Professional Documents

Culture Documents

Proj - Hira

Proj - Hira

Uploaded by

Vishal TiwariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Proj - Hira

Proj - Hira

Uploaded by

Vishal TiwariCopyright:

Available Formats

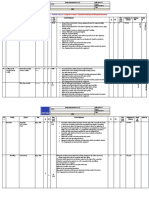

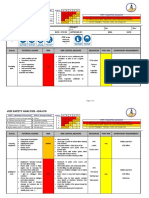

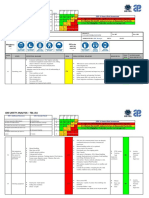

Doc.

Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Infrequent Work relief. Anti glare screens will

be provided for the monitors.

1 Administrative functions ADM -01 Computer operations N CRT monitor radiations Eye strain N 5 5 25 0.25 6.25 LR

OH&S Management in Office - OCP - IT -

Chapter 5

Fatigue relief allowed; no instances of

Computer operations; Key continuous operations which other wise

Repetitive work; extended

2 Administrative functions ADM -02 board operations; Seating N Repetitive strain injury N 2 10 20 0.5 10 LR would result in stated harm

work time (in one stretch)

systems OH&S Management in Office - OCP - IT -

Chapter 5

Infrastructure designed to provide sufficient

light and air.

3 Administrative functions ADM -03 Office work N Improper ventilation Physical discomfort N 10 5 50 0.25 12.5 MR

OH&S Management at Offices and Sites

- OCP - OH&S - Chapter 4

Personnel competence ensured. While using

Co2 type extinguishers care is taken to

Improper handling / fixing

ensure the person holds the hose at the

4 Administrative functions ADM -04 of portable fire N Fall of objects / equipment Injury N 2 10 20 0.5 10 LR

correct position

extinguishers / equipment

OH&S Management at Offices and Sites

- OCP - OH&S - Chapter 4

Personnel competence ensured. Emergency

preparedness, Fire drill and First Aid training

conducted to create awareness. No smoking

AN/ Burn injury / signs displayed wherever necessary. Proper

5 Administrative functions ADM -05 Fire fighting Fire / Smoke N 2 15 30 0.5 15 MR

E suffocation house-keeping and storage of materials

ensured.

OH&S Management at Offices and Sites

- OCP - OH&S - Chapter 4

Personnel competence ensured; Licensed

Accidental hits of operator operates the machinery. Work

Operation of JCB /

6 Construction - Excavation EXC -01 N Machinery and / or its parts Injury N 2 15 30 0.5 15 MR carried out under supervision

Excavators

on personnel Trenching and Excavation - OCP - OH&S

Chapter 9

Proper barricading and sign boards ensured.

Vehicles are not allowed to operate near the

Movement of vehicles / edge of excavation

Accidental fall of vehicles Injury to workers

7 Construction - Excavation EXC -02 equipments close to the AN N 5 15 75 0.25 18.75 MR Barricades and Signage - OCP - OH&S

into the pit working below.

edge of excavation Chapter 7

Trenching and Excavation - OCP - OH&S

Chapter 9

Vehicles are not allowed to operate near the

edge of excavation. The excavated soil heaps

Suffocation /

Movement of vehicles / Vibration of machinery may are kept at a safe distance from the edge of

breathlessness

8 Construction - Excavation EXC -03 equipments close to the N cause cave-in or N 5 15 75 0.5 37.5 HR excavation. Proper shoring and strutting

resulting in Personnel

edge of excavation collapse/land slide ensured.

death

Trenching and Excavation - OCP - OH&S

Chapter 9

Prepared by: Project Head Approved by: Management Representative Page 1 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

The soil is cut in an angle inclined away from

the excavation so as to prevent the falling of

loose soil. Proper shoring of excavated soil

Suffocation /

done to prevent it from caving in. The

Working at low levels of Collapse / land slide of breathlessness

9 Construction - Excavation EXC -04 AN N 5 15 75 1 75 HR excavated soil heaps are kept at a safe

excavated areas loose soil resulting in Personnel

distance from the edge of excavation.

death

sufficient angle of repose is maintained.

Trenching and Excavation - OCP - OH&S

Chapter 9

The entire area which is getting excavated is

barricaded and adequate sign / warning

Working at low levels of boards are kept to ensure that people do not

10 Construction - Excavation EXC -05 AN Slips/Trips/Falls Injury N 2 15 30 1 30 HR

excavated areas fall into the excavated portion.

Trenching and Excavation - OCP - OH&S

Chapter 9

Personnel competence ensured; Licensed

Accidental hits of operator operates the machinery. Work

Soil back-filling using Tipper

11 Construction - Excavation EXC -06 N Machinery and / or its parts Injury N 2 15 30 0.5 15 MR carried out under supervision

/ JCB

on personnel Trenching and Excavation - OCP - OH&S

Chapter 9

Dewatering done at regular intervals to

prevent stagnation of water in the trenches

Personnel walking at Slips / Falls in Water thereby preventing any slippage and fall of

12 Construction - Excavation EXC -07 AN Injury N 2 15 30 1 30 HR

excavated work locations stagnated trenches personnel.

Trenching and Excavation - OCP - OH&S

Chapter 9

Identify and provide suitable numbers of

Construction - Excavation Flooding due to excessive Slips / Falls in Water Can cause drowning dewatering pumps of adequate capacity

13 EXC -08 N N 2 10 20 0.5 10 LR

(beyond 3.0 m) rain / underground water stagnated trenches situation Trenching and Excavation - OCP - OH&S

Chapter 9

Industrial safety pin & plugs are used.

Insulated & safely secured electrical conduits

Pumping out water from are used for transmission thereby avoiding

14 Construction - Excavation EXC -09 AN Live wire contact Electrical shock N 2 15 30 1 30 HR

excavated pits any live wire contact.

Safe practices and House Keeping - OCP

- OH&S Chapter 5

Area cordoned off and guarded against

unauthorized entry and necessary sign

Pumping out water from boards / warning boards are kept at relevant

15 Construction - Excavation EXC -10 N Slips / Falls Injury N 5 5 25 0.75 18.75 MR

excavated pits places

Trenching and Excavation - OCP - OH&S

Chapter 9

Prepared by: Project Head Approved by: Management Representative Page 2 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Obtain permission from competent

authorities, prior to excavation if required.

Locate the position of buried utilities by

referring to relevant drawings. Start digging

Contact with buried electric

16 Construction - Excavation EXC -11 AN Electrocution Severe injury N 2 15 30 1 30 HR manually to locate the exact position of

cables

buried utilities and thereafter use mechanical

means

Trenching and Excavation - OCP - OH&S

Chapter 9

Obtain permission from competent

authorities, prior to excavation if required.

Locate the position of buried utilities by

referring to relevant drawings. Start digging

Contact with buried Gas/oil

17 Construction - Excavation EXC -12 AN Explosion Severe injury N 2 15 30 1 30 HR manually to locate the exact position of

pipelines

buried utilities and thereafter use mechanical

means

Trenching and Excavation - OCP - OH&S

Chapter 9

Use of face mask, hand gloves and safety

shoes are mandatory

Nausea; poisoning and

Inhaling of hazardous Safe Practices and House Keeping - OCP

18 Construction - Excavation EXC -13 Antitermite treatment N toxic side effects; loss N 2 15 30 0.75 22.5 MR

chemical vapours - OH&S Chapter 5

of consciousness

Personal Protective Equipment - OCP -

OH&S Chapter 10

Injury due to cylinder Certified cylinders in use

19 Construction - Excavation EXC -14 Water proofing AN LPG Cylinders Y 2 15 30 0.5 15 MR

burst Hot work - OCP - OH&S Chapter 11

Industrial safety pin & plugs are used.

Insulated & safely secured electrical conduits

are used for transmission thereby avoiding

20 Concreting - Site Mix PCC -01 Operation of concrete mixer AN Live wire contact Electrical shock N 2 15 30 1 30 HR any live wire contact. Proper Earthing of

equipments ensured.

Safe Practices and House Keeping - OCP

- OH&S Chapter 5

Relevant PPE like rubber gloves and gum

Handling of ingredients Hands and foot might boots worn by workers

21 Concreting - Site Mix PCC -02 Mixing of ingredients N N 5 10 50 0.75 37.5 HR

with raw hands and legs get injured Personal Protective Equipment - OCP -

OH&S Chapter 10

Work carried out under supervision. Safety

cages provided around motors so as to

Parts of body or cloth of

prevent cloth or parts of the body from

22 Concreting - Site Mix PCC -03 Revolving of concrete mixer AN personnel getting caught Injury N 5 15 75 0.5 37.5 HR

getting caught while in operation

while in operation

Power Tools and Machinery - OCP -

OH&S Chapter 18

Prepared by: Project Head Approved by: Management Representative Page 3 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Proper caution is exercised and work

executed under proper supervision. Ensure

proper lighting arrangements if concreting is

23 Concreting PCC -04 Laying concrete N Slips / Falls Injury N 5 5 25 1 25 MR

done at night

Safe Practices and House Keeping - OCP

- OH&S Chapter 5

Proper caution is exercised and work

executed under proper supervision.

24 Footings and Columns FC -01 Laying of Re-bars N Contact with sharp edges Injury N 5 5 25 0.75 18.75 MR

Personal Protective Equipment - OCP -

OH&S Chapter 10

Prepared by: Project Head Approved by: Management Representative Page 4 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Safety shoes will be provided to personnel in

the site. Exposed portion of the rod to be

25 Footings and Columns FC -02 Walking near re-bars N Contact with sharp edges Injury N 5 5 25 0.75 18.75 MR provided with protective covering

Personal Protective Equipment - OCP -

OH&S Chapter 10

Proper caution is exercised while lifting and

the personnel are provided with PPE and

Column box fixing and

26 Footings and Columns FC -03 AN Fall of column box Injury N 5 15 75 1 75 HR work executed under proper supervision.

dismantling

Material handling and Storage - OCP -

OH&S Chapter 15

Caution is exercised while executing the

Injury due to fall from work. Personnel are provided with safety

27 Scaffolding and shuttering SS -01 Erection of scaffolding N Working at height height / hit by falling N 5 15 75 0.75 56.25 HR belts and helmets and work executed under

objects proper supervision.

Scaffoding - OCP - OH&S Chapter 13

Proper care taken to ensure scaffolding is

erected by a competent person and checked

regularly for any possible defects. Scaffolds

28 Scaffolding and shuttering SS -02 Anchoring and bracing N Collapse of scaffold Injury N 5 15 75 0.75 56.25 HR are designed for maximum load carrying

capacity. Care is taken not to overload the

scaffolds.

Scaffoding - OCP - OH&S Chapter 13

Caution is exercised while executing the

work. Personnel are provided with PPE and

Handling of scaffold

29 Scaffolding and shuttering SS -03 N Fall / hit of objects Injury N 5 5 25 1 25 MR work executed under proper supervision.

elements

Scaffoding - OCP - OH&S Chapter 13

Fall protection - OCP - OH&S Chapter 14

The equipment is provided with a hood for

guarding against any mishaps. Proper PPE is

provided to personnel involved in the job.

30 Scaffolding and shuttering SS -04 Sawing wood with machine N Contact with sharp blades Severe injury N 5 10 50 0.5 25 MR Hand extension tool is in practice for cutting

small pieces.

Power Tools and Machinery - OCP -

OH&S Chapter 18

Proper PPE is provided to personnel involved

in the job

Personal Protective Equipment - OCP -

31 Scaffolding and shuttering SS -05 Sawing wood with machine N Hit by chipped wood pieces Injury N 5 10 50 0.75 37.5 HR

OH&S Chapter 10

Power Tools and Machinery - OCP -

OH&S Chapter 18

Caution is exercised while executing the

Steel bar cutting and Handling and shifting of Slips / falls / hit by falling work. Personnel are provided with PPE and

32 SBC -01 N Severe injury N 5 15 75 0.75 56.25 HR

bending steel bars objects work executed under proper supervision.

Fall Protection - OCP - OH&S Chapter 14

Prepared by: Project Head Approved by: Management Representative Page 5 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Caution is exercised while executing the

Steel bar cutting and Cutting and bending steel Dust generation and flying work. Personnel are provided with PPE

33 SBC -02 N Injury to eye N 5 10 50 0.75 37.5 HR

bending bars manually / by machine of small parts Personal Protective Equipment - OCP -

OH&S Chapter 10

Caution is exercised while executing the

work. Personnel are provided with PPE and

Steel bar cutting and Placing and tying of

34 SBC -03 N Trip / fall Injury N 5 5 25 1 25 MR work executed under proper supervision.

bending reinforcement bars

Personal Protective Equipment - OCP -

OH&S Chapter 10

Traning on usage of power tools is provided

to all the workmen.

Introduced a system of issuing power tools

AN/

35 Power Tools PT-01 Usage of power tools Improper usage Injury / death N 5 15 75 0.5 37.5 HR only to authorized workmen. The issue time

E

and duration are all tracked.

Power Tools and Machinery - OCP -

OH&S Chapter 18

Caution is exercised while executing the

work. Work executed under proper

Batching plant / concrete

36 BP -01 Shifting of material N Fall Injury N 5 5 25 1 25 MR supervision.

mixer operation

Material Handling and Storage - OCP -

OH&S Chapter 15

Prepared by: Project Head Approved by: Management Representative Page 6 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Signs mentioning the speed limit for vehicles

inside construction site area is kept at

Batching plant / concrete relevant places. Licensed personnel drive the

37 BP -02 Shifting of material N Hit by moving vehicle Injury N 5 10 50 0.5 25 MR

mixer operation vehicles.

Equipments, Vehicles and Traffic Safety

- OCP - OH&S Chapter 8

Helper at hand to indicate proper position

Placing in position of RMC Vehicle hitting structures /

38 Concreting CC -01 N Injury N 5 10 50 0.5 25 MR Equipments, Vehicles and Traffic Safety

truck personnel

- OCP - OH&S Chapter 8

Helper at hand to indicate proper position

Placing in position of RMC Vehicle hitting structures /

39 Concreting CC -02 N Property damage N 5 10 50 0.5 25 MR Equipments, Vehicles and Traffic Safety

truck personnel

- OCP - OH&S Chapter 8

Steps taken to ensure that the noise is within

the allowable limits.Maintenance of the pump

done at regular intervals to maintain noise

40 Concreting CC -03 Pumping RMC N Noise of slurry pump Hearing impairment Y 10 5 50 0.75 37.5 HR

within allowable limits.

Personal Protective Equipment - OCP -

OH&S Chapter 10

Caution is exercised while executing the

Pumped concrete hitting

41 Concreting CC -04 Pumping RMC AB Injury N 5 5 25 1 25 MR work. Work executed under proper

persons due to line rupture

supervision. Area cordoned off

Preventive maintenance of hoists done at

regular intervals to avoid any mishaps due to

Hoist operation; wire rope Injury due to hit by

42 Concreting CC -05 Moving RMC by hoist N Y 2 15 30 0.5 15 MR wire rope snapping.

snapping falling objects

Cranes and Hoists - OCP - OH&S

Chapter 16

Safety belt and helmet mandatory for

working at height. Safety nets are also

provided at relevant areas to arrest any fall.

Concreting at edges / cut-

43 Concreting CC -06 N Fall from height Severe Injury N 5 15 75 0.5 37.5 HR Proper guard rails / barricades provided

out areas / heights

wherever required

Personal Protective Equipment - OCP -

OH&S Chapter 10

Maintenance of the vibrators done at regular

intervals to maintain noise within allowable

Compacting of concrete by

44 Concreting CC -07 N High vibration Personal discomfort Y 10 5 50 0.75 37.5 HR limits. PPE usage is mandatory

vibrator

Personal Protective Equipment - OCP -

OH&S Chapter 10

Fall while removing nails / Use of PPE is mandatory

45 Concreting CC -08 Deshuttering N contact with pointed Injury N 10 5 50 1 50 HR Personal Protective Equipment - OCP -

objects OH&S Chapter 10

Prepared by: Project Head Approved by: Management Representative Page 7 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Working at heights for

various purposes, viz, Use of safety belt, helmet is mandatory.

scaffold fabricating, Safety nets are also provided at relevant

46 General Gen-01 N Fall from height Severe injury N 5 15 75 0.75 56.25 HR

concreting, window, grill places to arrest any fall.

and frame fixing, plastering, Fall Protection - OCP - OH&S Chapter 14

painting, external finishing

Prepared by: Project Head Approved by: Management Representative Page 8 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Working at heights for

various purposes, viz, Work area barricaded; Use of helmet

scaffold fabricating, Hit by objects falling from mandatory. Care is taken not to throw or

47 General Gen-02 N Severe injury N 5 15 75 0.5 37.5 HR

concreting, window, grill above drop materials from height.

and frame fixing, plastering, Fall Protection - OCP - OH&S Chapter 14

painting, external finishing

Lifting tools / tackles are subject to periodic

Material handling by hoist /

Failure of lifting tools / inspection

48 General Gen-03 winches / tower crane / N Severe injury Y 5 15 75 0.75 56.25 HR

tackle Cranes and Hoists - OCP - OH&S

mobile crane

Chapter 16

Limit switches are subject to periodic

Material handling by hoist /

inspection

49 General Gen-04 winches / tower crane / N Failure of limit switches Severe injury Y 5 15 75 0.75 56.25 HR

Cranes and Hoists - OCP - OH&S

mobile crane

Chapter 16

Lifting tools / tackles and limit switches are

Material handling by hoist / Failure of lifting tools /

subject to periodic inspection

50 General Gen-05 winches / tower crane / N tackle; Failure of limit Property damage Y 5 15 75 0.5 37.5 HR

Cranes and Hoists - OCP - OH&S

mobile crane switches

Chapter 16

Work area barricaded. Helper at hand for

Material handling by hoist / indication position. Licensed operators

Collision with moving

51 General Gen-06 winches / tower crane / N Severe injury N 5 15 75 0.5 37.5 HR operate the equipments.

objects

mobile crane Cranes and Hoists - OCP - OH&S

Chapter 16

Caution is exercised while executing the

Material handling by hoist / work. Work executed under proper

Person / body part caught

52 General Gen-07 winches / tower crane / N Severe injury N 5 15 75 0.5 37.5 HR supervision. Area cordoned off

between

mobile crane Cranes and Hoists - OCP - OH&S

Chapter 16

Material handling by hoist / Work area barricaded. Safety nets provided

53 General Gen-08 winches / tower crane / N Fall of material Severe injury N 5 15 75 0.75 56.25 HR to arrest the falling of materials

mobile crane Fall Protection - OCP - OH&S Chapter 14

Trained personnel operate the equipment.

Material handling by hoist / The maximum safe working load shall be

Injury / property

54 General Gen-09 winches / tower crane / N Exceeding design load N 5 15 75 0.75 56.25 HR marked on all lifting equipments.

damage

mobile crane Cranes and Hoists - OCP - OH&S

Chapter 16

Trained personnel operate the equipment.

Care is taken not to allow boom or other

Material handling by hoist /

Contact with overhead parts to come within 3m reach of overhead

55 General Gen-10 winches / tower crane / N Electrocution / Fire Y 2 15 30 0.5 15 MR

electrical lines HT cables

mobile crane

Cranes and Hoists - OCP - OH&S

Chapter 16

Prepared by: Project Head Approved by: Management Representative Page 9 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Insulated tools are used; High voltage

Provisioning of temporary protection hand gloves and shoes are in use

56 General Gen-11 AN Contact with live wire Electrical shock Y 2 15 30 0.75 22.5 MR

electrical supply Electrical Safety - OCP - OH&S Chapter

17

Cutting of stone slabs / Face mask, Goggles are in use

57 General Gen-12 Marbles / Tiles / Concrete N Dust generation Health hazard; Silicosis N 5 15 75 0.5 37.5 HR Personal Protective Equipment - OCP -

bricks OH&S Chapter 10

Cutting of stone slabs / Trained personnel operate the equipment

58 General Gen-13 Marbles / Tiles / Concrete N Contact with sharp blades Injury N 5 15 75 0.75 56.25 HR Power Tools and Machinery - OCP -

bricks OH&S Chapter 18

Prepared by: Project Head Approved by: Management Representative Page 10 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Connections provided by authorized and

Provisioning of permanent trained personnel; maintenance work carried

Contact with high voltage

59 General Gen -14 electrical supply; HT Yard; N Severe injury Y 5 15 75 0.5 37.5 HR out after isolating the supply

line

Installation of transformers Electrical Safety - OCP - OH&S Chapter

17

DGs are provided with an enclosure to

Installation and operation of maintain noise level below stipulated limits.

60 General Gen -15 N Noise Hearing impairment Y 10 10 100 0.5 50 HR

DG set during construction Power Tools and Machinery - OCP -

OH&S Chapter 18

Oil absorbing material available near storage

area to arrest any possible leakage. Surface

Storage of Diesel / Petrol / Slippery floor due to

61 General Gen -16 AN Slips / falls N 2 10 20 0.5 10 LR tidiness ensured

Paints leakage

Spill Prevention - OCP - Env (Projects)

Chapter 9

All the inflammable materials are stored

separately. Fire extinguishers and fire -

buckets are kept readily available near the

Storage of Diesel / Petrol / storage.

62 General Gen -17 E Fire hazard Burn injury N 2 15 30 1 30 HR

Paints Safe practices and House Keeping - OCP

- OH&S Chapter 5

Material Handling and Storage - OCP -

OH&S Chapter 15

Dust mask is given to personnel involved in

the job

Storage of cement / sand Personal Protective Equipment - OCP -

63 General Gen -18 N Dust generation Respiratory problems N 10 5 50 1 50 HR

and aggregate OH&S Chapter 10

Material Handling and Storage - OCP -

OH&S Chapter 15

Fire extinguishers are kept readily available

near the area where wood work is carried

out.

Storage of wood and

64 General Gen -19 N Fire hazard Burn injury N 2 15 30 1 30 HR Personal Protective Equipment - OCP -

plywood

OH&S Chapter 10

Material Handling and Storage - OCP -

OH&S Chapter 15

Speed controls are in place. Licensed

Vehicle movement inside Person getting hit by personnel operate the vehicle.

65 General Gen -20 N Injury N 2 15 30 1 30 HR

the site area moving vehicle Equipments, Vehicles and Traffic Safety

- OCP - OH&S Chapter 8

Goggle and helmet are worn

Personal Protective Equipment - OCP -

66 General Gen -21 Manual chipping of concrete N Flying concrete chips Eye injury N 5 10 50 0.75 37.5 HR

OH&S Chapter 10

Demolition - OCP - OH&S Chapter 20

Prepared by: Project Head Approved by: Management Representative Page 11 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Daily inspection of work area done before the

work starts for any possible oxygen

deficiency and as and when it is needed. A

Suffocation leading to

Working in confined areas Inadequate supply of stand-by person is stationed outside the

67 General Gen -22 N unconsciousness / N 2 10 20 1 20 MR

and ducts oxygen confined space for monitoring and handling

death

any emergency.

Confined Spaces - OCP - OH&S Chapter

19

Artificial lighting arrangements are done to

Working in confined areas execute the work.

68 General Gen -23 N Insufficient light Injury N 2 10 20 1 20 MR

and ducts Confined Spaces - OCP - OH&S Chapter

19

Proper sign boards are put at relevant places

to warn / guide personnel. Openings are

properly barricaded. Caution flags are kept

69 General Gen -24 Site inspection N Fall / Trip / slip Injury N 2 5 10 1 10 LR

wherever necessary.

Barricades and signage - OCP - OH&S

Chapter 7

Proper sign boards are put at relevant places

to warn / guide personnel. Work carried out

Collision with moving

70 General Gen -25 Site inspection N Injury N 2 5 10 1 10 LR under proper supervision

objects

Barricades and signage - OCP - OH&S

Chapter 7

Mask are used

Arc welding, gas cutting, Personal Protective Equipment - OCP -

71 General Gen -26 N Exposure to fumes Suffocation N 10 5 50 0.75 37.5 HR

welding, grinding OH&S Chapter 10

Hot Work - OCP - OH&S Chapter 11

Usage of welding shields and other relevant

PPE insisted

Arc welding, gas cutting,

72 General Gen -27 N Exposure to welding arc Eye injury N 10 5 50 0.75 37.5 HR Personal Protective Equipment - OCP -

welding, grinding

OH&S Chapter 10

Hot Work - OCP - OH&S Chapter 11

Industrial safety pin & plugs are used.

Insulated & safely secured electrical conduits

are used for transmission thereby avoiding

Arc welding, gas cutting, any live wire contact.

73 General Gen -28 AN Contact with live wires Electrical shock N 2 10 20 1 20 MR

welding, grinding Safe practices and House Keeping - OCP

- OH&S Chapter 5

Electrical Safety - OCP - OH&S Chapter

17

Goggles are worn

Arc welding, gas cutting,

74 General Gen -29 N Flying splinters Eye injury N 10 5 50 0.75 37.5 HR Personal Protective Equipment - OCP -

welding, grinding

OH&S Chapter 10

PPE provided

Arc welding, gas cutting,

75 General Gen -30 N Exposure to hot surface Burn injury N 5 5 25 1 25 MR Personal Protective Equipment - OCP -

welding, grinding

OH&S Chapter 10

Prepared by: Project Head Approved by: Management Representative Page 12 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Preventive maintenance of equipments done

Arc welding, gas cutting, at regular intervals

76 General Gen -31 N Broken grinding wheel Injury N 5 5 25 1 25 MR

welding, grinding Power Tools and Machinery - OCP -

OH&S Chapter 18

Fire extinguishers available in close proximity

Arc welding, gas cutting,

77 General Gen -32 E Fire Burn injury N 2 15 30 0.5 15 MR Safe practices and House Keeping - OCP

welding, grinding

- OH&S Chapter 5

Leaking cylinders are taken off the site.

Arc welding, gas cutting, Fire due to explosion of Cylinders are kept in vertical position.

78 General Gen -33 E Severe burn injury Y 2 15 30 0.5 15 MR

welding, grinding cylinders Cylinders are certified

Hot Work - OCP - OH&S Chapter 11

Personnel competence is ensured. 'A -

Frames' are used to keep the granite intact

79 General Gen -34 Storage of Granite N Fall of material Severe injury N 5 15 75 0.5 37.5 HR thereby preventing the fall

Material Handling and Storage - OCP -

OH&S Chapter 15

Personnel competence is ensured. 'A -

Frames' are used to keep the glass intact

80 General Gen -35 Storage of Glass N Fall of material Severe injury N 5 15 75 0.5 37.5 HR thereby preventing the fall

Material Handling and Storage - OCP -

OH&S Chapter 15

Normally disposed of by burying them in

81 General Gen -36 Disposal of broken glass N Contact with sharp edges Injury N 2 10 20 0.5 10 LR

deep trenches so as to avoid possible contact

Speed limits and traffic rules observed

strictly. Safety helmets / belts are worn.

Defensive driving advised.

Severe injury,

82 General Gen -37 Commutation to sites N Accidents Y 5 15 75 0.5 37.5 HR Equipments, Vehicles and Traffic Safety

sometimes fatal

- OCP - OH&S Chapter 8

Personal Protective Equipment - OCP -

OH&S Chapter 10

Work carried out under supervision.

Additional cover is provided for the vibrator

Usage of vibrators for Cloth of personnel getting so as to prevent the cloth from getting

83 General Gen -38 N Injury N 5 10 50 0.5 25 MR

concreting caught while in operation caught.

Power Tools and Machinery - OCP -

OH&S Chapter 8

Face mask, Goggles are in use;

Usage of demolition / Core

84 General Gen -39 N Dust generation Health hazard; Silicosis Y 5 10 50 0.5 25 MR Personal Protective Equipment - OCP -

cutting machines

OH&S Chapter 10

Prepared by: Project Head Approved by: Management Representative Page 13 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Noise level below stipulated limits. Ear muffs

are provided to personnel involved in the

Usage of demolition / Core

85 General Gen -40 N Noise Hearing impairment Y 5 10 50 0.5 25 MR work

cutting machines

Personal Protective Equipment - OCP -

OH&S Chapter 10

Water borne diseases / Frequent cleaning of tanks. Use of

86 General Gen -41 Labour camps N Ill health N 2 5 10 0.5 5 LR

break out of epidemic disinfectants. Cleanliness of area is ensured.

Security personnel at camp are trained on fire

fighting and emergency preparedness in case

AN/

87 General Gen -42 Labour camps Fire break out Burns, injuries N 5 10 50 0.5 25 MR of break out of fire

E

Fire prevention - OCP - OH&S Chapter

21

All the tanks in the labour camp bulit with

AN/ Can cause injury /

88 General Gen -43 Labour camps Collapse of water tank N 2 15 30 0.25 7.5 LR block work are demolished and replaced with

E death if falls on labour

sintex or concterte tanks

Industrial safety pin and plugs. Insulated and

safely secured electrical conduits are used for

transmission. Rubber hand gloves, rubber

mats and other PPE are provided. All

Electrical installation and Can cause connections are given through ELCBs.

89 General Gen -43 AN short circuiting N 5 15 75 0.5 37.5 HR

usage Electrocution or Fire Earthing of machineries and equipments

ensured.

Electrical Safety - OCP - OH&S Chapter

17

Site Execution - OCP - M&E Chapter 6

Display voltage and current ratings

prominently with 'Danger' signs. Ensure

Bursting of system can approved cable size, voltage grade and type.

Electrical installation and Overloading of electrical

90 General Gen -44 AN occur which leads to Y 5 10 50 0.5 25 MR Do not allow unauthorized connections.

usage system

fire Electrical Safety - OCP - OH&S Chapter

17

Site Execution - OCP - M&E Chapter 6

Do not lay unarmoured cable directly on

ground, wall, trees etc. Maintain the required

Improper laying of Can cause

Electrical installation and safe distance from HT cables.

91 General Gen -45 AN overhead and underground Electrocution and prove Y 2 15 30 0.5 15 MR

usage Electrical Safety - OCP - OH&S Chapter

transmission lines / cables fatal

17

Site Execution - OCP - M&E Chapter 6

Face ladder while climbing. Always use both

hands. Keep the ladders free of grease and

Severe injury /

92 General Gen -46 Ladders N Slippage and fall N 5 10 50 0.5 25 MR other spills. Tie the top end of the ladder

sometimes fatal

securely.

Ladders - OCP - OH&S Chapter 12

Prepared by: Project Head Approved by: Management Representative Page 14 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Tool box talks are conducted on daily basis

explaining safety and importance of work.

Unawareness / Lack of Can result in an Safety videos are shown on daily basis

93 Behavioural Hazard BH -01 Human Behaviour N N 5 15 75 0.5 37.5 HR

Knowledge accident focussing on behaviours during work.

General Safety Practices - OCP - OH&S

Chapter 3

Tool box talks are conducted on daily basis

explaining safety and importance of work.

Over confident / Taking Can result in an Safety videos are shown on daily basis

94 Behavioural Hazard BH -02 Human Behaviour N N 5 15 75 0.5 37.5 HR

Risk accident focussing on behaviours during work.

General Safety Practices - OCP - OH&S

Chapter 3

Tool box talks are conducted on daily basis

explaining safety and importance of work.

Can result in an Safety videos are shown on daily basis

95 Behavioural Hazard BH -03 Human Behaviour N Fear to operate / work N 5 10 50 0.5 25 MR

accident focussing on behaviours during work.

General Safety Practices - OCP - OH&S

Chapter 3

Tool box talks are conducted on daily basis

explaining safety and importance of work.

Can result in an Safety videos are shown on daily basis

96 Behavioural Hazard BH -04 Human Behaviour N Negligence N 5 15 75 0.5 37.5 HR

accident focussing on behaviours during work.

General Safety Practices - OCP - OH&S

Chapter 3

Tool box talks are conducted on daily basis

explaining safety and importance of work.

Can create health Safety videos are shown on daily basis

97 Behavioural Hazard BH -05 Human Behaviour N Wrong habits N 5 10 50 0.5 25 MR

problems/Intoxication focussing on behaviours during work.

General Safety Practices - OCP - OH&S

Chapter 3

Tool box talks are conducted on daily basis

explaining safety and importance of work.

Can result in an Safety videos are shown on daily basis

98 Behavioural Hazard BH -06 Human Behaviour N Arrogance N 5 15 75 0.5 37.5 HR

accident focussing on behaviours during work.

General Safety Practices - OCP - OH&S

Chapter 3

Tool box talks are conducted on daily basis

explaining safety and importance of work.

Can result in an Safety videos are shown on daily basis

99 Behavioural Hazard BH -07 Human Behaviour N Physical & emotional N 5 15 75 0.5 37.5 HR

accident focussing on behaviours during work.

General Safety Practices - OCP - OH&S

Chapter 3

Prepared by: Project Head Approved by: Management Representative Page 15 of 17

Doc.Ref: SDL/EHS/007

SDL - PROJECTS Hazard identification and risk assessment Revision No.: 2.4

Date: 27.12.2010

Condition N /AN / E

Residual Risk level

Severity of harm

Initial Risk level

Probability of

Legal requirement

Control scale

occurrence

YES / NO

Risk Level

Department / Function / HIRA Controls in place / Planned / PPEs /

Sl.No Activity Hazard Harm

Process Ref. No other details

Tool box talks are conducted on daily basis

explaining safety and importance of work.

Distracting,teasing, Can result in an Safety videos are shown on daily basis

100 Behavioural Hazard BH -08 Human Behaviour N N 5 15 75 0.5 37.5 HR

horseplay accident focussing on behaviours during work.

General Safety Practices - OCP - OH&S

Chapter 3

The wheel barrows are not filled to the brim.

Maintenance of the wheel barrows are done

on a regular basis. The tyre pressure is

checked regularly. The wheel barrows are

Transportation of sand for can result in accidents, moved steadily. Care is taken during the

101 General Gen - 47 N toppling of wheel barrow N 10 5 50 0.5 25 MR

Plastering, block work, tiling injuries movement to avoid the toppling hazard.No

horse play or rash moving of the wheel

barrows is permitted.

Material Handling and Storage - OCP -

OH&S Chapter 15

Prepared by: Project Head Approved by: Management Representative Page 16 of 17

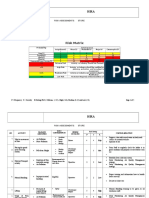

Severity Scale

Example related to

Rating Scale Severity scale Example related to health

safety

Nuisance and irritation (e.g. Superficial injuries;

5 Slight Harm Headaches); Ill health leading to minor cuts and bruises;

discomfort (diarrhea) eye irritation from dust.

Partial hearing loss; dermatitis;

Lacerations; Burns;

Asthma; Work related upper limb

10 Moderate harm Concussion; Serious

disorder; Ill health leading to

sprains; Minor fractures.

permanent minor disability

Acute fatal diseases; Severe life Fatal injuries;

15 Extreme harm shortening diseases; Permanent Amputations; Multiple

substantial disability. injuries; Major fractures.

Likelihood scale

Likelihood Examples for the likelihood

Rating Scale

scale scale

Typically experienced once in ten

2 Unlikely years during the working lifetime of

an individual

Typically experienced once in 6

5 Likely

months or an year by an individual

Typically experienced at least once

10 Very likely

in a month or more by an individual

Likelihood of Severity of the harm

harm Slight Harm Moderate harm Extreme harm

Unlikely LOW RISK MEDIUM RISK MEDIUM RISK

Likely RISK HIGH RISK HIGH RISK

Very Likely HIGH RISK HIGH RISK HIGH RISK

Likelihood of Severity of the harm

harm 5 10 15

2 10 20 30

5 25 50 75

10 50 100 150

Score Range Risk

Category

0-10 LOW RISK

11 - 30 MEDIUM RISK

31 and above HIGH RISK

Control score Controls in place

0.75 Only PPEs

0.50 Only admin / operational / engg control in place

0.25 Engg & admin & operational controls in place

1 None

Initial Risk Score

Control Score 10 20 25 30 50 75 100 150

0.75 7.5 15 18.75 22.5 37.5 56.25 75 112.5

0.50 5 10 12.5 15 25 37.5 50 75

0.25 2.5 5 6.25 7.5 12.5 18.75 25 37.5

1 10 20 25 30 50 75 100 150

You might also like

- Height Work - HIRADocument1 pageHeight Work - HIRARuchin Jain91% (11)

- Scaffolding Erection & Dismantling Work Risk AssessmentsDocument3 pagesScaffolding Erection & Dismantling Work Risk AssessmentsSarfraz RandhawaNo ratings yet

- Final HIRA - GBLDocument49 pagesFinal HIRA - GBLAbdul Rasheed MangrioNo ratings yet

- Hazrd Identification & Risk Assessment: Mmf100 Nov 2009 - Pm/105/01 © Mott Macdonald 2009Document2 pagesHazrd Identification & Risk Assessment: Mmf100 Nov 2009 - Pm/105/01 © Mott Macdonald 2009SuperuserAsadhussainNo ratings yet

- Master HiraDocument88 pagesMaster Hiravivek vj100% (2)

- All HiraDocument40 pagesAll Hirarameese muhammed100% (2)

- Hira DineshDocument11 pagesHira DineshDurai GunasekaranNo ratings yet

- HIRA For Civil WorkDocument11 pagesHIRA For Civil WorkYogesh Nath100% (3)

- PLT - H&S - Project HIRA - (R 13) 191125Document115 pagesPLT - H&S - Project HIRA - (R 13) 191125soubhagyaNo ratings yet

- 03-HIRA For Welding Work .Document2 pages03-HIRA For Welding Work .archit kamat89% (9)

- GDCL Hazard Identification and Risk Assessment Hira Register Part I PDFDocument16 pagesGDCL Hazard Identification and Risk Assessment Hira Register Part I PDFReddy sekharNo ratings yet

- Master Register of 24 HSE Points ESEPPL May & JuneDocument71 pagesMaster Register of 24 HSE Points ESEPPL May & Juneuttam mishraNo ratings yet

- HIRA FormatDocument2 pagesHIRA FormatSachin Yashwant kumbharNo ratings yet

- HIRA (Pipeline Construction Work)Document28 pagesHIRA (Pipeline Construction Work)sheerazali90% (10)

- HSE Action TrackerDocument3 pagesHSE Action TrackerLouis Danny90100% (1)

- Concrete WorkDocument1 pageConcrete WorkChandruNo ratings yet

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- HIRA MechanicalDocument6 pagesHIRA Mechanicalsufiyan sskNo ratings yet

- HIRADocument47 pagesHIRANaresh Kumar83% (6)

- HIRA For TATA Project - Tool RoomDocument124 pagesHIRA For TATA Project - Tool Roomvivek vjNo ratings yet

- HIRA For Solar Roof Top Work at ExcavationDocument2 pagesHIRA For Solar Roof Top Work at ExcavationPampanagouda Yadav100% (8)

- ABC - ra.CWSS.19-HIRA-Erection of Precast Columns, BeamsDocument5 pagesABC - ra.CWSS.19-HIRA-Erection of Precast Columns, BeamsShafie ZubierNo ratings yet

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. AhmadNo ratings yet

- PRECA HIRA Precast Element InstalationDocument14 pagesPRECA HIRA Precast Element InstalationAmitkumar SinghNo ratings yet

- Severity Rating I, Probability Rating P: Categories of Hazards: Physical/Chemical/Ergonomic/Biological/PsychosocialDocument21 pagesSeverity Rating I, Probability Rating P: Categories of Hazards: Physical/Chemical/Ergonomic/Biological/PsychosocialKiran ChenchalaNo ratings yet

- HIRA Revised Drain WorkDocument11 pagesHIRA Revised Drain WorkNagadevan GovindanNo ratings yet

- HIRA NewDocument107 pagesHIRA NewPrabhakaran Gurunathan100% (1)

- Hazard Identification and Risk Assessment Form: Project ProcessDocument4 pagesHazard Identification and Risk Assessment Form: Project ProcessAli Al-GhamghamNo ratings yet

- Hoist Erection Operation & Maintenance Work - R0 - 30.09.2017Document6 pagesHoist Erection Operation & Maintenance Work - R0 - 30.09.2017Nikhil Manjrekar100% (1)

- Hazards Identification and Risk Assessment - New FormatDocument2 pagesHazards Identification and Risk Assessment - New FormatBIIS QAQC Babu Siva100% (1)

- Hira PDFDocument69 pagesHira PDFChíld Çhïññæ Çøôl100% (2)

- Hira For Fabrication Work of Steel Structure - CMRLDocument21 pagesHira For Fabrication Work of Steel Structure - CMRLmahesh naik0% (2)

- HIRA PaintingDocument2 pagesHIRA PaintingAjit Bhosale75% (8)

- Master Hazards Risks RegisterDocument113 pagesMaster Hazards Risks RegisterIvanNo ratings yet

- Hira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Document3 pagesHira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Mithlesh Singh75% (4)

- Risk Assesment Tie-In (Mechanical)Document5 pagesRisk Assesment Tie-In (Mechanical)Galih SukmaNo ratings yet

- Hira FormatDocument6 pagesHira FormatMOJIB33% (6)

- Daily Safe Start Template.Document2 pagesDaily Safe Start Template.Peter CaelenNo ratings yet

- Risk Assessments - StoreDocument5 pagesRisk Assessments - Storederwaishjee1100% (1)

- Peb HiraDocument2 pagesPeb HiraRANJEET SINGH100% (1)

- Hira WordDocument69 pagesHira WordGokul p100% (2)

- HIRA For Stores ActivityDocument5 pagesHIRA For Stores ActivityRohit Singh100% (22)

- HIRA - Height WorkDocument3 pagesHIRA - Height WorkHiralal Pattanayak100% (2)

- HIRADocument6 pagesHIRAvijay kumar singhNo ratings yet

- Hazard Identification and Risk Assessment Form: Location Activities Hazard ControlsDocument6 pagesHazard Identification and Risk Assessment Form: Location Activities Hazard ControlsVikas SinghNo ratings yet

- JSA-018 Lifting With Mobile CraneDocument5 pagesJSA-018 Lifting With Mobile CraneOmar Dhieb100% (1)

- RA Overhead CraneDocument5 pagesRA Overhead CraneRandy Adisyah100% (2)

- Index of OP Project HIRA Activities ID No. Activities Remarks Format NoDocument7 pagesIndex of OP Project HIRA Activities ID No. Activities Remarks Format NoSameer JogasNo ratings yet

- OHSDocument19 pagesOHSAshok PatelNo ratings yet

- Hazard Identification & Risk Assessment (HIRA) - ProcedureDocument16 pagesHazard Identification & Risk Assessment (HIRA) - ProcedureDivakar80% (10)

- Summer Preparedness PlanDocument20 pagesSummer Preparedness PlanGovind Kumar100% (1)

- Hazard Identification and Risk Assessment VirtualDocument33 pagesHazard Identification and Risk Assessment VirtualGyanendra Narayan Nayak100% (1)

- JSA Unloading & SHIFTING by Manually 10-01-2017Document16 pagesJSA Unloading & SHIFTING by Manually 10-01-2017PAVANKUMAR100% (1)

- JSA For Fabrication WorksDocument11 pagesJSA For Fabrication Workssurendra behera100% (3)

- 003-JSA Pipe Loading and OffloadingDocument8 pages003-JSA Pipe Loading and OffloadingMoaatazz NouisriNo ratings yet

- JSA-017 Lifting With ForkliftDocument3 pagesJSA-017 Lifting With ForkliftMoaatazz Nouisri67% (6)

- 001.hira - Proj - April23Document42 pages001.hira - Proj - April23Vinay PandeyNo ratings yet

- C4. Hiradec - Oil Top Up, Replacement, Sampling & Filtration MachineDocument2 pagesC4. Hiradec - Oil Top Up, Replacement, Sampling & Filtration MachinePankaj PandeyNo ratings yet

- C5. HIRADEC - #Cutting and WeldingDocument2 pagesC5. HIRADEC - #Cutting and WeldingPankaj PandeyNo ratings yet

- C3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Document1 pageC3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Pankaj PandeyNo ratings yet

- Expence VC DesignDocument1 pageExpence VC DesignVishal TiwariNo ratings yet

- Organisation Chart For Formwork Cell: Deputy Manger at R.ODocument7 pagesOrganisation Chart For Formwork Cell: Deputy Manger at R.OVishal TiwariNo ratings yet

- David Easton's System ApproachDocument4 pagesDavid Easton's System ApproachVishal Tiwari100% (2)

- Bank-Advance-Cash VoucherDocument1 pageBank-Advance-Cash VoucherVishal TiwariNo ratings yet

- Sipls DesignDocument1 pageSipls DesignVishal TiwariNo ratings yet

- Almonds ViewsDocument7 pagesAlmonds ViewsVishal TiwariNo ratings yet

- Unit - Ii Behavioralism: TH THDocument11 pagesUnit - Ii Behavioralism: TH THVishal Tiwari100% (1)

- PEB DrawingsDocument1 pagePEB DrawingsVishal Tiwari100% (1)

- SR No Delayed Milestone Completion DateDocument3 pagesSR No Delayed Milestone Completion DateVishal TiwariNo ratings yet

- Comparative Politics Evolution Nature and ScopeDocument7 pagesComparative Politics Evolution Nature and ScopeVishal TiwariNo ratings yet

- Project Schedule - Project ADocument2 pagesProject Schedule - Project AVishal TiwariNo ratings yet

- PAPER-1 - Political Science PDFDocument76 pagesPAPER-1 - Political Science PDFVishal TiwariNo ratings yet

- S.No. Environment& OH&S Issue Yes No N/A Remarks/corrective Action Needed A General Safety at SiteDocument2 pagesS.No. Environment& OH&S Issue Yes No N/A Remarks/corrective Action Needed A General Safety at SiteVishal Tiwari50% (2)

- Fire Fighting BomDocument6 pagesFire Fighting BomVishal TiwariNo ratings yet

- Pre Qualification - CivilDocument1 pagePre Qualification - CivilVishal TiwariNo ratings yet

- ETP DetailsDocument42 pagesETP DetailsVishal TiwariNo ratings yet

- Peb DesignDocument1 pagePeb DesignVishal TiwariNo ratings yet

- 1 Design Code: Loading Considerations SR No DescriptionDocument4 pages1 Design Code: Loading Considerations SR No DescriptionVishal TiwariNo ratings yet

- Daily Manpower ReportDocument1 pageDaily Manpower ReportVishal TiwariNo ratings yet

- EHS PlanDocument37 pagesEHS PlanVishal TiwariNo ratings yet

- Eve of Independence Class 11 Ncert NotesDocument5 pagesEve of Independence Class 11 Ncert NotesVishal TiwariNo ratings yet

- Norms For Consumption of Materials For Building WorksDocument1 pageNorms For Consumption of Materials For Building WorksVishal TiwariNo ratings yet

- List of Periodic CometsDocument8 pagesList of Periodic CometsLeonardoNo ratings yet

- g241 ManualDocument14 pagesg241 ManualValmac ServicesNo ratings yet

- CH 4 Triangle CongruenceDocument84 pagesCH 4 Triangle CongruenceNap Do100% (1)

- Compare Tensile Properties of Polymers To Metals, Discuss DifferencesDocument5 pagesCompare Tensile Properties of Polymers To Metals, Discuss DifferencesTeh Boon SiangNo ratings yet

- DSC Vibration Modeling PDFDocument25 pagesDSC Vibration Modeling PDFFahmi AdamNo ratings yet

- MemesDocument5 pagesMemesMagdalena CastroNo ratings yet

- Cultural Center PrecedentDocument19 pagesCultural Center PrecedentJoana Novarinda CarissaNo ratings yet

- FICHA TECNICA 40-Liter InsufflatorDocument2 pagesFICHA TECNICA 40-Liter InsufflatorMaria AlejandraNo ratings yet

- Developing A Stage-Discharge Relation For Open Channel FlowDocument4 pagesDeveloping A Stage-Discharge Relation For Open Channel Flowastewayb_964354182No ratings yet

- Bolts Base Plate Design To Eurocode PDFDocument4 pagesBolts Base Plate Design To Eurocode PDFSơn Nguyễn-LêNo ratings yet

- Trucos Gta 5Document2 pagesTrucos Gta 5Beto CarrilloNo ratings yet

- 7 - Pictorial ProjectionDocument48 pages7 - Pictorial Projectionapi-3815216100% (6)

- HSE-04 - Hot Work PermitDocument3 pagesHSE-04 - Hot Work PermitMaheshwor Man Joshi100% (1)

- GRI 3 - Material Topics 2021Document30 pagesGRI 3 - Material Topics 2021Yob YnnosNo ratings yet

- Psi-prospec-Vinyl Concrete PatchDocument3 pagesPsi-prospec-Vinyl Concrete PatchAMAURY DE JESUS GOMEZNo ratings yet

- Electronic-Devices-Circuits - PDF - Google DriveDocument5 pagesElectronic-Devices-Circuits - PDF - Google DriveNileshIndulkarNo ratings yet

- Ankyloglossia and Other Oral TiesDocument17 pagesAnkyloglossia and Other Oral Tiesdikiprestya391No ratings yet

- Ship Maneuvering Under Human ControlDocument106 pagesShip Maneuvering Under Human ControlAnil Kumar DashNo ratings yet

- M99T2 Alarm ManualDocument1 pageM99T2 Alarm ManualEd Eduard EddNo ratings yet

- Sound: One Mark QuestionsDocument11 pagesSound: One Mark QuestionsSrividhya ManikandanNo ratings yet

- Railway, Tunnel&HarbourDocument8 pagesRailway, Tunnel&HarbourDanish BhatNo ratings yet

- EDC Lab Manual (Exp - 5)Document8 pagesEDC Lab Manual (Exp - 5)Osama AsgharNo ratings yet

- Trunking Final - 2019Document47 pagesTrunking Final - 2019C SDNo ratings yet

- NASPO 2021 Ceragon Price ListDocument115 pagesNASPO 2021 Ceragon Price Listpayam79bNo ratings yet

- Kelas 4 Bahasa InggrisDocument2 pagesKelas 4 Bahasa InggrissofiNo ratings yet

- Chongqing Cummins Engine Co. LTDDocument3 pagesChongqing Cummins Engine Co. LTDYadhira Dominguez ZuritaNo ratings yet

- Gas Station + Culturaol LoadgeDocument67 pagesGas Station + Culturaol Loadgeabrham astatikeNo ratings yet

- Beginners Guide To Digital ElectronicsDocument3 pagesBeginners Guide To Digital ElectronicsSuperusNovusNo ratings yet

- CerebellumDocument14 pagesCerebellumapi-508474347No ratings yet

- 1998sep - RJ LocalfailuresofearthdamsDocument10 pages1998sep - RJ LocalfailuresofearthdamsdewminiNo ratings yet