0.66 0.69 0.72 0.75 0.79 0.84 0.89 0.95 1.03 1.12 1.23 1.38 1.58 1.86 2.28 2.98

162.6 89 0.62 0.64 0.67 0.69 0.73 0.76 0.80 0.85 0.91 0.98 1.06 1.16 1.29 1.46 1.69 2.02 2.55

165.9 90 0.60 0.62 0.65 0.67 0.70 0.73 0.77 0.82 0.87 0.93 1.00 1.09 1.21 1.35 1.53 1.82 2.23

168.9 91 0.58 0.60 0.63 0.65 0.68 0.71 0.74 0.78 0.83 0.89 0.95 1.03 1.13 1.26 1.43 1.65 1.98

171.9 92 0.57 0.59 0.61 0.63 0.66 0.69 0.72 0.75 0.80 0.85 0.91 0.98 1.07 1.18 1.32 1.51 1.78

174.9 93 0.55 0.57 0.59 0.61 0.64 0.66 0.69 0.73 0.77 0.81 0.87 0.93 1.01 1.11 1.23 1.39 1.61

178.0 94 0.54 0.56 0.58 0.59 0.62 0.64 0.67 0.70 0.74 0.78 0.83 0.89 0.96 1.04 1.15 1.29 1.48

181.1 95 0.53 0.54 0.56 0.58 0.60 0.62 0.65 0.68 0.71 0.75 0.80 0.85 0.91 0.99 1.08 1.20 1.36

185.0 96.3 0.51 0.53 0.54 0.56 0.58 0.60 0.62 0.65 0.68 0.71 0.75 0.80 0.86 0.92 1.00 1.11 1.24

187.4 97 0.50 0.52 0.53 0.55 0.57 0.59 0.61 0.63 0.66 0.70 0.73 0.78 0.83 0.89 0.97 1.06 1.18

190.6 98 0.49 0.50 0.52 0.53 0.55 0.57 0.59 0.61 0.64 0.67 0.71 0.75 0.79 0.85 0.92 0.99 1.1

193.9 99 0.48 0.49 0.51 0.52 0.54 0.55 0.57 0.60 0.62 0.65 0.68 0.72 0.76 0.81 0.87 0.95 1.04

197.2 100 0.47 0.48 0.49 0.51 0.52 0.54 0.56 0.58 0.60 0.63 0.66 0.69 0.73 0.78 0.83 0.90 0.98

214.2 105 0.42 0.43 0.44 0.45 0.46 0.47 0.49 0.50 0.52 0.54 0.56 0.58 0.61 0.64 0.67 0.71 0.76

232.3 110 0.37 0.38 0.39 0.40 0.41 0.42 0.43 0.44 0.46 0.47 0.48 0.50 0.52 0.54 0.56 0.59 0.62

T able 6 : E vaporator C apacity F actors – R - 2 2 , R 1 3 4 a

Condensing

Pressure (psig) Entering Wet-Bulb Temperature (°F)

Condensing

R-22 R-134a Temp (°F) 50 52 54 56 58 60 62 64 66 68 70 72 74 76 78 80 82

155.7 95.2 85 0.79 0.82 0.86 0.82 0.95 1.01 1.08 1.16 1.26 1.39 1.55 1.75 2.03 2.44 3.08 — —

158.2 97.1 86 0.77 0.80 0.83 0.80 0.92 0.98 1.04 1.11 1.20 1.31 1.45 1.63 1.87 2.20 2.70 3.53 —

160.7 98.9 87 0.74 0.77 0.81 0.77 0.89 0.94 1.00 1.06 1.14 1.24 1.36 1.52 1.72 2.00 2.40 3.03 —

163.2 100.7 88 0.72 0.75 0.78 0.75 0.86 0.90 0.96 1.02 1.09 1.18 1.29 1.42 1.60 1.83 2.16 2.65 3.47

165.8 102.6 89 0.70 0.73 0.76 0.73 0.83 0.87 0.92 0.98 1.04 1.12 1.22 1.34 1.49 1.69 1.96 2.35 2.97

168.4 104.3 90 0.68 0.71 0.73 0.71 0.80 0.84 0.89 0.93 0.99 1.07 1.15 1.26 1.39 1.56 1.79 2.11 2.59

171.0 106.2 91 0.66 0.69 0.71 0.69 0.77 0.81 0.85 0.90 0.95 1.02 1.10 1.19 1.31 1.46 1.65 1.92 2.31

173.7 108.1 92 0.65 0.67 0.69 0.67 0.75 0.78 0.82 0.86 0.92 0.98 1.05 1.13 1.24 1.37 1.53 1.76 2.07

176.4 110.0 93 0.63 0.65 0.67 0.65 0.73 0.76 0.79 0.83 0.88 0.94 1.00 1.08 1.17 1.28 1.43 1.62 1.88

179.1 111.9 94 0.61 0.63 0.66 0.63 0.70 0.73 0.77 0.81 0.85 0.90 0.96 1.03 1.11 1.21 1.34 1.51 1.73

181.8 113.9 95 0.60 0.62 0.64 0.62 0.69 0.71 0.74 0.78 0.82 0.86 0.92 0.98 1.06 1.15 1.26 1.40 1.59

184.6 115.9 96 0.59 0.60 0.62 0.60 0.67 0.69 0.72 0.75 0.79 0.83 0.88 0.94 1.01 1.09 1.19 1.32 1.48

187.4 117.5 97 0.57 0.59 0.61 0.59 0.65 0.67 0.70 0.73 0.76 0.80 0.85 0.90 0.96 1.04 1.13 1.24 1.38

190.2 119.9 98 0.56 0.58 0.59 0.58 0.63 0.65 0.68 0.71 0.74 0.78 0.82 0.87 0.92 0.99 1.07 1.17 1.29

193.0 122.1 99 0.55 0.56 0.58 0.56 0.62 0.64 0.66 0.69 0.72 0.75 0.79 0.83 0.88 0.95 1.02 1.11 1.22

195.9 124.1 100 0.54 0.55 0.56 0.55 0.60 0.62 0.64 0.67 0.69 0.73 0.76 0.80 0.85 0.91 0.97 1.05 1.15

210.7 149.6 105 0.48 0.49 0.51 0.49 0.53 0.55 0.56 0.58 0.60 0.63 0.65 0.68 0.71 0.75 0.79 0.84 0.90

226.4 146.4 110 0.44 0.45 0.46 0.45 0.48 0.49 0.50 0.52 0.53 0.55 0.57 0.59 0.61 0.64 0.67 0.70 0.74

T able 7 : S uction T emperature T able 8 : S uction T emperature

F actors – R - 7 1 7 ( A mmonia ) F actors – R - 2 2 , R 1 3 4 a

Suction Temperature (°F) -20 -10 0 10 20 30 40 50 Suction Temperature (°F) -20 -10 0 10 20 30 40 50

Capacity Factor 1.14 1.11 1.07 1.04 1.00 0.98 0.95 0.93 Capacity Factor 120 1.16 1.13 1.09 1.06 1.03 1.00 0.98

20 Q uestions ? C all 4 1 0 . 7 9 9 . 6 2 0 0 or visit W W W . B A L T I M O R E A I R C O I L . C O M

You might also like

- Hermetic scroll compressor technical data and performanceDocument6 pagesHermetic scroll compressor technical data and performanceAli AlchmreNo ratings yet

- Maneurop MT 36G4EVE SpecificationsDocument10 pagesManeurop MT 36G4EVE SpecificationssaurabhNo ratings yet

- Model: ZR72KCE-TFD: Technical DataDocument9 pagesModel: ZR72KCE-TFD: Technical DataZakiFroidNo ratings yet

- Zr380kce TWDDocument9 pagesZr380kce TWDzeeshanmianNo ratings yet

- Katalog Komposisi Lengkap New VersionDocument8 pagesKatalog Komposisi Lengkap New VersionSontani PurnamaNo ratings yet

- Sz300a4aaaDocument8 pagesSz300a4aaah1234bNo ratings yet

- Copeland ZP61KCE-TFD scroll compressor technical dataDocument5 pagesCopeland ZP61KCE-TFD scroll compressor technical dataCuellar ChumaceroNo ratings yet

- Catálogo Completo ContatoresDocument239 pagesCatálogo Completo ContatoresdiegoparodeNo ratings yet

- Zr61k3e TFDDocument12 pagesZr61k3e TFDShacheendra SharmaNo ratings yet

- TWH27N TWH54N TWH120N TWH210N TWH430NDocument1 pageTWH27N TWH54N TWH120N TWH210N TWH430Nmohamed salahNo ratings yet

- Model: SH380: Technical DataDocument7 pagesModel: SH380: Technical Datavds94No ratings yet

- Zb19kce TFDDocument15 pagesZb19kce TFDfrio industrialNo ratings yet

- Copeland ZBD30KCE-TFD scroll compressor specsDocument6 pagesCopeland ZBD30KCE-TFD scroll compressor specsarpac tecnologiaNo ratings yet

- Parts Inventory Listing with Item Descriptions and CostsDocument6 pagesParts Inventory Listing with Item Descriptions and CostsEdwin UruetaNo ratings yet

- Zr108kce TFDDocument9 pagesZr108kce TFDmuthuveerNo ratings yet

- Model: ZR61KCE-TFD: Technical DataDocument12 pagesModel: ZR61KCE-TFD: Technical Datapete geroiNo ratings yet

- FLUJODECARGACONTIG1Document57 pagesFLUJODECARGACONTIG1Maria Alejandra Rodríguez CotovettNo ratings yet

- Model: ZR250KCE-TWD: Technical DataDocument9 pagesModel: ZR250KCE-TWD: Technical DataBalaji DhandapaniNo ratings yet

- A2D302 Maintenance Cost Performance 2021Document16 pagesA2D302 Maintenance Cost Performance 2021Raul TicllacuriNo ratings yet

- NACA Profile Data AvdDocument221 pagesNACA Profile Data AvdrickbunnellNo ratings yet

- Power-Based Cycle Life Efficiency Model SpreadsheetDocument11 pagesPower-Based Cycle Life Efficiency Model SpreadsheetthisisjineshNo ratings yet

- Model: MTZ50: Technical DataDocument8 pagesModel: MTZ50: Technical DataВасилий Андреевич КомпанецNo ratings yet

- Comparative Brif DayDocument6 pagesComparative Brif DayGeorgiana Condurache VizinteanuNo ratings yet

- Model: SZ125: Technical DataDocument10 pagesModel: SZ125: Technical Datajake1000No ratings yet

- K>S>Hk&^Wkdͳhd/Ke͕,>Keϯϭͳϭϱͳϯϭϯϯzd^D&Kzk>>/Z/^/Etθ:,ͺZkdkͺ^WDocument2 pagesK>S>Hk&^Wkdͳhd/Ke͕,>Keϯϭͳϭϱͳϯϭϯϯzd^D&Kzk>>/Z/^/Etθ:,ͺZkdkͺ^WGautam SaraffNo ratings yet

- Longitudinal Strength: Limit CurvesDocument5 pagesLongitudinal Strength: Limit CurvesAndi BagusNo ratings yet

- Zr125kce TFDDocument9 pagesZr125kce TFDmuthuveerNo ratings yet

- El-Std Motor-BpDocument3 pagesEl-Std Motor-Bpjhonyzero27No ratings yet

- ASTM Curve Data for Oil Distillation PercentagesDocument1 pageASTM Curve Data for Oil Distillation PercentagesMarco Antonio Fernández SalazarNo ratings yet

- Caracteristicas Tecnicas Dos Motores 04-2010Document2 pagesCaracteristicas Tecnicas Dos Motores 04-2010tiagosubtil7422No ratings yet

- Calculo de caida de tension y regulacion en circuitos electricosDocument7 pagesCalculo de caida de tension y regulacion en circuitos electricosJaime Hernandez MateusNo ratings yet

- Assignment 1 Table On Cost Analysis Complete The Table Based On The Different Cost Concepts and Their CalculationDocument2 pagesAssignment 1 Table On Cost Analysis Complete The Table Based On The Different Cost Concepts and Their CalculationVenkatesh mNo ratings yet

- Catalog Standard Motor LTS PDFDocument20 pagesCatalog Standard Motor LTS PDFYogesh BadheNo ratings yet

- Diseño de La Linea de Conducción: Tramo Longitud Diametro Clase Velocidad CaudalDocument6 pagesDiseño de La Linea de Conducción: Tramo Longitud Diametro Clase Velocidad CaudalDeyvin VilcapomaNo ratings yet

- Depreciation Chart for Assets of ABC Pvt LtdDocument6 pagesDepreciation Chart for Assets of ABC Pvt LtdROHIT KUMARNo ratings yet

- Inquiries Data-KkDocument44 pagesInquiries Data-KkSunil RahangdaleNo ratings yet

- Model: ZR190KCE-TFD: Technical DataDocument9 pagesModel: ZR190KCE-TFD: Technical DataBalaji DhandapaniNo ratings yet

- Zr190kce TFDDocument9 pagesZr190kce TFDnaser712No ratings yet

- Danfoss SH300A4ACB SpecificationsDocument7 pagesDanfoss SH300A4ACB SpecificationsTirto KenconoNo ratings yet

- Hardness ConversionDocument11 pagesHardness ConversionSimon RisteskiNo ratings yet

- Tabela API 6ADocument2 pagesTabela API 6AFeromont KvalitetNo ratings yet

- Diferenciales CostosDocument25 pagesDiferenciales CostosMohammed Portilla CamaraNo ratings yet

- Free - Proxy - List (Canada)Document2 pagesFree - Proxy - List (Canada)Julaeha BandungNo ratings yet

- Zr160kce TFDDocument9 pagesZr160kce TFDmuthuveerNo ratings yet

- P.31020116G006 TPREL-130MW(DC)-Pavagada PR00039828 Project DetailsDocument12 pagesP.31020116G006 TPREL-130MW(DC)-Pavagada PR00039828 Project DetailsvineethNo ratings yet

- Tablas R134a MORANDocument5 pagesTablas R134a MORANBlasNo ratings yet

- International University of Rabat Fall Semester 2021 School of Aerospace EngineeringDocument39 pagesInternational University of Rabat Fall Semester 2021 School of Aerospace EngineeringAmine HaidaouiNo ratings yet

- Products That Perform...By People Who CareDocument16 pagesProducts That Perform...By People Who CareFalak KhanNo ratings yet

- Cirrus Design Section 5 SR22 Performance DataDocument23 pagesCirrus Design Section 5 SR22 Performance DataDon BachnerNo ratings yet

- Red BookDocument17 pagesRed Bookamin peyvandNo ratings yet

- 20220817-Room MarginDocument34 pages20220817-Room MarginBinh AnNo ratings yet

- US Steel CalculatorDocument10 pagesUS Steel CalculatorKarthic KeyanNo ratings yet

- Wolfson - Eenheid (High Speed)Document5 pagesWolfson - Eenheid (High Speed)Oscar GarayNo ratings yet

- Stock Single-Acting Telescopic Cylinders With CC, DB, and DC MountsDocument5 pagesStock Single-Acting Telescopic Cylinders With CC, DB, and DC MountsMICHAEL MONGUINo ratings yet

- P202301 PR B CS STD 0001Document16 pagesP202301 PR B CS STD 0001Nitin SakpalNo ratings yet

- GPL Series: Valve Regulated Lead Acid BatteryDocument1 pageGPL Series: Valve Regulated Lead Acid BatteryDaniel Porto RodriguesNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Oct. 23, Doc. 2Document1 pageOct. 23, Doc. 2jesus casas garayNo ratings yet

- Gea Automatic Purger 271681Document4 pagesGea Automatic Purger 271681jesus casas garayNo ratings yet

- Oct. 31, Doc. 1Document1 pageOct. 31, Doc. 1jesus casas garayNo ratings yet

- Oct. 31, Doc. 2Document1 pageOct. 31, Doc. 2jesus casas garayNo ratings yet

- Boarding pass details for Jose Alfredo CasasDocument1 pageBoarding pass details for Jose Alfredo Casasjesus casas garayNo ratings yet

- Modulate Action Catalog EN PDFDocument59 pagesModulate Action Catalog EN PDFjesus casas garayNo ratings yet

- Bimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55Document7 pagesBimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55jesus casas garayNo ratings yet

- CXVB Selection 20110404Document6 pagesCXVB Selection 20110404jesus casas garayNo ratings yet

- DS PM0202 en Co 3672Document4 pagesDS PM0202 en Co 3672mkfe2005No ratings yet

- ALFA LAVAL Fittings CatalogDocument76 pagesALFA LAVAL Fittings Catalogjesus casas garayNo ratings yet

- RELAY ISO9002 FEATURESDocument2 pagesRELAY ISO9002 FEATURESMarudhasalamMarudhaNo ratings yet

- Compact Substation in 40 CharactersDocument5 pagesCompact Substation in 40 CharactersMarcWorldNo ratings yet

- MiniPUR Melter SystemDocument2 pagesMiniPUR Melter SystemNordson Adhesive Dispensing SystemsNo ratings yet

- Implementation of Standalone PV Micro Grid with Multi-level convertersDocument6 pagesImplementation of Standalone PV Micro Grid with Multi-level convertersSakshiDawarNo ratings yet

- Understanding Energy Methods and Measuring TechniquesDocument57 pagesUnderstanding Energy Methods and Measuring TechniquesEdu SalamancaNo ratings yet

- Static Kramer Drive - T.moodleyDocument14 pagesStatic Kramer Drive - T.moodleyThuven Moodley100% (1)

- Moura Power Station Trip ReportDocument5 pagesMoura Power Station Trip ReportAleks PetNo ratings yet

- Power Quality Performance of A Grid-Tie Photovoltaic System in ColombiaDocument7 pagesPower Quality Performance of A Grid-Tie Photovoltaic System in ColombiaMauro LozNo ratings yet

- SPS 9 - Week 2Document25 pagesSPS 9 - Week 2Merry Cris RamoNo ratings yet

- Cabling Networks PDFDocument111 pagesCabling Networks PDFkisan singhNo ratings yet

- Section 4 Electric Motors Unit 19 Motor ControlsDocument23 pagesSection 4 Electric Motors Unit 19 Motor Controlsasimnaqvi2003No ratings yet

- Control of Grid-Forming Application For Fuel CelleDocument7 pagesControl of Grid-Forming Application For Fuel Celledckien2002No ratings yet

- Metro Vendor ListDocument1 pageMetro Vendor ListHaasini DentalcareNo ratings yet

- Solar Constructions Flex SlopeDocument5 pagesSolar Constructions Flex SlopeAnonymous bZFcjUbwvNo ratings yet

- Ms Ems Series: Three-Phase Asynchronous MotorsDocument3 pagesMs Ems Series: Three-Phase Asynchronous MotorsCarlos Gallardo SanchezNo ratings yet

- H63H64Document1 pageH63H64MinamPeruNo ratings yet

- AC/DC Adaptor/ChargerDocument2 pagesAC/DC Adaptor/ChargerHans VerschoorNo ratings yet

- Ubtd Diesel Rotary Ups Brochure enDocument12 pagesUbtd Diesel Rotary Ups Brochure enFELIXDEJNo ratings yet

- Apple CSRDocument10 pagesApple CSRapi-547362757No ratings yet

- CNC Feed DrivesDocument26 pagesCNC Feed DrivesAndrejNo ratings yet

- Maintenance ChecklistDocument6 pagesMaintenance ChecklistJk LeeNo ratings yet

- Manual Temporizador TH3M PDFDocument10 pagesManual Temporizador TH3M PDFMauricio Barraza FigueroaNo ratings yet

- The Twelve Dimensions of CreationDocument5 pagesThe Twelve Dimensions of CreationklatifdgNo ratings yet

- ECO 55 O (L) C 2 - Two Stage Light Oil Burners - Products - Ecostar Combustion SystemsDocument3 pagesECO 55 O (L) C 2 - Two Stage Light Oil Burners - Products - Ecostar Combustion SystemsUno MariconNo ratings yet

- 6FTJ-150B-Battery Sacred Sun PDFDocument3 pages6FTJ-150B-Battery Sacred Sun PDFJhon SendokNo ratings yet

- Design Simulation and Hardware Implementation of Soft Switching Based Induction Heating System PDFDocument7 pagesDesign Simulation and Hardware Implementation of Soft Switching Based Induction Heating System PDFNjabulo XoloNo ratings yet

- Power 6393: Power 6393, Modular Power SupplyDocument2 pagesPower 6393: Power 6393, Modular Power Supplyghhg ioiiNo ratings yet

- Cleanbc Industrial Incentive Program (Ciip) : Application SupportDocument7 pagesCleanbc Industrial Incentive Program (Ciip) : Application SupportKumar AyushNo ratings yet

- Steam Plant MCQsDocument5 pagesSteam Plant MCQsJustin LivingstonNo ratings yet

- Engenius Erectors Private Limited: A Brief Outline of a Leading Power Plant Construction CompanyDocument61 pagesEngenius Erectors Private Limited: A Brief Outline of a Leading Power Plant Construction CompanyManjesh BnNo ratings yet