Professional Documents

Culture Documents

Thomas and Ramaswamy - 2007 - Mechanical Properties of Steel Fiber-Reinforced Co

Uploaded by

violettaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thomas and Ramaswamy - 2007 - Mechanical Properties of Steel Fiber-Reinforced Co

Uploaded by

violettaCopyright:

Available Formats

Mechanical Properties of Steel Fiber-Reinforced Concrete

Job Thomas1 and Ananth Ramaswamy2

Abstract: This paper presents the results from an experimental program and an analytical assessment of the influence of addition of

Downloaded from ascelibrary.org by Cochin University of Science and Technology on 08/10/14. Copyright ASCE. For personal use only; all rights reserved.

fibers on mechanical properties of concrete. Models derived based on the regression analysis of 60 test data for various mechanical

properties of steel fiber-reinforced concrete have been presented. The various strength properties studied are cube and cylinder compres-

sive strength, split tensile strength, modulus of rupture and postcracking performance, modulus of elasticity, Poisson’s ratio, and strain

corresponding to peak compressive stress. The variables considered are grade of concrete, namely, normal strength 共35 MPa兲, moderately

high strength 共65 MPa兲, and high-strength concrete 共85 MPa兲, and the volume fraction of the fiber 共V f = 0.0, 0.5, 1.0, and 1.5%兲. The

strength of steel fiber-reinforced concrete predicted using the proposed models have been compared with the test data from the present

study and with various other test data reported in the literature. The proposed model predicted the test data quite accurately. The study

indicates that the fiber matrix interaction contributes significantly to enhancement of mechanical properties caused by the introduction of

fibers, which is at variance with both existing models and formulations based on the law of mixtures.

DOI: 10.1061/共ASCE兲0899-1561共2007兲19:5共385兲

CE Database subject headings: Compressive strength; Tensile strength; Steel fibers; Concrete, reinforced.

Introduction 85 MPa兲 with various fiber dosages 共V f = 0, 0.5, 1.0, and 1.5%兲.

An empirical relationship for various mechanical properties of

In earlier studies 共Ghosh et al. 1989; Agrawal et al. 1996; Gao et SFRC has been proposed. The proposed model attempts to bring

al. 1997; Padmarajaiah 1999; Song and Hwang 2004兲, the out the significance of fiber matrix interaction in all the strength

improvement in mechanical properties in concrete due to the ad- properties.

dition of steel fibers were expressed as a function of fiber- This study reports the experimental results of the strength

reinforcing index 共RI= V f L f / f 兲 and concrete strength. Hannant properties of SFRC, namely, cube and cylinder compressive

共1978兲 has discussed the role played by both the fiber content 共V f 兲 strength, split tensile strength, modulus of rupture, modulus of

and the fiber aspect ratio 共L f / f 兲 in the workability, and strength elasticity, Poisson’s ratio, and strain corresponding to peak com-

enhancement of steel fiber-reinforced concrete 共SFRC兲. Hannant pressive stress. Empirical relationships were developed for vari-

共1978兲 captured the strength contribution of the fiber in the com- ous strength properties based on the regression analysis of the 60

posite through the combined influence of both factors, namely, test data. It is expected that these proposed models would be

fiber content 共V f 兲 and the fiber aspect ratio 共L f / f 兲 through the helpful in assessing the strength properties of fiber-reinforced

RI. Most of these models 共Ghosh et al. 1989; Agrawal et al. 1996; concrete based on the matrix strength and fiber-RI.

Gao et al. 1997; Padmarajaiah 1999兲 were developed based on the

test data of a single grade of concrete. The mechanical strength

properties SFRC are closely related to the fiber parameters, ma- Experimental Program

trix strength, and their interaction. However, the matrix strength

fiber interaction has not been considered in the earlier studies. Details of the standard test specimens, namely, cubes, cylinders

The fiber matrix interaction is an important factor that represents and prisms are given in Table 1. Five specimens each were cast

the strength enhancement due to the fiber bridging action across using each grade of concrete 共35, 65, and 85 MPa兲 and tested.

the microcracks in the concrete matrix. The present study reports The weight of the constituent materials per 1 m3 of concrete ar-

on the test data for various strength grades of SFRC 共35, 65, and rived at based on absolute volume method 关IS: 10262 共BIS 1982兲兴

for various concrete mixes is given in Table 2. Blended-type ce-

1

Lecturer, Dept. of Civil Engineering, Cochin Institute of Science and ment having a specific gravity 3.14 was used for the study. River

Technology, Cochin, Kerala, India; formerly, Research Scholar, IISc sand 共⬍4.75 mm兲 of specific gravity 2.62 was used as fine aggre-

Bangalore. E-mail: job_thomas@cusat.ac.in gate and crushed stone aggregate 共⬍10 mm兲 of specific gravity

2

Associate Professor, Dept. of Civil Engineering, Indian Institute of 2.69 was used as the coarse aggregate. Sulphonated naphthalene

Science, Bangalore, India 共corresponding author兲. E-mail: ananth@ polymer based superplasticizer was used for the preparation of

civil.iisc.ernet.in moderately high strength 共65 MPa兲 and high-strength concrete

Note. Associate Editor: Nemkumar Banthia. Discussion open until 共85 MPa兲. Silica fume was used for high-strength concrete

October 1, 2007. Separate discussions must be submitted for individual

共85 MPa兲. The fibers used were of hooked-end type 共Fig. 1兲 glued

papers. To extend the closing date by one month, a written request must

be filed with the ASCE Managing Editor. The manuscript for this paper

in bundles having a length of 30 mm and aspect ratio of 55. The

was submitted for review and possible publication on September 15, fiber dosage was varied 共V f 兲 between 0.0 and 1.5% 共Table 2兲. All

2005; approved on May 4, 2006. This paper is part of the Journal of the specimens were cured in water for a period of 28 days and

Materials in Civil Engineering, Vol. 19, No. 5, May 1, 2007. ©ASCE, then tested.

ISSN 0899-1561/2007/5-385–392/$25.00. The cube and cylinder specimens were tested to determine the

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / MAY 2007 / 385

J. Mater. Civ. Eng. 2007.19:385-392.

Table 1. Specimens for the Assessment of Strength Properties of SFRC

Number

Dimensions of specimens

Strength property Specimen 共mm兲 for each mix

Cube compressive strength Cube 150⫻ 150⫻ 150 5

Cylinder compressive strength Cylinder 150 ⫻ 300 5

Splitting tensile strength Cylinder 150 ⫻ 300 5

Modulus of rupture Prism 100⫻ 100⫻ 500 5

Modulus of elasticity Cylinder 150 ⫻ 300 5 Fig. 1. Hooked-end steel fiber 共all dimensions are in millimeter兲

Downloaded from ascelibrary.org by Cochin University of Science and Technology on 08/10/14. Copyright ASCE. For personal use only; all rights reserved.

Poisson’s ratio Cylinder 150 ⫻ 300 5

Stress–strain behavior Cylinder 150 ⫻ 300 5

B represents the contribution of matrix strength–fiber interaction

explicitly, which depends on the pullout characteristics of fiber

compressive strength according to IS: 516 共BIS 1959兲. Cylinder from the matrix. The third term represents the contribution of the

specimens were tested for split tensile strength according to IS: fiber dosage and fiber geometry. The coefficients represent the

5816 共BIS 1999兲. Modulus of rupture test was carried out accord- factors, namely, orientation of fiber, shape of the fiber, surface

ing to IS: 516 共BIS 1959兲. Modulus of elasticity and Poisson’s characteristics, etc., that contribute to the strength of the fiber-

ratio of concrete were determined using the standard cylinder reinforced concrete. Hence, the coefficients of the predictive

specimens 共BIS 1959兲. equation obtained based on the regression analysis of the test data

of the present study partially characterizes the type of the fiber

used. In earlier models 共Taerwe 1992; Agrawal et al. 1996; Gao et

Strength Prediction Models al. 1997; Padmarajaiah 1999; Song and Hwang 2004兲 based on

the law of mixtures, contribution of matrix represented by first

Based on the regression analysis of the 60 test data, empirical and fibers represented by third term of Eq. 共1兲 only was consid-

models have been developed for predicting the strength properties ered and the fiber matrix interaction term represented by the sec-

of fiber-reinforced concrete. The proposed strength prediction ond term of Eq. 共1兲 was ignored. The variation of the values of

models accounts for the interaction of matrix strength with fiber. the strength properties predicted using a model consisting of only

The general form of the proposed strength prediction model is first and third terms of Eq.共1兲 when compared with the corre-

given by sponding test result was found to be significant. The strength

predictive models for various mechanical properties of SFRC ac-

f SFRC = A共f ⬘cu兲␣1 + B共f ⬘cu兲␣2RI + C RI 共1兲 counting for the matrix strength–fiber interaction explicitly as

where f SFRC⫽strength property 共cylinder strength/split tensile given by the second term of Eq. 共1兲 is found to predict the corre-

strength/modulus of rupture兲 of the steel fiber-reinforced con- sponding test results quite accurately. The regression models of

crete; A, B, and C⫽regression coefficients; f ⬘cu⫽28-day cube various strength properties are presented in Table 3.

compressive strength of the matrix 共plain concrete兲; and

RI⫽fiber-reinforcing index 共V f L f / f 兲. The value of ␣1 has been

assumed to take a value of 0.5 or 1.0 as used in the conventional Results and Discussion

established method. The value of ␣1 in the prediction models of

Poisson’s ratio and strain corresponding to the peak compressive The test data of various strength properties of SFRC are presented

stress has been obtained by regression analysis of the test data of in Fig. 2. The addition of fibers increased the various strength

plain concrete having no fibers. The value of ␣2 has been as- properties of concrete. The average strength of SFRC based on

sumed to take a value of 0.5 or 1.0 so as to get minimum devia- the five test data is presented in Table 4.

tion for predicted results from the corresponding test data. The The average increase in cube compressive strength 共f cuF ⬘ 兲 due

first term with coefficient A represents the contribution of strength to the addition of steel fibers 共V f = 1.5% 兲 was found to be minimal

of the plain concrete or matrix. The second term with coefficient 共3.65% in normal-strength concrete, 2.65% in moderately high-

Table 2. Weights of Constituent Materials for 1 m3 Concrete

Moderately

Item Unit Normal-strength concrete high-strength concrete High-strength concrete

⬘

f cu MPa 35 35 35 35 65 65 65 65 85 85 85 85

Vf % 0 0.5 1 1.5 0 0.5 1 1.5 0 0.5 1 1.5

Water kg 190 190 190 190 158 158 158 158 140 140 140 140

Cement kg 400 400 400 400 450 450 450 450 450 450 450 450

Fine aggregate kg 610 600 600 590 610 610 600 600 630 625 620 615

Coarse aggregate kg 1,130 1,120 1,110 1,110 1,140 1,130 1,120 1,110 1,170 1,160 1,150 1,140

Silica fume kg — — — — — — — — 50 50 50 50

Super plasticizer L — — — — 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5

Fiber kg — 40 80 120 — 40 80 120 — 40 80 120

Water/共cement+silica fume兲 kg 0.48 0.48 0.48 0.48 0.35 0.35 0.35 0.35 0.28 0.28 0.28 0.28

Note: Density of super plasticizer⫽1,200 kg/ m3 or 1.2 kg/ L.

386 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / MAY 2007

J. Mater. Civ. Eng. 2007.19:385-392.

Table 3. Strength Prediction Models for SFRC

Serial

number Property description Prediction model

1 Cube compressive strength ⬘ = f cu + 0.014f cuRI+ 1.09RI 共MPa兲

f cuF

2 Cylinder compressive strength ⬘ = 0.84f cu

f cuF ⬘ + 0.046f cu

⬘ RI+ 1.02RI 共MPa兲

3 Split tensile strength ⬘ 兲0.5 + 0.288共f cu

f spcF = 0.63共f cu ⬘ 兲0.5RI+ 0.052RI 共MPa兲

4 Modulus of rupture ⬘ 兲0.5 + 0.295共f cu

FflF = 0.97共f cu ⬘ 兲0.5RI+ 1.117RI 共MPa兲

5 Poisson’s ratio ⬘ 兲0.167 + 0.0001f cu

cF = 0.01共f cu ⬘ RI+ 0.012RI

Downloaded from ascelibrary.org by Cochin University of Science and Technology on 08/10/14. Copyright ASCE. For personal use only; all rights reserved.

6 Modulus of elasticity ⬘ 兲0.5 + 0.42共f cu

EcF = 4.58共f cu ⬘ 兲RI+ 0.39RI 共GPa兲

7 Strain at peak compressive stress ⬘ 兲0.3943 + 3.5788f cu

ocF = 关493.4共f cu ⬘ RI+ 484.95RI兴 ⫻ 106

strength concrete, and 2.59% in high-strength concrete兲 as shown

in Table 4. The average increase in the cylinder compressive

⬘ 兲 due to the addition of steel fibers 共V f = 1.5% 兲 was

strength 共f cyF

found to be quite small at 8.33% in normal-strength concrete,

6.10% in moderately high-strength concrete, and 4.60% in high-

strength concrete 共Table 4兲. The maximum value of the standard

deviation in the test results was found to be 2.5%. The small

increase in the compressive strength due to the addition of steel

fibers 共V f = 0 – 1.5% 兲 of various grades of concrete is shown in

Figs. 2共a and b兲.

Unlike concrete in compression, use of fibers, increases the

split tensile strength 共f spcF兲 due to the addition of steel fibers

共V f = 1.5% 兲 by 38.2% in normal-strength concrete, 41.2% in mod-

erately high-strength concrete and 38.5% in high-strength con-

crete 共Table 4兲. The variation of split tensile strength 共f spcF兲 due to

the addition of steel fibers 共V f = 1.5% 兲 is shown in Fig. 2共c兲. The

increase in modulus of rupture 共f flF兲 due to the addition of steel

fibers 共V f = 1.5% 兲 was found to be 46.2% in normal-strength con-

crete, 38.8% in moderately high-strength concrete and 40.0% in

high-strength concrete 共Table 4兲. The variation of modulus of

rupture 共f flF兲 due to the addition of steel fibers 共V f = 1.5% 兲 is

shown in Fig. 2共d兲. The increase in the tensile strengths, namely,

split tensile strength 共f spcF兲 and the modulus of rupture 共f flF兲 due

to the addition of the fibers is due to the action of fibers across the

cracks in the concrete matrix. Fig. 3 shows the load displacement

response of 65 MPa concrete for various fiber dosages. It is clear

that the increase in fiber content enhances the tensile strength

characteristics. The post-cracking response is significantly en-

hanced with increased fiber dosages across different concrete

strength 共35, 65, and 8 MPa兲 as seen in Fig. 4.

The variation in the Poisson’s ratio of the concrete 共cF兲 due to

the addition of steel fibers was marginal 关Fig. 2共e兲兴. The value of

Poisson’s ratio was found to be varying from 0.18 to 0.22 for

various grades of concrete 共Table 4兲. Poisson’s ratio of SFRC

共cF兲 is computed based on the observations at initial stages of

loading, where the fibers do not play a significant role in the load

sustenance. Thus, the addition of fibers did not show significant

variation in Poisson’s ratio of concrete 共cF兲.

The increase in modulus of elasticity 共EcF兲 due to the addition

of steel fibers 共V f = 1.5% 兲 was found to be 8.3% in normal-

strength concrete, 9.2% in moderately high-strength concrete, and

8.2% in high-strength concrete 共Table 4兲. The variation of modu-

lus of elasticity 共EcF兲 due to the addition of fibers 共V f = 1.5% 兲 is

shown in Fig. 2共f兲. As these measurements for modulus of elas-

ticity were in the linear region of the stress–strain response, the

effect of fibers was not pronounced.

The increase in strain corresponding to the peak compressive Fig. 2. Effect of reinforcing index of fiber on various strength

stress 共ocF兲 due to the addition of steel fibers 共V f = 1.5% 兲 was properties of SFRC

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / MAY 2007 / 387

J. Mater. Civ. Eng. 2007.19:385-392.

Table 4. Comparison of Experimental Results with the Strength Results Predicted Using the Proposed Models

35 MPa Grade 65 MPa Grade 85 MPa Grade

a a

Property RI Experiment Model 共4兲 / 共3兲 Experiment Model 共7兲 / 共6兲 Experiment Model 共10兲 / 共9兲a

⬘ 共MPa兲

f cuF 0.000 36.6 36.6 1.00 66.6 66.6 1.00 86.1 86.1 1.00

0.275 37.0 37.0 1.00 67.1 67.2 1.00 86.5 86.7 1.00

0.550 37.5 37.5 1.00 67.5 67.7 1.00 87.0 87.3 1.00

0.825 37.9 37.9 1.00 68.4 68.3 1.00 88.3 88.0 1.00

⬘ 共MPa兲

f cyF 0.000 29.8 30.7 1.03 56.0 55.8 1.00 72.4 72.2 1.00

0.275 30.5 31.4 1.03 57.0 57.0 1.00 73.6 73.5 1.00

Downloaded from ascelibrary.org by Cochin University of Science and Technology on 08/10/14. Copyright ASCE. For personal use only; all rights reserved.

0.550 31.2 32.1 1.03 57.8 58.1 1.01 74.8 74.9 1.00

0.825 32.3 32.9 1.02 59.4 59.2 1.00 77.0 76.3 0.99

⬘ 共MPa兲

FspcF 0.000 3.93 3.82 0.97 5.19 5.16 0.99 5.76 5.86 1.02

0.275 4.37 4.32 0.99 5.81 5.82 1.00 6.48 6.61 1.02

0.550 4.87 4.81 0.99 6.49 6.48 1.00 7.20 7.36 1.02

0.825 5.43 5.30 0.98 7.33 7.14 0.97 7.98 8.11 1.02

f flF 共MPa兲 0.000 5.20 5.27 1.01 7.20 7.11 0.99 8.00 8.08 1.01

0.275 6.00 6.07 1.01 8.00 8.08 1.01 9.20 9.14 0.99

0.550 6.80 6.86 1.01 9.20 9.05 0.98 10.40 10.20 0.98

0.825 7.60 7.66 1.01 10.00 10.01 1.00 11.20 11.26 1.01

cF 0.000 0.182 0.181 0.99 0.201 0.201 1.00 0.210 0.209 0.99

0.275 0.186 0.186 1.00 0.204 0.206 1.01 0.215 0.215 1.00

0.550 0.191 0.190 0.99 0.213 0.211 0.99 0.221 0.221 1.00

0.825 0.195 0.195 1.00 0.219 0.216 0.98 0.228 0.227 0.99

EcF 共GPa兲 0.000 28.7 27.7 0.97 37.5 37.4 1.00 41.7 42.5 1.02

0.275 29.4 28.5 0.97 38.6 38.4 1.00 43.0 43.7 1.02

0.550 30.2 29.3 0.97 39.8 39.5 0.99 44.0 44.9 1.02

0.825 31.1 30.1 0.97 41.0 40.6 0.99 45.1 46.1 1.02

ocF 0.000 1.9⫻ 10−3 2.0⫻ 10−3 1.06 2.6⫻ 10−3 2.58 0.97 2.8⫻ 10−3 2.8⫻ 10−3 1.01

0.275 2.0⫻ 10−3 2.2⫻ 10−3 1.08 2.7⫻ 10−3 2.78 1.02 3.0⫻ 10−3 3.0⫻ 10−3 1.02

−3 −3

0.550 2.2⫻ 10 2.3⫻ 10 1.08 2.9⫻ 10−3 2.98 1.02 3.2⫻ 10−3 3.2⫻ 10−3 1.01

−3 −3

0.825 2.5⫻ 10 2.5⫻ 10 1.02 3.4⫻ 10−3 3.19 0.93 3.5⫻ 10−3 3.5⫻ 10−3 0.99

a

Numbers in parentheses represent the corresponding values in the columns.

found to be 29.5% in normal-strength concrete, 29.4% in moder- Comparison of Predicted and Experimental Results

ately high-strength concrete, and 27.0% in high-strength concrete

共Table 4兲. The variation in the strain corresponding to the peak The predicted value of the various strength properties of SFRC

compressive stress 共ocF兲 due to the addition of steel fibers has been compared with the experimental results of the present

共V f = 1.5% 兲 for the various grades of concrete is shown in Fig. study 共Table 4兲 and also with the test data reported in the litera-

2共g兲. The increase in strain corresponding to compressive strength

is due to the confinement effect induced by the distributed steel

fibers in a concrete matrix.

Fig. 4. Postcracking strength enhancements in SFRC with different

Fig. 3. Load deflection response in SFRC prism 共65 MPa concrete兲 fiber contents for different concrete mixes

388 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / MAY 2007

J. Mater. Civ. Eng. 2007.19:385-392.

Tensile Strength

Figs. 5共c and d兲 compare the test data of tensile strength of SFRC,

namely, split tensile strength and modulus of rupture from the

present test results with the corresponding predictions from mod-

els 共Table 3兲. The proposed models predicted the experimental

results of the present study quite accurately. However, scatter was

seen in the predicted data of test results reported in the literature

共Figs. 5共c and d兲兲. A higher magnitude has been predicted for the

tensile strength of SFRC reported in the literature. The variation

Downloaded from ascelibrary.org by Cochin University of Science and Technology on 08/10/14. Copyright ASCE. For personal use only; all rights reserved.

in the tensile strengths of SFRC reported by various investigators

may be due to the difference in degree of compaction, mix pro-

portions, loading rate in the test procedure, aggregate to fiber

length scales etc.

Hueste et al. 共2004兲 developed models for the tensile strength

of the plain concrete based on the statistical analysis of various

test data and the models are given by

f spc = 0.55冑 f ⬘cy for 40 MPa ⬍ f ⬘cy ⬍ 90 MPa 共2兲

f fl = 0.83冑 f ⬘cy for 40 MPa ⬍ f ⬘cy ⬍ 90 MPa 共3兲

The equivalent strength prediction models developed in the

present study are given by

f spc = 0.63冑0.83f ⬘cy = 0.57冑 f ⬘cy for 30 MPa ⬍ f ⬘cy ⬍ 75 MPa

共4兲

f fl = 0.87冑0.83f ⬘cy = 0.79冑 f ⬘cy for 30 MPa ⬍ f ⬘cy ⬍ 75 MPa

共5兲

The comparison of the coefficients in Eqs. 共2兲 and 共3兲 with Eqs.

共4兲 and 共5兲 shows that the proposed models show good agreement

with the models proposed by Hueste et al. 共2004兲 for plain

concrete.

Poisson’s Ratio

Fig. 5共e兲 compares the Poisson’s ratio of SFRC test results with

the corresponding value predicted using models reported in Table

Fig. 5. Comparison of test data of the present study and test data 3. Fig. 5共e兲 indicates that the proposed model predicts the Pois-

reported in the literature with the predicted data using the proposed son’s ratio accurately. The literature reporting on the Poisson’s

models ratio of the concrete is limited. The value of Poisson’s ratio of

65 MPa grade concrete reported by Padmarajaiah 共1999兲 was

0.26 for plain concrete and 0.31 for fiber-reinforced concrete,

which is slightly higher than the predicted value. This variation

ture 共Agrawal et al. 1996; Ashour et al. 2000; Gao et al. 1997; may be due to the difference in the aggregate proportion, aggre-

Ghosh et al. 1989; Hueste et al. 2004; Irvani 1996; Oh 1992; gate size and variation in the rate of loading.

Padmarajaiah 1999; Song and Hwang 2004; Taerwe 1992兲. Fig. 5

shows the comparison for the different response quantities.

Modulus of Elasticity

The predicted value of the modulus of elasticity of SFRC has

Compressive Strength been compared with the experimental results and is presented in

Fig. 5共f兲. The proposed model 共Table 4兲 predicted the test results

Average values of the test results of the compressive strengths accurately. The model proposed by Irvani 共1996兲 for the modulus

⬘ and f cyF

共f cuF ⬘ 兲 have been compared with the corresponding pre- of elasticity of the plain concrete 关Eq. 共6兲兴 is in good agreement

dicted strength. The comparison indicates that the proposed com- with the model proposed in this study 关Eq. 共7兲兴

pressive strength model predicts the cube compressive strength

and cylinder compressive strength of the present test program and Ec = 0.82 ⫻ 4.7冑 f ⬘cy = 3.8冑 f ⬘cy 共GPa兲

that reported in earlier literature quite accurately 关Figs. 5共a and

b兲兴. for 55 MPa ⬍ f ⬘cy ⬍ 125 MPa 共6兲

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / MAY 2007 / 389

J. Mater. Civ. Eng. 2007.19:385-392.

Table 5. Contribution of Individual Terms in Strength Properties in Eq. 共1兲

Strength ⬘ 兲␣2

B共f cuF C

property RI ⬘ 兲␣1

A共f cuF 共RI兲 关100共4兲兴 / 关共4兲 + 共6兲兴a 共RI兲 关100共6兲兴 / 关共4兲 + 共6兲兴a

⬘ 共MPa兲

f cuF 0.000 36.6 0.0 0 0.0 0

0.275 36.6 0.1 32 0.3 68

0.550 36.6 0.3 32 0.6 68

0.825 36.6 0.4 32 0.9 68

⬘ 共MPa兲

f cyF 0.000 30.6 0.0 0 0.0 0

0.275 30.6 0.5 62 0.3 38

Downloaded from ascelibrary.org by Cochin University of Science and Technology on 08/10/14. Copyright ASCE. For personal use only; all rights reserved.

0.550 30.6 0.9 62 0.6 38

0.825 30.6 1.4 62 0.8 38

⬘ 共MPa兲

f spcF 0.000 3.82 0.00 0 0.00 0

0.275 3.82 0.48 97 0.01 3

0.550 3.82 0.96 97 0.03 3

0.825 3.82 1.44 97 0.04 3

f flF共MPa兲 0.000 5.27 0.00 0 0.00 0

0.275 5.27 0.49 62 0.31 38

0.550 5.27 0.98 62 0.61 38

0.825 5.27 1.47 62 0.92 38

cF 0.000 0.182 0.000 0 0.000 0

0.275 0.182 0.001 23 0.003 77

0.550 0.182 0.002 23 0.007 77

0.825 0.182 0.003 23 0.010 77

EcF 共GPa兲 0.000 27.7 0 0 0 0

0.275 27.7 0.7 87 0.1 13

0.550 27.7 1.4 87 0.2 13

0.825 27.7 2.1 87 0.3 13

ocF 0.000 2.04⫻ 10−3 0.00 0 0.00 0

0.275 2.04⫻ 10−3 3.79⫻ 10−5 22 1.33⫻ 10−4 78

0.550 2.04⫻ 10−3 7.57⫻ 10−5 22 2.67⫻ 10−4 78

−3

0.825 2.04⫻ 10 1.14⫻ 10−4 22 4.00⫻ 10−4 78

Note: Columns 共5兲 and 共7兲 represent the contribution percentage in the increase of each strength property due to the addition of fibers of the second and

third terms of Eq. 共1兲, respectively.

a

Numbers in the brackets/parentheses represent the corresponding values in the column.

Ec = 4.6冑0.83f ⬘cy = 4.2冑 f ⬘cy 共GPa兲 for 30 MPa ⬍ f ⬘cy ⬍ 75 MPa vidual contribution of the various terms are computed and com-

pared 共Tables 5 and 6兲. The second and third term in Eq. 共1兲

共7兲 represents the effect of matrix strength to fiber interaction. The

The comparison of the predicted strength and test results of the percentage contribution of the second term of Eq. 共1兲 in the total

present study and that reported in the literature has been presented increase in the strength property of SFRC of 35 and 85 MPa

in Fig. 5共f兲. The modulus of elasticity reported by Ashour et al. grade due to the addition of fibers is presented in Column 5 of

共2000兲 was the secant modulus evaluated at a stress level of Tables 5 and 6, respectively. Similarly, the contribution of third

⬘ . The proposed model for predicting the modulus of elas-

0.5f cyF term of Eq. 共1兲 is presented in Column 7 of Tables 5 and 6. The

ticity 共Table 3兲 developed based on the stress-strain response up contribution of the fiber–matrix interaction term 关second term in

⬘ predicted slightly higher magnitude compared with the

to 0.4f cyF Eq. 共1兲兴 varies for various strength properties. The comparison of

test results reported by Ashour et al. 共2000兲. the contribution of individual terms indicated that the contribution

of the fiber–matrix interaction term is significant in computing the

increased benefits due to the addition of fibers in concrete matrix.

Strain at Peak Compressive Stress

The prediction models for mechanical properties of SFRC re-

The strain at peak compressive stress predicted using proposed ported have been presented in Table 7. The average value of the

regression model 共Table 4兲 has been compared with the corre- ratio of predicted results to the test results of the present study

sponding experimental results and presented in Fig. 5共g兲. The and standard deviation of this ratio is also presented in Table 7.

comparison indicated that proposed model predicts the experi- The average value of the ratio of the predicted strength to test

mental data quite accurately. result is an indication of the performance of the model and the

standard deviation is indicative of the scatter in the computed

ratio. The cube compressive strength and the cylinder compres-

Contribution of Fiber–Matrix Interaction sive strength predicted using the earlier models 共Agrawal et al.

1996; Padmarajaiah 1999; Song and Hwang 2004兲 was also found

To bring out the contribution of fiber–matrix interaction term in to be in good agreement with the test data of the present study

Eq. 共1兲, the generalized form of the prediction model, the indi- 共Table 7兲. The tensile strengths, namely, split tensile strength and

390 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / MAY 2007

J. Mater. Civ. Eng. 2007.19:385-392.

Table 6. Contribution of Individual Terms in Strength Properties of SFRC in Eq. 共1兲 共85 MPa兲

⬘ 兲␣2

B共f cuF C

Strength property RI ⬘ 兲␣1

A共f cuF 共RI兲 关100共4兲兴 / 关共4兲 + 共6兲兴c 共RI兲 关100共6兲兴 / 关共4兲 + 共6兲兴c

⬘ 共MPa兲

f cuF 0.000 86.1 0.0 0 0.0 0

0.275 86.1 0.3 52 0.3 48

0.550 86.1 0.6 52 0.6 48

0.825 86.1 0.9 52 0.9 48

⬘ 共MPa兲

f cyF 0.000 72.1 0.0 0 0.0 0

0.275 72.1 1.1 80 0.2 20

Downloaded from ascelibrary.org by Cochin University of Science and Technology on 08/10/14. Copyright ASCE. For personal use only; all rights reserved.

0.550 72.1 2.2 80 0.5 20

0.825 72.1 3.3 80 0.8 20

⬘ 共MPa兲

f spcF 0.000 5.86 0.00 0 0.00 0

0.275 5.86 0.74 98 0.01 2

0.550 5.86 1.47 98 0.03 2

0.825 5.86 2.21 98 0.04 2

f flF 共MPa兲 0.000 8.08 0.00 0 0.00 0

0.275 8.08 0.75 71 0.31 29

0.550 8.08 1.50 71 0.61 29

0.825 8.08 2.25 71 0.92 29

cF 0.000 0.209 0.000 0 0.000 0

0.275 0.209 0.002 41 0.003 59

0.550 0.209 0.004 41 0.006 59

0.825 0.209 0.007 41 0.010 59

EcF 共GPa兲 0.000 42.5 0.0 0 0.0 0

0.275 42.5 1.0 91 0.1 9

0.550 42.5 2.1 91 0.2 9

0.825 42.5 3.2 91 0.3 9

ocF 0.000 2.86⫻ 10−3 0.00 0 0.00 0

0.275 2.86⫻ 10−3 8.90⫻ 10−5 40 1.33⫻ 10−4 60

−3

0.550 2.86⫻ 10 1.78⫻ 10−5 40 2.67⫻ 10−4 60

0.825 2.86⫻ 10−3 2.67⫻ 10−4 40 4.00⫻ 10−4 60

Note: Columns 共5兲 and 共7兲 represent the contribution percentage in the increase of each strength property due to the addition of fibers of the second and

third terms of Eq. 共1兲, respectively.

c

Numbers in the brackets/parentheses represent the corresponding values in the column.

Table 7. Comparison of Results of the Present Study with the Predicted Results Using Strength Models Reported Earlier

Predicted strength

Property Investigator Predicted model Average Standard deviation

⬘ 共MPa兲

f cuF Agrawal et al. 共1996兲 ⬘ = f cu

f cuF ⬘ + 0.106共RI兲 − 2.65⫻ 10 共RI兲 + 2.28⫻ 10 共RI兲

−5 2 −6 3 0.99 0.01

Padmarajaiah 共1999兲 ⬘ = f cu

f cuF ⬘ + 1.998共RI兲 1.00 0.00

⬘ 共MPa兲

f cyF Song and Hwang 共2004兲 ⬘ = f cy

f cyF ⬘ + 15.12共V f 兲 − 4.17共V f 兲2 0.97 0.02

Padmarajaiah 共1999兲 ⬘ = f cy

f cyF ⬘ + 2.274共RI兲 0.99 0.01

⬘ 共MPa兲

f spcF Ghosh et al. 共1989兲 ⬘ 共1 − V f 兲 + 0.573共RI兲 + 0.571

f spcF = 0.11f cu 1.29 0.25

Padmarajaiah 共1999兲 ⬘ 兲0.5 / 3 + 1.918共RI兲

f spcF = 共f cu 0.57 0.04

f flF 共MPa兲 Ghosh et al. 共1989兲 ⬘ 共1 − V f 兲 + 0.79共RI兲

f flF = 0.15f cu 1.17 0.24

Padmarajaiah 共1999兲 f flF = f flF + 4.419共RI兲 1.05 0.05

cF Gao et al. 共1997兲 cF = c关1 − 0.172共RI兲兴 0.90 0.08

Padmarajaiah 共1999兲 cF = c + 0.03704共RI兲 1.04 0.03

Ecf 共GPa兲 Gao et al. 共1997兲 EcF = Ec关1 + 0.173共RI兲兴 1.03 0.02

Padmarajaiah 共1999兲 EcF = Ec + 2440.2共RI兲 0.99 0.01

ocF Taerwe 共1992兲 ⬘

ocF = oc + 0.0115f cyF 0.89 0.10

Padmarajaiah 共1999兲 ocF = oc + 1.15⫻ 10−3共RI兲 1.07 0.06

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / MAY 2007 / 391

J. Mater. Civ. Eng. 2007.19:385-392.

modulus of rupture predicted using the existing models 共Padma- f ⬘cu , fcuF

⬘ ⫽ cube compressive strength of plain concrete

rajaiah 1999; Ghosh et al. 1989兲 showed some scatter 共Table 7兲. and fiber-reinforced concrete, respectively;

The variation in the predictions of tensile strength of SFRC may f ⬘cy , f cyF

⬘ ⫽ cylinder compressive strength of plain

be because these models have been developed based on test re- concrete and fiber-reinforced concrete,

sults of a single grade of concrete. The predicted values of Pois- respectively;

son’s ratio, modulus of elasticity, and strain corresponding to peak f fl , f flF ⫽ modulus of rupture of plain concrete and

compressive stress using the existing models showed deviation up fiber-reinforced concrete, respectively;

to 10% 共Table 7兲. The proposed models given in Table 4 account- f spc , f spcF ⫽ split tensile strength of plain concrete and

ing for the fiber-matrix interaction for predicting the strength fiber-reinforced concrete, respectively;

properties of SFRC predicted the test results quite accurately. L f ⫽ length of the fiber;

Downloaded from ascelibrary.org by Cochin University of Science and Technology on 08/10/14. Copyright ASCE. For personal use only; all rights reserved.

RI ⫽ reinforcing index of fiber 共V f L f / f 兲;

V f ⫽ volume fraction of the fiber;

Conclusions oc , ocF ⫽ strain corresponding to peak compressive

stress of plain concrete and fiber-reinforced

Based on the present study, following conclusions are drawn: concrete, respectively;

• The maximum increase in the compressive strength, modulus c , cF ⫽ Poisson’s ratio of plain concrete and

of elasticity, and Poisson’s ration due to the addition of steel fiber-reinforced concrete, respectively;

fibers was found to be quite small 共less than 10%兲 in various ⫽ diameter; and

grades of concrete 共35, 65, and 85 MPa兲. f ⫽ diameter of the fiber.

• The maximum increase in the tensile strength, namely, split

tensile strength and modulus of rupture due to the addition of References

steel fibers, was found to be about 40% in various grades of

concrete 共35, 65, and 85 MPa兲 and is the primary justification

Agrawal, R., Singh, A. K., and Singhal, D. 共1996兲. “Effect of fiber rein-

for using fibers in concrete. The post-cracking response is sig- forcing index on compressive strength and bond strength of steel fiber

nificantly enhanced with fiber dosages across the different con- reinforced concrete.” Institute of Engineers (India), 77共1兲, 37–40.

crete grades. Ashour, S. A., Wafa, F. F., and Kamal, M. I. 共2000兲. “Effect of concrete

• The maximum increase in the strain corresponding to the peak compressive strength and tensile reinforcement ration on the flexural

compressive strength was found to be about 30% in various behavior of fibrous concrete beams.” Eng. Struct., 22共9兲, 1145–1158.

grades of concrete 共35, 65, and 85 MPa兲. Enhanced peak strain Bureau of Indian Standards 共BIS兲. 共1959兲. “Methods of test for strength

capacity is another significant benefit derived from the use of of concrete.” IS: 516, BIS, New Delhi, India.

fibers. Bureau of Indian Standards 共BIS兲. 共1982兲. “Recommended guidelines for

• The proposed empirical models derived based on the regres- concrete mix design.” IS: 10262, BIS, New Delhi, India.

Bureau of Indian Standards 共BIS兲. 共1999兲. “Splitting tensile strength of

sion analysis of 60 test data of the present study predicted the

concrete: Method of test.” IS: 5816, BIS, New Delhi, India.

strength properties of the steel fiber-reinforced concrete quite Gao, J., Sun, W., and Morino, K. 共1997兲. “Mechanical properties of steel

accurately. Thus, the proposed strength prediction models can fiber reinforced high strength light weight concrete.” Cem. Concr.

be used for the assessment of the strength properties of SFRC Compos., 19, 307–313.

based on the grade of concrete and fiber-RI. Ghosh, S., Battacharya, C., and Ray, S. P. 共1989兲. “Tensile strength of

• The comparison of the contribution of individual terms indi- steel fiber reinforced concrete.” Institute of Engineers (India), 69共1兲,

cated that the contribution of the fiber–matrix interaction term 222–227.

is significant in computing the increased benefits due to the Hannant, D. J. 共1978兲. Fibre cements and fibre concretes, Wiley, New

addition of fibers in concrete matrix. This term has not been York.

considered in earlier models reported in the literature and does Hueste, M. B. D., Chompreda, P., Trejo, D., Cline, D. B. H., and Keating,

not appear in the prediction models based on law of mixtures. P. B. 共2004兲. “Mechanical properties of high strength concrete for

It is expected that the prediction models proposed in this study prestressed members.” ACI Struct. J., 101共4兲, 457–465.

Irvani, S. 共1996兲. “Mechanical properties of high performance concrete.”

would be useful to compute the mechanical strength properties of

ACI Mater. J., 93共5兲, 416–426.

SFRC, which are the input parameters for flexure and shear de- Oh, B. H. 共1992兲. “Flexural analysis of reinforced concrete beams con-

sign or analysis methods of SFRC structures. taining steel fibers.” J. Struct. Eng., 118共10兲, 2821–2836.

Padmarajaiah, S. K. 共1999兲. “Influence of fibers on the behavior of high

strength concrete in fully/partially prestressed beams: an experimental

and analytical study.” Ph.D. thesis, Indian Institute of Science, Ban-

Notation galore, India.

Song, H. W., and Hwang, S. 共2004兲. “Mechanical properties of high

The following symbols are used in this paper: strength reinforced concrete.” Constr. Build. Mater., 18, 669–673.

Ec , EcF ⫽ modulus of elasticity of plain concrete and Taerwe, L. R. 共1992兲. “Influence of steel fibers on strain softening of high

fiber-reinforced concrete, respectively; strength concrete.” ACI Mater. J., 89共1兲, 54–60.

392 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / MAY 2007

J. Mater. Civ. Eng. 2007.19:385-392.

You might also like

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Stress-Strain Behavior of Steel Fiber-Reinforced Concrete in CompressionDocument9 pagesStress-Strain Behavior of Steel Fiber-Reinforced Concrete in CompressionMohamed ZITOUNINo ratings yet

- Gopal A Rat Nam 1987Document18 pagesGopal A Rat Nam 1987manayagamaryjoy9No ratings yet

- Loading Rate Effect On Pullout Behavior of Deformed Steel FibersDocument9 pagesLoading Rate Effect On Pullout Behavior of Deformed Steel FibersangthiankongNo ratings yet

- Chup by Mumtaz MuftiDocument14 pagesChup by Mumtaz MuftiWasim AbbassNo ratings yet

- Article 5 - Mechanical Properties of Concrete Reinforced With Corrugated Steel Fiber Under Unixial Compression and TensionDocument13 pagesArticle 5 - Mechanical Properties of Concrete Reinforced With Corrugated Steel Fiber Under Unixial Compression and Tensionsara.marrok17No ratings yet

- Presumption of Shear Strength of Steel Fiber Reinforced Concrete Beam Using Artificial Neural Network ModelDocument8 pagesPresumption of Shear Strength of Steel Fiber Reinforced Concrete Beam Using Artificial Neural Network ModelCRISTIAN PERCY PARDO JONo ratings yet

- Es 149 - Research Methods (Cyralie B. Maglipac)Document9 pagesEs 149 - Research Methods (Cyralie B. Maglipac)Matet MaglipacNo ratings yet

- A Comparative Study of Flexural and Shear Behavior of Ultra-High-Performance Fiber-Reinforced Concrete BeamsDocument12 pagesA Comparative Study of Flexural and Shear Behavior of Ultra-High-Performance Fiber-Reinforced Concrete BeamsJoaquinNo ratings yet

- De 9 Abd 92 D 4596873Document12 pagesDe 9 Abd 92 D 4596873thetsoeNo ratings yet

- 2° Paper - Aci UniDocument9 pages2° Paper - Aci UniKAUSSNo ratings yet

- Comparison of Mechanical Properties of Unidirectional and Woven Cabon, Glass and Aramid Fibre With Epoxi PDFDocument4 pagesComparison of Mechanical Properties of Unidirectional and Woven Cabon, Glass and Aramid Fibre With Epoxi PDFDavid LydNo ratings yet

- Review PaperDocument1 pageReview PaperC RAJ GOVIND G.CHANDRASEKARANNo ratings yet

- Flexural Strength of RC Beams With GFRP Laminates: Sing-Ping Chiew, M.ASCE Qin Sun and Yi YuDocument10 pagesFlexural Strength of RC Beams With GFRP Laminates: Sing-Ping Chiew, M.ASCE Qin Sun and Yi YuAjay KumarNo ratings yet

- Analysis of FRP-Strengthened RC Beam-Column JointsDocument11 pagesAnalysis of FRP-Strengthened RC Beam-Column JointsCu ToànNo ratings yet

- Long-Term Behavior of Prestressed Composite Beams at Service Loads For One YearDocument8 pagesLong-Term Behavior of Prestressed Composite Beams at Service Loads For One YearLauNo ratings yet

- Review On Fiber Reinforced ConcreteDocument12 pagesReview On Fiber Reinforced ConcreteJames Augustine100% (1)

- 2938-Article Text-2698-1-10-20230304Document6 pages2938-Article Text-2698-1-10-20230304doomflare2000xNo ratings yet

- Fiber-Reinforced Concrete With Low Content of Recycled Steel Fiber - Shear BehaviourDocument15 pagesFiber-Reinforced Concrete With Low Content of Recycled Steel Fiber - Shear BehaviourLương Chiến ThắngNo ratings yet

- Pstruct 2017 04 064Document14 pagesPstruct 2017 04 064Willian RodriguesNo ratings yet

- Construction and Building Materials: M. Mastali, A. DalvandDocument14 pagesConstruction and Building Materials: M. Mastali, A. DalvandVenkat RamanNo ratings yet

- Tiwari 2020 IOP Conf. Ser. Mater. Sci. Eng. 961 012009Document14 pagesTiwari 2020 IOP Conf. Ser. Mater. Sci. Eng. 961 012009Muhammad AwaisNo ratings yet

- J Conbuildmat 2019 117043Document10 pagesJ Conbuildmat 2019 117043civilstructure.singhbrothersNo ratings yet

- Performance of Shallow Reinforced Concrete Beams With Externally Bonded Steel-Reinforced PolymerDocument8 pagesPerformance of Shallow Reinforced Concrete Beams With Externally Bonded Steel-Reinforced PolymerMishraq ul quraishNo ratings yet

- Effect of Change in Volume Fraction On Mechanical Properties of Glass Fiber-Epoxy Resin CompositesDocument4 pagesEffect of Change in Volume Fraction On Mechanical Properties of Glass Fiber-Epoxy Resin Compositesrahul reddyNo ratings yet

- Chen2001 PDFDocument8 pagesChen2001 PDFCarlo Gimarino SalazarNo ratings yet

- JRCE - Volume 8 - Issue 3 - Pages 72-86Document18 pagesJRCE - Volume 8 - Issue 3 - Pages 72-86Ismail MohammedNo ratings yet

- Rafique 2021Document14 pagesRafique 2021ganeshNo ratings yet

- Residual Strength of Rock MassesDocument10 pagesResidual Strength of Rock MassestrinitrocainaNo ratings yet

- Delta ConcreteDocument7 pagesDelta ConcreteHari AppathuraiNo ratings yet

- IJEAS0305013Document3 pagesIJEAS0305013erpublicationNo ratings yet

- 11-Flexural Behavior of SFRC - Testing and ModelingDocument9 pages11-Flexural Behavior of SFRC - Testing and ModelingTùng HìNo ratings yet

- Experimental Study of Fatigue Flexural Performance of Concrete Beams Reinforced With Hybrid GFRP and Steel BarsDocument11 pagesExperimental Study of Fatigue Flexural Performance of Concrete Beams Reinforced With Hybrid GFRP and Steel BarsBesian SinaniNo ratings yet

- Strengthening of Shear Deficient Reinforced Concrete Beams Retrofitted With Cement-Based CompositesDocument12 pagesStrengthening of Shear Deficient Reinforced Concrete Beams Retrofitted With Cement-Based Compositesalaa hassoonNo ratings yet

- Punching Capacity Nguyen-Minh2012Document12 pagesPunching Capacity Nguyen-Minh2012Ashraf Gomah Mohamed ElshamandyNo ratings yet

- Prediction of Axial Compressive Strength For FRP-Confined Concrete Compression MembersDocument12 pagesPrediction of Axial Compressive Strength For FRP-Confined Concrete Compression MembersDoua AbdouNo ratings yet

- Experimental Study On Hybrid Fiber Reinforced Concrete - A ReviewDocument12 pagesExperimental Study On Hybrid Fiber Reinforced Concrete - A ReviewJames AugustineNo ratings yet

- Narayanan and Darwish-Use of Steel Fibre As Shear ReinforcementDocument12 pagesNarayanan and Darwish-Use of Steel Fibre As Shear ReinforcementSmith Abutu Simon JohnNo ratings yet

- Finite Element Analysis of Steel Fiber-Reinforced Concrete (SFRC) : Validation of Experimental Tensile Capacity of Dog-Bone SpecimensDocument8 pagesFinite Element Analysis of Steel Fiber-Reinforced Concrete (SFRC) : Validation of Experimental Tensile Capacity of Dog-Bone SpecimensBAGARAGAZA RomualdNo ratings yet

- Seismic of Encased BeamDocument21 pagesSeismic of Encased BeamvardhangargNo ratings yet

- Effect of Fibre Volume Fraction On Fatigue Behaviour of Glass FibreDocument8 pagesEffect of Fibre Volume Fraction On Fatigue Behaviour of Glass FibreMiranti AuliaNo ratings yet

- Graybeal UHPCcompression ACImat Mar2007Document7 pagesGraybeal UHPCcompression ACImat Mar2007IngénieurCivilNo ratings yet

- 01 PROVA AUTOR riemAO2089 ENDocument14 pages01 PROVA AUTOR riemAO2089 ENDANIEL MARCOS DE LIMA E SILVANo ratings yet

- Properties of Polyester Polymer Concrete With GlassDocument12 pagesProperties of Polyester Polymer Concrete With GlassMohammad AasimuddinNo ratings yet

- Comparison of Mechanical PropertiesDocument4 pagesComparison of Mechanical PropertiesFatima OudahNo ratings yet

- AFBAD2A10971Document10 pagesAFBAD2A10971Samuel NkereuwemNo ratings yet

- 1 s2.0 S0950061818314557 MainDocument13 pages1 s2.0 S0950061818314557 MainDillon YeongNo ratings yet

- Publication 13Document7 pagesPublication 13Vishnu KalyanNo ratings yet

- Experimental Research On Bond Behaviors BetweenDocument4 pagesExperimental Research On Bond Behaviors BetweenSameerKareeeemNo ratings yet

- Ajme 6 2 5Document10 pagesAjme 6 2 5Abel MulugetaNo ratings yet

- Mechanical Behaviour of Aluminum Particulate Epoxy Composite - Experimental Study and Numerical SimulationDocument9 pagesMechanical Behaviour of Aluminum Particulate Epoxy Composite - Experimental Study and Numerical SimulationTRNADEWNo ratings yet

- Cea18 14825581Document14 pagesCea18 14825581suprakash samantaNo ratings yet

- Review On Constitutive ModelsDocument21 pagesReview On Constitutive ModelsISHITA ROY CHOUDHURYNo ratings yet

- Mastali 2017Document15 pagesMastali 2017Shivam SinghNo ratings yet

- 1 s2.0 S0950061816317093 Main PDFDocument11 pages1 s2.0 S0950061816317093 Main PDFDaniela Gonzalez BetancurNo ratings yet

- Flexural Behavior of Lightweight Concrete Beams Encomp - 2017 - Case Studies in PDFDocument14 pagesFlexural Behavior of Lightweight Concrete Beams Encomp - 2017 - Case Studies in PDFarindamNo ratings yet

- Influence of Steel Fiber On Compressive Properties of Ultra-High Performance Fiber-Reinforced ConcreteDocument12 pagesInfluence of Steel Fiber On Compressive Properties of Ultra-High Performance Fiber-Reinforced ConcreteGemiezNo ratings yet

- J Conbuildmat 2011 08 002Document9 pagesJ Conbuildmat 2011 08 002Haider AliNo ratings yet

- Seismic Performance of Steel-Encased Composite ColumnsDocument21 pagesSeismic Performance of Steel-Encased Composite ColumnsatyanNo ratings yet

- Materi Pertambangan Bagian 4Document16 pagesMateri Pertambangan Bagian 4Tri Joko P SudarmoNo ratings yet

- Meškėnas Et Al. - 2017 - Experimental Investigation of Cracking Behaviour oDocument6 pagesMeškėnas Et Al. - 2017 - Experimental Investigation of Cracking Behaviour oviolettaNo ratings yet

- Abbass Et Al. - 2019 - Experimental Investigation On The Effect of SteelDocument14 pagesAbbass Et Al. - 2019 - Experimental Investigation On The Effect of SteelviolettaNo ratings yet

- Lee Et Al. - 2015 - Compressive Behavior of Fiber-Reinforced ConcreteDocument18 pagesLee Et Al. - 2015 - Compressive Behavior of Fiber-Reinforced ConcreteviolettaNo ratings yet

- Abed and Alhafiz - 2018 - Finite Element Simulation of The Flexural BehaviorDocument5 pagesAbed and Alhafiz - 2018 - Finite Element Simulation of The Flexural BehaviorviolettaNo ratings yet

- Al-Kamyani Et Al. - 2019 - Impact of Shrinkage On Crack Width and DeflectionsDocument10 pagesAl-Kamyani Et Al. - 2019 - Impact of Shrinkage On Crack Width and DeflectionsviolettaNo ratings yet

- Technical Data Sheet Steel Fibers With Hooked Ends: PerformanceDocument2 pagesTechnical Data Sheet Steel Fibers With Hooked Ends: PerformanceviolettaNo ratings yet

- Ashour Et Al. - 2000 - Effect of The Concrete Compressive Strength and TeDocument14 pagesAshour Et Al. - 2000 - Effect of The Concrete Compressive Strength and TeviolettaNo ratings yet

- Steel Fibers: Leading The WayDocument1 pageSteel Fibers: Leading The WayviolettaNo ratings yet

- Mechanical Properties of Steel Fiber Reinforced Self-Compacting ConcreteDocument8 pagesMechanical Properties of Steel Fiber Reinforced Self-Compacting ConcreteviolettaNo ratings yet

- PSI Steel Fiber C6560Document2 pagesPSI Steel Fiber C6560violettaNo ratings yet

- Tsega HailuDocument85 pagesTsega HailuviolettaNo ratings yet

- Novocon HE1050 DatasheetDocument2 pagesNovocon HE1050 DatasheetviolettaNo ratings yet

- Benning Et Al. - MONITORING CRACK ORIGIN AND EVOLUTION AT CONCRETEDocument6 pagesBenning Et Al. - MONITORING CRACK ORIGIN AND EVOLUTION AT CONCRETEviolettaNo ratings yet

- Dias-da-Costa Et Al. - 2014 - Curvature Assessment of Reinforced Concrete BeamsDocument16 pagesDias-da-Costa Et Al. - 2014 - Curvature Assessment of Reinforced Concrete BeamsviolettaNo ratings yet

- Study On Behavior of RC Framed Corner Joints Using Fem TechniqueDocument4 pagesStudy On Behavior of RC Framed Corner Joints Using Fem TechniqueviolettaNo ratings yet

- Hoult Et Al. - 2016 - Measuring Crack Movement in Reinforced Concrete UsDocument14 pagesHoult Et Al. - 2016 - Measuring Crack Movement in Reinforced Concrete UsviolettaNo ratings yet

- Thin-Film Interference - Wikipedia, The Free EncyclopediaDocument4 pagesThin-Film Interference - Wikipedia, The Free EncyclopediananotoysNo ratings yet

- Dubbel Handbook of Mechanical Engineering PDFDocument918 pagesDubbel Handbook of Mechanical Engineering PDFprajakt_pie50% (4)

- Chapter 2 - Work, Energy and Power - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatDocument85 pagesChapter 2 - Work, Energy and Power - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatskjNo ratings yet

- 1hsb425455 1en2 DescriptionDocument10 pages1hsb425455 1en2 Descriptionmardaleadrian6810No ratings yet

- Design and Analysis of Trapezoidal Bucket Excavator For BackhoeDocument8 pagesDesign and Analysis of Trapezoidal Bucket Excavator For BackhoecahyoNo ratings yet

- 2a - Precision-Interferometer-Experiment 1Document27 pages2a - Precision-Interferometer-Experiment 1Brenda CruzNo ratings yet

- Dynamic Analysis of Railway Bridges by Means of The Spectral MethodDocument10 pagesDynamic Analysis of Railway Bridges by Means of The Spectral Methodewa1988No ratings yet

- What Is Camera Calibration - MATLAB & SimulinkDocument5 pagesWhat Is Camera Calibration - MATLAB & SimulinkFreddy Doni Hutson PaneNo ratings yet

- International Marine Coating Hydro Blasting StandardsDocument14 pagesInternational Marine Coating Hydro Blasting Standardsamin_corporation100% (1)

- Bostik Rheology Training Nov2nd, 2011 in AsiaDocument13 pagesBostik Rheology Training Nov2nd, 2011 in Asiapopmart21No ratings yet

- An Overview of Orthodontic WiresDocument6 pagesAn Overview of Orthodontic WiresDr.kaviyarasuNo ratings yet

- Chapter 2Document33 pagesChapter 2mtas97No ratings yet

- 1 s2.0 S0006349517304411 mmc2 PDFDocument21 pages1 s2.0 S0006349517304411 mmc2 PDFBrandon LEeNo ratings yet

- Engineering Mechanics PPT 2Document57 pagesEngineering Mechanics PPT 2muralikrishna1917100% (2)

- Pengaruh Ketebalan Substrat Mikroserat Acak Polipropilena Terhadap Kinerja Filtrasi Udara Membran Nanoserat PoliakrilonitrilDocument10 pagesPengaruh Ketebalan Substrat Mikroserat Acak Polipropilena Terhadap Kinerja Filtrasi Udara Membran Nanoserat PoliakrilonitrilRiva NNo ratings yet

- Manual de Servicio Samsung Awt24famea PDFDocument56 pagesManual de Servicio Samsung Awt24famea PDFJesus TubiñezNo ratings yet

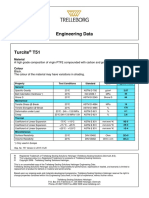

- Turcite T51 Engineering DataDocument1 pageTurcite T51 Engineering DataAntonio Rivera VillavicencioNo ratings yet

- Why Ceramics Are BrittleDocument5 pagesWhy Ceramics Are Brittlehorizon9630% (1)

- (PDF) Concrete Cracks Repair Using Epoxy ResinDocument18 pages(PDF) Concrete Cracks Repair Using Epoxy ResinAakanksha SaxenaNo ratings yet

- Free Download Here: Iso 2768 MK PDFDocument2 pagesFree Download Here: Iso 2768 MK PDFbksinghsNo ratings yet

- PTC-155A & CTC-155C Replace The ITC155A: ComparisonDocument2 pagesPTC-155A & CTC-155C Replace The ITC155A: ComparisonSabilalArifNo ratings yet

- LAB10 Heat Conduction ReportDocument8 pagesLAB10 Heat Conduction ReportSyfNo ratings yet

- Edfa-Wdm Optical Network Design and Development Using Optisystem SimulatorDocument10 pagesEdfa-Wdm Optical Network Design and Development Using Optisystem SimulatorJenyNo ratings yet

- Vibration Monitoring and AnalysisDocument56 pagesVibration Monitoring and AnalysisMithlesh SharmaNo ratings yet

- Spekteknis Portable Residual Stress AnalyzerR1Document2 pagesSpekteknis Portable Residual Stress AnalyzerR1RYHAN PRATAMANo ratings yet

- Module 1-Review of General ChemistryDocument17 pagesModule 1-Review of General ChemistryMicth Laica BetoyaNo ratings yet

- Right Container, Right Place, Right Time: Refrigerated ContainersDocument8 pagesRight Container, Right Place, Right Time: Refrigerated ContainersEl AskNo ratings yet

- Structural Design and Analysis of FPSO Topside Module SupportsDocument10 pagesStructural Design and Analysis of FPSO Topside Module Supportscaic351b100% (1)

- General Ser Vice Ball Valves: GB SeriesDocument13 pagesGeneral Ser Vice Ball Valves: GB SeriesRyan DuhonNo ratings yet

- Piezoelectric Material As Transducer & Energy Harvester Front PagesDocument8 pagesPiezoelectric Material As Transducer & Energy Harvester Front PagesAmbientNo ratings yet

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Basic Digital Signal Processing: Butterworths Basic SeriesFrom EverandBasic Digital Signal Processing: Butterworths Basic SeriesRating: 5 out of 5 stars5/5 (1)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CFrom EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Chasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItFrom EverandChasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItRating: 4 out of 5 stars4/5 (25)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsFrom EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongNo ratings yet

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionFrom EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataFrom EverandLaminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataNo ratings yet

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Safety Theory and Control Technology of High-Speed Train OperationFrom EverandSafety Theory and Control Technology of High-Speed Train OperationRating: 5 out of 5 stars5/5 (2)

- Electrical (Generator and Electrical Plant): Modern Power Station PracticeFrom EverandElectrical (Generator and Electrical Plant): Modern Power Station PracticeRating: 4 out of 5 stars4/5 (9)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Gas Turbines: A Handbook of Air, Land and Sea ApplicationsFrom EverandGas Turbines: A Handbook of Air, Land and Sea ApplicationsRating: 4 out of 5 stars4/5 (9)

- Mechanical Vibrations and Condition MonitoringFrom EverandMechanical Vibrations and Condition MonitoringRating: 5 out of 5 stars5/5 (1)