Professional Documents

Culture Documents

Quality Assurance Plan: Dover India PVT LTD

Quality Assurance Plan: Dover India PVT LTD

Uploaded by

Deepak UpadhyayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Assurance Plan: Dover India PVT LTD

Quality Assurance Plan: Dover India PVT LTD

Uploaded by

Deepak UpadhyayCopyright:

Available Formats

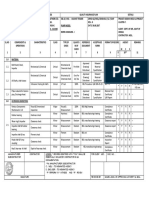

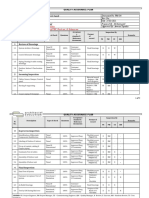

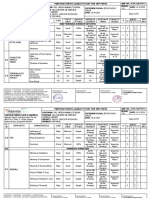

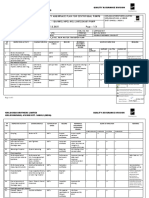

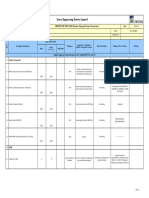

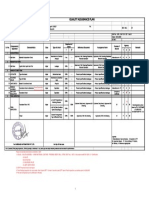

QUALITY ASSURANCE PLAN DOVER INDIA PVT LTD

NAME OF THE CUSTOMER - QAP REV NO./DATE: DOC NO. : DOV/QAP/03

NAME OF CLIENT - PO NO.

PUMP DESCRIPTION GA DWG NO. - REV.NO

INSPECTION

SL.NO ITEMS & OPERATION CHARACTERISTIC TYPE / METHOD OF CHECK EXTENT OF CHECK REFERENCE DOCUMENTS ACCEPTANCE NORMS FORMAT OF RECORD

PSG CUSTOMER

1 RECEIVING INSPECTION

? Please mention

REVIEW OF CERTIFICATE OF P.O / CERTIFICATE OF AS PER CERTIFICATE OF CERTIFICATE OF

1.1 PUMP MODEL CONFIRMATION / MATERIAL 100% R R

COMPLIANCE COMPLIANCE COMPLIANCE COMPLIANCE

AS PER GA DRAWING / CERTIFICATE OF

VISUAL Chemical & physical

AS PER GA DRAWING /

1.2 BELT MODEL CONFIRMATION 100% R R

Chemical & physical Analysis CATALOGUE CATALOGUE COMPLIANCE MTC/ITR EN 10204, 3.1

Properties certification

AS PER GA DRAWING & AS PER GA DRAWING & CERTIFICATE OF

1.3 PULLEY MODEL CONFIRMATION VISUAL Chemical & physical 100%

CATALOGUE / PO CATALOGUE COMPLIANCE MTC/ITR EN R10204, 3.1 R

Chemical & physical Analysis certification

Properties

AS PER GA DRAWING & AS PER GA DRAWING & CERTIFICATE OF

1.4 COUPLING MODEL CONFIRMATION VISUAL Chemical & physical 100% R

CATALOGUE / PO CATALOGUE COMPLIANCE MTC/ITR EN 10204, 3.1 R

Chemical & physical Analysis certification

Properties

2 FINAL INSPECTION VISUAL /DIMENSION MEASURING TAPE / SCALE 1/MODEL AS PER GA DRAWING AS PER GA DRAWING ITR P R

NO LEAKAGE & NO PRESSURE

NITROGEN LEAK TEST LEAKAGE NO LEAKAGE LEAK TEST REPORT

DROP Hydrostatic test for

3 1/MODEL LEAK TEST PROCEDURE P W - 1/MODEL

Casing/Housing Leakage & tightness

pressure test Check min.10 min holding time

MECHANICAL RUN TEST AT NOLOAD AS PER RUN TEST

4 RUNNING CONDITION RUNNING THE PUMP FOR 5 MINS 1/MODEL RUN TEST PROCEDURE TEST REPORT P W - 1/MODEL

CONDITION PROCEDURE

AS PER PAINTING AS PER PAINTING

5 PAINTING APPEARANCE & DFT VISUAL & DFT METER 1/MODEL ITR P R

PROCEDURE` PROCEDURE`

LEGEND NOTES

P PERFORM H HOLD

V VERIFICATION ITR INSPECTION TEST REPORT

R REVIEW DOC DECLARATION OF CONFIRMITY

1. All Raw material (Shaft, Housing/casing, vanes, pully, belt, block, spring etc.) MTC's are on accordance with EN 10204, 3.1 certification shall be required

2. Please mention the Houasing/Casing inspection parameter & clause.

PREPARED BY

3. Please mention shaft inspection stages APPROVED BY

You might also like

- 201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0Document1 page201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0muchamad yasin100% (1)

- Valves - Kirloskar BrothersDocument4 pagesValves - Kirloskar BrothersJaydev ChakrabortyNo ratings yet

- Quality Assurance Plan For Austenitic Stainless Steel Welded Pipe AS PER ASTM A 312, Latest Edtion Vendor: Jindal Quality Tubular LimitedDocument2 pagesQuality Assurance Plan For Austenitic Stainless Steel Welded Pipe AS PER ASTM A 312, Latest Edtion Vendor: Jindal Quality Tubular Limitedamit rajputNo ratings yet

- Dept of WR., Govt. of OdhishaDocument3 pagesDept of WR., Govt. of OdhishaNaveen NagisettiNo ratings yet

- Uae Oil & Gas DirectoryDocument1,586 pagesUae Oil & Gas DirectoryChristopher Robin Richardson87% (23)

- Cessna 182 Check ListDocument6 pagesCessna 182 Check ListravNo ratings yet

- QAPDocument46 pagesQAPAkash Singh TomarNo ratings yet

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- Qap For Jib CraneDocument2 pagesQap For Jib CraneSuaib VCSNo ratings yet

- Cofmow ItpDocument7 pagesCofmow ItpAjay HazarikaNo ratings yet

- Field Quality Plan: KSK Power Company LimitedDocument6 pagesField Quality Plan: KSK Power Company LimitedGayatree RathoreNo ratings yet

- ITP For Blasting and PaintingDocument9 pagesITP For Blasting and PaintingVinayaga MoorthiNo ratings yet

- Inspection & Test Plan Advance Valves Butterfly ValvesDocument2 pagesInspection & Test Plan Advance Valves Butterfly Valvessyed jafarNo ratings yet

- Itp PRDSDocument3 pagesItp PRDSDwi Mulyanti Dwimulyantishop100% (1)

- Acc Fqap Rev 1 - DundigalDocument2 pagesAcc Fqap Rev 1 - DundigalHema NandhNo ratings yet

- Qap - Iso - TankDocument2 pagesQap - Iso - TankMani MaNo ratings yet

- Field Quality PlanDocument2 pagesField Quality PlanPurnima VermaNo ratings yet

- Quality Assurance Plan: Page 1 of 2 Vendor: Pump Model: Project: Quantity: CustomerDocument4 pagesQuality Assurance Plan: Page 1 of 2 Vendor: Pump Model: Project: Quantity: CustomerDeepak UpadhyayNo ratings yet

- Final - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFDocument1 pageFinal - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFRishabh VermaNo ratings yet

- Qap Amtp-Cp-Qc 01 Dlfbe Tco r6Document10 pagesQap Amtp-Cp-Qc 01 Dlfbe Tco r6Бауыржан ЖусуповNo ratings yet

- Inspection Test PlanDocument141 pagesInspection Test PlanKoya ThangalNo ratings yet

- Control PlanDocument4 pagesControl PlanJosué PérezNo ratings yet

- Quality Assurance Plan For Api Pump (Qap)Document3 pagesQuality Assurance Plan For Api Pump (Qap)sanjay joshiNo ratings yet

- Acc - Fqap - P3011 - R2 - RewaDocument2 pagesAcc - Fqap - P3011 - R2 - RewaHema NandhNo ratings yet

- Issue Date: 30/06/2021 Sabtank: Inspection Test PlanDocument9 pagesIssue Date: 30/06/2021 Sabtank: Inspection Test PlanArun Koshy AlexanderNo ratings yet

- Quality Plan and Checklist (HVAC) - Sandvik G BlockDocument3 pagesQuality Plan and Checklist (HVAC) - Sandvik G BlockParasNo ratings yet

- 07 - Apollo - Iocl - Actuator GTV - R1Document1 page07 - Apollo - Iocl - Actuator GTV - R19893203028No ratings yet

- Client:-Project: - Consultant: - Contaractor: - Name of PanelDocument1 pageClient:-Project: - Consultant: - Contaractor: - Name of PanelChaturbhai HadiyalNo ratings yet

- SH 47Document1 pageSH 47keshav chaturvediNo ratings yet

- ITP RefractoryDocument1 pageITP RefractoryADOFSLNo ratings yet

- 3086 11939sampleQAPDocument1 page3086 11939sampleQAPSRIKANTA SAHOO-CUTNo ratings yet

- Qap - NRLDocument1 pageQap - NRLStructures ProductionNo ratings yet

- RFA 15 LV Terminal LugsDocument3 pagesRFA 15 LV Terminal Lugsjohn.lopezNo ratings yet

- Gpe-Fat OverviewDocument5 pagesGpe-Fat Overviewn.hartonoNo ratings yet

- Photometer 2975Document13 pagesPhotometer 2975GMP SolutionNo ratings yet

- Plan de Surveillance Pièce PlastiqueDocument2 pagesPlan de Surveillance Pièce PlastiqueFida GhanmiNo ratings yet

- QAP FormatsDocument13 pagesQAP Formatsavvari sureshNo ratings yet

- Vibrating Screen QAP-17Document8 pagesVibrating Screen QAP-17Mohammad AdilNo ratings yet

- QAP (WO No. 58 & 59) PDFDocument3 pagesQAP (WO No. 58 & 59) PDFKailasNo ratings yet

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDocument6 pages1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongNo ratings yet

- WHRS QapDocument31 pagesWHRS Qapmd shahabuddeenNo ratings yet

- QAP-093-Dangote-IRP Rev1Document4 pagesQAP-093-Dangote-IRP Rev1MonaNo ratings yet

- QAP HMEL 7480000754 L08722A501-SignedDocument3 pagesQAP HMEL 7480000754 L08722A501-SignedSuyog GawandeNo ratings yet

- Msi Pilote A-123 InglesDocument25 pagesMsi Pilote A-123 InglesAbdiel GarciaNo ratings yet

- Aprroved QAP-1883-R01-15122022Document1 pageAprroved QAP-1883-R01-15122022Pavul RajNo ratings yet

- ITP Low Tempt Test - RevDocument6 pagesITP Low Tempt Test - RevAgus GunawanNo ratings yet

- ITP - (PIPING & Project Documents) PDFDocument5 pagesITP - (PIPING & Project Documents) PDFSUNNY BOSSNo ratings yet

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocument53 pagesA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONNo ratings yet

- ITP For Fabrication & Erection of TanksDocument20 pagesITP For Fabrication & Erection of TanksosersNo ratings yet

- Quality Assurance Plan - CivilDocument11 pagesQuality Assurance Plan - CivilDeviPrasadNathNo ratings yet

- RFA 20 ES Electric Transformer DetailsDocument6 pagesRFA 20 ES Electric Transformer Detailsjohn.lopezNo ratings yet

- ATTACHMENTDocument10 pagesATTACHMENTAgus SuriptoNo ratings yet

- 01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Document29 pages01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Eljo AndsNo ratings yet

- Inspection Test Plan: Provision To Supply and Delivery of V-Cone Flowmeter For Tiong A and Bekok ADocument7 pagesInspection Test Plan: Provision To Supply and Delivery of V-Cone Flowmeter For Tiong A and Bekok AMUHAMMAD ABHAR AMZAR BIN ZAMZURINo ratings yet

- ITP Steel Structure Rev.01Document2 pagesITP Steel Structure Rev.01Imam SyarifudinNo ratings yet

- Magnetic Level Gauge: DOC NO. QR/QC/F/14Document1 pageMagnetic Level Gauge: DOC NO. QR/QC/F/14sunshine dreamNo ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Itp 116Document4 pagesItp 116muralidmurthyNo ratings yet

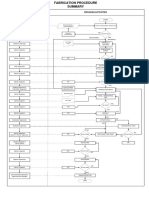

- Fabrication FlowchartDocument1 pageFabrication FlowchartDonny100% (1)

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- $RP0EVX9Document4 pages$RP0EVX9hemanth rompilliNo ratings yet

- Inspection and Test Plan (Itp) :: Floating Ball ValvesDocument1 pageInspection and Test Plan (Itp) :: Floating Ball ValvesDeepak UpadhyayNo ratings yet

- Auto On Off Ball Valve Suresales - Commented - QAP - REV-01Document1 pageAuto On Off Ball Valve Suresales - Commented - QAP - REV-01Deepak UpadhyayNo ratings yet

- AF291 Chilling Unit Hiver QAP.Document4 pagesAF291 Chilling Unit Hiver QAP.Deepak UpadhyayNo ratings yet

- QPS-C5 Industrial & Costal Painting Procedure-OP - PP - WI - 006 - C5 PDFDocument4 pagesQPS-C5 Industrial & Costal Painting Procedure-OP - PP - WI - 006 - C5 PDFDeepak UpadhyayNo ratings yet

- Perfomance Curve - ZP 130-4-DC-NLL PDFDocument1 pagePerfomance Curve - ZP 130-4-DC-NLL PDFDeepak UpadhyayNo ratings yet

- Motor Painting Specification: C5M (According ISO 12944)Document1 pageMotor Painting Specification: C5M (According ISO 12944)Deepak UpadhyayNo ratings yet

- Corrosion Science and Engineering - Course Material PDFDocument481 pagesCorrosion Science and Engineering - Course Material PDFDeepak UpadhyayNo ratings yet

- Cryomec Supercharger PDFDocument2 pagesCryomec Supercharger PDFDeepak UpadhyayNo ratings yet

- KTC BricksDocument55 pagesKTC BricksKiran KumarNo ratings yet

- Pk55xx Rfk55xx 29007799r001 Install Man FR Du It enDocument32 pagesPk55xx Rfk55xx 29007799r001 Install Man FR Du It enGary DonaldsonNo ratings yet

- Topic 2 - Intro To Data Science Machine LearningDocument30 pagesTopic 2 - Intro To Data Science Machine LearningMadhu Evuri67% (3)

- Migrate Data Protector 7.0x To Data Protector 9.0xDocument9 pagesMigrate Data Protector 7.0x To Data Protector 9.0xVikram ReddyNo ratings yet

- Different Types of Conveyor ComponentsDocument2 pagesDifferent Types of Conveyor ComponentsMatt Suarez TudgeNo ratings yet

- Multi Idler Belt Weigher Bvd2050gbDocument4 pagesMulti Idler Belt Weigher Bvd2050gbAnthonyNo ratings yet

- Transportation Decision PDFDocument4 pagesTransportation Decision PDFeric_mdisNo ratings yet

- 04 Professional Resume Template in WordDocument1 page04 Professional Resume Template in WordDevarajanNo ratings yet

- TE Dorman Smith Product Portofolio 2011Document182 pagesTE Dorman Smith Product Portofolio 2011Ashby KbNo ratings yet

- Y4it Narrative ReportDocument8 pagesY4it Narrative ReportSeah100% (1)

- 2SA1943Document7 pages2SA1943gotcha75No ratings yet

- System DevelopmentDocument4 pagesSystem DevelopmentSayed HossainNo ratings yet

- PCB Design and Fabrication ProcessDocument46 pagesPCB Design and Fabrication ProcessNishant NeogyNo ratings yet

- H. S. Bawa - Manufacturing Processes-1Document296 pagesH. S. Bawa - Manufacturing Processes-1Mechpec MechNo ratings yet

- ME2M ReportDocument2 pagesME2M ReportscribdjpdNo ratings yet

- Centrifugal Water FiltrationDocument3 pagesCentrifugal Water Filtrationnieav280No ratings yet

- Profile: Contact InformationDocument3 pagesProfile: Contact InformationMahesh KhabraniNo ratings yet

- R&D Update - Design Rules For Forming Aluminum Stampings-Part 1 - The FabricatorDocument5 pagesR&D Update - Design Rules For Forming Aluminum Stampings-Part 1 - The FabricatorSIMONENo ratings yet

- Perodua Part 1Document35 pagesPerodua Part 1doctoraspire50% (10)

- Session 1 Introduction To Pm2Document39 pagesSession 1 Introduction To Pm2kavithagowriNo ratings yet

- Cutting Tool EngineeringDocument92 pagesCutting Tool EngineeringMichael Naím Dévora QuintanarNo ratings yet

- Pressure Temperature Regulating Valve: Model 4504Document9 pagesPressure Temperature Regulating Valve: Model 4504AlexNo ratings yet

- Part 3-Chap 2 - Classification of Buildings Based On OccupanciesDocument60 pagesPart 3-Chap 2 - Classification of Buildings Based On Occupanciesfaruque65No ratings yet

- Screwdriver Bit SectionDocument30 pagesScrewdriver Bit SectionnamkvalNo ratings yet

- Bsai™ & Bsaig™Document4 pagesBsai™ & Bsaig™kztro066No ratings yet

- Basics of A Jet EngineDocument34 pagesBasics of A Jet EngineRavii Kantt KumarNo ratings yet

- Why Is India Not Ahead of Pakistan in Building Fighter Planes, While India Is Way Ahead in Space Technology, EtcDocument32 pagesWhy Is India Not Ahead of Pakistan in Building Fighter Planes, While India Is Way Ahead in Space Technology, EtcAditya BhuyanNo ratings yet

- Solomon Nigatu 0859/16 2. Getawa Melese ..... .0427/16Document32 pagesSolomon Nigatu 0859/16 2. Getawa Melese ..... .0427/16عبدالقادر مكونن سعيدNo ratings yet