Professional Documents

Culture Documents

RM Raw Materail Procurement-Qulaity

RM Raw Materail Procurement-Qulaity

Uploaded by

Rohit Vishwakarma0 ratings0% found this document useful (0 votes)

40 views1 pageThis document outlines the risk management process for raw material procurement at MF Group of Industries. It identifies potential failure modes such as receiving raw materials that do not meet specifications. Current controls to prevent this include supplier self-assessment audits and inspections, while incoming inspection reports are used for detection. The risk priority number is calculated as 70 based on potential severity, occurrence, and detection. No additional mitigation actions are required since the RPN is below 100.

Original Description:

Original Title

RM Raw materail procurement-Qulaity

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the risk management process for raw material procurement at MF Group of Industries. It identifies potential failure modes such as receiving raw materials that do not meet specifications. Current controls to prevent this include supplier self-assessment audits and inspections, while incoming inspection reports are used for detection. The risk priority number is calculated as 70 based on potential severity, occurrence, and detection. No additional mitigation actions are required since the RPN is below 100.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views1 pageRM Raw Materail Procurement-Qulaity

RM Raw Materail Procurement-Qulaity

Uploaded by

Rohit VishwakarmaThis document outlines the risk management process for raw material procurement at MF Group of Industries. It identifies potential failure modes such as receiving raw materials that do not meet specifications. Current controls to prevent this include supplier self-assessment audits and inspections, while incoming inspection reports are used for detection. The risk priority number is calculated as 70 based on potential severity, occurrence, and detection. No additional mitigation actions are required since the RPN is below 100.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

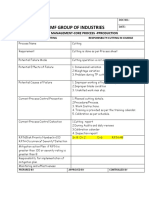

DOC NO:

MF GROUP OF INDUSTRIES DATE:

RISK MANAGEMENT-CORE PROCESS -PURCHASE

SUB PORCESS-RAW MATERAIL PROCUREMENT RESPONISBILTY:PROCESS OWNER

Process Name Raw material procurement

Requirement Quality of the raw material as per specification

Potential Failure Mode Quality of the raw material is not as per specification

Potential Effects of failure Production stop

Potential Causes of Failure 1.During supply material is dispatched with out

inspection

Current Process Control Prevention 1. Supplier self-assessment form audited conducted by

the customer on regular basis.

Current Process Control Detection 1.Incoming Inspection report

Monitoring and effectiveness of By Vendor rating procedure

preventive action plan method

R.P.N(Risk Priority Number)<=100 S= 7 O= 2 D=5 R.P.N=70

R.P.N=Occurrence*Severity*Detection

Mitigation action Plan: if R.P.N is

greater than 100 or severity rating is

greater than 8

Responsibility for implementation of

mitigation plan

Monitoring and effectiveness

PREPARED BY APPROVED BY CONTROLLED BY

You might also like

- Template - Traceability Audit Checklist (Example)Document2 pagesTemplate - Traceability Audit Checklist (Example)Floreid100% (14)

- 1) Procedure For Product SafetyDocument2 pages1) Procedure For Product SafetyGANESH BORUDE100% (2)

- Example HACCP StudyDocument10 pagesExample HACCP StudyAdnan MeghaniNo ratings yet

- Incoming Inspection-Qmp-Qc-01Document2 pagesIncoming Inspection-Qmp-Qc-01Rohit VishwakarmaNo ratings yet

- RM Raw Materail Procurement - DeilveryDocument1 pageRM Raw Materail Procurement - DeilveryRohit VishwakarmaNo ratings yet

- RM Packing and DespatchDocument1 pageRM Packing and DespatchRohit VishwakarmaNo ratings yet

- RM Incoming Inspection PlanDocument1 pageRM Incoming Inspection PlanRohit VishwakarmaNo ratings yet

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionDocument1 pageMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionRohit VishwakarmaNo ratings yet

- MF Group of Indutries: Risk Management-Core Process - Quality AssuranceDocument1 pageMF Group of Indutries: Risk Management-Core Process - Quality AssuranceRohit VishwakarmaNo ratings yet

- MF Group of Industries: Risk Management-Core Process - ProductionDocument2 pagesMF Group of Industries: Risk Management-Core Process - ProductionRohit VishwakarmaNo ratings yet

- UntitledDocument9 pagesUntitledJinna SmaNo ratings yet

- RM Metallography TestDocument2 pagesRM Metallography TestRohit VishwakarmaNo ratings yet

- Rakhmat Budi Yuwono Quality Risk Management An Implementation in IndustriDocument38 pagesRakhmat Budi Yuwono Quality Risk Management An Implementation in IndustriAbdul NasirNo ratings yet

- FDA Risk Management PlanDocument4 pagesFDA Risk Management PlanroseannparadoNo ratings yet

- HR Risk AssessmentDocument37 pagesHR Risk AssessmentCathleya Marie CoNo ratings yet

- MF Group of Industries: Risk Management-Core Process - PproductionDocument2 pagesMF Group of Industries: Risk Management-Core Process - PproductionRohit VishwakarmaNo ratings yet

- PDPMAN-FM-119 - Quality Assurance Tender Evaluation Report - Rev4Document4 pagesPDPMAN-FM-119 - Quality Assurance Tender Evaluation Report - Rev4LesegoNo ratings yet

- Rely On Laboratory Recognition by Conformity Assessment BodiesDocument4 pagesRely On Laboratory Recognition by Conformity Assessment BodiesANU M ANo ratings yet

- Quality AssuranceDocument1 pageQuality AssuranceMarisa Signar100% (1)

- Template Traceability Audit Checklist ExampleDocument2 pagesTemplate Traceability Audit Checklist ExampleTrinh DuNo ratings yet

- Antonio Regadio Regulatory Affairs (RMP) PAPPI 15th BiCon 11 Mar 2016Document52 pagesAntonio Regadio Regulatory Affairs (RMP) PAPPI 15th BiCon 11 Mar 2016Kim Cyrelle Samson Umbalin100% (2)

- Lifecycle Approach To Process Validation: Best Practices and StrategiesDocument31 pagesLifecycle Approach To Process Validation: Best Practices and StrategiesSally PujaNo ratings yet

- Example Procedure For Process ValidationDocument5 pagesExample Procedure For Process ValidationTeti Azril100% (2)

- Enterprise Risk Management Section 3Document7 pagesEnterprise Risk Management Section 3Camilo EspinosaNo ratings yet

- 4 Context of The Organization 4.1 Understanding The Organization and Its ContextDocument5 pages4 Context of The Organization 4.1 Understanding The Organization and Its ContextkarthiksaadhanaNo ratings yet

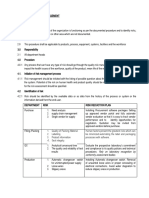

- Standard Operating Procedure For Risk AsDocument9 pagesStandard Operating Procedure For Risk Asjihan shafiraNo ratings yet

- Msa - QSP - 01 - Risk Assessment and Mitigation PlanDocument11 pagesMsa - QSP - 01 - Risk Assessment and Mitigation PlanVasudevan GovindarajNo ratings yet

- Cleaning Validation Cleaning Validation Is A Validation Program To VerifyDocument27 pagesCleaning Validation Cleaning Validation Is A Validation Program To Verify董彬彬100% (2)

- Risk Management Plan of Healthteach Nutritionals IncDocument8 pagesRisk Management Plan of Healthteach Nutritionals Inccompliance neilanztruckingNo ratings yet

- JHGFDDocument10 pagesJHGFDNIMANo ratings yet

- 203 LSS Gbo - FmeaDocument47 pages203 LSS Gbo - FmeaRocker byNo ratings yet

- Project Audit Check List WQTDocument2 pagesProject Audit Check List WQTFarhani YaakonNo ratings yet

- (QSP-QA-08) Process For Internal Rejection HandelingDocument4 pages(QSP-QA-08) Process For Internal Rejection HandelingMUNENDRA SHAKYANo ratings yet

- Customer Complaint HandlingDocument3 pagesCustomer Complaint HandlingNageswara raoNo ratings yet

- 21st Century CGMPDocument13 pages21st Century CGMPVidya PasalkarNo ratings yet

- Training MaterialDocument26 pagesTraining MaterialnvloanNo ratings yet

- Problem Solving: BesterfieldDocument17 pagesProblem Solving: BesterfieldPrince RajputNo ratings yet

- QM 01 ANNEX II Key Busines ProcessDocument4 pagesQM 01 ANNEX II Key Busines ProcessVinod SaleNo ratings yet

- Hazard Identification Techniques Hazard Identification: HazardDocument5 pagesHazard Identification Techniques Hazard Identification: HazardMDR PRAPHUNo ratings yet

- Supplier Qualification...Document5 pagesSupplier Qualification...elmiraNo ratings yet

- Presentatie Deelsessie 1 E Van Asselt 0 PDFDocument31 pagesPresentatie Deelsessie 1 E Van Asselt 0 PDFnguyen ngoc HieuNo ratings yet

- Top 5 Ways To Prevent Foreign Material ContaminationDocument42 pagesTop 5 Ways To Prevent Foreign Material ContaminationTamsos D537No ratings yet

- Strategies To Write Effective Validation ProtocolDocument33 pagesStrategies To Write Effective Validation ProtocolschumonNo ratings yet

- Chapter 3.2022.englishDocument59 pagesChapter 3.2022.englishcamnhu622003No ratings yet

- V. 08 - 09 2009 SUGAR Lo Res PDFDocument12 pagesV. 08 - 09 2009 SUGAR Lo Res PDFProjects AddwiseNo ratings yet

- ##-QSP-05 Risk Assessment and ManagementDocument11 pages##-QSP-05 Risk Assessment and Managementrajiv100% (2)

- Is Security & Risk: ManagementDocument25 pagesIs Security & Risk: Managementhilda_oktavianni5178No ratings yet

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceDocument2 pagesMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceRohit VishwakarmaNo ratings yet

- HAZAN ProcessDocument21 pagesHAZAN ProcessmkkamarajNo ratings yet

- 2006 09 FDA - Ind Statistics SlidesDocument36 pages2006 09 FDA - Ind Statistics SlidesSudhagarNo ratings yet

- Malik Animal Wanda (PVT.) LTD: Project Supply Chain ManagementDocument17 pagesMalik Animal Wanda (PVT.) LTD: Project Supply Chain ManagementUsman KhanNo ratings yet

- VAL 185 Guidance For The Use of Risk Assessment in Validation SampleDocument3 pagesVAL 185 Guidance For The Use of Risk Assessment in Validation SampleSameh MostafaNo ratings yet

- 07 - Risk ReductionxDocument20 pages07 - Risk ReductionxAdriana HubleaNo ratings yet

- Product RecallDocument4 pagesProduct Recalldileepkumar.gNo ratings yet

- ZRH 10Document67 pagesZRH 10Rahmat DennyNo ratings yet

- ISO 45001 2018 Incident Investigation and Reporting Procedure SampleDocument5 pagesISO 45001 2018 Incident Investigation and Reporting Procedure SampleAmr EssamNo ratings yet

- ISO 45001 2018 Incident Investigation and Reporting Procedure SampleDocument5 pagesISO 45001 2018 Incident Investigation and Reporting Procedure SampleAmr EssamNo ratings yet

- HACCPExample1 PDFDocument6 pagesHACCPExample1 PDFSaraa HusainNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- TAKT TimeDocument10 pagesTAKT TimeRohit VishwakarmaNo ratings yet

- HIRADocument2 pagesHIRARohit VishwakarmaNo ratings yet

- Annexure - 8 - Anti Bribery PolicyDocument1 pageAnnexure - 8 - Anti Bribery PolicyRohit VishwakarmaNo ratings yet

- Punjab General Industries Private Limited Job Hazard AnalysisDocument7 pagesPunjab General Industries Private Limited Job Hazard AnalysisRohit VishwakarmaNo ratings yet

- Application:: Home Branch CodeDocument7 pagesApplication:: Home Branch CodeRohit VishwakarmaNo ratings yet

- Report No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeDocument1 pageReport No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeRohit VishwakarmaNo ratings yet

- Punjab General Industries Private Limited: Hazard Identification and Risk Assessment (HIRA)Document9 pagesPunjab General Industries Private Limited: Hazard Identification and Risk Assessment (HIRA)Rohit VishwakarmaNo ratings yet

- Legal & Other RequirementDocument2 pagesLegal & Other RequirementRohit VishwakarmaNo ratings yet

- Operation ControlDocument2 pagesOperation ControlRohit VishwakarmaNo ratings yet

- Responsibility For Waste ControlDocument8 pagesResponsibility For Waste ControlRohit VishwakarmaNo ratings yet

- MF Group of Industries: Risk Management-Core Process - PproductionDocument2 pagesMF Group of Industries: Risk Management-Core Process - PproductionRohit VishwakarmaNo ratings yet

- MF Group of Industries: Risk Management-Core Process - ProductionDocument2 pagesMF Group of Industries: Risk Management-Core Process - ProductionRohit VishwakarmaNo ratings yet

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceDocument2 pagesMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceRohit VishwakarmaNo ratings yet

- Control of documents-QMP-SYS-01Document5 pagesControl of documents-QMP-SYS-01Rohit VishwakarmaNo ratings yet

- RM Metallography TestDocument2 pagesRM Metallography TestRohit VishwakarmaNo ratings yet

- Contract Review-QMP-MK-01Document5 pagesContract Review-QMP-MK-01Rohit VishwakarmaNo ratings yet

- Control and Monitoring Measuring and Testing EquipmentDocument3 pagesControl and Monitoring Measuring and Testing EquipmentRohit VishwakarmaNo ratings yet

- Breakdown Maintenenace-QMP-MNT-02Document3 pagesBreakdown Maintenenace-QMP-MNT-02Rohit VishwakarmaNo ratings yet

- Corrective action-QMP-SYS-06Document7 pagesCorrective action-QMP-SYS-06Rohit Vishwakarma100% (1)

- Stores - QMP-ST-01Document5 pagesStores - QMP-ST-01Rohit VishwakarmaNo ratings yet

- Management Review-Qmp-Sys-03Document3 pagesManagement Review-Qmp-Sys-03Rohit VishwakarmaNo ratings yet

- Internal Audit - QMP-SYS-04Document5 pagesInternal Audit - QMP-SYS-04Rohit VishwakarmaNo ratings yet

- Training (HR) - QMP-HR-01Document3 pagesTraining (HR) - QMP-HR-01Rohit VishwakarmaNo ratings yet