Professional Documents

Culture Documents

SIP-Fire Pump Installation

Uploaded by

jonas monaresOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIP-Fire Pump Installation

Uploaded by

jonas monaresCopyright:

Available Formats

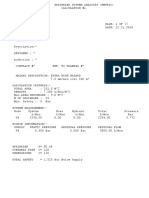

SITE INSTRUCTION PROCESS Reference No:

Reference No:

Fire and Jockey Pump Installation

SITEVER

INSTRUCTION SIP-FP-0001

PROCESS Page of 10 SIP-FP-0001

001

Fire and Jockey Pump Installation

1.0 Introduction

2.0 Purpose

3.0 Scope

4.0 Application

5.0 Materials/ Equipment

6.0 Procedure

7.0 Points to Note

8.0 References

Version Date Authored by: Reviewed by: Approved by:

Caddy Hung

001 10/17/19 Engr. Jonas F. Monares Engr. Kevin F. Galiza.

Ken Shen

Rapidsteel Builders Incorporated

15A Toclong Road, Brgy. Toclong, Kawit Cavite, 1005 Philippines

Telephone: (046) 434-5660

www.rapidsteel.ph

SITE INSTRUCTION PROCESS

Reference No:

Fire and Jockey Pump Installation SIP-FP-0001

VER 001 Page 1 of 10

1.0 INTRODUCTION

A fire pump is designed to increase water pressure. The pump intake and discharge piping must be

capable of flowing the required volume to which the pump will add the needed pressure for fire

protection. The pump can be started manually, but is usually arranged to start automatically upon a

drop in system pressure or the activation of a fire suppression system.

A Jockey pump is a small pump connected to a fire sprinkler system and is intended to maintain

pressure in a fire protection piping system to an artificially high level so that the operation of a single

fire sprinkler will cause a pressure drop which will be sensed by the fire pump automatic controller,

causing the fire pump to start. The jockey pump is essentially a portion of the fire pump's control

system. A jockey pump is sized for a flow less than the flow to one sprinkler in order to ensure a system

pressure drop. Jockey pumps are typically small multistage centrifugal pumps, and do not have to be

listed or certified for fire system application. The control equipment for jockey pumps may however

carry approvals. Jockey pumps should be sized for 3% of the flow of the main fire pump and to provide

10psi more pressure than the main fire pump.

2.0 PURPOSE

Fire pumps are needed for main reason; to protect lives & properties against fire by supplying adequate

water supply to automatic sprinklers or standpipe systems. To meet building codes & insurance

requirements.

3.0 SCOPE

Provide a complete fire pumps system as defined by the latest edition of NFPA20.

4.0 APPLICATION

Fire pumps are powered by an electric motor or diesel engine. The sprinkler system pressure drops

significantly when one or more fire sprinklers are activated or alternatively when other firefighting

connections are opened, causing a pressure drop.

Types of building where fire pumps are used:

1. High Rise Building:

If fire breaks out in a room on the top storey of high rise building, sprinkler heads may need extra

help creating the water pressure required to douse the flames.

2. Storage Warehouse:

Large expanses of space have higher water pressure demands if a fire begins to spread. Warehouse

is a prime example because they don’t have walls or doors to slow the fire as its spread.

Rapidsteel Builders Incorporated

15A Toclong Road, Brgy. Toclong, Kawit Cavite, 1005 Philippines

Telephone: (046) 434-5660

www.rapidsteel.ph

SITE INSTRUCTION PROCESS

Reference No:

Fire and Jockey Pump Installation SIP-FP-0001

VER 001 Page 2 of 10

3. Building with water storage tanks:

In most cases. A building’s sprinkler system is supplied with water from the city. If your building has

on site storage for fire sprinklers, you should certainly plan on installing a pump to create water

pressure in case of a fire.

Listing Authorities;

1. Underwriters Laboratories (UL)

2. Factory Mutual Research Corporation (FM)

Allowable Pump Types:

1. Horizontal Split Case

2. Vertical In-line

3. End Suction

4. Vertical Turbines

Rapidsteel Builders Incorporated

15A Toclong Road, Brgy. Toclong, Kawit Cavite, 1005 Philippines

Telephone: (046) 434-5660

www.rapidsteel.ph

SITE INSTRUCTION PROCESS

Reference No:

Fire and Jockey Pump Installation SIP-FP-0001

VER 001 Page 3 of 10

Jockey (pressure maintenance) pumps and

jockey controllers need not be listed for fire

protection service.

“The primary or standby fire pump shall not be

used as a pressure maintenance pump.”

A jockey pump should be sized such that it

CANNOT meet the flow demand of a single

sprinkler fixture.

5. TOOLS & EQUIPMENT / MATERIALS

A. TOOLS & EQUIPMENT

Gantry Chain Block Nylon Sling

Shackle D-Type Open Wrench Crimping Pliers

Welding Machine Wire Brush Fire Blanket

Rapidsteel Builders Incorporated

15A Toclong Road, Brgy. Toclong, Kawit Cavite, 1005 Philippines

Telephone: (046) 434-5660

www.rapidsteel.ph

SITE INSTRUCTION PROCESS

Reference No:

Fire and Jockey Pump Installation SIP-FP-0001

VER 001 Page 4 of 10

Rotary Drill Grinder Metal Cutter

Safety Rubber Boots Safety Helmet with Glasses Vises

B. MATERIALS AND CONSUMABLES

Measuring tape Safety Gloves Verner Caliper

Level Bar Welding Rod Oxyacetylene

Rapidsteel Builders Incorporated

15A Toclong Road, Brgy. Toclong, Kawit Cavite, 1005 Philippines

Telephone: (046) 434-5660

www.rapidsteel.ph

SITE INSTRUCTION PROCESS

Reference No:

Fire and Jockey Pump Installation SIP-FP-0001

VER 001 Page 5 of 10

Oxyacetylene Cutter Welding Mask Welding Apron

Welding Gloves Welding Glass Respirator Mask

6. PROCEDURE

A. Site planning

Receiving: Upon receiving the pump, it should be inspected for damage or shortages. If damage

has occurred, file a claim immediately with the company that delivered the pump. If the manual

is removed from the crating, do not lose or misplace.

B. Preparation

1. Check Approved Plan

Review and Evaluate the AFC-Approved for Construction

PLAN (Mechanical Plans) based on actual condition of the

site.

Rapidsteel Builders Incorporated

15A Toclong Road, Brgy. Toclong, Kawit Cavite, 1005 Philippines

Telephone: (046) 434-5660

www.rapidsteel.ph

SITE INSTRUCTION PROCESS

Reference No:

Fire and Jockey Pump Installation SIP-FP-0001

VER 001 Page 6 of 10

2. Foundation

The foundation should be sufficient substantial for form a

level, rigid support for combined weight of pump and

driver & maintain alignment of the installed unit.

Foundation bolts, of the proper size should be imbedded in

the concrete. A pipe sleeve, about 2 ½” diameters larger

that the bolts should be used to allow final positioning of

the bolt.

3. Mounting

Position the unit on the foundation and level the pump

base, using metal shims, so that pump shaft is in vertical

alignment and pump suction and discharge flanges are level

in both vertical and horizontal plane. Base may be grouted

following alignment. Use a plumb line from floor above to

establish centerline of pump and flexible drive shaft and

bearings.

Rapidsteel Builders Incorporated

15A Toclong Road, Brgy. Toclong, Kawit Cavite, 1005 Philippines

Telephone: (046) 434-5660

www.rapidsteel.ph

SITE INSTRUCTION PROCESS

Reference No:

Fire and Jockey Pump Installation SIP-FP-0001

VER 001 Page 7 of 10

4. Field Alignment

The faces of coupling halves should be spaced far enough

apart so that they cannot strike each other when the driver

rotor is moved toward the pump. The necessary tools for

checking the alignment of a flexible coupling are a straight

edge and taper gauge or a set of feeler gauges. Parallel

alignment check is made by placing a straight edge across

both coupling rims at the top, bottom and at both sides.

Correction for angular and parallel misalignment is made

by adjusting the shim under the driver. After each change,

it is necessary to recheck the alignment of the coupling

halves as adjustment in one direction may disturb

adjustment already made in another direction.

5. Grouting

Grouting compensates for unevenness in the foundation

and prevents vibration and shifting after mounting is

complete. Build a form around the base plate to contain

the grout, and sprinkle area with water to obtain a good

bond. The base should be completely filled with a good

quality, non-shrinking grout. The usual mixture two (2)

parts sand with sufficient water to flow freely. It is also

desirable to grout the leveling pieces, shims or wedges in

place. Foundation bolts should be fully tightened when

grout has hardened, usually about 48 hours after pouring.

Shim under the driver. After each change, it is necessary to

recheck the alignment of the coupling halves as

adjustment in one direction may disturb adjustment

already made in another direction.

Rapidsteel Builders Incorporated

15A Toclong Road, Brgy. Toclong, Kawit Cavite, 1005 Philippines

Telephone: (046) 434-5660

www.rapidsteel.ph

SITE INSTRUCTION PROCESS

Reference No:

Fire and Jockey Pump Installation SIP-FP-0001

VER 001 Page 8 of 10

6. Piping:

The suction piping, if not installed properly, is a potential

source of faulty operation. To achieve best performance, PIPING

provide for the following:

(a) Avoid using elbows close to the pump suction

flange. A minimum of six pipe diameters of straight

pipe should always be located between the elbow and

suction inlet. If elbows are used, they should be long

radius type.

(b) Suction pipe should be a minimum one size

larger than the suction flange. Suction pipe should

terminate at 'the suction flange of the pump through

an "eccentric reducer". Never install suction piping

that is smaller in diameter than the pump suction

flange.

(c) Suction throttling must never be attempted. This

could cause cavitation and damage to the pump.

(d) If a strainer is installed in the suction piping,

it must have a net free area of at least three (3)

times the area of the suction pipe. It should be

checked and cleaned periodically. The openings in

the screen must be .smaller than the sphere size

allowed for the impeller. Contact factory for

maximum sphere size.

(e) When the source of supply is feeding more than one

pump, separate suction lines are recommended.

Rapidsteel Builders Incorporated

15A Toclong Road, Brgy. Toclong, Kawit Cavite, 1005 Philippines

Telephone: (046) 434-5660

www.rapidsteel.ph

SITE INSTRUCTION PROCESS

Reference No:

Fire and Jockey Pump Installation SIP-FP-0001

VER 001 Page 9 of 10

7. POINTS TO NOTE

1. Never connect a fire pump to piping, always

start piping from unit

2. Use as few bends as possible and preferably

long radius ones.

3. Support of the piping at the pump may be

made by two pipes hangers, floor saddle or

floor flanges, place on line close to pump.

Rapidsteel Builders Incorporated

15A Toclong Road, Brgy. Toclong, Kawit Cavite, 1005 Philippines

Telephone: (046) 434-5660

www.rapidsteel.ph

SITE INSTRUCTION PROCESS

Reference No:

Fire and Jockey Pump Installation SIP-FP-0001

VER 001 Page 10 of 10

4. Layout the suction line with a continual rise

towards the pump without high points, thus

eliminating possibility of air pockets.

5. Install, at all pumps suction, a straight pipe

of a length equivalent to 4-6 times its

diameter.

8. REFERENCES

Installation and operation manual centrifugal Pumps by Weinman.

Installation and operating manual for fire pumps by Armstrong.

NFPA-20 Standard for the installation of stationary Pumps for Fire Protection.

Fire Pump System in NFPA 20 Standard - ETNA

https://maker.pro/custom/tutorial/the-basic-mechanical-tools-you-need-for-your-workshop

https://interestingengineering.com/25-tools-every-engineer-should-have-to-fix-everything

Rapidsteel Builders Incorporated

15A Toclong Road, Brgy. Toclong, Kawit Cavite, 1005 Philippines

Telephone: (046) 434-5660

www.rapidsteel.ph

SITE INSTRUCTION PROCESS

Reference No:

Fire and Jockey Pump Installation SIP-FP-0001

VER 001 Page of 10

Rapidsteel Builders Incorporated

15A Toclong Road, Brgy. Toclong, Kawit Cavite, 1005 Philippines

Telephone: (046) 434-5660

www.rapidsteel.ph

You might also like

- Sprinkler System Installation ProcedureDocument3 pagesSprinkler System Installation ProcedureDong VanraNo ratings yet

- Teas Cookbook 6.8Document13 pagesTeas Cookbook 6.8Natalia CruzNo ratings yet

- Theatre History ProjectDocument5 pagesTheatre History Projectapi-433889391No ratings yet

- Havc Underground Piping MosDocument5 pagesHavc Underground Piping MosYusuf Ziya DilbazNo ratings yet

- Green Oasis Mall Water Pump CalculationsDocument19 pagesGreen Oasis Mall Water Pump CalculationsKashif SiddiquiNo ratings yet

- Smoke Ventilator Installation MethodDocument51 pagesSmoke Ventilator Installation MethodShah Muzzamil100% (1)

- Magnum IOM - (Rev H)Document53 pagesMagnum IOM - (Rev H)ibromishNo ratings yet

- 6.4 - Sprinklers For Concealed Spaces and Raised Floors PDFDocument1 page6.4 - Sprinklers For Concealed Spaces and Raised Floors PDFHaitham MohammadNo ratings yet

- Raw Water System - Flushing Procedure 1Document4 pagesRaw Water System - Flushing Procedure 1AdelNo ratings yet

- AHU Commissioning Report DF016eDocument8 pagesAHU Commissioning Report DF016evishwas salunkheNo ratings yet

- Pre-Commissioning Check List (SAMSUNG DVMS)Document3 pagesPre-Commissioning Check List (SAMSUNG DVMS)Uzair JavedNo ratings yet

- T&C Check List For Centrifugal Exhaust FansDocument1 pageT&C Check List For Centrifugal Exhaust Fansbeho2000No ratings yet

- Fire & Jockey Pump Installation GuideDocument13 pagesFire & Jockey Pump Installation Guidejonas monares100% (4)

- Design Calculation Sheet: Water Demand & Drainage FlowDocument5 pagesDesign Calculation Sheet: Water Demand & Drainage FlowAhmadNo ratings yet

- FAHU SubmittalDocument62 pagesFAHU SubmittalEngr.MmosaadNo ratings yet

- Master Plumbing BoqDocument15 pagesMaster Plumbing BoqNghiaNo ratings yet

- Juice in PakistanDocument9 pagesJuice in Pakistanrize1159100% (1)

- Fire Sprinkler Systems InstallationDocument6 pagesFire Sprinkler Systems InstallationSachin DarneNo ratings yet

- 3 Delay Analysis - 25 March 2014Document3 pages3 Delay Analysis - 25 March 2014Zitheeq UmarNo ratings yet

- 80% DAILY ACCOMPLISHMENT REPORT (Refurbishment of Coal Conduit Unit 2)Document3 pages80% DAILY ACCOMPLISHMENT REPORT (Refurbishment of Coal Conduit Unit 2)Jayson GabrielNo ratings yet

- Preaction System ManualDocument64 pagesPreaction System ManualAhmed Mohamed Rashed100% (1)

- A. Load Values, in Water Supply Fixture Units (Wsfu) For All AreasDocument4 pagesA. Load Values, in Water Supply Fixture Units (Wsfu) For All AreasIbrahim A. HameedNo ratings yet

- Fire Fighting System Inspection ReportDocument6 pagesFire Fighting System Inspection ReportIchsan Bahril100% (1)

- Preventive Maintenance of FDAS and Sprinkler SystemDocument6 pagesPreventive Maintenance of FDAS and Sprinkler SystemchocostarfishNo ratings yet

- Electrical Feeder System Method StatementDocument7 pagesElectrical Feeder System Method StatementAngelo Castro100% (1)

- Mep Questionnaire HospitalDocument7 pagesMep Questionnaire HospitalRaju KsnNo ratings yet

- Method Statement For Hvac Equipments InstallationDocument15 pagesMethod Statement For Hvac Equipments InstallationzahidNo ratings yet

- Two Stage Water Ring Vacuum Pump PDFDocument24 pagesTwo Stage Water Ring Vacuum Pump PDFvallamreddyNo ratings yet

- Fire SuppresionDocument1 pageFire Suppresionʞǝǝs Uǝ ƎpıɥNo ratings yet

- 1727 Plumbing Estimation SheetDocument1 page1727 Plumbing Estimation SheetMohammed JassimNo ratings yet

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocument3 pagesTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid ShaikhNo ratings yet

- Chiller PlantDocument1 pageChiller PlantSudhir KulkarniNo ratings yet

- Kruger Fan InstalltionDocument10 pagesKruger Fan Installtionjames_chan2178100% (1)

- 2023 SPMS Indicators As of MarchDocument22 pages2023 SPMS Indicators As of Marchcds documentNo ratings yet

- SCOPE-WORKS-GEOMEMBRANE-LINER-INSTALLATIONDocument3 pagesSCOPE-WORKS-GEOMEMBRANE-LINER-INSTALLATIONmamahsen100% (2)

- OMM-Kandis Residences (2019) PDFDocument38 pagesOMM-Kandis Residences (2019) PDFjo_eli_No ratings yet

- Research On Evolution Equations Compendium Volume 1Document437 pagesResearch On Evolution Equations Compendium Volume 1Jean Paul Maidana GonzálezNo ratings yet

- Extra High Hazard Sample Hydraulic CalculationsDocument15 pagesExtra High Hazard Sample Hydraulic CalculationszaszaNo ratings yet

- KRC Hetero FPS Installation Method StatementDocument34 pagesKRC Hetero FPS Installation Method StatementRM ENTERPRISESNo ratings yet

- Final Sprinkler BoqDocument4 pagesFinal Sprinkler Boqmohammedsarwat100% (1)

- Cable TakeoffDocument14 pagesCable TakeoffRudivic LumainNo ratings yet

- VRF & DX Split Type ACU Testing MethodologyDocument1 pageVRF & DX Split Type ACU Testing MethodologydamianNo ratings yet

- Lesson Plan 1Document9 pagesLesson Plan 1Dama Grace Casabuena100% (1)

- LVFR Sprinkler System RequirementsDocument4 pagesLVFR Sprinkler System RequirementsridwanNo ratings yet

- Fire Alarm System Maintenance 2Document3 pagesFire Alarm System Maintenance 2renvNo ratings yet

- QCDFSS-6.7 - Fire Pumps - Arabic Version of Rev ADocument4 pagesQCDFSS-6.7 - Fire Pumps - Arabic Version of Rev AAnoirNo ratings yet

- DESCRIPTIONS Garbage ChuteDocument12 pagesDESCRIPTIONS Garbage ChuteYasser Fathy AlyNo ratings yet

- Commissioning Request and Check List (Form 9180)Document5 pagesCommissioning Request and Check List (Form 9180)Sraz MidniteNo ratings yet

- Mr. Slim System Pre-Commissioning and Installation Check ListDocument4 pagesMr. Slim System Pre-Commissioning and Installation Check Listamerico zambrano contrerasNo ratings yet

- Guidance for commissioning and maintaining new plumbing systemsDocument2 pagesGuidance for commissioning and maintaining new plumbing systemsdilimgeNo ratings yet

- Pressure Test Sample Form R2Document1 pagePressure Test Sample Form R2Bonaventure Nzeyimana100% (1)

- Duct Works ChecklistDocument1 pageDuct Works Checklistmd azmathNo ratings yet

- Technical Evaluation Report Fire Fighting EquipmentDocument12 pagesTechnical Evaluation Report Fire Fighting Equipmentsharjeel39No ratings yet

- RA-2 BILL ClubDocument15 pagesRA-2 BILL ClubSaurabh DwivediNo ratings yet

- HVAC - BOQ, Cost Estimate & ProcurementDocument6 pagesHVAC - BOQ, Cost Estimate & Procurementsunkk0369No ratings yet

- SKM Chiller Pre-Commissioning Check List Rev 20.06.2022Document2 pagesSKM Chiller Pre-Commissioning Check List Rev 20.06.2022Riju Scaria/EMD/QTRNo ratings yet

- Fire Services Department Circular Letter No. 2/94 Rules for Automatic Sprinkler InstallationsDocument39 pagesFire Services Department Circular Letter No. 2/94 Rules for Automatic Sprinkler Installationsahtin618No ratings yet

- Checklist For Pressure Testing Safely 2Document2 pagesChecklist For Pressure Testing Safely 2Jonathan CambaNo ratings yet

- Modern Fire Suppression Systems ExplainedDocument26 pagesModern Fire Suppression Systems ExplainedLawrence Ting0% (3)

- HVAC System: Exhaust FanDocument4 pagesHVAC System: Exhaust FanAnsari1918No ratings yet

- 04 05 PME Write ShopDocument3 pages04 05 PME Write Shopjamil diligNo ratings yet

- 345 Testing THDocument6 pages345 Testing THDjeisonSeccoNo ratings yet

- Installation of Chilled Water PumpsDocument1 pageInstallation of Chilled Water Pumpsmohamed farookNo ratings yet

- 5-Corrective Maintenance FahuDocument2 pages5-Corrective Maintenance FahuUmair LiaqatNo ratings yet

- Air Conditioner Repair and Maintenance ServicesDocument2 pagesAir Conditioner Repair and Maintenance ServicesadityasutarNo ratings yet

- Annual Servicing, Billing Statement and QuotationDocument43 pagesAnnual Servicing, Billing Statement and QuotationElma Alino Descartin100% (1)

- Speidel, M. O. (1981) - Stress Corrosion Cracking of Stainless Steels in NaCl Solutions.Document11 pagesSpeidel, M. O. (1981) - Stress Corrosion Cracking of Stainless Steels in NaCl Solutions.oozdemirNo ratings yet

- UNIX Unbounded 5 Edition: Amir AfzalDocument23 pagesUNIX Unbounded 5 Edition: Amir AfzalOsei BanningNo ratings yet

- Wind LoadsDocument5 pagesWind LoadsMGNo ratings yet

- The LOMA Weekly Herald Volume 1 Issue 6Document6 pagesThe LOMA Weekly Herald Volume 1 Issue 6LOMA MaksNo ratings yet

- List of MBA Institutes in HyderabadDocument5 pagesList of MBA Institutes in Hyderabadebrandingindia1No ratings yet

- Igbe Religion's 21st Century Syncretic Response to ChristianityDocument30 pagesIgbe Religion's 21st Century Syncretic Response to ChristianityFortune AFATAKPANo ratings yet

- Final Order in The Matter of M/s Alchemist Capital LTDDocument61 pagesFinal Order in The Matter of M/s Alchemist Capital LTDShyam SunderNo ratings yet

- Resume AmarDocument3 pagesResume AmarAshraf YusofNo ratings yet

- Arijit Singh Lyrics: "Saawali Si Raat"Document1 pageArijit Singh Lyrics: "Saawali Si Raat"123No ratings yet

- G3335-90158 MassHunter Offline Installation GCMSDocument19 pagesG3335-90158 MassHunter Offline Installation GCMSlesendreNo ratings yet

- Civil Rights Web-QuestDocument5 pagesCivil Rights Web-Questapi-367833271No ratings yet

- JAWABAN UTS Bahasa Inggris II Keperawatan Dewi YuniarDocument3 pagesJAWABAN UTS Bahasa Inggris II Keperawatan Dewi Yuniarovan maysandyNo ratings yet

- The Kano Model: How To Delight Your CustomersDocument16 pagesThe Kano Model: How To Delight Your CustomersRoen RamonalNo ratings yet

- Volume 47, Issue 50, December 9, 2016Document45 pagesVolume 47, Issue 50, December 9, 2016BladeNo ratings yet

- Swift Group Technical HandbookDocument8 pagesSwift Group Technical HandbookLukasz WilkNo ratings yet

- Handbook+of+Global+Tuberculosis+Control - Chapter 5 - 2Document17 pagesHandbook+of+Global+Tuberculosis+Control - Chapter 5 - 2Dyah MustikawatiNo ratings yet

- News TIA Portal V15 and V15 1 enDocument43 pagesNews TIA Portal V15 and V15 1 enjohanNo ratings yet

- CFLM-1 Chapter 5Document17 pagesCFLM-1 Chapter 5Rico T. MusongNo ratings yet

- 9331 DCCBDocument5 pages9331 DCCBgopimodalavalasaNo ratings yet

- BuellRetailCatalog en USDocument76 pagesBuellRetailCatalog en USErcüment Kayacık100% (2)

- Dzone Trend Report Containers 2021Document52 pagesDzone Trend Report Containers 2021Diacamo MankungiNo ratings yet

- Competences Needed in Testing - Handout Manual PDFDocument97 pagesCompetences Needed in Testing - Handout Manual PDFCristina LucaNo ratings yet

- EVE 32 07eDocument45 pagesEVE 32 07eismoyoNo ratings yet

- Sensory Evaluation of FoodDocument38 pagesSensory Evaluation of FoodKHOZA SBUSISIWENo ratings yet