Professional Documents

Culture Documents

BB Rapidist-4 DataSheet e

BB Rapidist-4 DataSheet e

Uploaded by

Nicolae VisanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BB Rapidist-4 DataSheet e

BB Rapidist-4 DataSheet e

Uploaded by

Nicolae VisanCopyright:

Available Formats

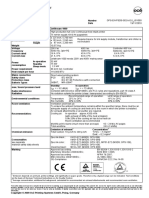

rapiDist-4 Process Analyzer

Sample

Quality filtered 50 µm, no suspended water, bubble-free

Consumption 20 to 40 l/h

Pressure at inlet 1 to 3 bar (14.5 to 43 psi)

Temperature at inlet max. +50 °C (+122 °F)

Temperature change max. 1K/min.

Viscosity max. 37 cSt at inlet temperature

Utilities

Instrument air

Consumption - Purge 8 Nm³/h while purging Ex p (12 mins)

approx. 1 Nm³/h (normal operation)

approx. 1.5 Nm³/h at 6 bar,

optional nitrogen generator is used

approx. 0.1 Nm³/h for purging Ex d

Explosion protection

(for gasoline application)

Marking ATEX II 2G IIC T4 Gb + oder -??? 5 bis 50 Nm³/h optional “Vortex“

Marking Pressure at inlet 5 to 7 bar (72 to 101.5 psi)

NEC 500 Class I, Div. 2, Group B,C, or D, T3 or T4 Quality humidity class 2 or better acc. to ISO8573.1

NEC 505 Class I, Zone 1, Coolant Plant water or integrated FKS 1.4 KWS

with Chiller: AEx d e ib mb px IIB+H2 T3 or T4 Consumption use of plant water: 20 to 40 l/h

without Chiller: AEx d e ib px IIB+H2 T4

Pressure at inlet plant water: 1 to 3 bar

CEC section 18 with Chiller: Ex d e ib mb px IIB+H2 T3 or T4 Temperature plant water: -5 °C to +40 °C; ± 0.5 K

without Chiller: Ex d e ib px IIB+H2 T4

Quality filtered 50 μm, pH 6 to 8

Certification pending

Analog outputs max. 8 outputs 4 to 20 mA, (max. resistance

Other approvals and certificates, see www.bartec.de 1000 Ω), active isolated on request

Analog inputs 4 to 20 mA, 160 Ω

Technical data Digital outputs DC 24 V; max. 0.5 A; sum alarm

Technology distillation Ready/Come-Read, Power identification

Method correlates with: Validation identification, Analysis Cycle Active

ASTM D86, DIN EN ISO 3405, IP 123 Digital inputs high: DC 15 to 28 V; low: DC 0 to 4 V

Measuring range +20 °C to +400 °C (+68 °F to +752 °F) (max. 3 configurable Reset, Inhibit, Stream request, Validation request,

Repeatability ≤ DIN EN/ASTM D86 inputs) Decoking request, Automatic stream switching,

Reproducibility ≤ DIN EN/ASTM D86 Electrical data of signal outputs and inputs

Measuring cycle discontinuous, Control unit Central control unit Industrial PC

cycle time approx. 10 min for diesel Operating system Windows 7

cycle time approx. 15 min for gasoline Control software PACS

Product streams 2 x sample, 1 x validation HMI TFT display (multi-touch)

Display TFT display with touch function, 1024 x 768 pixel

Electrical data Keyboard virtual keyboard,

controlled via TFT display with touch function

Nominal voltage 230 VAC ± 10 %, 1 phase; 50 Hz/60 Hz

or 110 VAC +/- 10 %, 1 phase; 50 Hz/60 Hz Tube fittings Swagelok® 6 mm/12 mm/18 mm

with FKS 1,4-KWS other fittings on request

400 VAC +/- 10 %; 3 phase; 50 Hz/60 Hz Vent/Drain open to atmosphere

other ratings on request Dimensions (W x H x D) approx. 1150 x 1900 x 710 mm

Maximum approx. 700 W (analyzer only) Weight approx. 300 kg

power consumption incl. chiller for liquids: approx. 1600 W approx. 450 kg (incl. FKS 1.4-KWS)

Protection class IP 54 Space requirements right: 500 mm, left: 500 mm

Ambient temperature operation MODBUS interface MODBUS RTU/TCP (RS485, RS422, VDSL/FO

+5 °C to +40 °C (+41 °F to +104 °F) (IS) MODBUS/TCP via FOC is

storage Remote access remote software with modem, ISDN,

-20 °C to +60 °C (-4 °F to +140 °F) Ethernet via VDSL modem FO (FS)

Ambient humidity operation: 5 to 80 % , Sample line connections metric (6 mm/12 mm/18 mm)

03-0330-0919-08/2017-BBS-413684

relative humidity at +25 °C, non- corrosive Typ 6 mm

storage: 5 to 80 %, or imperial (1/4", ½", ¾")

relative humidity at +25 °C, non- corrosive Typ. ¼"

Important notice: rapiDist-4 is subject to continuous product improvement, specifications are preliminary and may be subject to change without notice.

If your technical data do not comply with existing data, please contact us for technical clarification.

BARTEC BENKE Phone: +49 40 72703-0 sales@bartec-benke.de www.bartec-benke.de

You might also like

- Periodontology - Periodontics Revisited, 1st Ed, Shalu BathlaDocument566 pagesPeriodontology - Periodontics Revisited, 1st Ed, Shalu BathlaWilan Dita Nesyia95% (19)

- Job Order Costing: Learning ObjectivesDocument50 pagesJob Order Costing: Learning ObjectivesTNo ratings yet

- PROBHeDocument7 pagesPROBHeFernando BatistaNo ratings yet

- Homework-1 Fall 2021Document1 pageHomework-1 Fall 2021Elif HalıcıNo ratings yet

- New NORMAL PUERPERIUMDocument21 pagesNew NORMAL PUERPERIUMvarshaNo ratings yet

- Finance Dissertation TopicsDocument2 pagesFinance Dissertation Topicsmonabiswas100% (1)

- Bartec Ibp AnalyserDocument2 pagesBartec Ibp AnalyserNishanth PillaiNo ratings yet

- BENKE RVP-4 - Datasheet Triple ExpansionDocument1 pageBENKE RVP-4 - Datasheet Triple ExpansionSadok KsirNo ratings yet

- Freeze/Cloud Point Process Analyzer FRP-4/CPA-4: Credible Solutions For The Oil and Gas IndustryDocument2 pagesFreeze/Cloud Point Process Analyzer FRP-4/CPA-4: Credible Solutions For The Oil and Gas IndustryNicolae VisanNo ratings yet

- APD72-D Automatic Dehydrator, 0.58 SCFM, 230V AC 50/60 HZDocument3 pagesAPD72-D Automatic Dehydrator, 0.58 SCFM, 230V AC 50/60 HZDaniel Hernando Buitrago NietoNo ratings yet

- APD72-D Automatic Dehydrator, 0.58 SCFM, 230V AC 50/60 HZDocument2 pagesAPD72-D Automatic Dehydrator, 0.58 SCFM, 230V AC 50/60 HZTrina Ritchell AquinoNo ratings yet

- ASL SA DSH013 Issue 1 EX 500Document2 pagesASL SA DSH013 Issue 1 EX 500Nwabuze IwunzeNo ratings yet

- Destilador AtmosfericoDocument4 pagesDestilador AtmosfericoWilliams MedinaNo ratings yet

- Valvula Proporcional Norgren Vp51Document1 pageValvula Proporcional Norgren Vp51Base SistemasNo ratings yet

- Valvula Proporcional Norgren Vp51Document1 pageValvula Proporcional Norgren Vp51Base SistemasNo ratings yet

- DE550016 BA 3 Select 01Document4 pagesDE550016 BA 3 Select 01seve1No ratings yet

- SONIMIX 2106: Best in Class Gas Mixer With The Unique Sonic Nozzle TechnologyDocument2 pagesSONIMIX 2106: Best in Class Gas Mixer With The Unique Sonic Nozzle TechnologyДмитрий ТарасенкоNo ratings yet

- THC8000Document2 pagesTHC8000kanaf11943No ratings yet

- Ops en Psds 002 Eu Js1000Document1 pageOps en Psds 002 Eu Js1000mana1345No ratings yet

- PROBHe MDocument7 pagesPROBHe MFernando BatistaNo ratings yet

- VariostatDocument2 pagesVariostatletphuongNo ratings yet

- Rail Gas Injector - Ig7 DakotaDocument10 pagesRail Gas Injector - Ig7 DakotaChristian Arias MontoroNo ratings yet

- Endress-Hauser Proline Prosonic Flow B 200 9B2B enDocument4 pagesEndress-Hauser Proline Prosonic Flow B 200 9B2B enAdrianus AjaNo ratings yet

- 140 Failsafe Series Current To Pressure, (I/P) Electronic ConverterDocument3 pages140 Failsafe Series Current To Pressure, (I/P) Electronic ConvertermohamedNo ratings yet

- Karcher HDS 1195-4 S Eco EngleskiDocument1 pageKarcher HDS 1195-4 S Eco EngleskivjakovljevicNo ratings yet

- Bluesolution-Hydratron Trykkpumpe 1240barDocument2 pagesBluesolution-Hydratron Trykkpumpe 1240barcacalot93No ratings yet

- Product Bulletin Fisher 846 Electro Pneumatic Transducer en 135686 PDFDocument12 pagesProduct Bulletin Fisher 846 Electro Pneumatic Transducer en 135686 PDFJesus RochaNo ratings yet

- EPI MP8840 DetailsDocument7 pagesEPI MP8840 DetailsAhsan HaseebNo ratings yet

- Dust Collector KOMPACDocument7 pagesDust Collector KOMPACHùng ThanhNo ratings yet

- Weputanew in Vent: Introducing The Ivent201 MriDocument2 pagesWeputanew in Vent: Introducing The Ivent201 MriArtem 521No ratings yet

- Fluidcontrol Unit Fcu 2000 Series: Description Technical DetailsDocument4 pagesFluidcontrol Unit Fcu 2000 Series: Description Technical Detailsjulya julyaNo ratings yet

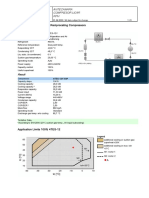

- Compresor 4tes-12 R507a t0 - 8 TC 45 AntecamaraDocument5 pagesCompresor 4tes-12 R507a t0 - 8 TC 45 AntecamaraArturo 1No ratings yet

- Differential Pressure Transmitter in Cleanroom-Conform Panel DesignDocument4 pagesDifferential Pressure Transmitter in Cleanroom-Conform Panel DesignengenheiroalencarNo ratings yet

- Valvula Proporcional Norgren Vp50sDocument1 pageValvula Proporcional Norgren Vp50sBase SistemasNo ratings yet

- Selection: Semi-Hermetic Reciprocating Compressors: Input ValuesDocument4 pagesSelection: Semi-Hermetic Reciprocating Compressors: Input ValuesFERNANDO RECALDENo ratings yet

- Horiba Apha-370: THC-Immission MonitorDocument2 pagesHoriba Apha-370: THC-Immission MonitorWhite MirageNo ratings yet

- GL50AA1Document4 pagesGL50AA1أبو زينب المهندسNo ratings yet

- Kion C11 / Kion C22: Evacuation & Refrigerant Charging Equipment For Flammable GasesDocument6 pagesKion C11 / Kion C22: Evacuation & Refrigerant Charging Equipment For Flammable GasesSylvain AguedaNo ratings yet

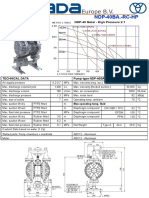

- Ndp-40ba.-Rc-Hp Data PDFDocument1 pageNdp-40ba.-Rc-Hp Data PDFпетро федорівNo ratings yet

- AX900 - Specification V1.2 2020.2.1Document6 pagesAX900 - Specification V1.2 2020.2.1AndresNo ratings yet

- LH135-4PES-15 R404A t0 - 25 Tamb 43Document4 pagesLH135-4PES-15 R404A t0 - 25 Tamb 43Bashir SalimNo ratings yet

- Orifice Plate Flowmeter: Rosemount IncDocument1 pageOrifice Plate Flowmeter: Rosemount IncJulian Camilo Segura BermudezNo ratings yet

- 1.1. SigDocument4 pages1.1. SigSaumik ShuvoNo ratings yet

- Comen A7 Anesthesia MachineDocument6 pagesComen A7 Anesthesia MachineNico Jr. NabuaNo ratings yet

- Endress-Hauser Proline Prowirl R 200 7R2C PTDocument12 pagesEndress-Hauser Proline Prowirl R 200 7R2C PTJoão PauloNo ratings yet

- Quotation: Hangzhou Rui Ya Electrical Appliance Co.,LtdDocument1 pageQuotation: Hangzhou Rui Ya Electrical Appliance Co.,Ltdruhy690No ratings yet

- Endress-Hauser Proline Prosonic Flow B 200 9B2B NLDocument4 pagesEndress-Hauser Proline Prosonic Flow B 200 9B2B NLZS MarolentoNo ratings yet

- AX800 - Specification V 1.2 2020.2.1Document6 pagesAX800 - Specification V 1.2 2020.2.1AndresNo ratings yet

- Valvula Proporcional Norgren 101xDocument2 pagesValvula Proporcional Norgren 101xBase SistemasNo ratings yet

- Level Switch: Up To 4 Switching Outputs Up To 2 Analogue Outputs Optional Temperature MeasurementDocument4 pagesLevel Switch: Up To 4 Switching Outputs Up To 2 Analogue Outputs Optional Temperature MeasurementAitziber Urdangarain OteguiNo ratings yet

- Model 51i Total Hydrocarbon Analyzer: Flame Ionization For The Detection of Total HydrocarbonDocument2 pagesModel 51i Total Hydrocarbon Analyzer: Flame Ionization For The Detection of Total HydrocarbonAnjang YudistriNo ratings yet

- Compreso 4ves-10 R507a t0 - 8 TC 45 Cuarto 0cDocument5 pagesCompreso 4ves-10 R507a t0 - 8 TC 45 Cuarto 0cArturo 1No ratings yet

- DatasheetDocument3 pagesDatasheetJohn UsaNo ratings yet

- Bitzer - 4GE-30-40P X 2comp - (1'C) - r407c - 070917 PDFDocument7 pagesBitzer - 4GE-30-40P X 2comp - (1'C) - r407c - 070917 PDFAgus CahyonoNo ratings yet

- SP4P2-B3: Proportional Pressure Reducing - Relieving Valve, Pilot OperatedDocument2 pagesSP4P2-B3: Proportional Pressure Reducing - Relieving Valve, Pilot OperatedДима ПолищукNo ratings yet

- Compressor SpecificationsDocument4 pagesCompressor Specificationsdaniyalahmad119No ratings yet

- Norgreen Ip Converter 140Document3 pagesNorgreen Ip Converter 140roxanaNo ratings yet

- Pressure Temperature Flow TrainerDocument3 pagesPressure Temperature Flow TrainerAli HadiNo ratings yet

- 3-Way Proportional Pressure Reducing Valve Spool Type, Direct-Acting UNF Cartridge - 350 BarDocument4 pages3-Way Proportional Pressure Reducing Valve Spool Type, Direct-Acting UNF Cartridge - 350 BarFloNo ratings yet

- Valvula Proporcional Norgren 140Document2 pagesValvula Proporcional Norgren 140Base SistemasNo ratings yet

- Orifice Plate ReportDocument1 pageOrifice Plate ReportdsdeNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Smart Manufacturing Solutions - Build Our Future With Digital TransformationDocument32 pagesSmart Manufacturing Solutions - Build Our Future With Digital TransformationNicolae VisanNo ratings yet

- Enclosures - Nuova ASPDocument156 pagesEnclosures - Nuova ASPNicolae VisanNo ratings yet

- Hawke Cable GlandsDocument48 pagesHawke Cable GlandsNicolae VisanNo ratings yet

- Digital Transformation in Process IndustriesDocument60 pagesDigital Transformation in Process IndustriesNicolae Visan100% (4)

- Viscosity Process Analyzer VISC-4Document4 pagesViscosity Process Analyzer VISC-4Nicolae VisanNo ratings yet

- Instrum Features: Hazardous Area ConnectorsDocument6 pagesInstrum Features: Hazardous Area ConnectorsNicolae VisanNo ratings yet

- Schuch Katalog 2016-17 LEDDocument119 pagesSchuch Katalog 2016-17 LEDNicolae VisanNo ratings yet

- FKS-CLM: Compact Air-Conditioning UnitDocument2 pagesFKS-CLM: Compact Air-Conditioning UnitNicolae VisanNo ratings yet

- Chromalox - Process Heater Systems PresentationDocument30 pagesChromalox - Process Heater Systems PresentationNicolae Visan100% (1)

- Freeze/Cloud Point Process Analyzer FRP-4/CPA-4: Credible Solutions For The Oil and Gas IndustryDocument2 pagesFreeze/Cloud Point Process Analyzer FRP-4/CPA-4: Credible Solutions For The Oil and Gas IndustryNicolae VisanNo ratings yet

- Turn-Key On-Line Analysis Systems Based On Spectroscopical Methods in The Near Infrared (NIR)Document14 pagesTurn-Key On-Line Analysis Systems Based On Spectroscopical Methods in The Near Infrared (NIR)Nicolae VisanNo ratings yet

- Schuch - Catalogue - Conventional LightingDocument208 pagesSchuch - Catalogue - Conventional LightingNicolae VisanNo ratings yet

- SIVACON S8 - Universal Mounting Design - 2017Document4 pagesSIVACON S8 - Universal Mounting Design - 2017Nicolae VisanNo ratings yet

- BB - Rapidist-4 Flyer - eDocument2 pagesBB - Rapidist-4 Flyer - eNicolae VisanNo ratings yet

- CEMS Group: Oil and Gas SolutionsDocument46 pagesCEMS Group: Oil and Gas SolutionsNicolae VisanNo ratings yet

- Electrical Safety Solutions enDocument244 pagesElectrical Safety Solutions enNicolae VisanNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFNicolae VisanNo ratings yet

- Try Out 2 SMK Tahun 2018/2019 Mapel Bahasa InggrisDocument10 pagesTry Out 2 SMK Tahun 2018/2019 Mapel Bahasa InggrisEvans Sii Jr.50% (2)

- Mercury (Element)Document15 pagesMercury (Element)zidaaanNo ratings yet

- Hubungan Tungau Debu Rumah Terhadap Angka Kejadian Rinitis Alergi Yang Berobat Di Poli THT Rsud Bangli TAHUN 2019Document12 pagesHubungan Tungau Debu Rumah Terhadap Angka Kejadian Rinitis Alergi Yang Berobat Di Poli THT Rsud Bangli TAHUN 2019RiskaaNo ratings yet

- Electrochemical CellDocument9 pagesElectrochemical CellchethanNo ratings yet

- Equipment Maintenance Filled UpDocument6 pagesEquipment Maintenance Filled UpShanto ChowdhuryNo ratings yet

- Early Development in BirdsDocument53 pagesEarly Development in BirdsMuqaddas NadeemNo ratings yet

- Sabino Rebagay Memorial High SchoolDocument7 pagesSabino Rebagay Memorial High SchoolRina RomanoNo ratings yet

- WC338 Weiler CatalogDocument16 pagesWC338 Weiler CatalogGerai AchazaNo ratings yet

- Perfume Accords (Leonard Payne) (Z-Library)Document277 pagesPerfume Accords (Leonard Payne) (Z-Library)longaeva91100% (1)

- Ts 6 Law Enforcement Training Catalog PDFDocument5 pagesTs 6 Law Enforcement Training Catalog PDFFelipe PalmaNo ratings yet

- Kuvarska TerminologijaDocument18 pagesKuvarska Terminologijas1a1s1k1aNo ratings yet

- 08chuyende2 - Timtudongnghia Trainghiabuoi5Document4 pages08chuyende2 - Timtudongnghia Trainghiabuoi5Nguyễn Tường Thảo MyNo ratings yet

- NLP-K Brochure - Neuro Linguistic Programming KinesiologyDocument2 pagesNLP-K Brochure - Neuro Linguistic Programming KinesiologyHomeschooling in IndiaNo ratings yet

- DairyDocument9 pagesDairyvikrantNo ratings yet

- CELLSDocument5 pagesCELLSJermaine CorpuzNo ratings yet

- 787 Walk 787-Walk 20120322 AllDocument91 pages787 Walk 787-Walk 20120322 Allapache9000No ratings yet

- Sci - What's The Science Behind This - Science & Math - 4chanDocument11 pagesSci - What's The Science Behind This - Science & Math - 4chanGeorge AryanitiNo ratings yet

- The Effect of Learning Styles On Academic Performance Among MMMC Student: A Cross Sectional StudyDocument11 pagesThe Effect of Learning Styles On Academic Performance Among MMMC Student: A Cross Sectional StudyRedz Der Tsar100% (2)

- Phyllodes Tumors of The Breast UpToDateDocument22 pagesPhyllodes Tumors of The Breast UpToDateSean SialanaNo ratings yet

- 2D Heat Transfer TutorialDocument180 pages2D Heat Transfer Tutorialsanojk_2000No ratings yet

- DA AO 8-SignedDocument24 pagesDA AO 8-SignedMaria Jezreel A. BernaldezNo ratings yet

- Novel Surgical Approach To AcalvariaDocument2 pagesNovel Surgical Approach To AcalvariaKezia Rachellea MustakimNo ratings yet

- NSO Level 1 Class 5 Question Paper 2019 Set B Part 2Document5 pagesNSO Level 1 Class 5 Question Paper 2019 Set B Part 2Anubhuti GhaiNo ratings yet

- Nitrogenous BasesDocument6 pagesNitrogenous BasesMaak Ali AnsariNo ratings yet

- Ayesha Amanat (Roll No. 48)Document4 pagesAyesha Amanat (Roll No. 48)Sikandar SaneenNo ratings yet