Professional Documents

Culture Documents

ERECTION METHOD STATEMENT Part 5

Uploaded by

joseph chewCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ERECTION METHOD STATEMENT Part 5

Uploaded by

joseph chewCopyright:

Available Formats

11.

3 ANCHOR BOLT TIGHTENNING

Anchor bolts shall be brought to a snug-tight

condition after the first tier is plumbed and the

columns are grouted .Snug tight is defined as the

tightness attained by the full effort of a man using

an ordinary typical spud wrench (see pictures).

Anchor bolts were applied 02 nuts with the nut

at the top called locked nut to avoid losing of nut

below.

Figure 1. Spud wrench

ERECTION METHOD STATEMENT rev01 Page : 26

11.4 CRANE RUNWAY BEAM ERECTION

Maximum Rate of

Item Description Tolerance

Change

¢ web

L=L+ L A = 3/8 “ 1/4 “/20’

Span L=L-A

A (Max) Theoretical

(Min) (A = 10cm) (6.3mm / 6m)

Support point span

(Typical)

¢ web B

B = 3/8 “ 1/4 “/20’

Straightness

(B= 10cm) (6.3mm / 6m)

Support point

(Typical) B

Theoretical ¢

Top beam for top running crane

Bottom of beam for under hung crane C

C = 3/8 “ 1/4 “/20’

Elevation

(C= 10cm) (6.3mm / 6m)

Support point

(Typical) Theoretical Height C

D

Beam to Beam D = 3/8 “ 1/4 “/20’

Top Running

(D=10cm) (6.3mm / 6m)

Top running

Beam to Beam E = 3/8 “ 1/4 “/20’

Under hung

(E= 10cm) (6.3mm / 6m)

Adjacent F = 1/8 “

NA

Beams

F (F =10cm)

Top running Under Hung

ERECTION METHOD STATEMENT rev01 Page : 27

11.5 APPENDIX 02 FRAME PLUMBING

B

11.5.1 By mean of Plumb bob

- As soon as all purlins, girts and eave struts have been

installed in the braced bay, it should be accurately

plumbed and squared to insure correct alignment of the

succeeding bays. This is accomplished by adjusting the

diagonal bracing and temporary bracing in the roof and

wall planes.

- With all the rods loosely installed, plumb the columns

of the rigid frame by tightening or loosening the nut on

the brace rods.

- Remember, when one brace rod is tightened, the other

rod must be loosened.

- When columns are plumb, sidewall brace rods should be A

finally tightened to a “TUT” condition.

- Dimension “B” must be the same as dimension “A” for Ridge

point

column to be plumb. See Fig. 1.

- The roof beams should be aligned in progression from

the eave to the ridge. Plumb the roof rafter at each

connection point and the ridge by tightening or

loosening the rods at those points. Plumb

bob

- Stretch a line across the flanges at the base of the

column. Drop a plumb bob from ridge point of the roof

rafter; adjust as necessary so that the plumb bob is in

line with line at base of columns. When this occurs the ridge is plumb. See fig. 2.

ERECTION METHOD STATEMENT rev01 Page : 28

11.5.2 By mean of Transit

- Locate Transit as shown

above.

- Make sure transit is

B absolutely level.

- Rotate transit until you get

the same exact tape reading

d at detail A&B. (Base of

column. Outside flange-see

detail).

A Transit

- Lock horizontal rotation of

location

Transit.

- Adjust rod bracing until the

tape reading at point a&b is

obtained at all points

indicated on above sketch

take all readings from the

same surface as “A” &

“B”equal (d).

ERECTION METHOD STATEMENT rev01 Page : 29

11.6 APENDIX 03 – ROD BRACING INSTALLATION

Brace rod/cable Rigid

with hillside frame

washer and nut

Wall Brace

rod

Roof Rafter

Wall brace detail at Haunch

Roof Brace rod Brace rod /cable with hillside

washer, flat washer & nut

Wall brace detail at roof rafter

Wall Brace rod

Brace rod with

Rigid hillside washer,

frame flat washer & nut

Hillside

washer

Brace rod/Cable

Cable Flange

Base Plate

Wall brace detail at column base

Figure 2 ROD BRACING INSTALLATION

ERECTION METHOD STATEMENT rev01 Page : 30

11.7 APENDIX 04 –RIGID FRAME DETAILS INSTALLATION

Eave Strut

Roof rafter

Roof rafter

Eave Strut Clip Roof rafter

High Strength

Bolts

Column

HAUNCH CONNECTION SPLICE CONNECTION

(Roof rafter to Column) (Between Roof rafters)

Column

Base Plate

BASE PLATE CONNECTION

(Column at Base)

Figure 3 RIGID FRAME DETAILS INSTALLATION

ERECTION METHOD STATEMENT rev01 Page : 31

12 REFERENCES

- AISC

- MBMA

ERECTION METHOD STATEMENT rev01 Page : 32

You might also like

- Practice Problems - ILD p0HnhAe Gfw7Ydy 4AQvyMpDocument9 pagesPractice Problems - ILD p0HnhAe Gfw7Ydy 4AQvyMpRitesh GaurNo ratings yet

- Retaining Wall - 8m With Traffic LoadDocument17 pagesRetaining Wall - 8m With Traffic LoadDev lamichhaneNo ratings yet

- Installation & Maintenance ManualDocument16 pagesInstallation & Maintenance ManualbryanshaoNo ratings yet

- Bearing Resistance OF Bolted Connections FOR Tubular Racking StructuresDocument10 pagesBearing Resistance OF Bolted Connections FOR Tubular Racking StructuresMassimo LatourNo ratings yet

- Baseplate MonorailDocument31 pagesBaseplate Monorailmohamad chandraNo ratings yet

- Steel Bridge Classification and ComponentsDocument29 pagesSteel Bridge Classification and ComponentsAbdulkhaliq AbdulyimahNo ratings yet

- Re-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionDocument4 pagesRe-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionMd. Hanif SanketNo ratings yet

- Manual: Engineering Calculation TemplateDocument8 pagesManual: Engineering Calculation TemplateHamiNo ratings yet

- Portal FrameDocument38 pagesPortal Framemohamed tarekNo ratings yet

- Ov Ed: Type 1 Masonry Support CalculationDocument12 pagesOv Ed: Type 1 Masonry Support Calculationshare4learnNo ratings yet

- Session 11 - Design of Steel ConnectionsDocument32 pagesSession 11 - Design of Steel Connectionsshan kumarNo ratings yet

- BS8110 Column DesignDocument11 pagesBS8110 Column DesignchaNo ratings yet

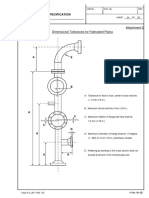

- Dimensional Tolerances of Fabricated PipesDocument1 pageDimensional Tolerances of Fabricated PipesMemed Permadi SatriyoNo ratings yet

- Capitulo 1-DDocument30 pagesCapitulo 1-DIranis E Lugo RodriguezNo ratings yet

- Ooc Opl Coo: 2. A. A) - :L - 1 - Fw/a ) B) - LDocument1 pageOoc Opl Coo: 2. A. A) - :L - 1 - Fw/a ) B) - LSean PamintuanNo ratings yet

- Column ConnectionDocument14 pagesColumn Connectionabhi aroteNo ratings yet

- FinElem Assign4 Energy&PlaneStress-1Document1 pageFinElem Assign4 Energy&PlaneStress-1Josue IñiguezNo ratings yet

- Load2: Analysis of Deck SlabDocument12 pagesLoad2: Analysis of Deck SlabJunaid100% (1)

- SMI-COMPOSITE Ver. 1.3Document13 pagesSMI-COMPOSITE Ver. 1.3JosHerreraVillalobosNo ratings yet

- Smi Steel Products Composite Castellated Beam Design ProgramDocument4 pagesSmi Steel Products Composite Castellated Beam Design ProgramSudip ShresthaNo ratings yet

- Base plate design calculations and stressesDocument29 pagesBase plate design calculations and stressessatyakamNo ratings yet

- College of Engineering & Computer Science Abu Dhabi UniversityDocument5 pagesCollege of Engineering & Computer Science Abu Dhabi UniversityAhmd MahmoudNo ratings yet

- Design of Square ColumnDocument4 pagesDesign of Square ColumnJm CampitanNo ratings yet

- Concrete Beam Haunch GuideDocument14 pagesConcrete Beam Haunch GuideraghuramsandeepNo ratings yet

- Reinforced Concrete T-Beam FormulasDocument9 pagesReinforced Concrete T-Beam Formulasjohn leo ramirezNo ratings yet

- Part 3Document14 pagesPart 3JOHNLEO RAMNo ratings yet

- 5.1-2 GA-A-MK3-7149003-R0-r1Document3 pages5.1-2 GA-A-MK3-7149003-R0-r1Hung NguyenNo ratings yet

- 2 CE133P Structural Elements (Robles) 2Document11 pages2 CE133P Structural Elements (Robles) 2chuck entocNo ratings yet

- Ov Ed: Type 1 M Asonry Support CalculationDocument12 pagesOv Ed: Type 1 M Asonry Support Calculationshare4learnNo ratings yet

- Lecture 10 (Shear and Moment Diagram, EtAl)Document29 pagesLecture 10 (Shear and Moment Diagram, EtAl)francisNo ratings yet

- Introduction to Strength of Materials ConceptsDocument38 pagesIntroduction to Strength of Materials ConceptsAlex JavierNo ratings yet

- SKS PILE punching check (final)Document3 pagesSKS PILE punching check (final)nileshNo ratings yet

- E TN CBD Aisc Asd89 008Document8 pagesE TN CBD Aisc Asd89 008Alvaro CalacioNo ratings yet

- UNIT NO. 5.5 Runway Beams With Cantilevers: Simple CantileverDocument8 pagesUNIT NO. 5.5 Runway Beams With Cantilevers: Simple CantileverYax ArogeNo ratings yet

- COLUMNASDocument10 pagesCOLUMNASRoger Geronimo Jiménez100% (1)

- Lecture On Strength of Materials 2014Document87 pagesLecture On Strength of Materials 2014BatsCrazy100% (1)

- Design of Rectangular Water Tanks Resting On Ground.Document5 pagesDesign of Rectangular Water Tanks Resting On Ground.ganesh.pg. GaniNo ratings yet

- Test Structural EngineerDocument17 pagesTest Structural EngineerkhaelNo ratings yet

- WWW - Manaresults.Co - In: Engineering MechanicsDocument2 pagesWWW - Manaresults.Co - In: Engineering MechanicsNoor IslamNo ratings yet

- UNIT NO. 6.5 Runway Beams With Cantilevers: Zero SlopeDocument6 pagesUNIT NO. 6.5 Runway Beams With Cantilevers: Zero SlopeAluosh AluoshNo ratings yet

- Counterfort Retaining Wall Design SummaryDocument48 pagesCounterfort Retaining Wall Design SummaryBhavanishankar ShettyNo ratings yet

- Patrones para Calzado Deportivo PDFDocument24 pagesPatrones para Calzado Deportivo PDFSonia Málaga Neira0% (1)

- Crane Beam DesignDocument13 pagesCrane Beam DesignMarcelo DelgadoNo ratings yet

- Counterfort Retaining Wall MCN PDFDocument12 pagesCounterfort Retaining Wall MCN PDFHoshear BakrNo ratings yet

- Column Base Plate DesignDocument1 pageColumn Base Plate DesignBunkun15No ratings yet

- Zadaca IptfDocument4 pagesZadaca IptfAmraNo ratings yet

- Broadband Circularly Polarized Spiral Antenna Array Using Sequentially Ritated TechniqueDocument8 pagesBroadband Circularly Polarized Spiral Antenna Array Using Sequentially Ritated TechniquerehanNo ratings yet

- Design Precast Boundary WallDocument70 pagesDesign Precast Boundary WallGajendra Bisht100% (2)

- Agitator Support DesignDocument3 pagesAgitator Support DesignSabir Nasim100% (2)

- Influence Lines For BeginnersDocument25 pagesInfluence Lines For BeginnersmeghlaNo ratings yet

- 19 T-Beam 01Document20 pages19 T-Beam 01S. M. ZAHIDUR RAHMAN 1301129No ratings yet

- Counterfort Wall - Stability and Toe SlabDocument26 pagesCounterfort Wall - Stability and Toe SlabGuransh Singh100% (1)

- S2 Slab Calculation PDFDocument1 pageS2 Slab Calculation PDFashishNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Handbook of Railroad Construction; For the use of American engineersFrom EverandHandbook of Railroad Construction; For the use of American engineersNo ratings yet

- ERECTION METHOD STATEMENT Part 1Document8 pagesERECTION METHOD STATEMENT Part 1joseph chewNo ratings yet

- ERECTION METHOD STATEMENT Part 4Document5 pagesERECTION METHOD STATEMENT Part 4joseph chewNo ratings yet

- ERECTION METHOD STATEMENT Part 2Document6 pagesERECTION METHOD STATEMENT Part 2joseph chewNo ratings yet

- Efficient Framing and Sheeting ErectionDocument6 pagesEfficient Framing and Sheeting Erectionjoseph chewNo ratings yet

- Pages From Term 1C & 3C PILC or XLPE 11 To 33 KV-3 PDFDocument2 pagesPages From Term 1C & 3C PILC or XLPE 11 To 33 KV-3 PDFjoseph chewNo ratings yet

- Pages From Term 1C & 3C PILC or XLPE 11 To 33 KV-4 PDFDocument1 pagePages From Term 1C & 3C PILC or XLPE 11 To 33 KV-4 PDFjoseph chewNo ratings yet

- 17Q3385324 - 20 - Dimension Drawing - (1HSA136-0487) PDFDocument1 page17Q3385324 - 20 - Dimension Drawing - (1HSA136-0487) PDFjoseph chewNo ratings yet

- Pages From Term 1C & 3C PILC or XLPE 11 To 33 KV PDFDocument1 pagePages From Term 1C & 3C PILC or XLPE 11 To 33 KV PDFjoseph chewNo ratings yet

- Pages From Term 1C & 3C PILC or XLPE 11 To 33 KV-2 PDFDocument2 pagesPages From Term 1C & 3C PILC or XLPE 11 To 33 KV-2 PDFjoseph chewNo ratings yet

- MS - Cable LayingDocument18 pagesMS - Cable Layingjoseph chewNo ratings yet

- Tightening Torques For Screws & BoltsDocument1 pageTightening Torques For Screws & Boltsjoseph chewNo ratings yet

- Tightening Torques For Screws & BoltsDocument1 pageTightening Torques For Screws & Boltsjoseph chewNo ratings yet

- Tray and Ladder Practice GuideDocument73 pagesTray and Ladder Practice GuidemariusrotaruNo ratings yet

- MS - Cable LayingDocument18 pagesMS - Cable Layingjoseph chewNo ratings yet

- Station Post Insulators CatalogDocument34 pagesStation Post Insulators CatalogJordan RileyNo ratings yet

- Rigid bus-bar fittings catalogueDocument38 pagesRigid bus-bar fittings catalogueabhi120783No ratings yet

- Effect of Shear Wall Location in Buildings Subjected To Seismic LoadsDocument11 pagesEffect of Shear Wall Location in Buildings Subjected To Seismic LoadsSujtth MathewNo ratings yet

- Ce522 - Introduction To LRFDDocument11 pagesCe522 - Introduction To LRFDPeter Adrian NgoNo ratings yet

- Ce 429st Pre-Final Exam - KeyDocument9 pagesCe 429st Pre-Final Exam - KeyAl-fin KaytingNo ratings yet

- CEN412 Slide2 - Stair and Overhead Water Tank DesignDocument30 pagesCEN412 Slide2 - Stair and Overhead Water Tank DesignEmran Hossain EmonNo ratings yet

- AR8501 Unit 2 MCQ: Steel Strength and Limit State Design PrinciplesDocument14 pagesAR8501 Unit 2 MCQ: Steel Strength and Limit State Design Principlessuresh kannanNo ratings yet

- GE Maintenance HangarDocument1 pageGE Maintenance HangarEden De GuzmanNo ratings yet

- Unit Running Meter: Taking Output 60 MDocument12 pagesUnit Running Meter: Taking Output 60 Mrami reddyNo ratings yet

- Foam Concrete: A Lightweight Building MaterialDocument36 pagesFoam Concrete: A Lightweight Building MaterialamitNo ratings yet

- Nehru Bridge Across River Tapti: Project Technical DetailsDocument2 pagesNehru Bridge Across River Tapti: Project Technical DetailsSagar GheewalaNo ratings yet

- Concrete Compression Test Report: 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150Document3 pagesConcrete Compression Test Report: 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150Okello StevenNo ratings yet

- Input: Design of Ties As Per BS 8110 Rw014 - Stone GroveDocument6 pagesInput: Design of Ties As Per BS 8110 Rw014 - Stone Grovethanigai veluNo ratings yet

- Deep Foundation TypesDocument20 pagesDeep Foundation TypesAlcohol You LaterNo ratings yet

- Rural Road Works RatesDocument87 pagesRural Road Works RatesRoopesh Chaudhary100% (1)

- RVT350Document26 pagesRVT350kcprazwalNo ratings yet

- 4.6 Pile Details and Retaining Wall Details (Ajay Kushwaha)Document1 page4.6 Pile Details and Retaining Wall Details (Ajay Kushwaha)AJAY KUSHWAHA PILLAI HOC COANo ratings yet

- Mr. Saifeldeen Alsmani Abdelkareem StructreDocument24 pagesMr. Saifeldeen Alsmani Abdelkareem StructretahaelnourNo ratings yet

- IRC-SP-51 - Load Testing of BridgesDocument11 pagesIRC-SP-51 - Load Testing of BridgesRamesh90% (20)

- Structural Strength Characteristics of Cement-Cassava Peel Ash Blended ConcreteDocument11 pagesStructural Strength Characteristics of Cement-Cassava Peel Ash Blended ConcreteMUSTAPHA SHEHU ABUBAKARNo ratings yet

- Is 456 2000-Withamend-3Document137 pagesIs 456 2000-Withamend-3Muhammad HasanNo ratings yet

- RCC Cantilever Slab DesignDocument1 pageRCC Cantilever Slab DesigndaxeshNo ratings yet

- TALAT Lecture 2710: Static Design ExampleDocument82 pagesTALAT Lecture 2710: Static Design ExampleCORE MaterialsNo ratings yet

- Boq of House Type 250m - Tikrit CityDocument4 pagesBoq of House Type 250m - Tikrit CityHasan NabeelNo ratings yet

- Design of RCC SlabsDocument7 pagesDesign of RCC SlabsprashmceNo ratings yet

- Member Requirement: Classification of Section For DuctilityDocument4 pagesMember Requirement: Classification of Section For DuctilityWilly SetiawanNo ratings yet

- GITC 4th Floor C N D Repairs BOQDocument4 pagesGITC 4th Floor C N D Repairs BOQAbhisheK MishrANo ratings yet

- Report Example ColumnDocument46 pagesReport Example ColumnvirgoknNo ratings yet

- Calculations ReducedDocument24 pagesCalculations ReducedMihnea CostacheNo ratings yet

- Floor Vibrations: Design For Walking ExcitationDocument18 pagesFloor Vibrations: Design For Walking ExcitationHattori HanzoNo ratings yet

- Design of Steel Shelter FinalDocument63 pagesDesign of Steel Shelter Finalalaa4altaie100% (2)

- Gps PillarDocument6 pagesGps PillarKosygin LeishangthemNo ratings yet