Professional Documents

Culture Documents

Precast Roof Slab PDF

Uploaded by

ChuksbozmentOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Precast Roof Slab PDF

Uploaded by

ChuksbozmentCopyright:

Available Formats

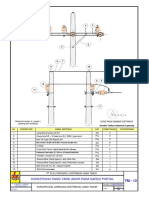

Project Job Ref.

EFFLUENT TREATMENT PLANT, NLNG BONNY, RIVERS DEL/2019-200

DELTEC ENGINEERING LIMITED Section Sheet no./rev.

PLOT 576 14 STR., DDPA ESTATE

PRECAST ROOF SLAB 1

UGBORIKOKO EFFURUN

Calc. by Date Chk'd by Date App'd by Date

DELTA STATE

CIE 2/13/2020 EOB 2/11/2020 SAI 2/12/2020

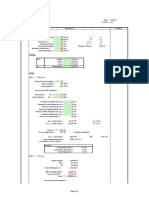

RC SLAB DESIGN

In accordance with EN1992-1-1:2004 incorporating corrigendum January 2008 and the recommended values

Tedds calculation version 1.0.18

200

5225

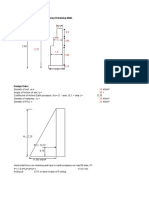

Slab definition

Slab reference name; P.ROOF SLAB

Overall slab depth; h = 200 mm

Number of spans; Nspans = 1

First support; Simple

Last support; Simple

; ;;

Nominal cover to bottom reinforcement; cnom_b = 40 mm

Loading

Ratio of quasi-permanent to ultimate load; rq = 0.800

Concrete properties

Concrete strength class; C30/37

Characteristic cylinder strength; fck = 30 N/mm2

Partial factor (Table 2.1N); C = 1.50

Compressive strength factor (cl. 3.1.6); cc = 1.00

Design compressive strength (cl. 3.1.6); fcd = 20.0 N/mm2

Mean axial tensile strength (Table 3.1); fctm = 0.30 N/mm2 (fck / 1 N/mm2)2/3 = 2.9 N/mm2

Maximum aggregate size; dg = 20 mm

Effective strength factor – exp.3.21; = 1.00

Effect. compr. zone height factor – exp.3.19; = 0.80

Ultimate strain - Table 3.1; cu2 = 0.0035

Shortening strain - Table 3.1; cu3 = 0.0035

K1 = 0.44

K2 = 1.25 (0.6 + 0.0014/cu2) = 1.25

Design value modulus of elasticity reinf – 3.2.7(4) Es = 200000 N/mm2

Reinforcement properties

Characteristic yield strength; fyk = 410 N/mm2

Partial factor (Table 2.1N); S = 1.15

Design yield strength (fig. 3.8); fyd = fyk / S = 356.5 N/mm2

Concrete cover to reinforcement

Nominal cover to bottom reinforcement; cnom_b = 40 mm

Fire resistance period to bottom of slab; Rbtm = 120 min

Axis distance to bottom reinft (Table 5.8); afi_b = 40 mm

Max bar diameter in bottom; max_b = 12 mm

Project Job Ref.

EFFLUENT TREATMENT PLANT, NLNG BONNY, RIVERS DEL/2019-200

DELTEC ENGINEERING LIMITED Section Sheet no./rev.

PLOT 576 14 STR., DDPA ESTATE

PRECAST ROOF SLAB 2

UGBORIKOKO EFFURUN

Calc. by Date Chk'd by Date App'd by Date

DELTA STATE

CIE 2/13/2020 EOB 2/11/2020 SAI 2/12/2020

Min. btm cover requirement with regard to bond; cmin,b_b = max_b = 12 mm

Reinforcement fabrication; Subject to QA system

Cover allowance for deviation; cdev = 5 mm

Min. required nominal cover to bottom reinft; cnom_b_min = max(afi_b - max_b / 2, cmin,b_b + cdev) = 34.0 mm

PASS - There is sufficient cover to the bottom reinforcement

Bending design checks

Redistribution ratio; = 1.0

Limiting value of K; K’ = (2 cc / C) (1 - ( - K1) / (2 K2)) ( ( - K1) / (2 K2)) =

0.196

Reinforcement design at midspan of span 1 (cl.6.1)

Length of span 1; l1 = 5225 mm

Design bending moment; Mp1 = 30.7 kNm/m

Reinforcement provided; 12 mm dia. bars at 100 mm centres;

Area provided; Asp1 = 1131 mm2/m

Effective depth to tension reinforcement; dp1 = h - cnom_b - p1 / 2 = 154.0 mm

K factor; K = Mp1 / (b dp12 fck) = 0.043

K < K' - Compression reinforcement is not required

Lever arm; z = min(0.95 dp1, dp1 / 2 [1 + (1 - 2 K / ( cc / C))0.5])

z = 146.3 mm

Area of reinforcement required for bending; Asp1_m = Mp1 / (fyd z) = 589 mm2/m

Minimum area required; Asp1_min = max(0.26 (fctm/fyk), 0.0013) b dp1 = 283 mm2/m

Area of reinforcement required; Asp1_req = max(Asp1_m, Asp1_min) = 589 mm2/m

PASS - Area of tension reinforcement provided is adequate (0.520)

Check reinforcement spacing

Reinforcement service stress; s = (fyk / S) min((Asp1_m/Asp1), 1.0) rq = ;148.4; N/mm2

Maximum allowable spacing (Table 7.3N); smax_p1 = 300 mm

Actual bar spacing; sp1 = 100 mm

PASS - The reinforcement spacing is acceptable

Shear design checks

Shear resistance constant (cl. 6.2.2); CRd,c = 0.18 N/mm2 / C = 0.12 N/mm2

Shear capacity check at support 1

; ;

Shear force; V1 = ;23.5; kN/m

Reinforcement provided; 12 mm dia. bars at 100 mm centres;

Area provided; Asd1 = 1005 mm2/m

Effective depth; dd1 = h - cnom_b - d1 / 2 = 152.0 mm

Effective depth factor (cl. 6.2.2); k = min(2.0, 1 + (200 mm / dd1)0.5) = 2.000

Reinforcement ratio; l = min(0.02, Asd1 / (b dd1)) = 0.0066

Minimum shear resistance (Exp. 6.3N); VRd,c_min = 0.035 N/mm2 k1.5 (fck / 1 N/mm2)0.5 b dd1

VRd,c_min = 82.4 kN/m

Shear resistance (Exp. 6.2a); VRd,c1 = max(VRd,c_min, CRd,c k (100l (fck/1 N/mm2))0.333 b dd1)

VRd,c1 = 98.7 kN/m

Project Job Ref.

EFFLUENT TREATMENT PLANT, NLNG BONNY, RIVERS DEL/2019-200

DELTEC ENGINEERING LIMITED Section Sheet no./rev.

PLOT 576 14 STR., DDPA ESTATE

PRECAST ROOF SLAB 3

UGBORIKOKO EFFURUN

Calc. by Date Chk'd by Date App'd by Date

DELTA STATE

CIE 2/13/2020 EOB 2/11/2020 SAI 2/12/2020

PASS - Shear capacity is adequate (0.238)

Shear capacity check at support 2

Shear force; V2 = 23.5 kN/m

Reinforcement provided; 16 mm dia. bars at 200 mm centres;

Area provided; Asd2 = 1005 mm2/m

Effective depth; dd2 = h - cnom_b - d2 / 2 = 152.0 mm

Effective depth factor (cl. 6.2.2); k = min(2.0, 1 + (200 mm / dd2)0.5) = 2.000

Reinforcement ratio; l = min(0.02, Asd2 / (b dd2)) = 0.0066

Minimum shear resistance (Exp. 6.3N); VRd,c_min = 0.035 N/mm2 k1.5 (fck / 1 N/mm2)0.5 b dd2

VRd,c_min = 82.4 kN/m

Shear resistance (Exp. 6.2a); VRd,c2 = max(VRd,c_min, CRd,c k (100l (fck/1 N/mm2))0.333 b dd2)

VRd,c2 = 98.7 kN/m

PASS - Shear capacity is adequate (0.238)

Deflection checks

Basic span-to-depth ratio deflection check span 1 (cl. 7.4.2)

Reference reinforcement ratio; 0 = (fck / 1 N/mm2)0.5 / 1000 = 0.0055

Required tension reinforcement ratio; = max(0.0035, Asp1_m / (b dp1)) = 0.0038

Required compression reinforcement ratio; ’ = Ascp1_req / (b dp1) = 0.0000

Structural system factor (Table 7.4N); K = 1.0

Basic span-to-depth ratio limit; ratiolim1_bas = K [11 + 1.5 (fck/1 N/mm2)0.5 0/ + 3.2 (fck/1 N/mm2)0.5 (0/ - 1)1.5]

(Exp. 7.16a); ratiolim1_bas = 27.77

Modified span-to-depth ratio limit;

ratiolim1 = min(1.5, (500 N/mm2/ fyk) (Asp1 / Asp1_m)) ratiolim1_bas = 41.65

Actual span-to-depth ratio; ratioact1 = l1 / dp1 = 33.93

PASS - Span-to-depth ratio is acceptable (0.815)

Reinforcement sketch

The following sketch is indicative only. Note that additional reinforcement may be required in accordance with clauses 9.2.1.2,

9.2.1.4 and 9.2.1.5 of EN 1992-1-1:2004 to meet detailing rules.

0

12

10

@

@

10

12

12 @100

You might also like

- Cube Test ReportDocument1 pageCube Test ReportShubham MareNo ratings yet

- Rockfall Protection DesignDocument5 pagesRockfall Protection DesignPrakash Singh RawalNo ratings yet

- Era View Brochure, Apartments For Rent and Sale Across Bahrain.Document20 pagesEra View Brochure, Apartments For Rent and Sale Across Bahrain.Era Rea EstateNo ratings yet

- Strength Behavior of Cement Treated Dredged SoilDocument20 pagesStrength Behavior of Cement Treated Dredged SoilTarhata KalimNo ratings yet

- Sample Interaction Diagram of ColumnDocument8 pagesSample Interaction Diagram of ColumnArvin Edsel Sioson100% (1)

- PILE ANALYSISDocument4 pagesPILE ANALYSISRuemu Godwin InikoriNo ratings yet

- 02-Design of Grade Slab - As Per TR-34Document42 pages02-Design of Grade Slab - As Per TR-34Anonymous Clm40C1No ratings yet

- Explanatory Examples On Indian Seismic Code IS 1893 (Part I)Document10 pagesExplanatory Examples On Indian Seismic Code IS 1893 (Part I)shadabg04No ratings yet

- Eu 022Document10 pagesEu 022Khurshed Alam IndiaNo ratings yet

- Pile Reinforcement - DPL Ver 0.6Document8 pagesPile Reinforcement - DPL Ver 0.6Antony GodwinNo ratings yet

- Masonry Retaining Wall - FinalDocument15 pagesMasonry Retaining Wall - Finalfarzi accoNo ratings yet

- IR Diaphram WallDocument2 pagesIR Diaphram Wallalfredo50% (2)

- Wallap Input Data Bada Chauraha Station Top Down Grid 08-11-750mm CS at 8.15mDocument18 pagesWallap Input Data Bada Chauraha Station Top Down Grid 08-11-750mm CS at 8.15msumit rawatNo ratings yet

- Additional Exercise (Solution)Document6 pagesAdditional Exercise (Solution)abdul al muhaiminNo ratings yet

- 19th Southeast Asian Geotechnical Conference ProceedingsDocument6 pages19th Southeast Asian Geotechnical Conference ProceedingsSen HuNo ratings yet

- Heat of Hydration StressesDocument7 pagesHeat of Hydration StressesAnkur BarsainyaNo ratings yet

- 1 PDFDocument22 pages1 PDFNeeraj Sharma0% (1)

- Pile Capacity Comp./UpliftDocument2 pagesPile Capacity Comp./UpliftPankaj Sherwal100% (1)

- Determination of Point of Fixity As Per TomlinsonDocument3 pagesDetermination of Point of Fixity As Per TomlinsonHanafiahHamzahNo ratings yet

- Crack Width CalculationsDocument1 pageCrack Width CalculationsdfdgggNo ratings yet

- GEO TALK Ground AnchorDocument50 pagesGEO TALK Ground AnchorWidodo WidodoNo ratings yet

- PJPT Project Precast Plank Design CalculationsDocument2 pagesPJPT Project Precast Plank Design CalculationsalexanderNo ratings yet

- Design and Construction of Anchored and Strutted Sheet Pile WallsDocument37 pagesDesign and Construction of Anchored and Strutted Sheet Pile WallsphamducquangNo ratings yet

- Analysis of Bearing Capacity Driven PileDocument22 pagesAnalysis of Bearing Capacity Driven PileGEOMAHESHNo ratings yet

- Effe. Section HeightDocument132 pagesEffe. Section HeightNaresh SharmaNo ratings yet

- 5CT2 - Stability of DwallDocument2 pages5CT2 - Stability of Dwallloc khaNo ratings yet

- MS of Segment Casting - 12345Document7 pagesMS of Segment Casting - 12345Anup SrivastavaNo ratings yet

- Design of Base Raft: Title Conveyor Tunnel 1Bc-3Document6 pagesDesign of Base Raft: Title Conveyor Tunnel 1Bc-3Uttam Kumar GhoshNo ratings yet

- Borehole No.: ABH 39 Water Table For Calculation: 6.15 M Zone Factor (Zone-III) 0.16Document4 pagesBorehole No.: ABH 39 Water Table For Calculation: 6.15 M Zone Factor (Zone-III) 0.16debapriyoNo ratings yet

- Design and Construction of Geosynthetic Reinforced EmbankmentsDocument57 pagesDesign and Construction of Geosynthetic Reinforced EmbankmentsZakee MohamedNo ratings yet

- Deep BeamDocument7 pagesDeep Beamarifi_civilNo ratings yet

- ISI Load Test March 2014Document20 pagesISI Load Test March 2014Projects CortexNo ratings yet

- Culvert Calculation Sheet RT 0+790 - 02.10.2019Document9 pagesCulvert Calculation Sheet RT 0+790 - 02.10.2019malithNo ratings yet

- Calculations of Pile Capacity of Pile: K EI TDocument5 pagesCalculations of Pile Capacity of Pile: K EI Tgaurav sharmaNo ratings yet

- Concrete Pull Out Check PDFDocument1 pageConcrete Pull Out Check PDFMaliki MuhammedNo ratings yet

- Skin Friction and Pile DesignDocument7 pagesSkin Friction and Pile DesignNaveen RNo ratings yet

- PRESTRESSED BRIDGE TITLEDocument19 pagesPRESTRESSED BRIDGE TITLEAziz ul HakeemNo ratings yet

- Road Estimate FormatDocument7 pagesRoad Estimate Formatalok jhaNo ratings yet

- Narayangharh-Mugling HighwayDocument85 pagesNarayangharh-Mugling HighwayRm1262No ratings yet

- Design of Retaining WallDocument8 pagesDesign of Retaining WallLeena RodricksNo ratings yet

- UNIT II WATER TANKS Underground Rectangu PDFDocument42 pagesUNIT II WATER TANKS Underground Rectangu PDFEgyptian ResearcherNo ratings yet

- Setha's CV & Cover LetterDocument10 pagesSetha's CV & Cover LetterMen Keo RathaNo ratings yet

- MOS Trial Trench WorkDocument20 pagesMOS Trial Trench Workg.chandra mohanNo ratings yet

- Individual Footing With MomentsDocument2 pagesIndividual Footing With MomentseramitdhanukaNo ratings yet

- Calculations by Yg Plot 55 & 56 01.02.23Document63 pagesCalculations by Yg Plot 55 & 56 01.02.23Shanil BussooaNo ratings yet

- Rock Bolt Capacity CalculationDocument2 pagesRock Bolt Capacity CalculationROHIT PADHARIA100% (1)

- Jubail Island Development crack width calculationsDocument16 pagesJubail Island Development crack width calculationstaha abu el hanaNo ratings yet

- ProtaStructure Suite 2016 Whats NewDocument41 pagesProtaStructure Suite 2016 Whats NewPlacid FabiloNo ratings yet

- Noise Barriers Supply and Installation For Burfiwala Lane & Gokhale Road Junction FlyoverDocument20 pagesNoise Barriers Supply and Installation For Burfiwala Lane & Gokhale Road Junction FlyoverAvinash JagtapNo ratings yet

- Crack Width Calculation ExampleDocument3 pagesCrack Width Calculation Examplebernie romeroNo ratings yet

- Precast Concrete ConstructionDocument71 pagesPrecast Concrete ConstructionMahad AbdiNo ratings yet

- 3.1-Pile Design Calculation For Boundary (p1 To p50)Document24 pages3.1-Pile Design Calculation For Boundary (p1 To p50)layaljamal2No ratings yet

- Aci 10 - 08Document468 pagesAci 10 - 08corneliortizNo ratings yet

- MRT DRR-08 (8jun2021) (Replied by Neo)Document6 pagesMRT DRR-08 (8jun2021) (Replied by Neo)yin hoe ongNo ratings yet

- RC Beam Design CalculationsDocument4 pagesRC Beam Design CalculationsBuvanendran SanjeevanNo ratings yet

- Slab DesignDocument5 pagesSlab DesignSitche ZisoNo ratings yet

- Slab design summary and reinforcement checksDocument5 pagesSlab design summary and reinforcement checksShingirai JoeNo ratings yet

- RC MEMBER DESIGN CALCULATIONSDocument3 pagesRC MEMBER DESIGN CALCULATIONS郑 凯伦 Tey Kai LoonNo ratings yet

- RC Slab Design (En1992) - Slab DesignDocument5 pagesRC Slab Design (En1992) - Slab Designkennedy silewuNo ratings yet

- Floating RC Slab Design (EN1992)Document5 pagesFloating RC Slab Design (EN1992)Shingirai JoeNo ratings yet

- Soil Properties for LPILE & COM624P AnalysisDocument2 pagesSoil Properties for LPILE & COM624P Analysiswaleed4631100% (1)

- GEOTECH Soil ReportDocument15 pagesGEOTECH Soil ReportChuksbozmentNo ratings yet

- Precast Roof Slab PDFDocument3 pagesPrecast Roof Slab PDFChuksbozmentNo ratings yet

- Erosion Control ChecklistDocument2 pagesErosion Control ChecklistChuksbozmentNo ratings yet

- Calculation of Deflections Due To Shrinkage & CreepsDocument2 pagesCalculation of Deflections Due To Shrinkage & CreepsChuksbozmentNo ratings yet

- Complete RCC Design Very ImportantDocument41 pagesComplete RCC Design Very ImportantAmal PremachandranNo ratings yet

- Sika Concrete Repair & Protection To en 1504 Brochure NZ 0614Document56 pagesSika Concrete Repair & Protection To en 1504 Brochure NZ 0614Gandhi HammoudNo ratings yet

- FOURFLOORS BeamDesDocument31 pagesFOURFLOORS BeamDesChuksbozmentNo ratings yet

- Recruitment Resume Template For Unity RefineryDocument6 pagesRecruitment Resume Template For Unity RefineryChuksbozmentNo ratings yet

- 30,000ltrs Overhead Water Tank Support Tower and FoundationDocument23 pages30,000ltrs Overhead Water Tank Support Tower and FoundationChuksbozment67% (3)

- Recruitment Resume Template For Unity RefineryDocument6 pagesRecruitment Resume Template For Unity RefineryChuksbozmentNo ratings yet

- 30,000ltrs Overhead Water Tank Support Tower and FoundationDocument23 pages30,000ltrs Overhead Water Tank Support Tower and FoundationChuksbozment67% (3)

- Precast Roof SlabDocument4 pagesPrecast Roof SlabChuksbozmentNo ratings yet

- FOURFLOORS BeamDesDocument31 pagesFOURFLOORS BeamDesChuksbozmentNo ratings yet

- Structural Analysis and Design of 132KV Power TransmissionDocument30 pagesStructural Analysis and Design of 132KV Power TransmissionChuksbozmentNo ratings yet

- 30,000ltrs Overhead Water Tank Support Tower and FoundationDocument23 pages30,000ltrs Overhead Water Tank Support Tower and FoundationChuksbozment67% (3)

- Pull Out Resistance of Roof FastenersDocument41 pagesPull Out Resistance of Roof FastenersChuksbozment100% (1)

- Foundation AnalysisDocument7 pagesFoundation AnalysisChuksbozmentNo ratings yet

- Member StrengtheningDocument2 pagesMember StrengtheningNitin ParulNo ratings yet

- MSC Dissertation GuideDocument28 pagesMSC Dissertation GuideChuksbozmentNo ratings yet

- Tower Design CodesDocument10 pagesTower Design CodesMaribel Isaura Cunurana YapuchuraNo ratings yet

- UFGSDocument27 pagesUFGSChuksbozmentNo ratings yet

- Marine FendersDocument17 pagesMarine FendersVictor Manuel Bazaes Athens100% (1)

- Concrete Sheet Pile Design AnalysisDocument11 pagesConcrete Sheet Pile Design AnalysisChuksbozmentNo ratings yet

- 12 Cantilever StairsDocument15 pages12 Cantilever StairsGayathri Manjunath ShepurNo ratings yet

- Sheet Piling Analysis & Design in Accordance With BS EN1997-1:2004 - Code of Practice For Geotechnical Design and The UK National AnnexDocument7 pagesSheet Piling Analysis & Design in Accordance With BS EN1997-1:2004 - Code of Practice For Geotechnical Design and The UK National AnnexChuksbozmentNo ratings yet

- MSC Dissertation GuideDocument28 pagesMSC Dissertation GuideChuksbozmentNo ratings yet

- Condition 1: Maximum Axial (Compression) Capacity: InputDocument7 pagesCondition 1: Maximum Axial (Compression) Capacity: InputChuksbozmentNo ratings yet

- Eurocode 1 ComparisonDocument10 pagesEurocode 1 ComparisontbaysakNo ratings yet

- Sop of StringingDocument7 pagesSop of Stringingshubham shindeNo ratings yet

- ECB Installation GuideDocument2 pagesECB Installation GuideRicardo HernandezNo ratings yet

- AAAC ConductorsDocument14 pagesAAAC ConductorsDipanku GoswamiNo ratings yet

- Emaco Nanocrete R3 - PDS - ASEAN - 241110Document3 pagesEmaco Nanocrete R3 - PDS - ASEAN - 241110Andri AjaNo ratings yet

- Comparison of Major Wind Codes for Sri Lankan ContextDocument15 pagesComparison of Major Wind Codes for Sri Lankan Contextjoaobarbosa22No ratings yet

- Commercial Building ProjectDocument3 pagesCommercial Building ProjectSharif KhanNo ratings yet

- PHEONWJ-G-SPE-0101 0 - Structural and Piping Fabrication Quality ControlDocument11 pagesPHEONWJ-G-SPE-0101 0 - Structural and Piping Fabrication Quality ControlIksan Adityo Mulyo100% (1)

- Asphalt Pavement Design-The Design Guide L - Khazanovich PDFDocument44 pagesAsphalt Pavement Design-The Design Guide L - Khazanovich PDFYasruddin MtNo ratings yet

- Slab Shear CoefficientDocument1 pageSlab Shear CoefficientIsbel0% (1)

- Subsea Challenges in Deep PanukeDocument22 pagesSubsea Challenges in Deep Panukeharan2000No ratings yet

- Air Release Valve Val - 3Document1 pageAir Release Valve Val - 3Coordinador TecnicoNo ratings yet

- Hitachi Flexible Cable PDFDocument48 pagesHitachi Flexible Cable PDFLev AksenovskiiNo ratings yet

- Fire Fighting Coorse 2014Document100 pagesFire Fighting Coorse 2014ماشي عديها100% (1)

- 1-01 Accelerator Pedal and Control: 4JJ1,4JK1Document65 pages1-01 Accelerator Pedal and Control: 4JJ1,4JK1Obeth ThombiatoNo ratings yet

- Stone Mastic Asphalt Engineering GuideDocument9 pagesStone Mastic Asphalt Engineering Guidesatyam lodhiNo ratings yet

- As1684 Split Level c2 House BracingDocument43 pagesAs1684 Split Level c2 House BracingUday PratapNo ratings yet

- 60T0 Taurus v2 ENDocument16 pages60T0 Taurus v2 ENxianzaiegNo ratings yet

- Techniques For Seismic Isolation Retrofit Work While A Building Is Being UsedDocument6 pagesTechniques For Seismic Isolation Retrofit Work While A Building Is Being UsedJohnny Condori UribeNo ratings yet

- Concrete Structures: Oil & GasDocument16 pagesConcrete Structures: Oil & GasES RouzaNo ratings yet

- Australian Standard: 3959: FlooringDocument4 pagesAustralian Standard: 3959: FlooringJohn HoldingNo ratings yet

- DIT Robot ShooterDocument2 pagesDIT Robot ShooterFabiano MoraisNo ratings yet

- Beml Bd80 DozerDocument5 pagesBeml Bd80 DozerSanjay KulkarniNo ratings yet

- Evaluation of Epoxy Injection Method For Concrete Crack RepairDocument7 pagesEvaluation of Epoxy Injection Method For Concrete Crack RepairMohamed Ismail ShehabNo ratings yet

- Overall Final Project Report PDFDocument115 pagesOverall Final Project Report PDFSuraj yadavNo ratings yet

- BIM Management GuidelineDocument22 pagesBIM Management GuidelinemhamrawyNo ratings yet

- Part Cataloge Chain Hoist DK 10 SETDocument42 pagesPart Cataloge Chain Hoist DK 10 SETfatchur_demagNo ratings yet

- Ultra High Performance ConcreteDocument20 pagesUltra High Performance ConcretePavan Kumar63% (8)

- Research ProposalDocument6 pagesResearch ProposalAbdalla Mohamed Abdalla100% (3)

- Konstruksi Tiang Tarik Akhir Pada Gardu Portal: Konstruksi Jaringan Distribusi Jawa TimurDocument3 pagesKonstruksi Tiang Tarik Akhir Pada Gardu Portal: Konstruksi Jaringan Distribusi Jawa TimurrenggaNo ratings yet