Professional Documents

Culture Documents

Mathcad - C02-C2

Uploaded by

Krish ChandCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mathcad - C02-C2

Uploaded by

Krish ChandCopyright:

Available Formats

Client : Date : DEC-05

Project : Calc'd by : MS

Estimate no : Checked by : KP

Contract no :

Sheet no : C02-C2/1

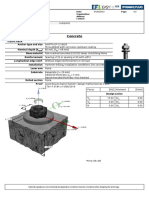

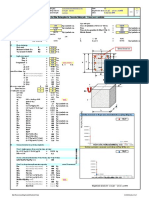

CONNECTION -C02-C2 ( CHS/SHS Bracing bar with spade plate slotted into section - Using cover plates )

BRACE CHS 219.1x8.0 F := 200kN

30

0(M

AX

)

CH 2 NOS 250 X 10 THK

20 S2 COVER PLATE

0k 19

N .1

103kN X8

31°

171.4kN

10

10

250(MIN)

UB 914x305x253

250x15 THK SPADE 22

0

0

PLATE

11

40

40

40

40

140(MIN)

15 THK

GUSSET PLATE

NOTES:-

All bolts are M20, grade 8.8,

All welds are 6 mm CFW

All beams & fittings are grade S275

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : MS

Estimate no : Checked by : KP

Contract no :

Sheet no : C02-C2/2

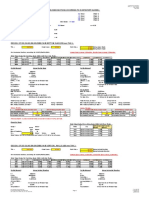

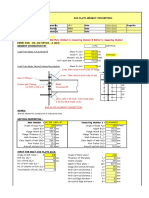

Material Properties

N

Design strength of S275 material py275 := 275 ⋅

up to & including 16 mm thk 2

mm

N

Design strength of S275 material py265 := 265 ⋅

beyond 16 mm thk and up to and 2

mm

including 40mm thk

N

Design strength of weld pw := 220 ⋅

2

mm

Bracing

Diameter of brace bar Db := 219.1 ⋅ mm

Thickness of brace bar tb := 8 ⋅ mm

Diameter of bolt d := 20mm

Diameter of hole Dh = 22 mm

No.of bolt rows nr := 1

No of bolt columns nc := 2

Total no. of bolts n= 2

Width of the spade / cover plate ws := 250mm

Thickness of spade plate ts := 15mm

Thickness of cover plate tc := 10mm

End distance local to free end of e1 := 40mm

spade plate

Gauge g := 110mm

Length of slot ls := 220mm

Net area coefficient Ke := 1.2

Check for Bolts

Check for shear capacity

Shear capacity of bolt Ps := 91.9kN Ps = 91.90 kN

F

Shear per bolt on double plane Fs := Fs = 50 kN

2⋅n

Ps (91.9 kN) > Fs (50 kN): Therefore O.k

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : MS

Estimate no : Checked by : KP

Contract no :

Sheet no : C02-C2/3

Check for bearing capacity of spade / gusset / cover plate

N

Bearing strength pbs := 460 ⋅

2

mm

Bearing Capacity per bolt hole Pbs := d ⋅ ts ⋅ pbs Pbs = 138.00 kN

Pbs (138 kN) > FS (50 kN): Therefore O.K.

Check for Tension capacity of spade plate

Effective area

⎣ (

Ae := min ⎡Ke ⋅ ws ⋅ ts − nc ⋅ Dh ⋅ ts , ws ⋅ ts⎤

⎦ ) Ae = 3708 mm

2

Tension capacity Pt := Ae ⋅ py275 Pt = 1019.70 kN

Pt (1019.7 kN) > F (200 kN): Therefore O.K.

Check for weld between spade plate & CHS

Length of weld. lw := 4 ⋅ ls lw = 880 mm

F kN

Shear per mm on weld FL := FL = 0.227

lw mm

FL

Size of weld required s req := s req = 1.48 mm

pw ⋅ 0.7

Adopt 6mm CFW

Check for compression capacity of cover plate

10

Thickness of cover plate tc = 10 mm

Max Effective length for Buckling Leff := 90mm

2

tc

0

11

Min radius of gyration ryy := 40

40 ryy = 2.89 mm

12 40

90 40

Leff

Slenderness ratio λ := 1.5 ⋅ λ = 46.8

ryy

N

Alllowable compressive strength pc = 241 ( B.S 5950-2000,Cl - 4.7.4 & TABLE 24)

2

mm

Max available dispersion length wd := 110mm

Compression capacity of cover plates Pc := 2wd ⋅ tc ⋅ pc Pc = 530.62 kN

Pc (530.6 kN) > F (200 kN): Therefore O.K.

Therefore adopt 2Nos 10 thk cover plate

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : MS

Estimate no : Checked by : KP

Contract no :

Sheet no : C02-C2/4

Check for shear capacity of CHS Bracing Wall

2

Shear area of CHS brace Av := 0.9 ⋅ ls ⋅ tb ⋅ 4 Av = 6336 mm

Shear capacity of CHS brace Fsw := 0.6 ⋅ py275 ⋅ Av Fsw = 1045.44 kN

Fsw (1045.44 kN) > F (200 kN): Therefore O.K.

Checks for Gusset Plate

Check for compression capacity of gusset plate

Thickness of gusset plate tg := 15mm

Max Effective length for Buckling Leff := 300mm

2

tg

Min radius of gyration ryy := ryy = 4.33 mm

12

Leff

Slenderness ratio λ := 1.5 ⋅ λ = 103.9

ryy

N

Alllowable compressive strength pc = 134 ( B.S 5950-2000,Cl - 4.7.4 & TABLE 24)

2

mm

Max available dispersion length wd := 110mm

within gusset

Compression capacity of the plate Pc := wd ⋅ tg ⋅ pc Pc = 220.43 kN

Pc (220.4 kN) > F (200 kN): Therefore O.K.

Weld between gusset and column web

Max Vertical component of brace force Fv := F ⋅ sin ( 31 ⋅ deg) Fv = 103.01 kN

Length available for welding Leff := ( 250 − 25 ) ⋅ mm Leff = 225 mm

Fv kN

Shear on weld FL := FL = 0.23

2 × Leff mm

FL

Size of weld required s := s = 1.49 mm

pw ⋅ 0.7

Adopt 6mm CFW

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : MS

Estimate no : Checked by : KP

Contract no :

Sheet no : C02-C2/5

Weld between gusset plate and baseplate

Max Horizontal component of Fh := F ⋅ cos ( 31 ⋅ deg) Fh = 171.43 kN

brace force

Length available for welding Leff := 140mm − 25mm Leff = 115 mm

Fh kN

Shear on weld FL := FL = 0.745

2 × Leff mm

FL

Size of weld required s := s = 4.84 mm

pw ⋅ 0.7

Adopt 6mm CFW

Variation no: Rev date Description

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- SNI 1727 2020 enDocument336 pagesSNI 1727 2020 enlisnzerNo ratings yet

- Mathcad - C02-C1Document5 pagesMathcad - C02-C1Krish ChandNo ratings yet

- Client: Project: Estimate No: Contract No: Sheet No: C06/C5/1Document8 pagesClient: Project: Estimate No: Contract No: Sheet No: C06/C5/1Krish ChandNo ratings yet

- Client: Project: Estimate No: Contract No: Sheet No: C06-C6/1Document7 pagesClient: Project: Estimate No: Contract No: Sheet No: C06-C6/1Krish ChandNo ratings yet

- Mathcad - C05-C2Document6 pagesMathcad - C05-C2Krish ChandNo ratings yet

- Mathcad - C08-C3Document6 pagesMathcad - C08-C3Krish ChandNo ratings yet

- Mathcad - C06-C10 PDFDocument7 pagesMathcad - C06-C10 PDFKrish ChandNo ratings yet

- Connection No - C08-C5: Loads: T-LoadingDocument6 pagesConnection No - C08-C5: Loads: T-LoadingKrish ChandNo ratings yet

- Mathcad - C06-C9 PDFDocument7 pagesMathcad - C06-C9 PDFKrish ChandNo ratings yet

- Connection No - C04-C1: Loads: 305X305X118 UCDocument5 pagesConnection No - C04-C1: Loads: 305X305X118 UCKrish ChandNo ratings yet

- Connection - C02-C3: (UC Bracing Bar, Flanges Stripped and Lapped On)Document5 pagesConnection - C02-C3: (UC Bracing Bar, Flanges Stripped and Lapped On)Krish ChandNo ratings yet

- Connection - C02-C5: (Combined Beam & Vertical Bracing Connection)Document7 pagesConnection - C02-C5: (Combined Beam & Vertical Bracing Connection)Krish ChandNo ratings yet

- Connection No-C08-C4: Vertical Shear Tie Force APG750X300X314 FV 1100kN: Fa 1100kNDocument5 pagesConnection No-C08-C4: Vertical Shear Tie Force APG750X300X314 FV 1100kN: Fa 1100kNKrish ChandNo ratings yet

- PTFE Plate BearingDocument1 pagePTFE Plate BearingChoi Lai LonNo ratings yet

- Mathcad - C02-C6Document8 pagesMathcad - C02-C6Krish ChandNo ratings yet

- Mathcad - C06-C8 PDFDocument7 pagesMathcad - C06-C8 PDFKrish ChandNo ratings yet

- FTB-Thermal Break-Structural-Calculation Method-10bDocument1 pageFTB-Thermal Break-Structural-Calculation Method-10bIan FloodNo ratings yet

- Bill of MaterialDocument1 pageBill of MaterialKevin GonzalesNo ratings yet

- Spreadsheets To BS 8110: Advisory Group Ground Floor Columns at B1, B2 Etc 91Document12 pagesSpreadsheets To BS 8110: Advisory Group Ground Floor Columns at B1, B2 Etc 91SimaoNo ratings yet

- Mathcad - C05-C1 PDFDocument4 pagesMathcad - C05-C1 PDFKrish ChandNo ratings yet

- Easyfix20220301132703 3Document3 pagesEasyfix20220301132703 3maniamjad321No ratings yet

- 0W430191-STR-051 - Squadcheck PipingDocument1 page0W430191-STR-051 - Squadcheck PipingNew BossNo ratings yet

- Concrete: Input DataDocument4 pagesConcrete: Input DataARYANo ratings yet

- Client: Project: Estimate No: Contract No: Sheet No: C06-C2/1Document5 pagesClient: Project: Estimate No: Contract No: Sheet No: C06-C2/1Krish ChandNo ratings yet

- Concrete: Input DataDocument4 pagesConcrete: Input DatadineshNo ratings yet

- Code Ref. Calculations Output: Column Size: 254 X 146 X 44.64kg/m UBDocument9 pagesCode Ref. Calculations Output: Column Size: 254 X 146 X 44.64kg/m UBkhewzyNo ratings yet

- Client: Project: Estimate No: Contract No: Sheet No: C06-C4/1Document7 pagesClient: Project: Estimate No: Contract No: Sheet No: C06-C4/1Krish ChandNo ratings yet

- Connection No - C08-C2: Shear Tying Force FV 600 KN : Fa 600 KNDocument6 pagesConnection No - C08-C2: Shear Tying Force FV 600 KN : Fa 600 KNKrish ChandNo ratings yet

- Connection No - C08-C6: Vertical Shear Tying Force FV 705 KN : Fa 705 KNDocument6 pagesConnection No - C08-C6: Vertical Shear Tying Force FV 705 KN : Fa 705 KNKrish ChandNo ratings yet

- Licad86061000010 F06Document1 pageLicad86061000010 F06Sakeel WagirkhanNo ratings yet

- Spreadsheets To BS 8110: Internal ColumnDocument12 pagesSpreadsheets To BS 8110: Internal ColumnCioabla BogdanNo ratings yet

- General Design Parameters (For Uncracked Section According To Is:3370 (Part-Ii) - 2009)Document6 pagesGeneral Design Parameters (For Uncracked Section According To Is:3370 (Part-Ii) - 2009)sumit_7285No ratings yet

- Mathcad - C06-C3Document5 pagesMathcad - C06-C3Krish ChandNo ratings yet

- Licad86061000009 F46Document1 pageLicad86061000009 F46Sakeel WagirkhanNo ratings yet

- Sub PLC Panel Wiring DiagramDocument9 pagesSub PLC Panel Wiring DiagramIyapparaj PazhaniNo ratings yet

- Shear 270Document4 pagesShear 270QuangKhảiNo ratings yet

- Spreadsheets To BS 8110: Advisory Group Columns at A1, A2 Etc RMW 94 CHG R68Document13 pagesSpreadsheets To BS 8110: Advisory Group Columns at A1, A2 Etc RMW 94 CHG R68Kem RaiNo ratings yet

- Anchor Bolt Base Plate Max FXcompDocument9 pagesAnchor Bolt Base Plate Max FXcomppandianNo ratings yet

- Spreadsheets To BS 8110Document10 pagesSpreadsheets To BS 8110Alma M. LaraNo ratings yet

- T Beam To BS 8110Document11 pagesT Beam To BS 8110Samitha SoysaNo ratings yet

- Column Base Plate Design (BS5950)Document2 pagesColumn Base Plate Design (BS5950)nicekannaNo ratings yet

- Connection - C03-C2: Client: Project: Estimate No: Contract No: Sheet No: C03-C2 / 1Document7 pagesConnection - C03-C2: Client: Project: Estimate No: Contract No: Sheet No: C03-C2 / 1Krish ChandNo ratings yet

- Spreadsheets To BS 8110: Internal ColumnDocument10 pagesSpreadsheets To BS 8110: Internal ColumnMohammad Twaha JaumbocusNo ratings yet

- RCC13 Punching ShearDocument10 pagesRCC13 Punching ShearMark Angelo FloresNo ratings yet

- RCC31R Rigorous One-Way SlabsDocument152 pagesRCC31R Rigorous One-Way SlabsMurthy GunaNo ratings yet

- Section B H Tension Reinforcement Compression Reinforcement MM MM MM MM MM No. Dia No. Dia No. Dia No. Dia No. Dia No. C C CDocument4 pagesSection B H Tension Reinforcement Compression Reinforcement MM MM MM MM MM No. Dia No. Dia No. Dia No. Dia No. Dia No. C C Cazamislam726537No ratings yet

- Spreadsheets To BS 8110Document10 pagesSpreadsheets To BS 8110T Satheesh KumarNo ratings yet

- Calculation Sheet: D B F VDocument1 pageCalculation Sheet: D B F Viwanguna71No ratings yet

- RCC13 Punching ShearDocument10 pagesRCC13 Punching Shearmathewsujith31No ratings yet

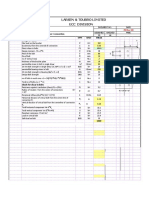

- Larsen & Toubro Limited Ecc Division: Description SYM Unit Value Design of BoltsDocument6 pagesLarsen & Toubro Limited Ecc Division: Description SYM Unit Value Design of BoltsSrishti Project ConsultantsNo ratings yet

- RCC13 Punching ShearDocument11 pagesRCC13 Punching ShearRodain NajjarNo ratings yet

- DE200012 - NS - 25 15 AM Atex - 25 25 AM AtexDocument3 pagesDE200012 - NS - 25 15 AM Atex - 25 25 AM AtexVincenzo CrippaNo ratings yet

- RCC13 Punching ShearDocument10 pagesRCC13 Punching ShearT Satheesh KumarNo ratings yet

- Licad86061000013 L14Document1 pageLicad86061000013 L14Sakeel WagirkhanNo ratings yet

- Spreadsheets To BS 8110Document10 pagesSpreadsheets To BS 8110bhoobNo ratings yet

- Corbel Design With Angle LimitDocument2 pagesCorbel Design With Angle LimitFrederick TanNo ratings yet

- PipeDocument5 pagesPipeTrishul Nath Pallay100% (1)

- Col Type 3 DesignDocument3 pagesCol Type 3 DesignIsaac JosephNo ratings yet

- Rct08 Column RectangularDocument4 pagesRct08 Column RectangularRuy ST GuerraNo ratings yet

- End Plate Beam To Column Moment ConnectionDocument84 pagesEnd Plate Beam To Column Moment ConnectionNguyen Duc CuongNo ratings yet

- Rukuruku Crossing Precast Option PDFDocument1 pageRukuruku Crossing Precast Option PDFKrish ChandNo ratings yet

- Rukuruku Crossing Details PDFDocument2 pagesRukuruku Crossing Details PDFKrish ChandNo ratings yet

- Engineering GuidelinesENGINEERING STANDARDS AND GUIDELINES FOR MARITIME STRUCTURESDocument34 pagesEngineering GuidelinesENGINEERING STANDARDS AND GUIDELINES FOR MARITIME STRUCTURESMohamed Elshahat OudaNo ratings yet

- Slab Design Span 7mDocument12 pagesSlab Design Span 7mKrish ChandNo ratings yet

- Rukuruku Crossing Drawing Cross Section Plan PDFDocument1 pageRukuruku Crossing Drawing Cross Section Plan PDFKrish ChandNo ratings yet

- Rukuruku Crossing Drawing T Beam Slab Option 2 PDFDocument1 pageRukuruku Crossing Drawing T Beam Slab Option 2 PDFKrish ChandNo ratings yet

- RUKURUKU CROSSING Slab Details PDFDocument1 pageRUKURUKU CROSSING Slab Details PDFKrish ChandNo ratings yet

- Rukuruku Crossing Localty Plan PDFDocument1 pageRukuruku Crossing Localty Plan PDFKrish ChandNo ratings yet

- Slab Design Span 7mDocument12 pagesSlab Design Span 7mKrish ChandNo ratings yet

- Tech Notes On Bolts PDFDocument41 pagesTech Notes On Bolts PDFKrish ChandNo ratings yet

- Bolts CatalogueDocument88 pagesBolts CatalogueAnandh PsNo ratings yet

- Hex Bolts - Minimum Tensile StressDocument4 pagesHex Bolts - Minimum Tensile StressskkongNo ratings yet

- Calculation Sheet: From Table 4.1 For Floor-Others (Distributed Imposed Action, Q)Document6 pagesCalculation Sheet: From Table 4.1 For Floor-Others (Distributed Imposed Action, Q)Krish ChandNo ratings yet

- Module 6 Bridge Engineering BatchDocument120 pagesModule 6 Bridge Engineering BatchKrish Chand100% (3)

- Bridge Design Very Useful PDFDocument326 pagesBridge Design Very Useful PDFKrish ChandNo ratings yet

- Flat Slab DesignDocument76 pagesFlat Slab Designyunuswsa97% (36)

- Check For Compression Welds Between Beam Flanges and End PlateDocument3 pagesCheck For Compression Welds Between Beam Flanges and End PlateKrish ChandNo ratings yet

- Connection - C03-C2: Client: Project: Estimate No: Contract No: Sheet No: C03-C2 / 1Document7 pagesConnection - C03-C2: Client: Project: Estimate No: Contract No: Sheet No: C03-C2 / 1Krish ChandNo ratings yet

- Mathcad - Template IndexDocument6 pagesMathcad - Template IndexKrish ChandNo ratings yet

- Single Span Beam: Untitled: Input TablesDocument1 pageSingle Span Beam: Untitled: Input TablesKrish ChandNo ratings yet

- Chapter 5 - Footings - Sp17!9!07Document38 pagesChapter 5 - Footings - Sp17!9!07aldwinNo ratings yet

- Prokon - C08-C4Document2 pagesProkon - C08-C4Krish ChandNo ratings yet

- Connection No - C04-C1: Loads: 305X305X118 UCDocument5 pagesConnection No - C04-C1: Loads: 305X305X118 UCKrish ChandNo ratings yet

- Column Design: Information SheetDocument2 pagesColumn Design: Information SheetKrish ChandNo ratings yet

- EarthfillingDocument6 pagesEarthfillingKrish ChandNo ratings yet

- Mathcad - C05-C1 PDFDocument4 pagesMathcad - C05-C1 PDFKrish ChandNo ratings yet

- Beam Example1Document2 pagesBeam Example1Indu ShresthaNo ratings yet

- Nzw14085 SD Beam 2Document10 pagesNzw14085 SD Beam 2Krm ChariNo ratings yet

- Sample - Solutions Manual Photonics 2nd Edition by SalehDocument1 pageSample - Solutions Manual Photonics 2nd Edition by Salehhadi farzinNo ratings yet

- Complete Welding ClipDocument163 pagesComplete Welding Clipharoub_nas100% (2)

- Classical MechanicsDocument4 pagesClassical MechanicsSamantha GreyNo ratings yet

- GALA TEST CERTIFICATE Size 4Document1 pageGALA TEST CERTIFICATE Size 4dow cMNo ratings yet

- EarthworksDocument26 pagesEarthworksRufa May Auingan YbiasNo ratings yet

- Dielectric AbsorptionDocument4 pagesDielectric AbsorptionbookbumNo ratings yet

- BE184P Exercise 1.1a SpectrophotometryDocument9 pagesBE184P Exercise 1.1a SpectrophotometryDen CelestraNo ratings yet

- AEMT Assignment1 2023Document2 pagesAEMT Assignment1 2023Sujay SNo ratings yet

- Solutions - Maths Workbook - 2 - Complex NumbersDocument101 pagesSolutions - Maths Workbook - 2 - Complex NumbersravimcanitNo ratings yet

- Dynamic Braking Resistor CalculationDocument10 pagesDynamic Braking Resistor CalculationMuugii AmgaaNo ratings yet

- Technical Documentation 14.5045 - Compressores HATLAPADocument116 pagesTechnical Documentation 14.5045 - Compressores HATLAPAGilson CardosoNo ratings yet

- Proximity Effect From An Andreev Perspectiv KlapwijkDocument19 pagesProximity Effect From An Andreev Perspectiv KlapwijkLinda ZhangNo ratings yet

- The Effect of Rotating Atomizer Geometry On The SaDocument7 pagesThe Effect of Rotating Atomizer Geometry On The SamazaherramazaniNo ratings yet

- MK Ji RB Evm HVM XVKV: GWM Q Avm Z N E Mevb KDocument4 pagesMK Ji RB Evm HVM XVKV: GWM Q Avm Z N E Mevb KPathokNo ratings yet

- 3va9988-0ba22-SHUNT TRIPDocument4 pages3va9988-0ba22-SHUNT TRIPLeonardo CAMARGO CAMARGONo ratings yet

- The Complete Hermes Programme For External Cylindrical GrindingDocument16 pagesThe Complete Hermes Programme For External Cylindrical GrindingFlavioNo ratings yet

- Exam 1 SolutionsDocument2 pagesExam 1 SolutionsPuto SantanaNo ratings yet

- ExCos-D enDocument5 pagesExCos-D enMd Abu BorhanNo ratings yet

- Capinig - Lab Activity 6 (Spherical Mirrors)Document3 pagesCapinig - Lab Activity 6 (Spherical Mirrors)Ellysa Mae Capinig RiedlerNo ratings yet

- Distillation - Session 4Document8 pagesDistillation - Session 4atif irshadNo ratings yet

- NIT Rourkela ME SyllabusDocument9 pagesNIT Rourkela ME SyllabusVisionateNo ratings yet

- Design and Constrution For LedDocument4 pagesDesign and Constrution For Ledvictoriawane00No ratings yet

- 15Document24 pages15danferreiro8318No ratings yet

- OPTI 370 Syllabus S22 (Updated)Document7 pagesOPTI 370 Syllabus S22 (Updated)AhmedphmaNo ratings yet

- Maths QuestionsDocument25 pagesMaths QuestionsSha YosiNo ratings yet

- Investigation On Mechanical Properties of Wire Arc Additive Manufacturing (Waam) of 316L Stainless Steel Using Fem Simulation and ExperimentDocument10 pagesInvestigation On Mechanical Properties of Wire Arc Additive Manufacturing (Waam) of 316L Stainless Steel Using Fem Simulation and ExperimentMohd AymanNo ratings yet

- Pressure Transmitter With Ceramic Sensor, Accuracy 0,5%Document2 pagesPressure Transmitter With Ceramic Sensor, Accuracy 0,5%essameldinNo ratings yet

- Cambridge Assessment International Education: Combined Science 0653/43 October/November 2019Document10 pagesCambridge Assessment International Education: Combined Science 0653/43 October/November 2019Dada LimNo ratings yet

- Deluge ValveDocument10 pagesDeluge ValvevpnrrajaNo ratings yet