Professional Documents

Culture Documents

Structural connection design calculations

Uploaded by

Krish ChandOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural connection design calculations

Uploaded by

Krish ChandCopyright:

Available Formats

Client : Date : DEC-05

Project : Calc'd by : MR

Estimate no : Checked by : SM

Contract no :

Sheet no :C02-C6/ 1

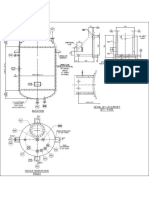

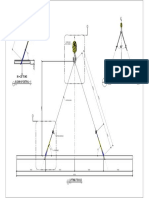

CONNECTION NO - C02-C6

LOADS:

Brace 152UC30 F := 237 ⋅ kN

LHS Beam 203UC46 Fx1 := 72 ⋅ kN Fv1 := 11kN Fh1 := 2kN

RHS Beam 254UC73 Fx2 := 127 ⋅ kN Fv2 := 96kN Fh2 := 25kN

205.2kN

23

7k

N

2 NOS 150x10 THK

°

60

WING PLATE

118.5kN

15

SLOTTED INTO GUSSET(TYP)

2U

C3

4 NOS 60x10 THK

0

FLANGE COVER PLATE(TYP)

A (MIN)

25

20

0(M

40

AX

)

70

A B

90 90

40 0

30

30

70 40

1

(MIN)

40

(MIN) 15 THK

70

GUSSET PLATE B NOTCH FLANGES

TO SUIT

40

50

EL 6.600

15 EL 6.575

90

65

240(MIN)

W.P

90

60 60

203UC46

254UC73

SECTION A-A SECTION B-B

254UC89 END PLATE 160x15THK

COL WEB BOLTS @ 90x/CRS

(TYP)

Notes

All bolts are M20 ,Gr.8.8

All weld sizes are 6mm CFW

All main steel & fittings are S275

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : MR

Estimate no : Checked by : SM

Contract no :

Sheet no :C02-C6/ 2

Sectional Properties

Column Dc := 260.3 ⋅ mm wc := 256.3 ⋅ mm Tc := 17.3 ⋅ mm tc := 10.3 ⋅ mm rc := 12.7 ⋅ mm

254UC89

LHS Beam Db1 := 203.2 ⋅ mm wb1 := 203.6mm Tb1 := 11 ⋅ mm tb1 := 7.2 ⋅ mm rb1 := 10.2 ⋅ mm

203UC46

RHS Beam Db2 := 254.1 ⋅ mm wb2 := 254.6mm Tb2 := 14.2 ⋅ mm tb2 := 8.6 ⋅ mm rb2 := 12.7 ⋅ mm

254UC73

Bracing Dbr := 157.6mm wbr := 152.9 ⋅ mm Tbr := 9.4mm tbr := 6.5 ⋅ mm rbr := 7.6mm

152UC30

Material Properties 2

Abr := 3830mm

N

Design strength of S275 material py275 := 275 ⋅

Up to & including 16 thk 2

mm

N

Design strength of S275 material py265 := 265 ⋅

beyond 16thk , up to and including 2

mm

40mm thk

N

Design strength of fillet weld pw := 220 ⋅

2

mm

Checks for bolts for 203UC46 beam to column web (worst case)

Bolt Diameter d := 20 ⋅ mm

Total no. of bolts n := 8

Bolt pitch p := 90mm

Bolt gauge g := 90mm

Shear Capacity of bolt Ps := 91.9kN

Tension Capacity of bolt Pnom := 110kN

Vertical component of brace force Fvb1 := F ⋅ sin ( 60deg) Fvb1 = 205.2 kN

Horizontal component of brace force Fhb1 := F ⋅ cos ( 60deg) Fhb1 = 118.5 kN

Fv1 + Fvb1

Total vertical shear per bolt Fsv := Fsv = 27.03 kN

n

Fh1

Hor. shear per bolt Fsh := Fsh = 0.5 kN

4

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : MR

Estimate no : Checked by : SM

Contract no :

Sheet no :C02-C6/ 3

2 2

Resultant shear per bolt Fs := Fsv + Fsh Fs = 27.04 kN

( (

min ⎡ max Fx1 , Fhb1 , Fx2⎤

⎣ ⎦ ))

Tension per bolt Ft := Ft = 29.63 kN

(conservatively) 4

Fs Ft

Check for combined shear and tension Ratio := + Ratio = 0.56

Ps Pnom

Ratio(0.56 ) < 1.4 : Therefore O.K.

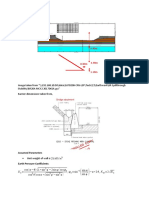

Check for weld between beam web and end plate 63

Tension per bolt Ft = 29.63 kN

108.10

Dispersion length on weld Ld := ( 92.2 + 63 )mm Ld = 155.2 mm

( for bottom bolt)

92.2

Dispersion on web Lw := 92.2mm

Ft ⋅ Lw

Tension on web Ftw := Ftw = 17.60 kN

Ld

Ftw kN

Tension per mm on web weld FT := FT = 0.191

Lw mm

Fv2 kN

Vertical shear per mm FL := FL = 0.240

(

2 ⋅ Db2 − 2 ⋅ Tb2 − 2 ⋅ rb2 ) mm

2

⎛ FT ⎞ kN

Resultant force per mm R1 := ⎜ + FL

2

R1 = 0.284

⎝ 1.25 ⎠ mm

R1

Size of fillet weld required s req := s req = 1.85 mm

0.7 ⋅ pw 63

Adopt 6mm CFW

108.10

Check for end plate

92.2

Weld b/w beam web & endplate s := 6 ⋅ mm

Ft ⎛g tb2 ⎞

Moment due to bolt force M := ⋅⎜ − − 0.8 ⋅ s M = 0.532 kN ⋅ m

2 ⎝2 2 ⎠

Dispersion length Ld = 155.2 mm (worst case)

M⋅6

Thickness of plate required treqd := treqd = 8.65 mm

py275 ⋅ Ld

Adopt 15mm thk end plate

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : MR

Estimate no : Checked by : SM

Contract no :

Sheet no :C02-C6/ 4

Check for bearing

Minimum thickness of connected ply tc = 10.3 mm

N

Bearing strength pbs := 460 ⋅

2

mm

Bearing Capacity (per bolt) Pbs := d ⋅ tc ⋅ pbs Pbs = 94.76 kN

2 2

⎛ Fv2 ⎞ ⎛ Fh2 ⎞

Applied load (per bolt) Fsb := ⎜ + Fsv + ⎜ + Fsh Fsb = 51.48 kN

⎝ 4 ⎠ ⎝ 4 ⎠

Pbs (94.76 kN) > Fsb (51.48 kN): Therefore O.K.

Check for brace bar (152UC30)

Bolt properties in brace bar

( Each flange plate)

Bolt Diameter d2 := 20 ⋅ mm

Diameter of hole Dh2 := 22mm

No of bolt rows on each side nr2 := 2

No of bolt columns nc2 := 1

Total no. of bolts n2 = 2

End distance et2 := 40mm

Pitch p2 := 70mm

Check for bolts in shear

F

Ffp := Ffp = 59.25 kN

Force on each flange plate 4

Ffp

Shear capacity of bolt Fs2 :=

n2 Fs2 = 29.63 kN

Ps (91.9 kN) > Fs2(29.62 kN): Therefore O.K.

Check for bolts in bearing

Minimum thickness of connected part Tbr = 9.4 mm

Bearing Capacity (

Pbs2 := d2 ⋅ Tbr ⋅ pbs ⋅ n2 ) Pbs2 = 172.96 kN

Pbs2 (172.96 kN) > Ffp(59.25 kN): Therefore O.K.

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : MR

Estimate no : Checked by : SM

Contract no :

Sheet no :C02-C6/ 5

Block shear capacity of brace bar

110

Net area coefficient k e := 1.2 k := 0.5

31.45

for S275

Shear length Lv1 := et2 + p2 Lv1 = 110 mm

90

31.45

Tensile length Lt1 := 31.45mm

Block Shear capacity

⎣ ⎣ (

Pr1 := 2 ⋅ ⎡0.6 ⋅ py275 ⋅ Tbr ⋅ ⎡Lv1 + k e ⋅ Lt1 − k ⋅ Dh2 ⎤⎤

⎦⎦ ) Pr1 = 417.343 kN

F

Tension acting on each Ffb := Ffb = 118.5 kN

flange of brace bar 2

Pr1 (417.3 kN) > Ffb (118.5 kN): Therefore O.K.

Check for cover plates

Check for compression capacity of cover plates

Thickness of cover plate tcp := 10mm

Max Effective length for Buckling Leff := 90mm

2

tcp

Min radius of gyration ryy := ryy = 2.887 mm

12

Leff

Slenderness ratio λ := 1.0 ⋅ λ = 31.177

ryy

N

pc = 260.39 ( B.S 5950-2000,Cl - 4.7.4 & TABLE 24)

2

mm

Cover plate width Wcp := 60mm

Compression capacity of the plate Pc := Wcp ⋅ tcp ⋅ pc Pc = 156.24 kN

Pc (156.2 kN) > Ffp (59.2 kN): Therefore O.K.

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : MR

Estimate no : Checked by : SM

Contract no :

Sheet no :C02-C6/ 6

Check for tension capacity of cover plates

Width of cover plate Wcp = 60 mm

Tension capacity of the cover plates ( )

PTc := Wcp − Dh2 ⋅ k e ⋅ tcp ⋅ py275 PTc = 125.4 kN

PTc (125.4 kN) > Ffp (59.2 kN): Therefore O.K.

Check for wing plates

90

30

(MIN)

Eccentricity between force from bolts ef := 45mm

to C/L of gusset

15

Moment induced on wing plate M := Ffp ⋅ ef M = 2666.25 kN ⋅ mm

60

Thickness of wing plate twp := 10mm

6⋅ M

Depth of wing plate reqd. Dwp := Dwp = 69.626 mm

1.2 ⋅ twp ⋅ py275

Adopt 150 mm depth wing plate ( For practical reasons )

Shear capacity of wing plate

Shear area of wing plate (

As := 2 ⋅ 0.9 ⋅ Dwp ⋅ twp ) As = 1253.261 mm

2

Shear capacity of wing plate Fwp := 0.6 ⋅ As ⋅ py275 Fwp = 206.788 kN

Force on wing plate Pwp := 2 ⋅ Ffp Pwp = 118.5 kN

Fwp (206.8 kN) > Pwp (118.5 kN): Therefore O.K.

Weld between wing plate and gusset

Length available for weld (

Lw := 2 ⋅ p2 + 2 ⋅ et2 ) Lw = 300 mm

Ffp kN

Longitudinal force acting on weld per mm Fvw := Fvw = 0.197

Lw mm

Fvw

Size of fillet weld s := s = 1.28 mm

0.7 ⋅ pw

Adopt 6 mm CFW

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : MR

Estimate no : Checked by : SM

Contract no :

Sheet no :C02-C6/ 7

Check for Compression Capacity of Gusset Plate

Thickness of gusset plate tg := 15mm

Dispersed width weff := Dbr weff = 157.6 mm

(Conservatively)

Maximum effective length for buckling Leff := 250mm

2

tg

Minimum radius of gyration of gusset ryy := ryy = 4.33 mm

12

1.5Leff

Slenderness ratio λ := λ = 86.603

ryy

N

Allowable compressive strength pc = 163.92

2

mm

Compression capacity Pc := weff ⋅ tg ⋅ pc Pc = 387.51 kN

Pc (387.51 kN) > F (237 kN): Therefore O.K.

Weld between gusset plate and beam flange

Horizontal component of brace force Fhb1 = 118.5 kN

Length available for welding l := 240 ⋅ mm Leff := l − 25 ⋅ mm Leff = 215 mm

Fhb1 kN

FL := FL = 0.276

e=101.6

Shear per mm on weld

2 × Leff mm

Eccentricity of weld from w.p e := 101.6 ⋅ mm

M := Fhb1 ⋅ e M = 12.04 kN ⋅ m

Moment due to eccentricity

M⋅6 kN

Tension per mm on weld FT := FT = 0.781

2 mm

2 ⋅ Leff

2

⎛ FT ⎞ kN

Resultant force per mm on weld R := ⎜ + FL

2

R = 0.683

⎝ 1.25 ⎠ mm

R

Size of fillet weld required s := s = 4.44 mm

pw ⋅ 0.7

Adopt 6mm CFW

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : MR

Estimate no : Checked by : SM

Contract no :

Sheet no :C02-C6/ 8

Weld between gusset plate and end plate

Vertical component of brace force Fvb1 = 205.2 kN

Length available for welding l := 185 ⋅ mm Leff := l − 25 ⋅ mm Leff = 160 mm

Fvb1 kN

Shear per mm on weld FL := FL = 0.641

Leff ⋅ 2 mm

FL

Size of fillet weld required s := s = 4.16 mm

0.7 ⋅ pw

Adopt 6mm CFW

Variation no: Rev date Description

You might also like

- Connection - C02-C5: (Combined Beam & Vertical Bracing Connection)Document7 pagesConnection - C02-C5: (Combined Beam & Vertical Bracing Connection)Krish ChandNo ratings yet

- Mathcad - C02-C2Document5 pagesMathcad - C02-C2Krish ChandNo ratings yet

- Connection Design for Bracing Bar between C02-C3Document5 pagesConnection Design for Bracing Bar between C02-C3Krish ChandNo ratings yet

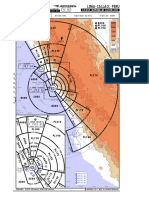

- Sbco Rnp-Z-Rwy-13 Iac 20220127Document1 pageSbco Rnp-Z-Rwy-13 Iac 20220127Pedro MonteiroNo ratings yet

- Chaos Theory in Welding - EUROJOIN 4 Dubrovnik 2001 PresentationDocument18 pagesChaos Theory in Welding - EUROJOIN 4 Dubrovnik 2001 PresentationMarjan SubanNo ratings yet

- Lift Lug and Earthing Lug Details for Reactor Vessel Dish EndDocument1 pageLift Lug and Earthing Lug Details for Reactor Vessel Dish EndRajesh PanchalNo ratings yet

- DS Linear Motors P01-23x80Document24 pagesDS Linear Motors P01-23x80carlos030476No ratings yet

- Same-Mdz-Doz Mendoza (El Plumerillo) 2213Document24 pagesSame-Mdz-Doz Mendoza (El Plumerillo) 2213Adrian RyserNo ratings yet

- 6 Soil - CompactionDocument58 pages6 Soil - CompactionLiv CBNo ratings yet

- Cape Town Intl: Radar Terrain Clearance ChartDocument1 pageCape Town Intl: Radar Terrain Clearance ChartWilliam DunnNo ratings yet

- SBVT Vor-T-Rwy-24 Iac 20181108Document1 pageSBVT Vor-T-Rwy-24 Iac 20181108PedroNo ratings yet

- sbct_vor-rwy-11_iac_20231102Document1 pagesbct_vor-rwy-11_iac_20231102Nivaldo FernandesNo ratings yet

- 10 0 20 40 30 50 H H (FT) Q (U.S. Gal / Min.) : N 3500 RPMDocument1 page10 0 20 40 30 50 H H (FT) Q (U.S. Gal / Min.) : N 3500 RPMLuis RaymundoNo ratings yet

- Novo Curtain MotorDocument7 pagesNovo Curtain MotorehvorovNo ratings yet

- Sbur Ndb-Rwy-17 Iac 20210909Document1 pageSbur Ndb-Rwy-17 Iac 20210909Pedro AlbaniNo ratings yet

- SPJC2023Document38 pagesSPJC2023jmarangitoNo ratings yet

- (IAC) Ils Z Rwy 35L: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 06'WDocument1 page(IAC) Ils Z Rwy 35L: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 06'WGuilherme Kazuo OgawaNo ratings yet

- (STAR) RWY 28R/28L Rnav Vunox 1C: Rnav 1. or RNP 1 Gnss ReqDocument1 page(STAR) RWY 28R/28L Rnav Vunox 1C: Rnav 1. or RNP 1 Gnss ReqLuiz SantosNo ratings yet

- Jeppesen Trip KitDocument25 pagesJeppesen Trip KitKyle BrandonNo ratings yet

- Bengt H FelleniusDocument37 pagesBengt H FelleniusshivaNo ratings yet

- Legends & Abbreviations Plate DetailsDocument1 pageLegends & Abbreviations Plate Detailsshashank sharmaNo ratings yet

- MDPC Airport InfoDocument28 pagesMDPC Airport InfoLiviu 22100% (1)

- Scalf00007766 (RFP) - T-Frame For Top Mount Chh-616Document1 pageScalf00007766 (RFP) - T-Frame For Top Mount Chh-616berkahharianNo ratings yet

- Cuiab' / Marechal Rondon, Intl (Sbcy) RWY 35 Rnav Donre 1B - Tenel 1A - Vania 1ADocument2 pagesCuiab' / Marechal Rondon, Intl (Sbcy) RWY 35 Rnav Donre 1B - Tenel 1A - Vania 1Athallesx47No ratings yet

- SBVT Rnp-A-Rwy-20 Iac 20231130Document2 pagesSBVT Rnp-A-Rwy-20 Iac 20231130João Pedro Santos da CruzNo ratings yet

- Dimensions Used in Analysis: 0.60m 7.40m 0.90m 1.50mDocument4 pagesDimensions Used in Analysis: 0.60m 7.40m 0.90m 1.50mSatha IyathuraiNo ratings yet

- Ball Float Steam Trap and Thermodynamic Steam TrapDocument2 pagesBall Float Steam Trap and Thermodynamic Steam Trappriyanka GNo ratings yet

- Bulgarian 20040920Document1 pageBulgarian 20040920tompahNo ratings yet

- Set1 Seg1 Q5Document1 pageSet1 Seg1 Q5hamza69naserNo ratings yet

- Sbms Adc-Sbms Adc 20220519Document2 pagesSbms Adc-Sbms Adc 20220519Pedro HenriqueNo ratings yet

- AERODROME CHART(ADC) FOR ORIXIMIN` / Trombetas (SBTB) WITH UPDATED INFORMATIONDocument2 pagesAERODROME CHART(ADC) FOR ORIXIMIN` / Trombetas (SBTB) WITH UPDATED INFORMATIONCMTD RafaelNo ratings yet

- Prop En1065 C-D35Document1 pageProp En1065 C-D35alessandroNo ratings yet

- LTBFDocument12 pagesLTBFİ. Çağlar YILDIRIMNo ratings yet

- โจทย์เพิ่มเติมเรียนพิเศษDocument3 pagesโจทย์เพิ่มเติมเรียนพิเศษFeLiNaNo ratings yet

- LIFTING TOOLS-Layout1Document1 pageLIFTING TOOLS-Layout1Mark L. AlmencionNo ratings yet

- Kx6k Sc02 6611kv Transformer-1 Protection Rev Za 15.03.2018Document82 pagesKx6k Sc02 6611kv Transformer-1 Protection Rev Za 15.03.2018Ravi Shankar VNo ratings yet

- IPATINGA / Usiminas (SBIP) Airport Chart Provides Key Flight InformationDocument2 pagesIPATINGA / Usiminas (SBIP) Airport Chart Provides Key Flight InformationJosé SilvaNo ratings yet

- SBBR Nirdi-1a-Rwy-11l Sid 20200423Document1 pageSBBR Nirdi-1a-Rwy-11l Sid 20200423Calebe TavaresNo ratings yet

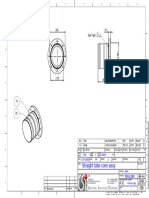

- Straight Tube Conn Assy: 90 10 2 Gas TightDocument1 pageStraight Tube Conn Assy: 90 10 2 Gas TightAndrei MihaiNo ratings yet

- Bridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryDocument2 pagesBridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryCesar Romero VilchezNo ratings yet

- Bridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryDocument2 pagesBridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design Summaryjklo12No ratings yet

- Sbbu - Rnav Gnss Z Rwy 32 - Iac - 20180524Document1 pageSbbu - Rnav Gnss Z Rwy 32 - Iac - 20180524Marinho ValdenioNo ratings yet

- Concrete Column Design Based On ACI 318-08: Input Data & Design SummaryDocument3 pagesConcrete Column Design Based On ACI 318-08: Input Data & Design SummaryShantonu DeyNo ratings yet

- ABL BOG: Skbo/Bog Bogota, ColombiaDocument2 pagesABL BOG: Skbo/Bog Bogota, ColombiaJAVIER TIBOCHANo ratings yet

- (With Tube) : Part No F Tol Inductance Rated DC Current SRF DCR Q FDocument1 page(With Tube) : Part No F Tol Inductance Rated DC Current SRF DCR Q FlouisNo ratings yet

- CARTA AEREA - SPJC - LIMA PERU PDFDocument46 pagesCARTA AEREA - SPJC - LIMA PERU PDFPedro Ernesto Dos ReisNo ratings yet

- Madeira, Madeira Is Lpma/Fnc: .Radar - Minimum.AltitudesDocument27 pagesMadeira, Madeira Is Lpma/Fnc: .Radar - Minimum.AltitudesToni HermanNo ratings yet

- Concentric Gauge 0.40: Qty-1NoDocument1 pageConcentric Gauge 0.40: Qty-1Noabrahamantone1No ratings yet

- SBVT Adc-Sbvt Adc 20190718Document2 pagesSBVT Adc-Sbvt Adc 20190718João Pedro Santos da CruzNo ratings yet

- Hibbeler Statics and Mechanics of Materials Global Ed SolDocument77 pagesHibbeler Statics and Mechanics of Materials Global Ed SolAaron PinedaNo ratings yet

- UMARUDINDocument1 pageUMARUDINUltra Medical SemarangNo ratings yet

- CCDC Conlan34Document1 pageCCDC Conlan34Luong LeNo ratings yet

- Power supply circuit diagramDocument1 pagePower supply circuit diagramSalvi Alonso100% (1)

- Adobe Scan 29 Nov 2022Document1 pageAdobe Scan 29 Nov 2022Devendra TyagiNo ratings yet

- Connection - C03-C2: Client: Project: Estimate No: Contract No: Sheet No: C03-C2 / 1Document7 pagesConnection - C03-C2: Client: Project: Estimate No: Contract No: Sheet No: C03-C2 / 1Krish ChandNo ratings yet

- Feroy Directional Valve SP70-ODocument2 pagesFeroy Directional Valve SP70-ODc Zhou100% (1)

- Client: Project: Estimate No: Contract No: Sheet No: C06-C6/1Document7 pagesClient: Project: Estimate No: Contract No: Sheet No: C06-C6/1Krish ChandNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Rukuruku Crossing Precast Option PDFDocument1 pageRukuruku Crossing Precast Option PDFKrish ChandNo ratings yet

- Rukuruku Crossing Localty Plan PDFDocument1 pageRukuruku Crossing Localty Plan PDFKrish ChandNo ratings yet

- Rukuruku Crossing Drawing Cross Section Plan PDFDocument1 pageRukuruku Crossing Drawing Cross Section Plan PDFKrish ChandNo ratings yet

- RUKURUKU CROSSING Slab Details PDFDocument1 pageRUKURUKU CROSSING Slab Details PDFKrish ChandNo ratings yet

- Rukuruku Crossing Drawing T Beam Slab Option 2 PDFDocument1 pageRukuruku Crossing Drawing T Beam Slab Option 2 PDFKrish ChandNo ratings yet

- Slab Design Span 7mDocument12 pagesSlab Design Span 7mKrish ChandNo ratings yet

- Calculation Sheet: From Table 4.1 For Floor-Others (Distributed Imposed Action, Q)Document6 pagesCalculation Sheet: From Table 4.1 For Floor-Others (Distributed Imposed Action, Q)Krish ChandNo ratings yet

- Hex bolt stress and load tablesDocument4 pagesHex bolt stress and load tablesskkongNo ratings yet

- Rukuruku Crossing Details PDFDocument2 pagesRukuruku Crossing Details PDFKrish ChandNo ratings yet

- Beam calculations for a single span beamDocument1 pageBeam calculations for a single span beamKrish ChandNo ratings yet

- Engineering GuidelinesENGINEERING STANDARDS AND GUIDELINES FOR MARITIME STRUCTURESDocument34 pagesEngineering GuidelinesENGINEERING STANDARDS AND GUIDELINES FOR MARITIME STRUCTURESMohamed Elshahat OudaNo ratings yet

- Slab Design Span 7mDocument12 pagesSlab Design Span 7mKrish ChandNo ratings yet

- Flat Slab DesignDocument76 pagesFlat Slab Designyunuswsa97% (36)

- Bolts CatalogueDocument88 pagesBolts CatalogueAnandh PsNo ratings yet

- Bridge Design Very Useful PDFDocument326 pagesBridge Design Very Useful PDFKrish ChandNo ratings yet

- Module 6 Bridge Engineering BatchDocument120 pagesModule 6 Bridge Engineering BatchKrish Chand100% (3)

- Tech Notes On Bolts PDFDocument41 pagesTech Notes On Bolts PDFKrish ChandNo ratings yet

- Check For Compression Welds Between Beam Flanges and End PlateDocument3 pagesCheck For Compression Welds Between Beam Flanges and End PlateKrish ChandNo ratings yet

- Job Sheet Weld AnalysisDocument2 pagesJob Sheet Weld AnalysisKrish ChandNo ratings yet

- Chapter 5 - Footings - Sp17!9!07Document38 pagesChapter 5 - Footings - Sp17!9!07aldwinNo ratings yet

- Connection design calculationsDocument6 pagesConnection design calculationsKrish ChandNo ratings yet

- Connection No - C04-C1: Loads: 305X305X118 UCDocument5 pagesConnection No - C04-C1: Loads: 305X305X118 UCKrish ChandNo ratings yet

- Mathcad - Template IndexDocument6 pagesMathcad - Template IndexKrish ChandNo ratings yet

- Nzw14085 SD Beam 2Document10 pagesNzw14085 SD Beam 2Krm ChariNo ratings yet

- Mathcad - C05-C1 PDFDocument4 pagesMathcad - C05-C1 PDFKrish ChandNo ratings yet

- Connection design calculationsDocument6 pagesConnection design calculationsKrish ChandNo ratings yet

- Column Design: Information SheetDocument2 pagesColumn Design: Information SheetKrish ChandNo ratings yet

- Connection - C03-C2: Client: Project: Estimate No: Contract No: Sheet No: C03-C2 / 1Document7 pagesConnection - C03-C2: Client: Project: Estimate No: Contract No: Sheet No: C03-C2 / 1Krish ChandNo ratings yet

- Construction Specification Earthfill CompactionDocument6 pagesConstruction Specification Earthfill CompactionKrish ChandNo ratings yet

- Beam Example1Document2 pagesBeam Example1Indu ShresthaNo ratings yet

- Mechanical Vibration G K Grover PDFDocument58 pagesMechanical Vibration G K Grover PDFbunty25% (4)

- CFD Momentum Equation PDFDocument18 pagesCFD Momentum Equation PDFMoloy UpadhyayNo ratings yet

- Mobility of MechanismsDocument17 pagesMobility of Mechanismsch pavan kumarNo ratings yet

- Lab Report#4Document15 pagesLab Report#4brayanNo ratings yet

- Column DesignDocument36 pagesColumn DesignGaurav KashyapNo ratings yet

- Unified Approach To Specifying The Psi-Angle Error Equation in Strapdown Inertial Navigation SystemsDocument7 pagesUnified Approach To Specifying The Psi-Angle Error Equation in Strapdown Inertial Navigation SystemsNaitik BarotNo ratings yet

- Experimental Analysis and Numerical Simulation of Hydraulic JumpDocument58 pagesExperimental Analysis and Numerical Simulation of Hydraulic JumpTirtha Roy BiswasNo ratings yet

- CH 5Document56 pagesCH 5Aldrin taduranNo ratings yet

- Von Mises Yield Criterion - WikipediaDocument7 pagesVon Mises Yield Criterion - WikipediaArpan NandyNo ratings yet

- FEA Pressure VesselDocument48 pagesFEA Pressure VesselnaimNo ratings yet

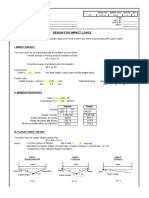

- Drop Object-Plastic HingeDocument8 pagesDrop Object-Plastic HingeBolarinwaNo ratings yet

- EC6403 Unit 3Document204 pagesEC6403 Unit 3Rajkumar PerumalNo ratings yet

- Separator DesignDocument3 pagesSeparator Designsondung4ver80% (5)

- Tutorial 2 Kinematics in One Dimension: H KM 95 H. KM 65Document2 pagesTutorial 2 Kinematics in One Dimension: H KM 95 H. KM 65Fareez SedakaNo ratings yet

- Resonance Revision DPP Physics 1 To 8 Sets JEE MAINS & ADVANCED 2022Document88 pagesResonance Revision DPP Physics 1 To 8 Sets JEE MAINS & ADVANCED 2022Golu kumarNo ratings yet

- Me2254 SM QBDocument15 pagesMe2254 SM QBhodvmkvecautoNo ratings yet

- Applied Fluid Mechanics Lab Manual 1565646222Document129 pagesApplied Fluid Mechanics Lab Manual 1565646222Matamoros De La Cruz JorgeNo ratings yet

- 07a70102 Finite Element Methods in Civil EngineeringDocument10 pages07a70102 Finite Element Methods in Civil EngineeringSamiullah MohammedNo ratings yet

- Discussion On Spin Prediction TechniquesDocument51 pagesDiscussion On Spin Prediction TechniquesShoaib JavedNo ratings yet

- Newton' S Laws: ©2008 by W.H. Freeman and CompanyDocument44 pagesNewton' S Laws: ©2008 by W.H. Freeman and CompanyHind AldahmaniNo ratings yet

- Transiting Quasites As A Possible TechnosignatureDocument3 pagesTransiting Quasites As A Possible TechnosignatureSangat BaikNo ratings yet

- Lab Guide - Kaplan TurbineDocument55 pagesLab Guide - Kaplan TurbineBonifacioNo ratings yet

- Physics Unit 1 Paper 2 May June 2015Document22 pagesPhysics Unit 1 Paper 2 May June 2015John SmithNo ratings yet

- Lecture Jan22 ForstudentsDocument24 pagesLecture Jan22 ForstudentsHimanshu KatheriaNo ratings yet

- PHY 1 Mod 09 Mod (Collision)Document9 pagesPHY 1 Mod 09 Mod (Collision)Shamim ImtiazNo ratings yet

- A8 - Explicit Nonlinear Analysis (Analyst) PDFDocument23 pagesA8 - Explicit Nonlinear Analysis (Analyst) PDFTomoyuki TadaNo ratings yet

- Mechanics of Machines II ExamsDocument2 pagesMechanics of Machines II ExamsCharles OndiekiNo ratings yet