Professional Documents

Culture Documents

WQT Smaw

Uploaded by

operation btut0 ratings0% found this document useful (0 votes)

130 views1 pageOriginal Title

WQT SMAW

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

130 views1 pageWQT Smaw

Uploaded by

operation btutCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

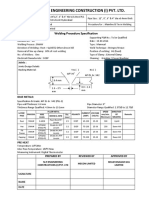

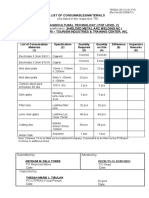

PQR/WPS WITNESS REPORT

COMAPNY NAME:.

REPORT NO: DATE:

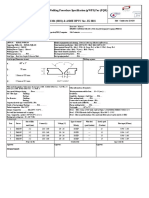

Welding Joint Details WPS No:WPS

PQR No: PQR-

Welding Process(es): SMAW

Type(s) : MANUAL

Welding Position: 1G

Welders/Welding Operator Name: VASHIST K. MISHRA

Welders/Welding Operator No: VM

Test Coupon Details Electrode/Filler Wire/Flux Details

Side-1 Side-2 Sr. No AWS Class Size (mm) Batch No/Lot no

E7018

MOC SA516 Gr70 SA516 Gr70 1 3.15

P. No 1 1 2

Gr. No 70 70 3

Size 750X600X25 750X600X25 4

Heat No 93240 93240 5

Backing:Without backing Contact Tube to work distance (SAW/GMAW/FCAW):

Shielding Gas- Purging Gas & Flow Rate:- Trailing Gas/Flow Rate:-

Welding M/C No: Gas Cup Size: ------ Tungsten Type/Size:-------

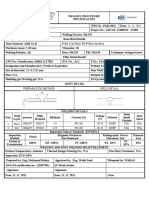

Welding Process Variable

Pass No Welding Polarity AWS Filler Prehea Interpass Current Voltage Travel Shielding Weld

Process Class Size t Temp Temp (A) (V) Speed (LPM) Metal

Filler (mm) ( °C) ( °C) (MM/MIN Thickness

)

ST

1 SIDE

ROOT PASS SAW DCEN E7018 3.15 - 60 160 20 500 - 2.5-3

HOT PASS 1 SAW DCEN E7018 3.15 - 82 180 22 500 - 5.5-6

HOT PASS 2 SAW DCEN E7018 3.15 - 100 200 24 475 - 8.0-8.5

HOT PASS 3 SAW DCEN E7018 3.15 - 120 200 24 475 - 10.5-11.0

CAP PASS SAW DCEN E7018 3.15 - 145 220 26 450 - 13.0-13.5

2ND SIDE - -

HOT PASS 1 SAW DCEN E7018 3.15 - 70 160 20 500 - 2.5-3

HOT PASS 2 SAW DCEN E7018 3.15 - 90 180 22 483 - 5.0-5.5

HOT PASS 3 SAW DCEN E7018 3.15 - 110 180 22 468 - 7.0-7.5

HOT PASS 4 SAW DCEN E7018 3.15 - 130 200 24 465 - 9.5-10

HOT PASS 5 SAW DCEN E7018 3.15 - 120 200 24 468 - 12.0-12.5

CAP PASS SAW DCEN E7018 3.15 - 145 220 26 450 - 14.5-15.0

Back Gauzing : Yes/No YES DP Test Result: Back Gauging Depth 1.5-2.0 MM

Visual Inspection After Welding As Per QW-194: PWHT:APPLIED

Test Coupon Identification

Final Remarks: Released For Radiography/Mechanical Testing

Test Witnessed By Test Verified By:

You might also like

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- Full Thickness Repair Welding Welding Procedure Specification (WPS) in Accordance With API 1104 21: 2016Document6 pagesFull Thickness Repair Welding Welding Procedure Specification (WPS) in Accordance With API 1104 21: 2016Juni KurniyantoNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- Welding Procedure Specification GuideDocument2 pagesWelding Procedure Specification GuidepoulmackNo ratings yet

- WPS 141-121 P460QH To SameDocument2 pagesWPS 141-121 P460QH To SameakisdassasNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- AWS D1.1 WPS for Butt Joint SMAW ProcedureDocument2 pagesAWS D1.1 WPS for Butt Joint SMAW ProcedureWahyu Lailil FaisNo ratings yet

- 4 - PREPARATION OF WPS - StudentDocument22 pages4 - PREPARATION OF WPS - Studentrazlan ghazaliNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Madina Trading WPS No. 017Document12 pagesMadina Trading WPS No. 017MAT-LIONNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- WPS - 018Document12 pagesWPS - 018MAT-LIONNo ratings yet

- PQR Procedure Qualification Record Krishna SteelDocument2 pagesPQR Procedure Qualification Record Krishna SteelHarshit Adwani100% (2)

- Madina Trading WPS DetailsDocument11 pagesMadina Trading WPS DetailsMAT-LIONNo ratings yet

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- MPEC WPS for 8Document1 pageMPEC WPS for 8Mecon HyderabadNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document2 pagesPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (1)

- Runsheet WPQT ModernDocument9 pagesRunsheet WPQT ModernYUDI IRMAWANTONo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- WPS 141-111 P460QH To SameDocument1 pageWPS 141-111 P460QH To SameakisdassasNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Welding Procedure Specification (AutoRecovered)Document2 pagesWelding Procedure Specification (AutoRecovered)virnmontalesNo ratings yet

- WPS - 010Document12 pagesWPS - 010MAT-LIONNo ratings yet

- As Run Sheet-Pqr-051Document14 pagesAs Run Sheet-Pqr-051Anonymous rYZyQQot550% (1)

- Prequalified X Qualified by Testing Procedure Qualification Records (PQR) YES .Document2 pagesPrequalified X Qualified by Testing Procedure Qualification Records (PQR) YES .Midhun K ChandraboseNo ratings yet

- PQR - Camsa-02Document1 pagePQR - Camsa-02Jean Carlo Gutarra SocualayaNo ratings yet

- 2G & 5GDocument2 pages2G & 5GRahul MoottolikandyNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Wps (Gtaw & Smaw)Document3 pagesWps (Gtaw & Smaw)Ramadhan AdityaNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR TIE-IN WORKSDocument6 pagesWELDING PROCEDURE SPECIFICATION FOR TIE-IN WORKSAshishNo ratings yet

- Draft WPS Welder R0Document51 pagesDraft WPS Welder R0R Bernanda Argandhi SaputraNo ratings yet

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDocument2 pages0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CMahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/ADocument1 pagePessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/AMahmoud HaggagNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateAmjad PathanNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagNo ratings yet

- WpsDocument3 pagesWpsPankaj KumarNo ratings yet

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- Welding Procedure Specification (WPS) : CÓDIGO: AC-FT-018 Versión: 01 FECHA: 24-05-2019 Página: 1 de 1Document2 pagesWelding Procedure Specification (WPS) : CÓDIGO: AC-FT-018 Versión: 01 FECHA: 24-05-2019 Página: 1 de 1cesarNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- Nisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)Document3 pagesNisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)pejman.imaniNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- WPS & PQR - LTM - QW - PipeDocument7 pagesWPS & PQR - LTM - QW - PipeKAMALNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Sabari Engineering PQRDocument3 pagesSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- WPS (Gtaw)Document2 pagesWPS (Gtaw)Ramadhan AdityaNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- WPQT SawDocument2 pagesWPQT Sawkiran144No ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Quality Control Form "Sample"Document23 pagesQuality Control Form "Sample"BernathTurnipNo ratings yet

- ISO 9001 Internal Audit Checklist GuidanceDocument8 pagesISO 9001 Internal Audit Checklist GuidanceFauzul MutaqinNo ratings yet

- PW3Document49 pagesPW3Mujaffar ShaikhNo ratings yet

- Factories Act 1948Document68 pagesFactories Act 1948Sreelakshmi KambapuNo ratings yet

- Indian Standard For Fire ExtinguisherDocument23 pagesIndian Standard For Fire Extinguisheroperation btutNo ratings yet

- Sammut bonniciSWOTDocument9 pagesSammut bonniciSWOTSimesh DuttaNo ratings yet

- Weld DefectsDocument5 pagesWeld Defectsoperation btutNo ratings yet

- Weld DefectsDocument5 pagesWeld Defectsoperation btutNo ratings yet

- Sammut bonniciSWOTDocument9 pagesSammut bonniciSWOTSimesh DuttaNo ratings yet

- Weld DefectsDocument5 pagesWeld Defectsoperation btutNo ratings yet

- Pestle PDFDocument26 pagesPestle PDFabubakarNo ratings yet

- Caracteristicas API 2HGr50 PDFDocument3 pagesCaracteristicas API 2HGr50 PDFFernandoBarreraDominguezNo ratings yet

- Consolidated Contractors Welding Procedure SpecificationDocument3 pagesConsolidated Contractors Welding Procedure Specificationsiva8000100% (1)

- Long seam weld estimationDocument16 pagesLong seam weld estimationTiago FerreiraNo ratings yet

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- List of Welding Procedures.: Client: Emirates Aluminium Company Limited. Gmmos Job #: 801-4690Document6 pagesList of Welding Procedures.: Client: Emirates Aluminium Company Limited. Gmmos Job #: 801-4690ravi00098No ratings yet

- American Welding Society (Auth.) - Welding Handbook - Volume 1 - Fundamentals of Welding (1976, Macmillan Education UK)Document386 pagesAmerican Welding Society (Auth.) - Welding Handbook - Volume 1 - Fundamentals of Welding (1976, Macmillan Education UK)Manuel85% (13)

- 2022 S5 ME MFG S - Welding IntroDocument109 pages2022 S5 ME MFG S - Welding IntroTom TambeNo ratings yet

- Asme IxDocument98 pagesAsme IxNam KhansomboonNo ratings yet

- SSAB's Ramor protection steels provide optimal ballistic resistanceDocument12 pagesSSAB's Ramor protection steels provide optimal ballistic resistanceehudingram6535No ratings yet

- API 577 API 577 Chapter-5 Chapter-5 Key Points Key PointsDocument4 pagesAPI 577 API 577 Chapter-5 Chapter-5 Key Points Key PointsElankumaran PeriakaruppanNo ratings yet

- Part B Question (2010)Document10 pagesPart B Question (2010)장재성100% (1)

- SMAW 10 Week 3-4Document4 pagesSMAW 10 Week 3-4Jessel Mejia Onza100% (2)

- 0-5452 ET 201i DC - ManualDocument52 pages0-5452 ET 201i DC - Manualmaverick kitaroNo ratings yet

- Welding IntroDocument38 pagesWelding IntroAloysi DelouizaNo ratings yet

- Welder IdentificationDocument9 pagesWelder Identificationdandiar1No ratings yet

- SMAW Welding Guidelines for Safety and ProceduresDocument28 pagesSMAW Welding Guidelines for Safety and ProceduresD S Sagar TripuramalluNo ratings yet

- Welding Safety: 29 CFR 1926.350-354 Subpart JDocument53 pagesWelding Safety: 29 CFR 1926.350-354 Subpart JDharmendra RajanNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- AwsDocument14 pagesAwssarkararup75% (4)

- List of WPS (Jerp) PDFDocument2 pagesList of WPS (Jerp) PDFAlam MD SazidNo ratings yet

- TESDA-OP-CO-01-F15 List of Consumables for Welding ProgramDocument1 pageTESDA-OP-CO-01-F15 List of Consumables for Welding ProgramFemee JisonNo ratings yet

- Parts List Bigblue700Document22 pagesParts List Bigblue700felipeNo ratings yet

- Meccoct18 12388Document10 pagesMeccoct18 12388MikeNo ratings yet

- Housekeeping Schedule SmawDocument8 pagesHousekeeping Schedule SmawWc-mark ChuvachucHuNo ratings yet

- General Specification For Welding and Weld Inspection EIL PDFDocument19 pagesGeneral Specification For Welding and Weld Inspection EIL PDFValesh MonisNo ratings yet

- 7560 MSF Method S-1 - Rev. 1Document41 pages7560 MSF Method S-1 - Rev. 1Bala MuruganNo ratings yet

- Sembcorp Marine Integrated Yard PteDocument3 pagesSembcorp Marine Integrated Yard PteMd. Mizanur Rahaman100% (1)

- Cahier de Soudage G 11950 - Ver B - WPS 14Document1 pageCahier de Soudage G 11950 - Ver B - WPS 14YassineElabdNo ratings yet

- Welding: Engr. Dheylvin Roy P. BuenaventuraDocument8 pagesWelding: Engr. Dheylvin Roy P. BuenaventuraEarl Justin EnriqueNo ratings yet

- BS EN 499 - Welding Consumables - Covered Electrodes For Man PDFDocument12 pagesBS EN 499 - Welding Consumables - Covered Electrodes For Man PDFVuong Tran VanNo ratings yet

- Construction of Two Semi Mobile HoppersDocument1 pageConstruction of Two Semi Mobile HoppersYassineElabdNo ratings yet