Professional Documents

Culture Documents

02-WI-Shutdown Procedures Ammonia Plant

Uploaded by

Atif Masood0 ratings0% found this document useful (0 votes)

320 views1 pageShut down of ammoni aplant

Original Title

02-WI-Shutdown procedures ammonia plant

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentShut down of ammoni aplant

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

320 views1 page02-WI-Shutdown Procedures Ammonia Plant

Uploaded by

Atif MasoodShut down of ammoni aplant

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

DOCUMENT CODE AMM-WI-QMS-002 REV. # 00 REV.

DATE 08/05/07 PAGE 1 of 1

WORK INSTRUCTION Ammonia Unit

TITLE: SHUT DOWN INSTRUCTION

STEPS:

1. SHUT DOWN PROCEDURE

1.1. Reduce the plant load at FRCa-104 to 6.8 div.

1.2. Open purge gas vent valve PiC-131 & close purge gas valve to fuel gas circuit of 101-B.

1.3. Stop PGRU.

1.4. Stop syn loop & ensure that SP-4/5 valves are closed.

1.5. Stop 103-J & shift the vent to PiC-121.

1.6. Adjust HS steam flow & pressure.

1.7. Reduce the gas load from 6.8 div to 6.6 div & adjust the firing at furnace accordingly.

1.8. Stop methanator & shift the vent to PiC-119.

1.9. Bypass LTSC & isolate it.

1.10. Close absorber inlet block valve & open SP-7 gradually.

1.11. Stop 107-J & keep catacarb solution running through 108-J.

1.12. Change over jacket water 101-C/103-D & transfer line to demin water.

1.13. Take 111-C online.

1.14. Stop 101-J.Ensure SP-3 valve is closed & steam to steam/air coil is opened.

1.15. Reduce gas load gradually to 4.0 div & adjust the furnace firing accordingly.

1.16. Reduce furnace out let temperature to 750C & stop the process gas to 101-B.

1.17. Isolate 103-B fuel & PRC-102.

1.18. Continue the flushing of 101-B with steam & maintain back pressure at 12

kg/cm2.Gradually reduce the furnace temperature at @ 60C per hour & bring it up

to 400C.

1.19. Stop steam let down from HS to MS header by informing Utilities palnt.Open

superheat vent valve.

1.20. Stop steam to 101-B.close all the corck valves of arch burners.

1.21. Stop auxiliary boiler burners.

1.22. Insert blind in the mixed feed line to 101-B.

1.23. Depressurize fuel gas header & insert blind in main natural gas line at battery limit.

1.24. Open top vent valve of 101-F (steam drum) at 8 kg/cm2 steam pressure.

1.25. Keep I.D fan running at 2500 rpm till the furnace is cooled down to room

temperature for safe entry.

1.26. Stop I.D fan.

PREPARED BY APPROVED BY REFERENCE 4.2.1 (d)

Shafiq Ahmed Muhammad Muazzam

Operating Instruction Manual

Staff Engineer UM

You might also like

- Heat Transfer Process TUT (After Mid Semester)Document11 pagesHeat Transfer Process TUT (After Mid Semester)vaishnavi singh100% (1)

- LPG RefrigeratorDocument29 pagesLPG RefrigeratorSodum MaheswarreddyNo ratings yet

- Positive Isolation StandardDocument21 pagesPositive Isolation Standardmadhulika100% (2)

- Phosphoric Acid Production: University of AlqadisiaDocument61 pagesPhosphoric Acid Production: University of AlqadisiaAram Nasih MuhammadNo ratings yet

- Overview Plant Utility SystemDocument7 pagesOverview Plant Utility SystemMuhammad Nur Fahmi NaimemNo ratings yet

- Mass Balance For CS2 PlantDocument3 pagesMass Balance For CS2 PlantAshish GoelNo ratings yet

- Summer Internship At: Haldia Petrochemicals LTDDocument11 pagesSummer Internship At: Haldia Petrochemicals LTDJyoti PrakashNo ratings yet

- Process Design Basics for Station Facility Electrical System DesignDocument4 pagesProcess Design Basics for Station Facility Electrical System DesignHenryOdohNo ratings yet

- COOLER REACTOR hAZOPDocument2 pagesCOOLER REACTOR hAZOPAmirul NazrenNo ratings yet

- 1.2.2 Thermodynamics and HYSYS - 5 PDFDocument26 pages1.2.2 Thermodynamics and HYSYS - 5 PDFWelisson SilvaNo ratings yet

- Air Pollution Control: Carbon Adsorption For Vocs: Course No: C03-013 Credit: 3 PDHDocument46 pagesAir Pollution Control: Carbon Adsorption For Vocs: Course No: C03-013 Credit: 3 PDHwangbeifuNo ratings yet

- Adhitya Wikan Tyoso-17031010156-Paralel D HAZARD AND OPERABILITY STUDYDocument4 pagesAdhitya Wikan Tyoso-17031010156-Paralel D HAZARD AND OPERABILITY STUDYsofi bachtiarNo ratings yet

- Hydrogen MSDSDocument9 pagesHydrogen MSDSSyifaBahiijAmalia100% (1)

- Cooling Tower CocDocument3 pagesCooling Tower Cocvikas_be17No ratings yet

- Cre Una PDFDocument164 pagesCre Una PDFChetana PatilNo ratings yet

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4From EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Rating: 5 out of 5 stars5/5 (1)

- Vacuum Dryer Instruction ManualDocument5 pagesVacuum Dryer Instruction ManualinstrutechNo ratings yet

- Acetone MSDSDocument9 pagesAcetone MSDSCeline TheeNo ratings yet

- Lecture 14-15 - Gas-Liquid Contact EquipmentDocument11 pagesLecture 14-15 - Gas-Liquid Contact EquipmentMihir Kumar MechNo ratings yet

- SMR Hydrogen Generators-Technologies and Producers 2009Document28 pagesSMR Hydrogen Generators-Technologies and Producers 2009Zoran JuricNo ratings yet

- Plate Column Distillation EfficiencyDocument7 pagesPlate Column Distillation EfficiencyVijay PrasadNo ratings yet

- Nitric Acid, 65% MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesNitric Acid, 65% MSDS: Section 1: Chemical Product and Company IdentificationpulmonerNo ratings yet

- BOG of LPGDocument6 pagesBOG of LPGTala Ramezani100% (1)

- Humidification and Air Conditioning: Lecture No. 8Document6 pagesHumidification and Air Conditioning: Lecture No. 8Anonymous UFa1z9XUANo ratings yet

- 2 5188584049941152568Document24 pages2 5188584049941152568Slem Hamed100% (1)

- Reaction CalorimetryDocument7 pagesReaction CalorimetrySankar Adhikari100% (1)

- Experiment 6 - Level Flow Trainer (Wlf922)Document11 pagesExperiment 6 - Level Flow Trainer (Wlf922)Abdul AzimNo ratings yet

- Hvac Q & ADocument26 pagesHvac Q & ArishimaranNo ratings yet

- Hexane RecoveryDocument15 pagesHexane Recoveryanurag_guyNo ratings yet

- Compressed Gas Safety - Eng. Onel IsraelDocument13 pagesCompressed Gas Safety - Eng. Onel IsraelOnel Israel Badro100% (1)

- Distillation Tower DesignDocument65 pagesDistillation Tower DesignAntonio SilvaNo ratings yet

- C2R Compressor & Turbine ShutdownDocument10 pagesC2R Compressor & Turbine ShutdownfvaefaNo ratings yet

- Properties of Gaseous FuelDocument7 pagesProperties of Gaseous FuelTin Aung KyiNo ratings yet

- Separation Processss Lecture NotesDocument17 pagesSeparation Processss Lecture NoteskeatyNo ratings yet

- Steam Jet EjectorsDocument4 pagesSteam Jet EjectorsMuhammad Kamal WisyaldinNo ratings yet

- Refinery Process DescriptionDocument24 pagesRefinery Process DescriptionjeyalaksNo ratings yet

- Utilities - Equipment ListDocument1 pageUtilities - Equipment ListsutanuprojectsNo ratings yet

- Chapter 5 Centrifugal CompressorDocument17 pagesChapter 5 Centrifugal CompressorfaranimohamedNo ratings yet

- Ammonia Machinery Room Ventilation Requirements Dtc-Engineering-bulletin-4Document11 pagesAmmonia Machinery Room Ventilation Requirements Dtc-Engineering-bulletin-4Sergio GarciaNo ratings yet

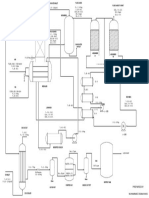

- Process Flow Diagram For Ammonia SynthesisDocument6 pagesProcess Flow Diagram For Ammonia SynthesisHanan Ahmed Ibrahim100% (1)

- Fermenter design specificationsDocument38 pagesFermenter design specificationsMilton Dela Rosa JrNo ratings yet

- Production of Sodium DithioniteDocument10 pagesProduction of Sodium DithioniteDhaval PadaliaNo ratings yet

- Heat Exchangers Design: Effectiveness - NTU MethodDocument35 pagesHeat Exchangers Design: Effectiveness - NTU MethodSaurabh SengarNo ratings yet

- HP Fuel Gas SystemDocument8 pagesHP Fuel Gas SystemAnonymous QSfDsVxjZNo ratings yet

- KG32903 Process Control and InstrumentationDocument40 pagesKG32903 Process Control and InstrumentationhellothereNo ratings yet

- Integrated Amine Degreasing Schedule 30mar2018Document1 pageIntegrated Amine Degreasing Schedule 30mar2018KhairulNo ratings yet

- Brochure DARCO H2S Odor ControlDocument8 pagesBrochure DARCO H2S Odor ControlErick MavenNo ratings yet

- Desalter Start Up ProcedureDocument2 pagesDesalter Start Up Procedureesakkiraj1590No ratings yet

- ReportDocument37 pagesReportAhsan Habib100% (1)

- Tutorial 9 Solutions 1Document5 pagesTutorial 9 Solutions 1Henry TranNo ratings yet

- A-One Consultant - Methanol & Other LicensesDocument12 pagesA-One Consultant - Methanol & Other LicensesWasim PathanNo ratings yet

- Amine Recovery Unit (ARU) : E. BayanjargalDocument12 pagesAmine Recovery Unit (ARU) : E. BayanjargalBayanjargal ErdeneeNo ratings yet

- Phosphoric Acid PDFDocument24 pagesPhosphoric Acid PDFabderrahimnNo ratings yet

- FlareDocument39 pagesFlareMuhammad Tahir RazaNo ratings yet

- FINAL EXAM CombustionDocument5 pagesFINAL EXAM CombustionJepoy torresNo ratings yet

- Power Plant OperationDocument199 pagesPower Plant OperationVijay Bhargav Badam83% (6)

- NGL1 V1 Sec 7Document203 pagesNGL1 V1 Sec 7varatharajan g rNo ratings yet

- Unit Normal Shutdown ProcedureDocument100 pagesUnit Normal Shutdown Procedureishak100% (1)

- Power Plant OperationDocument0 pagesPower Plant OperationSHIVAJI CHOUDHURYNo ratings yet

- House Keeping Procedure and ChecklistDocument10 pagesHouse Keeping Procedure and ChecklistAtif MasoodNo ratings yet

- Technical Proposal Calcium Ammonium Nitrate (Can) Plant Pakarab - PakistanDocument22 pagesTechnical Proposal Calcium Ammonium Nitrate (Can) Plant Pakarab - PakistanAtif MasoodNo ratings yet

- An Advanced Safety Proactive Method To Enhance Jet Fire Prevention, Mitigation and ControlDocument30 pagesAn Advanced Safety Proactive Method To Enhance Jet Fire Prevention, Mitigation and ControlAtif MasoodNo ratings yet

- Oracle Process Manufacturing (OPM) Operating Guide LinesDocument13 pagesOracle Process Manufacturing (OPM) Operating Guide LinesAtif Masood100% (1)

- CN MCC AND ESD - ScreensDocument13 pagesCN MCC AND ESD - ScreensAtif MasoodNo ratings yet

- Oti92597 PDFDocument310 pagesOti92597 PDFAtif MasoodNo ratings yet

- Title:: Project Code Document Title Report NoDocument8 pagesTitle:: Project Code Document Title Report NoAtif MasoodNo ratings yet

- Stripper To CondeserDocument1 pageStripper To CondeserAtif MasoodNo ratings yet

- 05june2020 20200106 Clinical Management Guidelines For COVID-19 Infection v2Document13 pages05june2020 20200106 Clinical Management Guidelines For COVID-19 Infection v2Murtaza HasanNo ratings yet

- CO2 Production Process Technical PDFDocument8 pagesCO2 Production Process Technical PDFAtif MasoodNo ratings yet

- CO2 Production Process Technical PDFDocument8 pagesCO2 Production Process Technical PDFAtif MasoodNo ratings yet

- Prepared By: Muhammad Osama AnisDocument1 pagePrepared By: Muhammad Osama AnisAtif MasoodNo ratings yet

- Natural Gas Cracking Unit For CO2 - Plant Manual: Section TopicDocument26 pagesNatural Gas Cracking Unit For CO2 - Plant Manual: Section TopicAtif MasoodNo ratings yet

- Can MCC and Esd ScreensDocument11 pagesCan MCC and Esd ScreensAtif MasoodNo ratings yet

- IFA PolicyDocument1 pageIFA PolicyAtif MasoodNo ratings yet

- 2333 - 001 CDM Relieve ValveDocument11 pages2333 - 001 CDM Relieve ValveAtif MasoodNo ratings yet

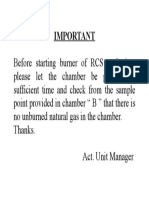

- Instruction of Burner StartupDocument1 pageInstruction of Burner StartupAtif MasoodNo ratings yet

- Basic Firefighting Tips 11.3.19Document1 pageBasic Firefighting Tips 11.3.19Atif MasoodNo ratings yet

- INTRO To Troubleshooting CourseDocument14 pagesINTRO To Troubleshooting CourseAtif MasoodNo ratings yet

- M-DA8-HS - Chapter 70Document105 pagesM-DA8-HS - Chapter 70JimyToasaNo ratings yet

- Elna 264 Parts ListDocument21 pagesElna 264 Parts Liststp717No ratings yet

- Flange 6Document5 pagesFlange 6Muhammad RafiNo ratings yet

- Circuito Carrileria JCB js200 Tier 3Document2 pagesCircuito Carrileria JCB js200 Tier 3PROSUCCA S.A.SNo ratings yet

- Chapter 2: Shafting: Shaft Combined StressDocument2 pagesChapter 2: Shafting: Shaft Combined StressJohnNo ratings yet

- HVAC Animal FacilityDocument14 pagesHVAC Animal Facilitysp suNo ratings yet

- HPS1000 Pump & GearboxDocument2 pagesHPS1000 Pump & GearboxFrederik CañabiNo ratings yet

- DRG Room Floor Plan-ModelDocument1 pageDRG Room Floor Plan-ModelRuman SiddiquiNo ratings yet

- PIPE STRESS ANALYSISDocument2 pagesPIPE STRESS ANALYSISAmit SharmaNo ratings yet

- Simple Mechanical Power HammerDocument3 pagesSimple Mechanical Power HammerGowda KadurNo ratings yet

- 005 SBH 750 9M (En)Document30 pages005 SBH 750 9M (En)Marman HuangNo ratings yet

- Pressure Parts ListDocument2 pagesPressure Parts ListRaji SuriNo ratings yet

- 1 - Method Statement For 22Kv Cable Installation Rev c02Document12 pages1 - Method Statement For 22Kv Cable Installation Rev c02Ahmed Nagy100% (2)

- Materials Approval ListDocument4 pagesMaterials Approval ListBala Krishna GallaNo ratings yet

- Const285 - Document - worksheetExteriorImprovementsProblems - B Chapter 17Document4 pagesConst285 - Document - worksheetExteriorImprovementsProblems - B Chapter 17Pablo LarreaNo ratings yet

- City Hall Plan 30x40Document1 pageCity Hall Plan 30x40Joy Dawis-AsuncionNo ratings yet

- Analisis Prinsip Kerja Alat Grate Cooler Di PT. Semen Baturaja (Persero) TBKDocument16 pagesAnalisis Prinsip Kerja Alat Grate Cooler Di PT. Semen Baturaja (Persero) TBKCia VhirgianiNo ratings yet

- Machine Tool and Machining: BroachingDocument29 pagesMachine Tool and Machining: BroachingFaisal Maqsood100% (1)

- Calibration CardSDocument4 pagesCalibration CardSNovia FebriatiNo ratings yet

- IEC 60364 - 1 - 2001 - Electrical Installation of BuildingsDocument80 pagesIEC 60364 - 1 - 2001 - Electrical Installation of BuildingsRebeca MancillaNo ratings yet

- Completion EquipmentDocument72 pagesCompletion EquipmentQingming MaNo ratings yet

- Power Transmitting ElementsDocument10 pagesPower Transmitting ElementsLAMPASA JOSE ROGER JR.No ratings yet

- PK 10000Document6 pagesPK 10000josempincNo ratings yet

- G Code M CodeDocument2 pagesG Code M CodeFAJAR PRASETYA 171244012No ratings yet

- Aerial Ropeways1Document60 pagesAerial Ropeways1Anshul yadavNo ratings yet

- Pra-Rancangan Pabrik Sabun Cair Dari Crude Palm Oil (Cpo) Dengan Kapasitas 20.000 Ton/TahunDocument1 pagePra-Rancangan Pabrik Sabun Cair Dari Crude Palm Oil (Cpo) Dengan Kapasitas 20.000 Ton/TahunNurulhafizNo ratings yet

- Pengaruh Perkuatan Mortar Jaket Dengan Variasi Konfigurasi Tulangan Longitudinal Bambu Pada Kolom Beton BertulangDocument7 pagesPengaruh Perkuatan Mortar Jaket Dengan Variasi Konfigurasi Tulangan Longitudinal Bambu Pada Kolom Beton Bertulangyudana monteiroNo ratings yet

- Flanges and Their Joints - Dimensions of Gaskets For Class-Designated FlangesDocument6 pagesFlanges and Their Joints - Dimensions of Gaskets For Class-Designated FlangesQC RegianNo ratings yet

- 3858 Parts CatalogueDocument48 pages3858 Parts CatalogueSergey Slomchinskiy100% (6)

- 321DLCR#209Document1 page321DLCR#209Kyaw Thet AungNo ratings yet