Professional Documents

Culture Documents

Cqi27 PT D

Uploaded by

lalitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cqi27 PT D

Uploaded by

lalitCopyright:

Available Formats

CQI-27

Special Process: Casting System Assessment

Version 1, 10/2015

PROCESS TABLE D - Aluminum Semi-Permanent Mold

All requirements given below are subordinate to customer specific requirements.

When performing the CQI-27 Casting Assessment the auditor shall verify foundry is conforming to customer requirements; including a customer approved Control Plan defining the

agreed upon inspection testing and frequencies.

*If minimum requirements are not met, provide supporting records to justify actual conditions.

What is the scope covered by this audit? The entire foundry? A specific product line? A specific part number? Other?

Describe the scope of the audit:

Observations / Comments

Pass / Fail /

Item Category/Process Step Minimum Requirement Not

about Actual

Applicable

Condition

1.0 Casting Design and Tooling

The semi-permanent mold process is to be used to produce the raw castings. The semi-

D1.1 Casting Process permanent mold process may include different types of cast machine equipment such

as: gravity die casting, tilt pour, and low pressure die cast.

1. Casting plant must be compliant to customer specific software requirements.

D1.2 Design Software 2. Casting plant must have and maintain customer specific requirements for math data

transfer for the tooling and for part Drawings / Models.

1. The design responsible party must complete an FEA (Finite Element Analysis) for the

casting. The ultimate tensile strength, yield strength, and percent elongation used in the

FEA must be over the lower limit of engineering requirement for the specified alloy for

similar applications.

2. The foundry should know the specific features of the casting where maximum

D1.3 FEA Analysis

stresses exceed 50% of the Yield Strength. For purposes of this assessment, the

expression "high stress" refers to any feature exceeding 50% of the Yield Strength.

3. Any high stress features identified in the FEA must be evaluated when casting

simulations are reviewed, and when establishing product audits such as wall thickness,

microstructure, hardness, x-ray, crack inspections.

1. The casting plant must use solidification modeling software such as MagmaSoft,

AnyCasting, ProCast, EKK, FLOW-3D or similar software approved by the customer

Product Engineering on the casting as part of the design process for the gating and

feeding system prior to tooling construction and prototype part submission. Simulation

D1.4 Casting Simulation must include both fill and solidification analysis.

2. Results must be reviewed with the Customer Product Engineering.

3. At any high stress features in the FEA, the simulation should avoid hot spots, air

entrapment, multiple metal fronts converging.

Single cavity dies are required. If the casting plant predicts a multi-cavity die will work,

D1.5 Single Cavity the proposal must be approved by customer Product Engineering. Casting simulations

must support that multi-cavity would be same quality, or better, than single cavity.

1. If the casting plant creates the raw casting drawing, that drawing must be approved

by the customer Product Engineering.

2. If the casting plant creates the tolerance limits between the raw casting drawing and

any other drawing, those tolerance limits must be approved by the customer Product

Engineering.

D1.6 Casting Datum 3. Whenever possible, the X-Y-Z datum surfaces used on

the machined components should be the same X-Y-Z datum surfaces as the raw

castings. This is for dimensional control purposes and minimizing datum shifts between

the casting and machined surfaces (one of the causal factors related to thin-wall

conditions).

4. The X-Y-Z raw casting datum surfaces should be on one piece of the tooling.

All production core boxes and dies / molds should be made from steel alloys unless

D1.7 Casting Tool Material

customer Product Engineering approves alternate material.

Core boxes must be designed such that filing on the locating surfaces of core prints is

D1.8 Core Box Design

not allowed. Avoid blow tubes, vents, parting lines on the locating surfaces.

Slotted contoured vents are recommended to be used on casting cavity surfaces of

D1.9 Core Box Vents

core tooling cavities.

1. Vents or Risers should be located where simulations show the last places to fill.

2. All molds should be vented to atmosphere unless the application includes vacuum or

D1.10 Mold Vents counter pressure.

3. Only slotted vents are to be used in the molds unless other types approved by

customer.

Molds must be built with venturi aspirator systems in order to minimize core gas related

D1.11 Design Feature problems unless customer approves alternative construction. Molds can be aspirated

out the bottom, ends, or sides.

D1.12 Design Feature Molds must be built with anti-float features to keep the cores in position during pouring.

© 2015 Automotive Industry Action Group 1

ISBN#: 978 1 60534 331 0

CQI-27

Special Process: Casting System Assessment

Version 1, 10/2015

PROCESS TABLE D - Aluminum Semi-Permanent Mold

All requirements given below are subordinate to customer specific requirements.

When performing the CQI-27 Casting Assessment the auditor shall verify foundry is conforming to customer requirements; including a customer approved Control Plan defining the

agreed upon inspection testing and frequencies.

*If minimum requirements are not met, provide supporting records to justify actual conditions.

What is the scope covered by this audit? The entire foundry? A specific product line? A specific part number? Other?

Describe the scope of the audit:

Observations / Comments

Pass / Fail /

Item Category/Process Step Minimum Requirement Not

about Actual

Applicable

Condition

The mold should have internal circuit connections to air and/or water lines with

Internal Mold Cooling Circuit regulated temperature and flow rates. The mold must be design with sufficient internal

D1.13

Design cooling circuits. These circuits must be confirmed with simulation software, and

approved by the customer.

1. Check-sheet verification to account for potential issues outside of the standard

Preventative Maintenance scope of work.

Mold Inspection 2. Internal mold water lines must be checked for mineral build up at every mold

D1.14

(Such as End of Run Inspection) teardown. If build up is present, waterlines must be cleaned to remove deposits. Some

customers may require water flow for each water circuit to be measured and

documented.

1. Molds must be recoated at a fixed frequency for preventative maintenance.

D1.15 Mold Preparation

2. Gages to check coating thickness are required when feasible.

1. Confirmation of de-calcification of the water flow lines.

2. Water and air line plumbing flow checks.

Pre- Release Checklist Elements 3. Thermocouple function check.

D1.16

Tool Room Specific 4. Ejector pin function check.

5. Steel Core and slide condition.

6. Other Items ( Hydraulic Connections, Air line Connections, Limit Switches).

1. The life of the tooling is tracked based on number of cycles.

2. There is an itemized list of regular maintenance items completed at pre-defined

frequencies.

D1.17 Tooling Maintenance 3. Checksheet to track completion of regular maintenance.

4. Abrasive systems (such as shot blast and hand grinding) not permitted for cleaning

tooling. Non-abrasive systems (such as dry ice, high pressure water blast, solvent

washing and ultrasonic) are required.

1. Replacement inserts (new steel), where there is a customer specific requirement, a

PPAP approval may be required. Customer specific requirements may require a

process change request submission with possible production trial run requirements.

2. All tooling repair (welding, grinding, machining, insert replacement) requires

D1.18 Tool Changes

dimensional verification (internal approval) prior to re-instituting the tool for production

volumes.

3. The supplier complies with all customer requirements related to which PPAP

requirements are needed when tooling is corrected.

1. All castings produced must be identified with customer branding requirements,

casting plant logo (as applicable), casting part number, cavity number, and cast date in

designated locations per customer requirements.

D1.19 Casting Traceability 2. In some applications, traceability to both casting machine and/or

measured process parameters specific to the casting may be required. Identification

must be accurate and readily visible on non-machined surfaces, and must not interfere

with parting lines, appearance, function, processing or assembly.

1. Gage and fixture plan must be reviewed and approved by customer. (May include in-

line gage equipment for 100% check of critical dimensions as identified on part

specification and/or part drawing.).

2. The dimensional accuracy of all fixtures and gages must be per Customer

requirements. Typically, all fixtures and gages shall be built to a tolerance that is 10% or

less of part working tolerance. Some customers may require all fixtures and gages to be

built to +/- 5 micron maximum accuracy (this refers to the actual gage, not the part).

D1.20 Fixtures and Gages

3. All surfaces of fixtures and gages which touch the part should be made from hard

tool steel.

4. The tips of all clamps on fixtures and gages may require to be built with replaceable

tips.

5. Variable gages must pass Gage R&R per AIAG or similar standard.

6. All fixtures and gages must be certified periodically either by in-house if capable or by

third party.

© 2015 Automotive Industry Action Group 2

ISBN#: 978 1 60534 331 0

CQI-27

Special Process: Casting System Assessment

Version 1, 10/2015

PROCESS TABLE D - Aluminum Semi-Permanent Mold

All requirements given below are subordinate to customer specific requirements.

When performing the CQI-27 Casting Assessment the auditor shall verify foundry is conforming to customer requirements; including a customer approved Control Plan defining the

agreed upon inspection testing and frequencies.

*If minimum requirements are not met, provide supporting records to justify actual conditions.

What is the scope covered by this audit? The entire foundry? A specific product line? A specific part number? Other?

Describe the scope of the audit:

Observations / Comments

Pass / Fail /

Item Category/Process Step Minimum Requirement Not

about Actual

Applicable

Condition

Cores

2.0

(Cold Box, Hot Box and Shell)

1. There must be an on-site sand lab equipped for checking core sand.

2. The sand lab must be capable of making audits for common parameters such as

Sieve analysis, loss on ignition (LOI), core strength tests, moisture.

D2.1 Sand Lab

3. Cold box and hot box mix recipe should be verified by measured weight of resins.

4. Weight of mixed core sand should be minimized; 6 to 10 blows typical, not to exceed

one hour of mixed sand.

Cores may be purchased, or blown in-house. If they are purchased, core supplier must

D2.2 Outsourced Cores

be in full compliance with this Process Table.

1. The compressed air supply for cold box blowers must have a dew point below -40º C.

2. Cold box core boxes must be designed with tamping pins in areas of casting

D2.3 Cold Box surfaces.

3. Cold box cores preferred to be stored in an environment below 40% humidity, special

rooms with temperature and humidity control may be necessary.

1. The compressed air supply for hot box blowers must have a dew point below -40º C.

2. Hot box core boxes must have internal thermocouples. The temperatures must be

displayed. There must be an alarm if the temperature is out of range. Automatic

D2.4 Hot Box

temperature adjustment is preferred.

3. Hot box cores preferred to be stored in an environment below 40%

humidity, special rooms with temperature and humidity control may be necessary.

Shell core boxes must have internal thermocouples. The temperatures must be

D2.5 Shell Core displayed. There must be an alarm if the temperature is out of range. Automatic

temperature adjustment is preferred.

Repair of cores requires customer approval for this practice. If allowed, the repairs must

D2.6 Core Repair

be done in the core department, not at the mold line.

There must be a regular audit to cut open cores to check to see if they are properly

D2.7 Cured Core Check

cured hard to the center.

1. If any cores are wet coated, they must be oven dried prior to use.

Coating / painting / dipping / spraying any liquids onto the cores is permitted as long as

the cores get baked dry. Includes water base, alcohol base, oil base, kerosene base,

D2.8 Core Coating

methylated spirits, or any other liquid.

2.The Baume or viscosity of coatings must be measured and controlled.

3. Coating tanks must have continuous mixing and filtering.

D2.9 Core Coating The use of graphite coatings is discouraged. They are a common cause of inclusions.

D2.10 Chaplet/Spacer Any chaplets or spacers used must be completely clean and dry.

Filing on cores at the cast machines is not allowed. Cores and core assemblies must be

D2.11 Core Preparation

thoroughly blown off from all sides before they are set into molds.

1.Cores must be thoroughly blown off from all sides before they are used to make core

assemblies.

2. Core assemblies must be gaged.

3. Cores and core assemblies must be inspected for damage or breakage before

D2.12 Core Assembly

delivery to the cast machines.

4. Inspection criteria must be clearly defined and displayed. Core defects and their

location should be documented.

5. Use of automated or manual assist setters are preferred for assembled core packs.

1. Cores must not be stacked touching each other. Adequate storage racks must be

provided to place cores in single layers.

D2.13 Core Storage

2. Racks, containers, trays, may need foam padding or similar as appropriate to protect

cores from damage during movement or handling.

© 2015 Automotive Industry Action Group 3

ISBN#: 978 1 60534 331 0

CQI-27

Special Process: Casting System Assessment

Version 1, 10/2015

PROCESS TABLE D - Aluminum Semi-Permanent Mold

All requirements given below are subordinate to customer specific requirements.

When performing the CQI-27 Casting Assessment the auditor shall verify foundry is conforming to customer requirements; including a customer approved Control Plan defining the

agreed upon inspection testing and frequencies.

*If minimum requirements are not met, provide supporting records to justify actual conditions.

What is the scope covered by this audit? The entire foundry? A specific product line? A specific part number? Other?

Describe the scope of the audit:

Observations / Comments

Pass / Fail /

Item Category/Process Step Minimum Requirement Not

about Actual

Applicable

Condition

1. During regular production, the core inventory must not exceed 48 hours, preferably

less than 24 hours. Customer approval required for more than 48 hours core inventory

D2.14 Core Inventory as a regular practice.

2. Cold box cores must have 2 hours minimum wait time after being blown before

placing in molds.

3.0 Cast Machines

1. A start up checklist must be used to confirm that all water and air lines are hooked up

as designed.

D3.1 Startup Procedure

2. Error proofed or color coded lines are required.

3. A checklist must be confirmed for every setup.

1. Startup sequence must account for cycles used to warm up the mold.

2. Auto scrap or manual method is

used to segregate warm up parts as scrap.

D3.2 Startup and Downtime Recovery 3. Cycle time must be measured for each casting cycle to account for cycle

interruptions, should they occur.

4. Auto scrap or manual method is used to separate parts after restarting from

interrupted cycles.

1. Pre-control charting is required, however continuous measurement systems with

alarm notification may be used in place of charting.

2. The cooling air and/or water should be automatically turned on / off based on the

mold temperature. Continuous measurement of die temperature is preferred.

D3.3 Die Temperature 3. For reference, when thermocouples in the molds are used it is recommended that the

target temperatures for control be at the same temperature as the Solidification

simulation model or established by use of designed experiments. Temperatures should

be displayed.

4. Flow meters are recommended on the exits of all water / oil lines.

D3.4 Mold Coating When needed, masks should be designed to protect critical areas from coating buildup.

D3.5 Mold Cleanliness Molds must be blown out each cycle before the slides close.

1. Each part may be cooled with water or air.

2. Extraction tools should be designed to clamp on the gating or risers without touching

the final casting product.

D3.6 Extraction Tools

3. Automatic extraction is preferred.

4. Automatic extractors should be programmed to scrap castings when parameters,

such as mold temperature, are out of range.

4.0 Metal Control

Incoming/Returned Material Raw /Returned materials must be stored without mixing them in marked storage areas

D4.1

Storage by type.

Primary metal may be required for some applications based on customer specific

D4.2 Source of Material

requirements.

1. Chemistry must be controlled at each key point in the process (melting, holding, and

pouring).

2. It is required to use ASTM E716 disk book molds (or approved equivalent) for

chemistry samples.

3. There must be a spectrometer on site for chemistry control. Industry Standards, such

as ASTM E1251, must be followed for sampling, verification, standardization and

calibration.

4.The spectrometer must have certified Master calibration Standards which cover the

range of each chemistry element being controlled. These Calibration Masters should

D4.3 Metal Chemistry

be on site.

5. A procedure must be posted near the spectrometer which clearly defines the

permissible tolerance range of the Master calibration Standards.

6. There must be control limits for all key elements of the material grade.

7. The Sludge Factor must be measured and should be controlled below 2.0, preferably

below 1.8. Maximum limit must be clarified prior to the start of production; and it will

affect what are the Iron (Fe) and Manganese (Mn) specifications.

SF = %Fe + 2X %Mn + 3X %Cr.

8. The recommended Iron:Manganese ratio target is 2:1.

For any elements with customer specified mandatory limits, these limits must be

D4.4 Chemistry

reduced by the tolerance permitted on the Master Calibration Standards.

© 2015 Automotive Industry Action Group 4

ISBN#: 978 1 60534 331 0

CQI-27

Special Process: Casting System Assessment

Version 1, 10/2015

PROCESS TABLE D - Aluminum Semi-Permanent Mold

All requirements given below are subordinate to customer specific requirements.

When performing the CQI-27 Casting Assessment the auditor shall verify foundry is conforming to customer requirements; including a customer approved Control Plan defining the

agreed upon inspection testing and frequencies.

*If minimum requirements are not met, provide supporting records to justify actual conditions.

What is the scope covered by this audit? The entire foundry? A specific product line? A specific part number? Other?

Describe the scope of the audit:

Observations / Comments

Pass / Fail /

Item Category/Process Step Minimum Requirement Not

about Actual

Applicable

Condition

The most frequent grain refinement additive is Titanium Boron.

1. If Titanium Boron is added either in-stream or in the ladle by an automated system

there must be an audit to confirm that wire is being measured for correct length and

D4.5 Grain Refinement

confirmation that wire is being dissolved for each mold cycle.

2. Grain refinement may be required by customer Product

Engineering.

1. The most frequent silicon modification element is Strontium.

D4.6 Silicon Modification

2. Silicon modification may be required by customer Product Engineering.

1. All metal should be rotary degassed before pouring. Degassing may be in a transfer

ladle or in a holder at the cast machine. The preferred design of the degassing unit is a

baffle plate or anti-vortex system.

2. The use of cast machines with integral melter/holders is discouraged. It is often

difficult to meet requirements for metal cleanliness and degassing. A minimum

expectation is a baffled chamber with a rotary degassing unit running continuously.

D4.7 Degassing

3. After rotary degassing, a vacuum gas sample must be taken in order to determine

the specific gravity. Calculate specific gravity of sample using weight in air vs. weight in

water method. The specific gravity must be within 0.10 of the theoretical maximum

based on the chemistry of the alloy and a maximum of -27 inches of Mercury vacuum

pressure. For many alloys, the theoretical maximum is around 2.70.

4. Depending on customer-specific requirements, vacuum gas sample testing may not

be required for each degassing cycle if the degassing unit monitors process parameters

including flow rate, RPM, and gas pressure.

Molten metal from the melting furnaces may be tapped directly to go to the cast line, or

D4.8 Metal Transfer it may be transferred to intermediate holders. If intermediate holders are used, they

must have heat.

The temperature of metal being delivered to a cast machine holding furnace must be

checked. The temperature of metal being delivered must be within internally specified

D4.9 Metal Transfer

control limits such that the cast machine holding furnace stays in specification.

1. Metal at the cast line may be in a ladle or in a holder.

2. If holders are used at the cast line, they must have heat.

3. If holders are used, the temperature output must be readable by the machine

operator. If the metal temperature in the holding furnace falls outside of the specified

Holding Metal Treatment and range, an alarm must be established to indicate an out of tolerance condition.

D4.10

Temperature Control 4. Holding furnaces at the cast machines must be capable of controlling metal

temperature at the metal extraction point to within +/- 5°C, unless the customer agrees

to a wider range.

5. Alloying into the cast machine holding furnaces or ladles is allowed, but must

be minimized in order to prevent defects such as inclusions.

5.0 Cast In Place Inserts

1. The customer Product Engineering must approve the source for cast in place inserts.

2. The insert source must implement Full Compliance with the applicable template

D5.1 Insert Source Process Table before PPAP. For example, a ductile iron bearing cap in a bedplate, the

casting source must implement Full Compliance with the Ductile Iron Casting Process

Table before PPAP.

1. Cast-in-place inserts must be pre-heated immediately prior to pouring metal into the

die.

D5.2 Insert Process Control 2. The cast-in-place inserts must be completely dry. The volatiles content on the inserts

must be audited, measured, and recorded.

3. The cast-in-place inserts must be properly stored (maintained clean and dry).

1. There must be a regular audit to section the castings to inspect the bonding of the

cast in place insert with the aluminum. Audit results must be documented.

D5.3 Insert Audit 2. Depending on customer design requirements, dye penetrant inspection may be

required on machined castings to inspect for cracks (or contact separation) around the

inserts. Audit results must be documented.

6.0 Pouring

D6.1 Filter Filters may be required by customer to be used in all molds.

1. If stationary auto pouring holders are used, they must have heat.

2. Stationary auto pouring holders must be capable of controlling metal temperature at

the metal extraction point to +/-10C.

D6.2 Auto Pouring

3. If stationary auto holders or tilting auto ladles are used, they should have an infrared

measurement sensor to check the temperature of the metal stream for each mold

poured. The device should alarm if the temperature is out of range.

© 2015 Automotive Industry Action Group 5

ISBN#: 978 1 60534 331 0

CQI-27

Special Process: Casting System Assessment

Version 1, 10/2015

PROCESS TABLE D - Aluminum Semi-Permanent Mold

All requirements given below are subordinate to customer specific requirements.

When performing the CQI-27 Casting Assessment the auditor shall verify foundry is conforming to customer requirements; including a customer approved Control Plan defining the

agreed upon inspection testing and frequencies.

*If minimum requirements are not met, provide supporting records to justify actual conditions.

What is the scope covered by this audit? The entire foundry? A specific product line? A specific part number? Other?

Describe the scope of the audit:

Observations / Comments

Pass / Fail /

Item Category/Process Step Minimum Requirement Not

about Actual

Applicable

Condition

1. Automatic pouring of molten metal into the mold is preferred. Manual pouring is

allowed if approved by customer.

D6.3 Metal Pouring

2. Dip wells should be covered when the holding furnace is not in use.

3. Metal ladles should be on heat at their home position.

Immersion temperature audit from each ladle or pour box to confirm that all molds were

D6.4 Batch Pour System

poured within specified temperature range.

Charging raw materials or scrap into the auto pouring holders or ladles and running

D6.5 Metal Quality

production out of them at the same time is prohibited.

Alloying into the auto pouring holders or ladles is allowed, but must be minimized in

D6.6 Alloying

order to prevent defects such as inclusions.

Ladles must be free of skull (aluminum oxide film) before entering the dip well. Visual

D6.7 Ladle Cleanliness

inspection criteria should be defined and posted in the work area.

D6.8 Ladle Design Best practice for ladle design uses a dam (hole in the back) to hold back the dross.

When pressure pour dosing furnaces are used, an inert gas or dry air may be used to

D6.9 Dosing Furnace pressurize the chamber. If air is used, the dew point must be less than -40º C,

preferably below -80º C.

Launders from dosing furnaces must be designed and maintained such that metal does

D6.10 Launders

not buildup in them.

1. Metal quality must be tested for oxide content. As a minimum verification PoDFA

D6.11 Oxide Control (Porous Disk Filter Analysis), or other analysis approved by customer.

2. Dip wells must be frequently skimmed to minimize the dross accumulation.

It is recommended that equipment computer programs or mechanical limits for pouring

D6.12 Machine Settings and cycle times are protected from non-authorized changes so that only authorized

personnel can change the program or settings.

Cast machine should have real time closed loop monitoring which is either tied into the

extractor/robot control or creates an alarm when key parameters are beyond control

D6.13 Control Limits

limits. Castings that are outside the control limits must be segregated for additional

inspections.

7.0 Low Pressure Casting Process

1. Machine must have real time monitoring capability for chamber pressure, metal

position in tube, cavity fill time, mold temperature, metal temperature, and cycle time.

2. When applicable, flow monitoring transducers should be in place for cooling lines.

D7.1 Process Profile Monitoring

3. Cast machine should have real time closed loop monitoring which is either tied into

the extractor/robot control or creates an alarm when key parameters are beyond control

limits.

1. A coarse filter may be used in the top of the fill tube.

2. A fine filter may be used in the bottom of the fill tube.

D7.2 Fill Tube Best Practices 3. All fill tubes should be made of solid ceramic material. If the holding furnace is

stationary, the bottom end of the fill tube should be inside a fine filter chamber

submerged in the molten metal.

Inert gases are preferred. If dry air is used the dew point must be less than -40º C,

D7.3 Low Pressure Cover Gas

preferably below -80º C.

D7.4 Metal Quality Chemistry and density samples must be taken from the low pressure holding furnace.

1. If the holding furnace is stationary, pouring blocks with filters should be used when

filling the holder.

D7.5 Metal Quality

2. The holding furnace should be skimmed off after every

fill of the furnace.

The software for the fill/pressure profile should have an infinite number of channels

D7.6 Process Control

available for process options.

8.0 Post Processing and Heat Treating

© 2015 Automotive Industry Action Group 6

ISBN#: 978 1 60534 331 0

CQI-27

Special Process: Casting System Assessment

Version 1, 10/2015

PROCESS TABLE D - Aluminum Semi-Permanent Mold

All requirements given below are subordinate to customer specific requirements.

When performing the CQI-27 Casting Assessment the auditor shall verify foundry is conforming to customer requirements; including a customer approved Control Plan defining the

agreed upon inspection testing and frequencies.

*If minimum requirements are not met, provide supporting records to justify actual conditions.

What is the scope covered by this audit? The entire foundry? A specific product line? A specific part number? Other?

Describe the scope of the audit:

Observations / Comments

Pass / Fail /

Item Category/Process Step Minimum Requirement Not

about Actual

Applicable

Condition

Impact or clamping on the final part geometry is not allowed during core removal.

D8.1 De-Coring

Vibration is preferred for de-coring (instead of hammering).

Riser removal should be done with an accurate cutting process such as CNC, robot, or

D8.2 Riser Removal

saw, which accurately locates the casting.

1. All parts must be cooled to a defined temperature prior to fixturing for riser removal

and trimming.

D8.3 Trimming

2. Trimming operations must allow the part to be properly fixtured to prevent damage.

Automated part handling systems are preferred.

Heat treating must be before machining and may be in-house or outsourced. Heat

D8.4 Heat Treatment treating must be in compliance with CQI-9: Special Process: Heat Treat System

Assessment (HTSA), published by AIAG.

Any liquid quench must have automatic temperature control and agitation. Equipment

D8.5 Heat Treatment

must be capable to control quenching medium to within ± 5º C. Preferably over 80C.

D8.6 Heat Treatment Cold water not to be introduced to the quench tank while parts are being quenched.

D8.7 Heat Treatment The delay from solution heat treat into a quenchant must not exceed 30 seconds.

9.0 Inspection and Testing

Retained Material or Cleanliness Equipment must be available onsite to properly administer retained material inspection

D9.1

Requirement per customer requirements.

1. As a minimum, the casting plant shall have a programmable Coordinate Measuring

Machine (CMM) on site. The CMM must be run in an automatic mode. Where possible,

the application of point cloud/laser scanning inspection technology is preferred. When

used in combination with point cloud scanning technology, the CMM is considered the

“gage of record” for dimensional measurements because of precision associated with

D9.2 Dimensional Inspection - Part One the points measured.

2. The casting plant shall maintain a CMM hit point map/drawing showing all CMM hit

points that are agreed upon between the casting plant and the customer. (Point Cloud

Inspection/laser scanning can be used in place of CMM inspection if agreed upon with

customer Product Engineering).

3. The CMM program must include checking the flatness of each individual raw casting

datum surface if the datum pad is intended to be a flat surface. Preferably less than

0.250mm.

4. Point cloud/laser scanning inspection must use the part-design datum construction to

align the measurement data. Unless otherwise specified by the customer, "best-fit" data

alignment is not allowed.

D9.2 5. The casting plant is responsible for comparing the scan with the 3D Math Model. In

Dimensional Inspection - Part Two

(Continued) all cases the Point Cloud/laser scan must be aligned to the math model using the X-Y-Z

raw casting datum surfaces. Results must be shared with customer Product

Engineering and the responsible APQP Quality Engineer.

6. Point Cloud/laser scanning Inspection is recommended for prototype parts and PPAP

parts as defined by the customer specific requirements. The scanning may be out-

sourced.

There must be regular audits to section raw castings for wall thickness verification;

including any high stress features in the FEA. If the supplier is responsible for any

D9.3 Wall Thickness

machining, there must be regular audits to section machined castings for wall thickness

verification.

Supplier is responsible to acquire proper non-destructive inspection tools to evaluate for

D9.4 Internal Passages blocked passages. This may include boroscopes, endoscopes, probes, fiber optics, flow

meters, or X-ray.

© 2015 Automotive Industry Action Group 7

ISBN#: 978 1 60534 331 0

CQI-27

Special Process: Casting System Assessment

Version 1, 10/2015

PROCESS TABLE D - Aluminum Semi-Permanent Mold

All requirements given below are subordinate to customer specific requirements.

When performing the CQI-27 Casting Assessment the auditor shall verify foundry is conforming to customer requirements; including a customer approved Control Plan defining the

agreed upon inspection testing and frequencies.

*If minimum requirements are not met, provide supporting records to justify actual conditions.

What is the scope covered by this audit? The entire foundry? A specific product line? A specific part number? Other?

Describe the scope of the audit:

Observations / Comments

Pass / Fail /

Item Category/Process Step Minimum Requirement Not

about Actual

Applicable

Condition

1. There must be a regular audit to dye penetrant check (color check) or fluorescent

penetrant inspection (FPI) entire casting or sections of castings specified by customer;

Dye Penetrant Check and NaOH

D9.5 including any high stress features in the FEA.

Etch Castings

2. There must be on-site capability to cut and NaOH etch castings for internal

inspections. (NaOH is sodium hydroxide, also called caustic soda.).

1. The supplier shall have a real time fluoroscopic/X-ray unit on-site.

2. X-ray equipment must be capable of measuring the sensitivity and resolution so that

the system can be proven to meet customer requirements defined by product design

D9.6 X-ray

record.

3. X-ray audits must include any high stress features in the FEA.

4. For some applications, automated defect recognition may be required.

1. Customer must approve any salvage repair procedures. Casting repairs, such as

welding, epoxy, Devcon, and impregnation, are not permitted, unless approved by

customer Product Engineering.

2. If repairs are allowed, repair method and procedures must be approved by Customer

D9.7 Repairs

Product Engineering.

3. If straightening is allowed, a customer Product Engineering approved method is

required, normally with a fixtured, automated process. Manual methods should not be

used.

10.0 Material Properties

The supplier shall have a metallurgical lab located on-site with capabilities to analyze

chemistries, hardness, microstructure, area fraction porosity, dendritic arm spacing

D10.1 Laboratory Location

(DAS), silicon particle size, and any other features specified by customer Product

Engineering.

Material property testing must be defined per customer design records. Mechanical

properties testing must be available, preferably on site. Mechanical property testing

must include ultimate tensile strength, yield strength, and percent elongation. Some

D10.2 Material Property Testing customers may require yield strength to be measured by an extensometer attached to

the specimen. If retest or replacement is necessary must be with agreement of the

customer Product Engineering. Testing begins with prototypes and continues through

regular production.

The casting source must prepare test bars from a location approved by customer

Product Engineering. For example, these might be cut from a casting or from a

separately cast bar. Mechanical properties are often required from test bars cut from

D10.3 Mechanical Property

actual castings in an area designated on the engineering drawing or in the part quality

document. The test bar location in the casting will be dimensioned from casting

features.

1. Metallurgical examination is to be done by the supplier prior to any component

testing to insure microstructure meets engineering drawing specifications.

2. A metallograph image analyzer is preferred.

D10.4 Microstructure Analysis

3. Reference photographs must be readily available at the metallograph for all

microstructure requirements.

4. Microstructure audits must include any high stress features in the FEA.

1. Hardness testing is to be done per ASTM E10.

Supplier site must have certified Master blocks for auditing the calibration of the

hardness tester.

2. The Tolerance range for the Master block must be posted on the hardness tester.

3. The Tolerance range for the Master must not exceed +/- 3%.

4. The customer specified range for hardness must be reduced by the tolerance

D10.5 Hardness Testing

allowed on the hardness Master block.

5. Unless Product Engineering specifies otherwise, Brinell hardness test using a 500Kg

load, 10 mm diameter indenter, and 30 second dwell time.

6. Hardness to be measured at a specified location from customer Product Engineering.

7. If hardness readings are out of specification, all castings in the Lot shall be hardness

tested with any out-of-specification castings rejected.

© 2015 Automotive Industry Action Group 8

ISBN#: 978 1 60534 331 0

CQI-27

Special Process: Casting System Assessment

Version 1, 10/2015

PROCESS TABLE D - Aluminum Semi-Permanent Mold

All requirements given below are subordinate to customer specific requirements.

When performing the CQI-27 Casting Assessment the auditor shall verify foundry is conforming to customer requirements; including a customer approved Control Plan defining the

agreed upon inspection testing and frequencies.

*If minimum requirements are not met, provide supporting records to justify actual conditions.

What is the scope covered by this audit? The entire foundry? A specific product line? A specific part number? Other?

Describe the scope of the audit:

Observations / Comments

Pass / Fail /

Item Category/Process Step Minimum Requirement Not

about Actual

Applicable

Condition

The casting plant shall demonstrate the corrosion rate of metal shall not exceed

Maximum rate as customer requirement. If applicable and required by the Customer,

D10.6 Corrosion Testing

the corrosion test shall be salt spray (Reference ASTM B117) and humidity as customer

requirement.

11.0 Leak Testing

1. Acceptable methods for testing are: air under water, pressure decay, mass flow.

2. For applications where 100% verification is required it is preferred that pressure

decay or mass flow systems be used. Some customers may require 100% air under

water.

3. Leak rate specification must be defined on the product engineering document.

D11.1 Leak Test Requirement 4. It is preferred the internal volumes for each cavity be leak tested separately.

5. It is preferred castings be thoroughly dried before going to air decay leak test. An in-

line drier may be needed.

6. Some castings may also require 100% flow testing. If flow testing is required, this

must be automated equipment. Using round balls or probes is acceptable if customer

Product Engineering agrees.

It is preferred that the casting plant have a water dunk capability on site for determining

D11.2 Water Dunk Capability

the location of leaks on air decay rejects. The water temperature must be at least 20C.

© 2015 Automotive Industry Action Group 9

ISBN#: 978 1 60534 331 0

You might also like

- Cqi27 PT BDocument6 pagesCqi27 PT BlalitNo ratings yet

- Cqi27 Pt-ADocument7 pagesCqi27 Pt-AlalitNo ratings yet

- Cqi27 Process Table CDocument6 pagesCqi27 Process Table ClalitNo ratings yet

- Aircraft Manufacturing Concession: Non-Conforming Part From Manufacturing. Release As Concession RequestDocument4 pagesAircraft Manufacturing Concession: Non-Conforming Part From Manufacturing. Release As Concession Requestkrishbalu17No ratings yet

- CQI-27 Casting Process Tables Stakeholder Review Final PDFDocument213 pagesCQI-27 Casting Process Tables Stakeholder Review Final PDFSelvaraj Simiyon90% (10)

- Design: Vacuum Chambers and Special ComponentsDocument14 pagesDesign: Vacuum Chambers and Special ComponentsFilipe GiesteiraNo ratings yet

- Bridas de Anclaje 1Document16 pagesBridas de Anclaje 1RIGOBERTO PONCENo ratings yet

- Process Optimization of Pressure Die Casting To Eliminate Defect Using Cae SoftwareDocument5 pagesProcess Optimization of Pressure Die Casting To Eliminate Defect Using Cae SoftwareselvamNo ratings yet

- National Skill Competitions: Category: Manufacturing & Engineering TechnologyDocument11 pagesNational Skill Competitions: Category: Manufacturing & Engineering Technologyivan bernardNo ratings yet

- Chapter 01 Vacuum Chambers Special Components PDFDocument14 pagesChapter 01 Vacuum Chambers Special Components PDFmindrumihaiNo ratings yet

- Testing of CNC Machine Tools: Acceptance TestsDocument3 pagesTesting of CNC Machine Tools: Acceptance Testshe maNo ratings yet

- SECTION 08 44 13 Glazed Aluminum Curtain WallsDocument26 pagesSECTION 08 44 13 Glazed Aluminum Curtain WallsJuanPaoloYbañezNo ratings yet

- I3000 Brochure PDFDocument20 pagesI3000 Brochure PDFKevin NgoNo ratings yet

- KKKR3723 Part I IntroductionDocument11 pagesKKKR3723 Part I IntroductionPutriNo ratings yet

- Transformer Consulting US1Document2 pagesTransformer Consulting US1Torikul FauziNo ratings yet

- ICSSDocument4 pagesICSSabha singhNo ratings yet

- FAI - SH0071 - Rev 21 - 14oct19Document33 pagesFAI - SH0071 - Rev 21 - 14oct19anon_958736733100% (1)

- QC - 08 PTCDocument5 pagesQC - 08 PTCmahendraNo ratings yet

- Excel: InstrumentsDocument14 pagesExcel: Instrumentsdarsuboy161No ratings yet

- NASCO Supplier PPAP Submission Checklist: Purpose/Special Notes: Level: 1 2 3 4 5Document7 pagesNASCO Supplier PPAP Submission Checklist: Purpose/Special Notes: Level: 1 2 3 4 5amr ahmedNo ratings yet

- Summer Internship 2017: Department of Mechanical EngineeringDocument36 pagesSummer Internship 2017: Department of Mechanical EngineeringDivyansh SharmaNo ratings yet

- 027 Marconi CRM GroupDocument24 pages027 Marconi CRM GroupAmir IskandarNo ratings yet

- CASTING Design GuideDocument54 pagesCASTING Design GuideXin Yu75% (4)

- Industrial Applications of Robust Design Optimization: Karthik Chittepu CadfemDocument17 pagesIndustrial Applications of Robust Design Optimization: Karthik Chittepu Cadfem李庆森No ratings yet

- Amendment 1 PSPCLDocument3 pagesAmendment 1 PSPCLKoushik DeyNo ratings yet

- 7 - 01 - H - MANAGEMENT OF QUALITY OF INFORMATION MEANSDocument32 pages7 - 01 - H - MANAGEMENT OF QUALITY OF INFORMATION MEANSAsep SomantriNo ratings yet

- Shic A 0005Document2 pagesShic A 000501095902062ahmedNo ratings yet

- Coupling Inspection SOP GSE FinalDocument11 pagesCoupling Inspection SOP GSE FinalPravin Kangne100% (1)

- Substation Engineering and DesignDocument18 pagesSubstation Engineering and DesignslySmiles_76639No ratings yet

- Autodesk Nastran In-CAD PDFDocument43 pagesAutodesk Nastran In-CAD PDFFernando0% (1)

- Siemens AG Smart Infrastructure: SimoprimeDocument34 pagesSiemens AG Smart Infrastructure: SimoprimeIrwan AjoNo ratings yet

- Design and Manufacturing GuidelinesDocument10 pagesDesign and Manufacturing GuidelinesEdisson100% (1)

- Plastic Welding Quality Issues Prevention DetectionDocument4 pagesPlastic Welding Quality Issues Prevention DetectionCan ArslantaşNo ratings yet

- Magotteaux Millliners Cement Brochure en LR 4Document6 pagesMagotteaux Millliners Cement Brochure en LR 4Mostafa Ahamed Mhoumed RatibNo ratings yet

- Divisions: Transportation Decorated Products Plating & Enameling Southern OperationsDocument9 pagesDivisions: Transportation Decorated Products Plating & Enameling Southern OperationsMuralidhara BangaloreNo ratings yet

- Advanced Simulation of Rolling Element Bearings For Bearing Designers and Application EngineersDocument2 pagesAdvanced Simulation of Rolling Element Bearings For Bearing Designers and Application Engineersmohsin2014No ratings yet

- APQP MatrixDocument2 pagesAPQP Matrixkumar QA100% (2)

- GS 20-1-3 - MainbodyDocument31 pagesGS 20-1-3 - MainbodySubash ChandraboseNo ratings yet

- Module Details Gravity and Low Pressure Die Casting Technology C - Casting and Following ProcessesDocument5 pagesModule Details Gravity and Low Pressure Die Casting Technology C - Casting and Following ProcessessalimmalmaliNo ratings yet

- Deform News: Training DEFORM V12.1 & V12.1.1 ReleasesDocument2 pagesDeform News: Training DEFORM V12.1 & V12.1.1 ReleasesboladoxxNo ratings yet

- Catia Modules in DetailDocument57 pagesCatia Modules in DetailvinothNo ratings yet

- SZ Rapid Tooling CompanyDocument31 pagesSZ Rapid Tooling Companyزياد بوعلاڨيNo ratings yet

- MetalForming-Magazine 2021 06Document1 pageMetalForming-Magazine 2021 06waqar mansoorNo ratings yet

- CNC Turning: Technical DescriptionDocument10 pagesCNC Turning: Technical Descriptiongia1985No ratings yet

- Api 579-1 - Asme FFS-1 PaDocument14 pagesApi 579-1 - Asme FFS-1 PaZdravko Ivancic20% (5)

- CaseStudy FMEA Ball Mill V1Document2 pagesCaseStudy FMEA Ball Mill V1Andres Acosta RozoNo ratings yet

- S2-3-Model To Achieve SC Proof Transformers Without Increasing Number of Tests0 - Hassan Sayed-HV TrafoDocument3 pagesS2-3-Model To Achieve SC Proof Transformers Without Increasing Number of Tests0 - Hassan Sayed-HV TrafoMallikarjunNo ratings yet

- SD05wi1 Structural Inspection WorkpackDocument22 pagesSD05wi1 Structural Inspection WorkpackidrisNo ratings yet

- Simulation Applications For Alumina RefiningDocument4 pagesSimulation Applications For Alumina RefiningRogerio CannoniNo ratings yet

- Converting Design To PrototypeDocument4 pagesConverting Design To PrototypeRrdbjdNo ratings yet

- MES - Construction Quality Manual - Rev - 0Document55 pagesMES - Construction Quality Manual - Rev - 0Ishaan ThakerNo ratings yet

- Simufact - Welding 2015 E PrintDocument8 pagesSimufact - Welding 2015 E PrintJanatan ChoiNo ratings yet

- 1 SS PP 006Document24 pages1 SS PP 006SURAJ PRSADNo ratings yet

- Supreme Engineering CentreDocument20 pagesSupreme Engineering Centrevishnudno1No ratings yet

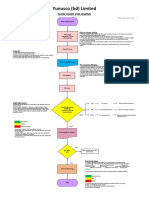

- Yunusco (BD) Limited: Flow Chart For SewingDocument1 pageYunusco (BD) Limited: Flow Chart For SewingMd. Nurunnabi SarkerNo ratings yet

- Lecture 2Document27 pagesLecture 2Anurag DubeyNo ratings yet

- Quiz 1Document33 pagesQuiz 1sashiniNo ratings yet

- WI01-QCD-03 Painting Inspection - 01jul20Document12 pagesWI01-QCD-03 Painting Inspection - 01jul20Phu PhuocNo ratings yet

- HIRA FormatDocument4 pagesHIRA FormatlalitNo ratings yet

- CQI 27 Casting (Blank Form)Document1 pageCQI 27 Casting (Blank Form)RonNo ratings yet

- KanbanDocument30 pagesKanbanlalitNo ratings yet

- DemingDocument1 pageDeminglalitNo ratings yet

- All About DemingDocument31 pagesAll About DeminglalitNo ratings yet

- Criteria For Aspect Impact AnalysisDocument1 pageCriteria For Aspect Impact AnalysislalitNo ratings yet

- Criteria For Hazard Risk AnalysisDocument1 pageCriteria For Hazard Risk AnalysislalitNo ratings yet

- Introducing The Open Banking StandardDocument12 pagesIntroducing The Open Banking StandardOpen Data Institute96% (25)

- SACS TrainingDocument4 pagesSACS Trainingasma100% (1)

- Manufacturing Process AssignmentDocument5 pagesManufacturing Process AssignmentPalani SuntharajanNo ratings yet

- Electrical Circuits 2 AssignmentDocument5 pagesElectrical Circuits 2 Assignmentangelo dedicatoriaNo ratings yet

- GGFHJDocument1 pageGGFHJanon_791172439No ratings yet

- Jeppesen 021 - 03 - PowerplantDocument274 pagesJeppesen 021 - 03 - PowerplantSadcat97% (29)

- Leybold Didactic EquipmentsDocument4 pagesLeybold Didactic EquipmentsAffo AlexNo ratings yet

- Program - 1:: Lab - Data Structure Using CDocument50 pagesProgram - 1:: Lab - Data Structure Using Ceshmnash9298No ratings yet

- Nursing ResumeDocument2 pagesNursing Resumeapi-655558844No ratings yet

- Personal Surveyor 200 User Handbook: Gas Measurement Instruments LTDDocument92 pagesPersonal Surveyor 200 User Handbook: Gas Measurement Instruments LTDGiang TrườngNo ratings yet

- CBSE Class 11 History Syllabus 2021-22Document12 pagesCBSE Class 11 History Syllabus 2021-22Muskan TiwariNo ratings yet

- 04-68350A Manual CCN DM01-DI01 PDFDocument47 pages04-68350A Manual CCN DM01-DI01 PDFtaha50% (2)

- Momentum Equation in Cylindrical Coordinate: Appendix BDocument8 pagesMomentum Equation in Cylindrical Coordinate: Appendix BAbdul Rauf AttariNo ratings yet

- Woldia University: The Role of Effective Communication in Resolving ConflictDocument17 pagesWoldia University: The Role of Effective Communication in Resolving ConflictMerry Hiyab100% (1)

- Creative FRP Design GuideDocument255 pagesCreative FRP Design GuideVincenzo Praturlon100% (1)

- Republic of The Philippines Social Security System MemberDocument1 pageRepublic of The Philippines Social Security System MemberreyNo ratings yet

- Progresive DPKDocument7 pagesProgresive DPKAmol WalunjNo ratings yet

- ADSA Assignment-1 Group - 3Document16 pagesADSA Assignment-1 Group - 3Animesh KumarNo ratings yet

- Geometry of Middle SurfaceDocument29 pagesGeometry of Middle SurfaceParth ShahNo ratings yet

- MSA WorksheetDocument33 pagesMSA WorksheetSandrawarman BalasundramNo ratings yet

- Aurelia Vallier SlidesDocument42 pagesAurelia Vallier SlidesSaddy KhanNo ratings yet

- Assignment 5 - PersonalityDocument1 pageAssignment 5 - PersonalityLavesh SethiaNo ratings yet

- TEST PearsonsDocument4 pagesTEST Pearsonsazertytyty000No ratings yet

- Four Gears ModelDocument13 pagesFour Gears ModelPratik PatilNo ratings yet

- Solidworks Inspection Data SheetDocument3 pagesSolidworks Inspection Data Sheetradule021No ratings yet

- Cat Reforming Part 2 3 PDF FreeDocument68 pagesCat Reforming Part 2 3 PDF FreeLê Trường AnNo ratings yet

- Bootstrap 3 All Classes List Cheat Sheet Reference PDF (2020) PDFDocument21 pagesBootstrap 3 All Classes List Cheat Sheet Reference PDF (2020) PDFHoney ShineNo ratings yet

- 4401 SyllabusDocument1 page4401 SyllabusTony LeungNo ratings yet

- Jasmi HashimDocument364 pagesJasmi HashimRudraraju ChaitanyaNo ratings yet

- Engine Bearing: Website Email Tel: Fax: 0086-577-86755433 0086-577-86755422Document27 pagesEngine Bearing: Website Email Tel: Fax: 0086-577-86755433 0086-577-86755422Суханов КонстантинNo ratings yet