100% found this document useful (3 votes)

3K views3 pagesDuct Inspection Checklist

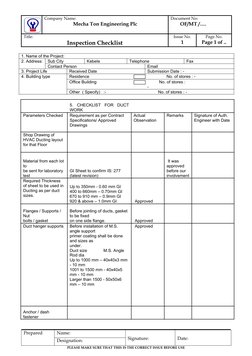

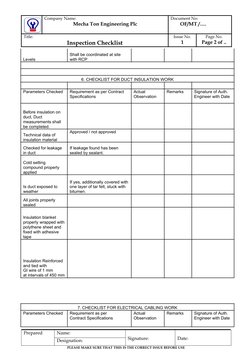

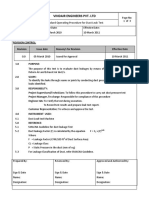

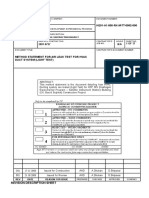

This 3 page inspection checklist is for a mechanical, electrical, and piping (MEP) project. It details inspection requirements for ductwork, insulation, and electrical cabling. The checklist includes parameters to check, contract specifications, observations, remarks, and signatures. It will be used to inspect the quality of ducting materials and layout, insulation application, and cable installation. Project details at the top provide the name, address, contact, and other relevant information.

Uploaded by

Haymanot BaynesagnCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

100% found this document useful (3 votes)

3K views3 pagesDuct Inspection Checklist

This 3 page inspection checklist is for a mechanical, electrical, and piping (MEP) project. It details inspection requirements for ductwork, insulation, and electrical cabling. The checklist includes parameters to check, contract specifications, observations, remarks, and signatures. It will be used to inspect the quality of ducting materials and layout, insulation application, and cable installation. Project details at the top provide the name, address, contact, and other relevant information.

Uploaded by

Haymanot BaynesagnCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

- Checklist for Duct Work

- Checklist for Duct Insulation Work

- Checklist for Electrical Cabling Work