Professional Documents

Culture Documents

Design of Square Column

Uploaded by

Jm CampitanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Square Column

Uploaded by

Jm CampitanCopyright:

Available Formats

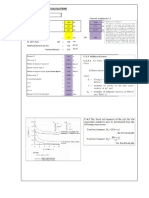

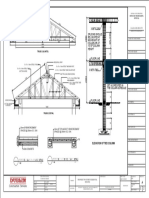

Project: Two Storey 3 Door Apartment General Notes:

Job No.: 20190228 Column C-3

Client: Emma Abueva

Design by: Engr.Mark Anthony V. Nigos

Date: 28 February, 2019

Sheet: 2 Of 5

Jerv Works Const. Ref: Reinforced Concrete Design, 6th ed., pg. 470, by Wang and Salmon

*Input data in green cells

RECTANGULAR COLUMN

with eccentric load

Allowable service load

Structural Notes:

1. ACI Code provides that the longitudinal steel shall be no less than 1% nor more than 8% ACI-10.9.1

and that at least 4 for tied columns.

2. No longitudinal bar shall be farther than 15 cm. clear on either side from such a laterally supported bar.

3. Lateral ties shall be at least 10mm in size for bars up to 32mm and at least 12mm in size for

35mm, 45mm, 57mm and bundled logitudinal bars.

Column no. 3 Total allowable

service load 3 -16mm

specification 622.72 kN

fc' 20.70 MPa

fy 276.00 MPa

structural system P

unbraced against sidesway b = 30 cm 2 - 16mm

service load e

service Dead load 150.00 kN

service Live load 150.00 kN

load eccentricity e - cm h = 30 cm

column (min. b or h = 20 cm)

least side b 30.00 cm

side h 30.00 cm OK- column capacity

concrete cover (min. 4 cm.) 4.00 cm

Lu, unsupported length 4.00 m

reinforcement (min. 4 - 16mm)

along side b along side h ties

main bar no of bar main bar no. of bar 10mm

16mm 3 16mm 3

actual bar ratio 1.79% should be 1 - 8%

Results

1. Service Dead Load capacity =311.36 kN

2. Service Live Load capacity = 311.36 kN

3. Compression controlled

4. Ties 10mm @ 26 cm. c. to c.

5. OK - longitudinal bar spacing

6. Slenderness effect critical - increase col. dimension

solution:

converted to U.S. unit

fc' 3002.121 psi

fy 40028.28 psi

service Dead load 33.723 kips

service Live load 33.723 kips

load eccentricity e 0 in.

least side b 11.811

side h 11.811 in.

concrete cover (min. 1.5 in.) 1.5748 in.

Lu, unsupported length 13.12 ft.

11.811 in.

Pn

11.811 in.

e 2.284 in.

9.527 in.

0.003

Pn

d"

d"" e

a=.85x

T Cc Cs

Check whether tension or compression controlled

d' dist. of vert. r-bar ctr .to edge of column 2.284 in.

d" dist. Of Pn to edge of concrete 5.9055 in.

d"" 3.6215

locate the neutral axis for the balance strain condition

e= 0

min e = .10*h 1.1811 in.

use max e 1.1811 in.

B1 0.85

but not less than 0.65

final B1 0.85 ACI-10.12.1

d = h - 2*b' 9.527 in.

xb = .003*d/(fy/Es+.003) 6.5249171 in.

ab = B1*xb 5.5461796 in.

compute the forces Cs,Cc and T

fy/Es 0.0013803

Cc = .85*fc*ab*b 167158.21 lb.

As' at side b = area of bar*no. of bars 0.9366 in^2

T = As*fy 37490.487 lb.

Є's >>>>> fy/Es

Є's = .003(xb-b'/xb) 0.0019499 >>>>>> 0.001380286 fy/Es

Compression steel yields

Cs=fy(As')-(B1*fc'*As') 35100.468 lb.

compute Pb and eb

Pb balance nominal strength = Cc+Cs-T 164768.1921 lb.

For rotational equilbrium about the plastic centroid

Pb*eb = Cc(d-a/2-d'')+Cs(d-d'-d'')+Td'' 786496.2329 in-lb

eb = Pb/Pb, in. 4.773349898 >>>>>>>> 1.1811 max e

THIS IS A COMPRESSION CONTROLLED

when the section is compression controlled use Method 1

otherwise use Method 2 tension controlled

Method 1

A. By static solution ( when compression controlled )

Pb = 164768.19 lb.

eb = 4.7733499 in.

determine the location of the neutral axis

Cs=A's(fy-.85fc') 35100.468 lbs

E

Cc=.B1fc'*b.85x) 25618.442 x

T = As*fs

d= 9.527

A B

T=As8fs=As*(Es*.003*(d-x))/x 776299.9734 - 81484.2

x

Taking moments about Pn,

0 = Cs*x-Cc*x+Tx

Cs*x = 127116.35

Cc*x

T*x

hence,

x3= 21775.676 1

x2= -302579.4 -13.89529

x= 335957.37 15.428103

I= -5622741 -258.212

NEWTON'S METHOD OF APPROXIMATION:

c= c' - fx/fx'

3+ 2

Ax Bx +Cx +D =0

1 -13.8953 15.4281 -258.211998 =0

3 -27.7906 15.4281

c' = 11.811 15.28096 14.24723514 14.10263 14.0999 14.0999 14.09990077 14.0999008 14.09990077 14.0999

fx = -366.749 301.1077 33.03410772 0.600191 0.000211 2.58E-11 0 0 0 0

f x' = 105.6926 291.2844 228.4401851 220.1601 220.0052 220.0052 220.0051717 220.005172 220.0051717 220.0052

c= 15.28096 14.24724 14.10262789 14.0999 14.0999 14.0999 14.099900769 14.09990 14.09990 14.100

c= 14.100

compute internal forces and strength Pn

Cs= 35100.468 lbs.

Cc= 361217.49 lbs.

T= -26427.08 lbs.

Pn = Cc + Cs - T 422745.03 lbs.

423 kips

check by a moment equation about the plastic centroid

0 = 127116.3467 + -95705.66 + -31410.68794

0 = -2.03727E-10

B. By Whitney Formula compression controlled - approximate method

determine the nominal compressive strength Pn

Pn = b*h*fc'/((3*h*e/d)+1.18)+As'/(e/(d-d')+.5)

nominal compressive strength Pn = 311734.74 lb.

312 kips

hence Pn = select conservative value between Method A and B

312 kips

Method 2 ( when tension controlled )

Cc = .85*fc'*a*b = .85*fc'*.85*x*b 25618.442 x

say y = .85*fc'*.85*b 25618.442

Cc = y*x

force equilibrium requires

Pn = Cc+Cs-T

say Q = Cs-T -2390.019 lb.

Q' = e+(d-d')/2 3.6215

Q'' = Cs(d-d') 254232.69

z = (Q'-d)/.425 -13.89529

z' = Q*Q'-Q''/(.425y) -24.14512

x 15.457343 in.

Therefore

Cc = y*x 395993.04 lb.

Pn = Cc+Cs-T 393603.02 lb.

394 kips

(required) Final Pn = 312 kips

(required) Final Pu = Pn*.7 218.4 kips

1.7LL 57.3291

1.4DL 47.2122

actual Pu = 1.7 LL + 1.4 DL 104.5413 kips << 218.4

OK- column capacity

% LL 0.5483871

%DL 0.4516129

ultimate live load capacity 119.76774 kips

ultimate dead load capacity 98.632258 kips

service live load capacity 70 kips

311.36 kN

service dead load capacity 70 kips

311.36 kN

check slenderness effect

min. col. dimension 11.811 in.

e= 1.1811 in.

r = .30*h 3.5433 in.

kLu/r 44.433156

22 22 >> 44.43315553

Slenderness effect critical - increase col. dimension

check reinforcement ratio ACI -10.8.4

Pg = Ast/Ag .01 >>>>>> 0.017903978 >>>>> .08

when condition is met, % of reinforcement OK

check reinforcement spacing

actual spacing 2.9911 in. >> 1.5

OK - longitudinal bar spacing

calculation of ties

ties spacing

s = 16*dia of longitudinal bar 10.0864 in.

s = 48*dia of ties 18.912 in.

s = least dimension of column 11.811 in.

selected least s 10.0864 in.

26 cm

You might also like

- 6.2.6.1 Design Criteria of Water TanksDocument17 pages6.2.6.1 Design Criteria of Water TanksARSENo ratings yet

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesFrom EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNo ratings yet

- Design of Rectangular Water Tanks Resting On Ground.Document5 pagesDesign of Rectangular Water Tanks Resting On Ground.ganesh.pg. GaniNo ratings yet

- Concrete Center - Strut-And-Tie Models - EC2 PDFDocument69 pagesConcrete Center - Strut-And-Tie Models - EC2 PDFJm CampitanNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Base Plate Anchor Bolt DesignDocument8 pagesBase Plate Anchor Bolt DesignnoneofyourbusineesNo ratings yet

- Tension Member DesignDocument97 pagesTension Member DesignJm CampitanNo ratings yet

- 230kV Equipment FoundationDocument4 pages230kV Equipment FoundationMian M Khurram100% (1)

- May 2022 Ce Board Exam Policarpio 4: Eview NnovationsDocument3 pagesMay 2022 Ce Board Exam Policarpio 4: Eview NnovationsKian Inductivo100% (1)

- Pile Design Cal - Rev-1Document9 pagesPile Design Cal - Rev-1Nitin SakpalNo ratings yet

- Triangle Beam B1Document6 pagesTriangle Beam B1sallysel90No ratings yet

- Deep BeamDocument20 pagesDeep BeamakhilaNo ratings yet

- 4.beam Design Singly and DoublyDocument10 pages4.beam Design Singly and DoublyReuben James BangaoilNo ratings yet

- Apartment BuildingDocument4 pagesApartment BuildingRadhika Khandelwal100% (1)

- Slab DesignDocument1 pageSlab DesignMadhu SudhanNo ratings yet

- PCA Rectangular - Tank Design ExampleDocument15 pagesPCA Rectangular - Tank Design ExampleConrad Otieno100% (4)

- Refresher - Structural Design and Construction: Inhinyero Review CenterDocument4 pagesRefresher - Structural Design and Construction: Inhinyero Review Centermichael SonuganNo ratings yet

- Input Data in Green Cells: OK-column CapacityDocument7 pagesInput Data in Green Cells: OK-column CapacityRenvil PedernalNo ratings yet

- 2017-CE May PDFDocument32 pages2017-CE May PDFKristin Argosino100% (2)

- Strap Beam DesignDocument18 pagesStrap Beam DesignRabin BhattaraiNo ratings yet

- Design Codes & ReferencesDocument9 pagesDesign Codes & Referencesnavneet3bawaNo ratings yet

- Bearing CheckDocument6 pagesBearing CheckdhanushkaNo ratings yet

- Baseplate-Kolom wf250Document79 pagesBaseplate-Kolom wf250Gary JonathanNo ratings yet

- One Way Slab Design: 1. Calculation of LoadDocument6 pagesOne Way Slab Design: 1. Calculation of LoadSaugat ThapaNo ratings yet

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Rating: 4.5 out of 5 stars4.5/5 (5)

- BASEPLT9Document5 pagesBASEPLT9Bunkun15No ratings yet

- 1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วDocument18 pages1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วsarafan leewan0% (1)

- High Rise Mixed-Use Space ProgrammingDocument4 pagesHigh Rise Mixed-Use Space ProgrammingNino YlaganNo ratings yet

- Appendix A1Document5 pagesAppendix A1Thomas Stephen100% (1)

- Light Weight ConcreteDocument27 pagesLight Weight ConcreteShashi KumarNo ratings yet

- RC Tank Design CalculationDocument8 pagesRC Tank Design CalculationNicholas ThompsonNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- 3.6 Sphere Plan: 3.0 Design - Concept and EvolutionDocument17 pages3.6 Sphere Plan: 3.0 Design - Concept and EvolutionDeena ShahirahNo ratings yet

- RCC Design of Toe-Slab: Input DataDocument2 pagesRCC Design of Toe-Slab: Input DataAnkitaNo ratings yet

- RCC Design of Heel-Slab: Input DataDocument2 pagesRCC Design of Heel-Slab: Input DataAnkitaNo ratings yet

- Jerv Works Const. Ref: Reinforced Concrete Structures, Pg. 149 By: R. Park & T. Paulay Circular ColumnDocument3 pagesJerv Works Const. Ref: Reinforced Concrete Structures, Pg. 149 By: R. Park & T. Paulay Circular ColumnreynoldNo ratings yet

- 2010NSCP Square Ftg. Square Col BESADocument13 pages2010NSCP Square Ftg. Square Col BESAKuroshiro Yameda100% (1)

- Steel Beam DesignDocument36 pagesSteel Beam DesignTan Choon LengNo ratings yet

- Moment ConnectionDocument5 pagesMoment ConnectionALPHYL BALASABASNo ratings yet

- CIVL4320 Assignment 2 Solution (2010)Document21 pagesCIVL4320 Assignment 2 Solution (2010)方方土No ratings yet

- 08 - Compression Member DesignDocument14 pages08 - Compression Member DesignAli ZubairNo ratings yet

- One Way and Two Way SlabDocument2 pagesOne Way and Two Way SlabQueenie Louise DasilioNo ratings yet

- RC-Rectangular FootingDocument5 pagesRC-Rectangular FootingJerielle Annika GetuabanNo ratings yet

- Slab Design-RajDocument6 pagesSlab Design-Rajankit kadamNo ratings yet

- Reference Computation OUTPUT (Imperial) Output (M: Transverse InteriorDocument4 pagesReference Computation OUTPUT (Imperial) Output (M: Transverse InteriordovermanNo ratings yet

- Structural Design of JackwellDocument10 pagesStructural Design of JackwellParas HarsheNo ratings yet

- Two Way SlabDocument4 pagesTwo Way SlabRichelle Faye VillaverdeNo ratings yet

- R03 21194 FF STA 37+615 Analisa&gambar H170&H210Document75 pagesR03 21194 FF STA 37+615 Analisa&gambar H170&H210lutfas viu2No ratings yet

- Steel and Structure Assignment 1Document6 pagesSteel and Structure Assignment 1menyiluNo ratings yet

- Base Plate Very EccentricityDocument2 pagesBase Plate Very EccentricityJetn SrisuthumNo ratings yet

- Calculation of Bearing Plate Dimension:: Beam SectionDocument2 pagesCalculation of Bearing Plate Dimension:: Beam Sectionk.m.ariful islamNo ratings yet

- One Way Slab Design 3Document3 pagesOne Way Slab Design 3Kenneth Peña JavierNo ratings yet

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- Situation 0Document2 pagesSituation 0Christian LuaresNo ratings yet

- A) Find The Slab Thickness ??????Document7 pagesA) Find The Slab Thickness ??????Engr Ghulam MustafaNo ratings yet

- 10 MM 8 MMDocument25 pages10 MM 8 MMyogeshkumar3089_8250No ratings yet

- Design of Support Sums NptelDocument10 pagesDesign of Support Sums NptelRADHE GRAPHICSNo ratings yet

- Esplana SteelDesignDocument1 pageEsplana SteelDesignNaigell SolomonNo ratings yet

- Design and Drawing of RC Structures: Dr. G.S.SureshDocument40 pagesDesign and Drawing of RC Structures: Dr. G.S.SureshvipinNo ratings yet

- Beam Design TemplateDocument9 pagesBeam Design TemplateWinston AdvinculaNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Capitan Macatubal Compro-1-1Document15 pagesCapitan Macatubal Compro-1-1Jm CampitanNo ratings yet

- Unless Otherwise Noted, The Content of This Course Material Is Licensed Under A Creative Commons Attribution 3.0 LicenseDocument24 pagesUnless Otherwise Noted, The Content of This Course Material Is Licensed Under A Creative Commons Attribution 3.0 LicenseJm CampitanNo ratings yet

- A B E C D A B E C D A B E C D A B E C D: Roof Beam Framing Plan Roof Framing PlanDocument1 pageA B E C D A B E C D A B E C D A B E C D: Roof Beam Framing Plan Roof Framing PlanJm CampitanNo ratings yet

- T - 1 LT - 1 T - 5: Column and Footing DetailsDocument1 pageT - 1 LT - 1 T - 5: Column and Footing DetailsJm CampitanNo ratings yet

- Beam Transition Reinforcement Detail: Schedule of BeamsDocument1 pageBeam Transition Reinforcement Detail: Schedule of BeamsJm CampitanNo ratings yet

- Gender and Society: Gender-Fair Language: College of Arts and SciencesDocument4 pagesGender and Society: Gender-Fair Language: College of Arts and SciencesJm CampitanNo ratings yet

- What Are Brackets and Corbels?Document11 pagesWhat Are Brackets and Corbels?Jm CampitanNo ratings yet

- College of Arts and SciencesDocument2 pagesCollege of Arts and SciencesJm CampitanNo ratings yet

- A B E C D A B E C D A B E C D A B E C D: Foundation Plan Footing Tie Beam Framing PlanDocument1 pageA B E C D A B E C D A B E C D A B E C D: Foundation Plan Footing Tie Beam Framing PlanJm CampitanNo ratings yet

- Construction NotesDocument1 pageConstruction NotesJm CampitanNo ratings yet

- RM 513 Research Methods: Engr. John Michael Z. Campitan, CE Course: Msce-SeDocument2 pagesRM 513 Research Methods: Engr. John Michael Z. Campitan, CE Course: Msce-SeJm CampitanNo ratings yet

- The Effect of Cassava Starch On The Durability Characteristics of ConcreteDocument29 pagesThe Effect of Cassava Starch On The Durability Characteristics of ConcreteJm CampitanNo ratings yet

- Ductility and Strength Behavior of Reinforced Concrete Columns Confined by Glass and Carbon FRP SheetsDocument23 pagesDuctility and Strength Behavior of Reinforced Concrete Columns Confined by Glass and Carbon FRP SheetsJm CampitanNo ratings yet

- Mitigation of The Effects of Blast Loads On A Reinforced Concrete StructuresDocument12 pagesMitigation of The Effects of Blast Loads On A Reinforced Concrete StructuresJm CampitanNo ratings yet

- The Effectiveness of Dried Water Hyacinth (Eichhornia Crassipes) Woven Into Mat To Prevent Soil ErosionDocument3 pagesThe Effectiveness of Dried Water Hyacinth (Eichhornia Crassipes) Woven Into Mat To Prevent Soil ErosionJm CampitanNo ratings yet

- The Effectiveness of Dried Water Hyacinth (Eichhornia Crassipes) Woven Into Mat To Prevent Soil ErosionDocument12 pagesThe Effectiveness of Dried Water Hyacinth (Eichhornia Crassipes) Woven Into Mat To Prevent Soil ErosionJm CampitanNo ratings yet

- Solution Manual Reinforced Concrete 5th Edition WightDocument26 pagesSolution Manual Reinforced Concrete 5th Edition WightJm CampitanNo ratings yet

- Mitigation of The Effects of Blast Loads On A Reinforced Concrete StructuresDocument12 pagesMitigation of The Effects of Blast Loads On A Reinforced Concrete StructuresJm CampitanNo ratings yet

- Solution Manual Reinforced Concrete 5th Edition WightDocument26 pagesSolution Manual Reinforced Concrete 5th Edition WightJm CampitanNo ratings yet

- 3 PB PDFDocument12 pages3 PB PDFJm CampitanNo ratings yet

- Failure Due To Blast Loading of R.C. StructuresDocument1 pageFailure Due To Blast Loading of R.C. StructuresJm CampitanNo ratings yet

- Advent Season 2020 DCLM San PabloDocument32 pagesAdvent Season 2020 DCLM San PabloJm CampitanNo ratings yet

- John Michael Z. Campitan: Civil EngineerDocument4 pagesJohn Michael Z. Campitan: Civil EngineerJm CampitanNo ratings yet

- Balanced, Tension-Controlled, and Compression-Controlled or Brittle Sections and FailureDocument2 pagesBalanced, Tension-Controlled, and Compression-Controlled or Brittle Sections and FailureJm CampitanNo ratings yet

- 3 Flexural Analysis/Design of Beam 3 Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of BeamDocument146 pages3 Flexural Analysis/Design of Beam 3 Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of BeamJm CampitanNo ratings yet

- Analysis of Beam Finding Nominal Strength in Flexure by Equivalent Rectangular StressDocument3 pagesAnalysis of Beam Finding Nominal Strength in Flexure by Equivalent Rectangular StressJm CampitanNo ratings yet

- Michelangelo Carlo MadernoDocument1 pageMichelangelo Carlo Madernoapi-596255492No ratings yet

- Barira Tahsin - ARC181 Annotated BibliographyDocument7 pagesBarira Tahsin - ARC181 Annotated BibliographyBarira TahsinNo ratings yet

- Structural Plan 4Document1 pageStructural Plan 4raymunddublinNo ratings yet

- Calyx Residences Frequently Asked QuestionsDocument2 pagesCalyx Residences Frequently Asked QuestionsRoiBogoCityNo ratings yet

- Concreting SopDocument9 pagesConcreting SopvivekNo ratings yet

- Theory of Design: Single and Double Loaded CorriorDocument21 pagesTheory of Design: Single and Double Loaded CorriorMohammad EhsanNo ratings yet

- Water: City of RichardsonDocument15 pagesWater: City of RichardsonSnezana RaicevicNo ratings yet

- BANDI R B WallsDocument22 pagesBANDI R B Wallsgtarun22guptaNo ratings yet

- Stromberg Architectural Full GlossaryDocument49 pagesStromberg Architectural Full GlossaryAna EscotoNo ratings yet

- HCPP-Kitchen Layout-PD-01-200212-PD-01 PDFDocument1 pageHCPP-Kitchen Layout-PD-01-200212-PD-01 PDFVõ Văn QuânNo ratings yet

- 1.A.0 Introduction: Loads For BuildingsDocument5 pages1.A.0 Introduction: Loads For BuildingsGeran GeraniumNo ratings yet

- Low Impact Secant-Pile Seawall For Protecting SR-A1A Along Flagler BeachDocument40 pagesLow Impact Secant-Pile Seawall For Protecting SR-A1A Along Flagler Beachsantanu mukherjeeNo ratings yet

- Repointing Rubble StoneworkDocument8 pagesRepointing Rubble StoneworkRoss CairnsNo ratings yet

- Pilgrimage: St. Peter's Square in Vatican CityDocument1 pagePilgrimage: St. Peter's Square in Vatican CitySonora147No ratings yet

- Essential Guide For BEPDocument40 pagesEssential Guide For BEPpombobspepetNo ratings yet

- Precast Concrete Block Egg-Shaped Drain (Pcbesd) : SY PerundingDocument4 pagesPrecast Concrete Block Egg-Shaped Drain (Pcbesd) : SY PerundingGan Chin PhangNo ratings yet

- DSGN 223 Architectural-Firm Esquisse01Document2 pagesDSGN 223 Architectural-Firm Esquisse01Matic, Jimuel MatthewNo ratings yet

- Milan 1945, The Reconstruction - Modernity, Tradition, ContinuityDocument10 pagesMilan 1945, The Reconstruction - Modernity, Tradition, ContinuityAchraf ToumiNo ratings yet

- Forster Resume PortfolioDocument2 pagesForster Resume Portfolioapi-257363000No ratings yet

- Le Corbusier's Imaginary Journey To The Far East - Geometry and Order Demonstrated in A Chinese PaintingDocument8 pagesLe Corbusier's Imaginary Journey To The Far East - Geometry and Order Demonstrated in A Chinese PaintingDanica SpasevskaNo ratings yet

- Ce 2405 Set2Document8 pagesCe 2405 Set2sheikNo ratings yet

- CV Daniel Libeskind ENDocument5 pagesCV Daniel Libeskind ENadediran adeyemiNo ratings yet

- 22 - RT609 - U - TYP - 010 - A Ducts DetailsDocument1 page22 - RT609 - U - TYP - 010 - A Ducts DetailsanooppattazhyNo ratings yet

- I. Ifugao and Its TribeDocument8 pagesI. Ifugao and Its TribeGerard EscandaNo ratings yet

- Subcontractor (ABID SB) 1Document22 pagesSubcontractor (ABID SB) 1Tariq MahmoodNo ratings yet

- Boundary Wall Agriculutre Office TaunsaDocument4 pagesBoundary Wall Agriculutre Office TaunsaGhaziNo ratings yet