Professional Documents

Culture Documents

2 Deflection Calculation (Main)

Uploaded by

OkeymanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 Deflection Calculation (Main)

Uploaded by

OkeymanCopyright:

Available Formats

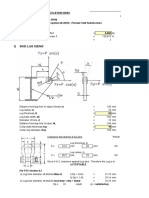

DEFLECTION CALCULATION FOR THE UQUO-IKIOT ABASI GAS PIPELINE LOWERING AUGUST 2013

Original Pipe Level

ѳ

X

Lowered Level

L1 L1

L1 = Transition Length

Where GAS = 0.60 and OIL = 0.72 ANSI B 31.4 (oil) or 31.8 (Gas)

P=(2St/D)*F*E*T

S SMYS 5,200 psi

t Wall thickness, in 0.50

D OD, in 18

F Design Factor 0.6

E Efficiency 1

T Temp Derating 1

P Maximum Pressure 173.33 psi

Maximum Allowable Stress 3,120 psi

Material Prorperties of Pipeline

Outside Diameter of Pipe, inches = 18

Corrossion Coat Thickness, inches = 0.50

Density of Asphalt enamel Coating 1400kg/m3

Pipe Material = API 5L X52

Wall Thickness, in = 0.5

Modulus of Elasticity, E = 30 x 106 psi

Moment of Inertia, I = 549.21in4

Factor of Safety, F = 0.72

Operating Pressure, P= 450 psi

Yield Strenght of Pipe Material = 30X106 psi

Lowering Level of Pipeline X = 700mm

Length of Pipeline to be loweredc, L= 200m

Transition length for Pipeline relocation, L1= 100m

Note:

Allowable Stress, Sa = Min Yield Strength, S * Factor of Safety, F = 37,440PSI

Min Yield Strenght for Steel Piping API 5L X52, Grade A = 30x106 psi

The Stresses associated with the lowereing of the pipeline includes:

(1) Bending Stress ơb;

(2) Axial Stress due to pipe extension, ơa;

(3) Longitudinal Stress due to Internalơip;

Radius of Curvature = 1 L1 2 + X 2

(Steel Buckling) X 2 2

(a) Bending Stress ơb = 2EXD

L12

Where L1 = 100m= 328.084ft

X = 700mm = 2.3 ft

ơb = 2x30x106 X 2.3 x 12 x 18 = 1923psi

(328.084x12)

(b) Axial Stress due to pipe extension ơa = 8 X 2

3 2 L1

6

ơa = 8 2.3x12 2 x 30x10 = 983psi

3 2x 328.08x12

© Longitudinal Stress due to Internal Pressure ơip

ơip = PD

4t

450 x 18 = 4,050 psi

4 x 0.5

EVOMEC GLOBAL SERVICES LIMITED

DEFLECTION CALCULATION FOR THE UQUO-IKIOT ABASI GAS PIPELINE LOWERING AUGUST 2013

The combined stress resulting from operation and displacement of the pipeline

would be;

ơ = ơb + ơa + ơip

= 1923 + 983 + 4050

6956 psi which is less than the minimum yield stress of AP52 GradeA

30x106

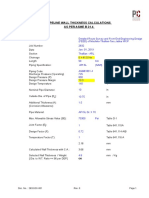

Radius of Curvature Computaton for 0.7m (2.3ft)

Radius of Curvature for the transition arcs is given by the relationship

Rc = 1 328.084x12 2 + 2.3x12 2 = 140405.74ft (3566.3m)

2.3x12 2 2

x = 1.0m(3.28ft) Rc = 3566.49m(11701.1ft)

x = 1.3m(4.26ft) Rc = 3566.7m(11701.9ft)

x = 1.6m(5.25ft) Rc = 3567m(11702.9ft)

X = 1.9m(6.23ft) Rc = 3567.4(11704.13ft)

X = 2.2m(7.21ft) Rc = 3567.86(11705.56ft)

Recommendations:

1 Upon comparing the combined stress as calculated, with the Minimum

Yield Stress for API 5L X52, Grade A , it shows that lowering the pipeline

to the proposed depth of 0.7m is completely safe. With reference to the

table below, a depth of 2.2m is still within the allowable limit.

REFERENCE:

API 5L Line Pipes Physical Prorperties

ASME B31.3 Process Piping 1996

ASME B31.8 Transportation and Distribution of Piping System

EVOMEC GLOBAL SERVICES LIMITED

DEFLECTION CALCULATION FOR THE UQUO-IKIOT ABASI GAS PIPELINE LOWERING AUGUST 2013

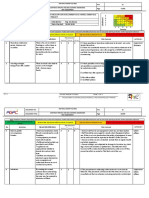

See Table for Technical Parameters

Bending

Lowering Half Horizontal Curved Elongatio Stresses(ps Hoop Combined Factor of

Height(m) Drop(m) CosAA(Radians) A (Degrees) Length(m) Length(m) n(m) i) Stress(psi) Stress(psi) Safety Radius(m)

0.7 0.35 1 0.00699 0.4 200 200.052 0.052 1,923 13,500 6,956 10.84% 3566.3

1 0.5 1 0.00999 0.57 200 200.052 0.052 2,743 13,500 8,792 8.56% 3566.49

1.3 0.65 0.9999 0.01299 0.74 200 200.052 0.052 3,562 13,500 10,984 7.07% 3566.7

1.6 0.8 0.9999 0.01599 0.92 200 200.052 0.052 4,388 13,500 13,555 6.03% 3567

1.9 0.95 0.9998 0.01899 1.09 200 200.052 0.052 5,211 13,500 16,477 5.25% 3567.4

2.2 1.1 0.9998 0.02199 1.26 200 200.052 0.052 6,034 13,500 19,759 4.65% 3567.86

EVOMEC GLOBAL SERVICES LIMITED

You might also like

- McDes1 Review Sample Problems - Pressure Vessel - Springs - FLywheelDocument20 pagesMcDes1 Review Sample Problems - Pressure Vessel - Springs - FLywheelAngeloTomalon100% (3)

- 5.a. Piping Fabrication PlanDocument15 pages5.a. Piping Fabrication PlanOkeyman100% (5)

- Design of MS Pipe Wall Thickness - Guwahati C 01Document6 pagesDesign of MS Pipe Wall Thickness - Guwahati C 01rvsingh17gmailcom100% (1)

- FRP Vessel Calc Asme RTP 1Document7 pagesFRP Vessel Calc Asme RTP 1GautamNo ratings yet

- Pile Stick Up LengthDocument16 pagesPile Stick Up LengthSai Sushank100% (1)

- Pile Rebar DesignDocument4 pagesPile Rebar DesignprakashNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Section C-3a - Fibre Optic Cable Installation Method StatementDocument16 pagesSection C-3a - Fibre Optic Cable Installation Method StatementOkeymanNo ratings yet

- Attachment 2. Execution Methodology OTUMARA Piling PDFDocument83 pagesAttachment 2. Execution Methodology OTUMARA Piling PDFOkeyman100% (1)

- Jacobians Functional Dependence Solved ProblemsDocument6 pagesJacobians Functional Dependence Solved ProblemsShubham100% (5)

- Astm C365-00Document3 pagesAstm C365-00Nasos MasourasNo ratings yet

- Inspire Cast FinalDocument195 pagesInspire Cast Finalamele25100% (1)

- LQ-Skirt Pile Stick Up CalsDocument12 pagesLQ-Skirt Pile Stick Up CalsSai SushankNo ratings yet

- Pan To Dynamics 110721Document65 pagesPan To Dynamics 110721Prof. TRDNo ratings yet

- RCC - Design Excel SheetDocument10 pagesRCC - Design Excel SheetYashas KatugamNo ratings yet

- Bridge BoxSectionDocument12 pagesBridge BoxSectionAgnichandra SubediNo ratings yet

- Mechanics of Materials Chap 08-02Document22 pagesMechanics of Materials Chap 08-02Melissa LaraNo ratings yet

- Mold Design Fundamental Calculation BATTERY COVERDocument7 pagesMold Design Fundamental Calculation BATTERY COVERrgrao85No ratings yet

- VSL CalDocument50 pagesVSL CalEmrahCayboyluNo ratings yet

- DesignDocument34 pagesDesignAbhay SuwalNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Pipe Support2of 5Document1 pagePipe Support2of 5Anonymous fLgaidVBhz100% (1)

- Api - 650 2008Document27 pagesApi - 650 2008WinsonLimHuiWahNo ratings yet

- Bab V Tugas Khusus: Gambar 5.1. Pompa Solar (P-201)Document5 pagesBab V Tugas Khusus: Gambar 5.1. Pompa Solar (P-201)Vayef FahraziNo ratings yet

- Annexure-2 (Section Design Calcs)Document107 pagesAnnexure-2 (Section Design Calcs)blisscutest beagleNo ratings yet

- Lift Calculation DemoDocument4 pagesLift Calculation Demoa_toups0% (1)

- 44.lifting Lug With Collar CalculationDocument44 pages44.lifting Lug With Collar CalculationAnonymous AyDvqg100% (1)

- Steel Section AISC360-10Document4 pagesSteel Section AISC360-10osman_sultan100% (1)

- Input EchoDocument6 pagesInput EchohgagNo ratings yet

- Design of Two Way Slab Modified 2Document12 pagesDesign of Two Way Slab Modified 2karthik_iitNo ratings yet

- Type Iv Aashto I - Girder Design Calculations: Garcia College of TechnologyDocument7 pagesType Iv Aashto I - Girder Design Calculations: Garcia College of TechnologyUnknown Engr.No ratings yet

- Torispherical HeadDocument5 pagesTorispherical HeadLiaquat AliNo ratings yet

- General Criteria For Design Steel StructureDocument12 pagesGeneral Criteria For Design Steel StructureSurat WaritNo ratings yet

- Corbel DesignDocument14 pagesCorbel Designnavneet3bawaNo ratings yet

- Foundation Design - 5110-P-001ABC - Rev 0Document11 pagesFoundation Design - 5110-P-001ABC - Rev 0Yatendra TyagiNo ratings yet

- PIPECALC ASME B31.4 - Rev 2Document24 pagesPIPECALC ASME B31.4 - Rev 2Mohsin RazaNo ratings yet

- Initial Load Test Pile-Calc (450 MM) Rev0Document2 pagesInitial Load Test Pile-Calc (450 MM) Rev0sathishNo ratings yet

- Laporan Tugas 3: Wellbore Performance: Mata Kuliah: Teknik Produksi (PE3103)Document6 pagesLaporan Tugas 3: Wellbore Performance: Mata Kuliah: Teknik Produksi (PE3103)Vini Nandi RahmaNo ratings yet

- Design of PierDocument18 pagesDesign of PierMrinal kayalNo ratings yet

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNo ratings yet

- Homework 3Document4 pagesHomework 3Lou GNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)stalin_83No ratings yet

- Upheaval Buckling CalculationDocument10 pagesUpheaval Buckling CalculationMoustafa Fares100% (1)

- KNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectDocument32 pagesKNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectrichardchiamNo ratings yet

- 10 Design of End AnchorageDocument2 pages10 Design of End AnchorageSulabh GuptaNo ratings yet

- AS 3600-2018 PT-SL Example 001Document6 pagesAS 3600-2018 PT-SL Example 001Aashu chaudharyNo ratings yet

- Solar 2x2 PDFDocument25 pagesSolar 2x2 PDFSurat Warit0% (1)

- CO2 Condenser 02-03-2023-15 PMDocument37 pagesCO2 Condenser 02-03-2023-15 PMahmad santosoNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Ricardo Paz SoldanNo ratings yet

- Tema Nozzle LoadDocument4 pagesTema Nozzle LoadkanhuNo ratings yet

- REPORT (3) - MergedDocument29 pagesREPORT (3) - MergedMoustafaNo ratings yet

- Fire Piping Astm A135Document2 pagesFire Piping Astm A135sinahimsNo ratings yet

- Slury Sump Calculation ReportDocument2 pagesSlury Sump Calculation ReportHasan arif KısaalioğluNo ratings yet

- Wedge Plate 6819M Stress Analysis ReportDocument13 pagesWedge Plate 6819M Stress Analysis ReportLavender HoneyNo ratings yet

- Column DesignDocument14 pagesColumn DesignAkash paudelNo ratings yet

- KAMC-CW Calc.Document45 pagesKAMC-CW Calc.MoustafaNo ratings yet

- The Dubai Chamber of Commerce and Industry Building ExtensionDocument22 pagesThe Dubai Chamber of Commerce and Industry Building ExtensionAhammad KabeerNo ratings yet

- Baffle Design - by MossDocument6 pagesBaffle Design - by MossshaishavNo ratings yet

- 11 TrunnionDocument21 pages11 TrunnionMitul PatelNo ratings yet

- PAEC2017 - Slab On Grade InvestigationDocument2 pagesPAEC2017 - Slab On Grade InvestigationSayavi Nicole Sayavi NickNo ratings yet

- Laporan MagangDocument17 pagesLaporan MagangBagaswara RamadhanNo ratings yet

- Design Data: Hostel Building Kaaf Uni Danniel Pascal StairDocument5 pagesDesign Data: Hostel Building Kaaf Uni Danniel Pascal StairDENCONo ratings yet

- Square Blind Flange With Stiffener ULDocument5 pagesSquare Blind Flange With Stiffener ULjoeriji100% (1)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsFrom EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNo ratings yet

- Section D - Engineering PlanDocument26 pagesSection D - Engineering PlanOkeymanNo ratings yet

- Uzu Sedo Gen Cw348814 00002 - r01 - Planning ProcedureDocument10 pagesUzu Sedo Gen Cw348814 00002 - r01 - Planning ProcedureOkeymanNo ratings yet

- AGP DNL ANOGP D14 0001method Statement For Installation of Chain Link Fence Rev 0Document16 pagesAGP DNL ANOGP D14 0001method Statement For Installation of Chain Link Fence Rev 0OkeymanNo ratings yet

- Uzu-Sedo-Gen - Cw348814-00003 - r01 - Progress Measurement and Reporting ProcedureDocument11 pagesUzu-Sedo-Gen - Cw348814-00003 - r01 - Progress Measurement and Reporting ProcedureOkeyman0% (1)

- AGP-DNL-ANOGP-F12-0001 Contract Specific HSSE Risk Control MeasuresDocument4 pagesAGP-DNL-ANOGP-F12-0001 Contract Specific HSSE Risk Control MeasuresOkeymanNo ratings yet

- Audit Reports - Register: Nigerian Westminster Dredging and Marine LimitedDocument4 pagesAudit Reports - Register: Nigerian Westminster Dredging and Marine LimitedOkeyman100% (1)

- Uzu With CPF Upgrade - Construction Execution PlanDocument46 pagesUzu With CPF Upgrade - Construction Execution PlanOkeymanNo ratings yet

- Gbaran PKG 1 Schedule FinalDocument2 pagesGbaran PKG 1 Schedule FinalOkeymanNo ratings yet

- Section C-3a - Cathodic Protection Installation Method StatementDocument18 pagesSection C-3a - Cathodic Protection Installation Method StatementOkeymanNo ratings yet

- Boiler Commissioning Procedure1Document62 pagesBoiler Commissioning Procedure1Okeyman100% (1)

- Uzu With CPF Upgrade - Interface Management PlanDocument20 pagesUzu With CPF Upgrade - Interface Management PlanOkeymanNo ratings yet

- HSE PlanDocument42 pagesHSE PlanOkeymanNo ratings yet

- Lifting & Hoisting Procedure - (GEN - AS - E - ) - 85874-G04-00010Document18 pagesLifting & Hoisting Procedure - (GEN - AS - E - ) - 85874-G04-00010OkeymanNo ratings yet

- SP53-1074.19.01 Audit Planning Schedule ListDocument4 pagesSP53-1074.19.01 Audit Planning Schedule ListOkeymanNo ratings yet

- Audit Report - Form: Nigerian Westminster Dredging and Marine LimitedDocument4 pagesAudit Report - Form: Nigerian Westminster Dredging and Marine LimitedOkeymanNo ratings yet

- Flushing and Hydrotest Procedure Rev 0Document10 pagesFlushing and Hydrotest Procedure Rev 0OkeymanNo ratings yet

- N L N G Preloading and Soil Monitoring P R o J e C T AUDITDocument1 pageN L N G Preloading and Soil Monitoring P R o J e C T AUDITOkeymanNo ratings yet

- Job Haxard Identification IaDocument10 pagesJob Haxard Identification IaOkeymanNo ratings yet

- Acpml Plant Fire Fighting PhilosophyDocument14 pagesAcpml Plant Fire Fighting PhilosophyOkeymanNo ratings yet

- Lifting - Stacking Procedure & Site PleanDocument20 pagesLifting - Stacking Procedure & Site PleanOkeymanNo ratings yet

- Project Quality System Procedure: Audit: Nigerian Westminster Dredging and Marine LimitedDocument9 pagesProject Quality System Procedure: Audit: Nigerian Westminster Dredging and Marine LimitedOkeymanNo ratings yet

- Seminar On Building Social Business PDFDocument15 pagesSeminar On Building Social Business PDFOkeymanNo ratings yet

- 2010 Workshop Wave Propagation Theory and The Testing of Deep FoundationsDocument22 pages2010 Workshop Wave Propagation Theory and The Testing of Deep Foundationsatac101No ratings yet

- Work Specific Health Management Gp-Abalas - Heal-001Document16 pagesWork Specific Health Management Gp-Abalas - Heal-001OkeymanNo ratings yet

- HARCON Profile CivilDocument19 pagesHARCON Profile CivilOkeymanNo ratings yet

- HSE Plan (Painting Project) PDFDocument42 pagesHSE Plan (Painting Project) PDFOkeymanNo ratings yet

- Steel Beam BracketDocument10 pagesSteel Beam BracketMohammed AyeshNo ratings yet

- Jsfa 6501Document8 pagesJsfa 6501FranklynElardNo ratings yet

- Fundamentals of Ultrasonic Phased Arrays - 171-180Document10 pagesFundamentals of Ultrasonic Phased Arrays - 171-180Kevin HuangNo ratings yet

- D38999/24WD35S N D38999/20WB35S N D38999/24WB35S N D38999/26WB35P N D38999/26WC35P NDocument49 pagesD38999/24WD35S N D38999/20WB35S N D38999/24WB35S N D38999/26WB35P N D38999/26WC35P NsdfsdfNo ratings yet

- Mathmatics and Physics 1 (Versie 7 Okt 2019) PDFDocument250 pagesMathmatics and Physics 1 (Versie 7 Okt 2019) PDFŁukasz MorozNo ratings yet

- SPM Phy Quantity of Heat IDocument13 pagesSPM Phy Quantity of Heat ICHINEMEREM EZEHNo ratings yet

- Edited and Compiled By: Haramaya University College of Natural and Computational Sciences Department of ChemistryDocument158 pagesEdited and Compiled By: Haramaya University College of Natural and Computational Sciences Department of Chemistrygetaneh achenifNo ratings yet

- Engeneering Notebook 2019-20Document39 pagesEngeneering Notebook 2019-20api-478966175No ratings yet

- Design of Structural Steel Pipe Racks PDFDocument12 pagesDesign of Structural Steel Pipe Racks PDFmobin1978100% (3)

- ps11 9Document11 pagesps11 9frak ksaNo ratings yet

- PowerLogic ION8650 - M8650A0C0H5E1B0ADocument4 pagesPowerLogic ION8650 - M8650A0C0H5E1B0AKevin GurungNo ratings yet

- Heidenhain ISO G CodesDocument7 pagesHeidenhain ISO G CodesZsolt HajduNo ratings yet

- New Radar Technology 8 500-10 500 MHZ BandDocument18 pagesNew Radar Technology 8 500-10 500 MHZ BandChinmaya_Mishr_4215No ratings yet

- MD Product Catalogue PROXIMITY ENGDocument194 pagesMD Product Catalogue PROXIMITY ENGETIENNENo ratings yet

- Hempadur 15130Document2 pagesHempadur 15130MuthuKumarNo ratings yet

- Maths-1b Imp (Chaitanya)Document35 pagesMaths-1b Imp (Chaitanya)goudjay808100% (1)

- HK MalikDocument840 pagesHK MalikHarsan Singh100% (1)

- Lab 3Document19 pagesLab 3Nosheen AliNo ratings yet

- Problems - Module 5Document7 pagesProblems - Module 5Tanvir Rajib 191-47-234No ratings yet

- Thumb Rules - Xls For Chemical EngineerDocument46 pagesThumb Rules - Xls For Chemical EngineerAnuj KaliyerNo ratings yet

- Objective PhysicsDocument4 pagesObjective PhysicsleoyodapieNo ratings yet

- Assignment No. 4 - 2020-21 PDFDocument2 pagesAssignment No. 4 - 2020-21 PDFnikhil khanwaniNo ratings yet

- Lesson 8 Shear or Diagonal Tension in RC BeamsDocument8 pagesLesson 8 Shear or Diagonal Tension in RC BeamsJoshua John JulioNo ratings yet

- RTV Silicone Rubber CoatingDocument7 pagesRTV Silicone Rubber CoatingJane ChatsiriphatthanaNo ratings yet

- CBSE Class 12 Maths Question Paper Solution 2020 Set 65-1-1Document12 pagesCBSE Class 12 Maths Question Paper Solution 2020 Set 65-1-1SA EED100% (1)

- Physics Notes For Class 12 Chapter 8 and 15 Electromagnetic Waves and Communicationommunication SystemsystemsDocument13 pagesPhysics Notes For Class 12 Chapter 8 and 15 Electromagnetic Waves and Communicationommunication SystemsystemsJaseela NaufalNo ratings yet

- O.M. - 14.0 - BT1000 - BT1500 - BT2000 Plus - BT3000 - Plus - BT3500 PDFDocument280 pagesO.M. - 14.0 - BT1000 - BT1500 - BT2000 Plus - BT3000 - Plus - BT3500 PDFmessaoud_fethi80% (10)