100% found this document useful (2 votes)

3K views10 pagesAux Boiler Onboard Test Procedure

_____________________________

Surveyor: _____________________________

Dung Quat Shipbuilding Industry Company

Code : B8239-M24

ONBOARD TEST PROCEDURE FOR Revision : 01/01

AUXILIARY BOILER Issued date : 21/12/2011

Sheet : 9/ 9

Inspection record

(Automatic function test) Form 2

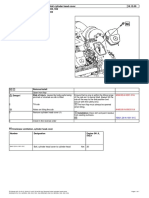

No. Description Set value Time delay Result Remark

1 Water level control 150-180 mm

2 Pre-purge time 30 sec

3 Post-purge time 60 sec

4 Burner start/stop 1.7

Uploaded by

Quyet PhungCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

3K views10 pagesAux Boiler Onboard Test Procedure

_____________________________

Surveyor: _____________________________

Dung Quat Shipbuilding Industry Company

Code : B8239-M24

ONBOARD TEST PROCEDURE FOR Revision : 01/01

AUXILIARY BOILER Issued date : 21/12/2011

Sheet : 9/ 9

Inspection record

(Automatic function test) Form 2

No. Description Set value Time delay Result Remark

1 Water level control 150-180 mm

2 Pre-purge time 30 sec

3 Post-purge time 60 sec

4 Burner start/stop 1.7

Uploaded by

Quyet PhungCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

- General

- Confirmation Test for No.1/2 Auxiliary Boiler

- Inspection Record Form 1

- Inspection Record Form 2