Professional Documents

Culture Documents

Mechanical Completion Instrument Cable DN-I013-A

Uploaded by

Aous H0 ratings0% found this document useful (0 votes)

38 views1 pageOriginal Title

30-FY-0001

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views1 pageMechanical Completion Instrument Cable DN-I013-A

Uploaded by

Aous HCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

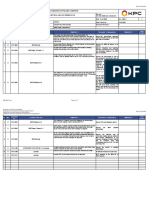

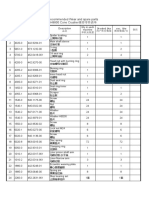

Mechanical Completion

DN-I013-A

Instrument Cable

Tag No. 30-FY-0001

Loop No.

Equipment Description: EXPORT OIL PUMP P-2200A DISCH FLOW –CABLE

System No. 30

Sub System No. 30.02

Location: CPF

Data Sheet:

Drawing Reference: KU-TWK-40-PR-PID-0201 /KU-TWK-40-IC-CON-0202

No. Items to be Checked OK N/A P/L

1 Cable is the correct type and size as per cable schedule

2 Cable glands are the correct type and size as per cable schedule

3 Glanding / Locknuts / & Approved Grease Applied.

4 Confirm cable source/destination route and segregation are correct

5 Check cable supports, cleating and banding are to specification

6 Bending radius satisfactory.

7 Check cable markers are correct at transits and at each end

8 Ensure IP sealing washers are fitted to glands, where applicable

9 Earthing in accordance with specification.

10 Confirm conductor continuity is correct

With all cores disconnected test insulation resistance values for core to core, core to earth

11 and core to screen. Minimum value: 25 M

(Test volts = 250/500 V for instrument and control cables)

12 Armour—GND MΩ.

13 Overall shield –GND MΩ.

14 All conductors –GND MΩ.

15 Each pair to shield MΩ.

16 Pair conductors MΩ.

17 Shield to shield MΩ.

18 Reconnect cable cores at both ends and confirm correct terminations/crimps

19 Confirm protective measures (e.g.: kick plates) are fitted correctly

20 Replace covers and check all bolts are correctly refitted

Completed By Accepted By Comments / Remarks:

Signature:

Print Name:

Date:

Company:

Page 1 of 1

You might also like

- 接线Document338 pages接线Peter zuuNo ratings yet

- Pre Commissioning Check ListDocument4 pagesPre Commissioning Check ListbajrangNo ratings yet

- CHECK LIST FOR MV CABLE INSTALLATIONDocument2 pagesCHECK LIST FOR MV CABLE INSTALLATIONAdil Hasanov100% (1)

- NAG 1/W5A580 Auto Transmission Diagnosis and RepairDocument42 pagesNAG 1/W5A580 Auto Transmission Diagnosis and RepairKamerom CunninghamNo ratings yet

- Honda Goldwing GL1100 Hondaline Fairing Installation ManualDocument8 pagesHonda Goldwing GL1100 Hondaline Fairing Installation ManualJarirmanNo ratings yet

- CabinetsDocument8 pagesCabinetsLarisa LoredanaNo ratings yet

- Electromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationFrom EverandElectromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationRating: 4 out of 5 stars4/5 (1)

- Catalogue: Grippers & AccessoriesDocument32 pagesCatalogue: Grippers & AccessoriesVladimirAgeevNo ratings yet

- Continuity & Insulation Resistance Test - CablesDocument8 pagesContinuity & Insulation Resistance Test - Cablesamer_arauf85% (20)

- Welding Machine - Equipment Fitness ChecklistDocument2 pagesWelding Machine - Equipment Fitness Checklistpartha100% (7)

- Terminaiton Kit SpecificaitonDocument5 pagesTerminaiton Kit SpecificaitonVaibhav ShahNo ratings yet

- CMIT 796 ELE 15.17!10!0010 - 0 - Data Sheet For PowerDocument4 pagesCMIT 796 ELE 15.17!10!0010 - 0 - Data Sheet For PowerELE FutureWillNo ratings yet

- A330 Aircraft Oil System DiagramDocument1 pageA330 Aircraft Oil System Diagramessid zouhaierNo ratings yet

- Gas Turbine - Compressor AlignmentDocument2 pagesGas Turbine - Compressor AlignmentNazmiNo ratings yet

- 12-SOP For Cable TerminationsDocument2 pages12-SOP For Cable TerminationsAbhay Godbole80% (5)

- Low Voltage Cable - Itr ADocument2 pagesLow Voltage Cable - Itr AHaider HassanNo ratings yet

- JOB REPORT ON MACHINE SHOP TURNINGDocument8 pagesJOB REPORT ON MACHINE SHOP TURNINGNur Akmal100% (1)

- VD 1233 330 Dig 001 1Document12 pagesVD 1233 330 Dig 001 1Reza AranNo ratings yet

- RM6 20150903 083022107Document3 pagesRM6 20150903 083022107Umer FarNo ratings yet

- Mechanical Completion L.V. Power, Control and Telecomm / Instrument CablesDocument4 pagesMechanical Completion L.V. Power, Control and Telecomm / Instrument CablesJalal AlbadriNo ratings yet

- Overhead Lines Andy PMDocument3 pagesOverhead Lines Andy PMengrandyNo ratings yet

- SIG de 22 Diagrama de Cableado TD3 B102 E 10Document10 pagesSIG de 22 Diagrama de Cableado TD3 B102 E 10Jorge PalacioNo ratings yet

- Mechanical Completion Instrument Cable DN-I013-ADocument1 pageMechanical Completion Instrument Cable DN-I013-AAous HNo ratings yet

- Electrical Construction Checklist System No:: Contracting & Trading LEAD-E-001Document2 pagesElectrical Construction Checklist System No:: Contracting & Trading LEAD-E-001Ahmad Karam SuliemanNo ratings yet

- IGCC-OPM-QUA-FMT-0130 Rev. 0 - Mechanical Completion Instrument CablesDocument1 pageIGCC-OPM-QUA-FMT-0130 Rev. 0 - Mechanical Completion Instrument CablesAhmedNo ratings yet

- Megnetrol-Kotron Smart RF-805-Level TransmitterDocument16 pagesMegnetrol-Kotron Smart RF-805-Level TransmitterSaeed VuNo ratings yet

- Guia Rápido - Bateria e Medidor Inteligente - HuaweiDocument19 pagesGuia Rápido - Bateria e Medidor Inteligente - HuaweiprojetosnortaoNo ratings yet

- General KabelDocument3 pagesGeneral Kabelwinandra 97No ratings yet

- Red670 - Line Diff 55onlyDocument11 pagesRed670 - Line Diff 55onlyMohd SalehNo ratings yet

- Instruction - Current and Voltage Instrument Transformers - Instruction For Installation, Use andDocument56 pagesInstruction - Current and Voltage Instrument Transformers - Instruction For Installation, Use anddaveadeNo ratings yet

- Sheath Test FormatDocument5 pagesSheath Test FormatAhmed FaragNo ratings yet

- C653 and C653A Alternators: This Symbol Is Used To Indicate Presence of Hazards That Can Cause Minor Property DamageDocument2 pagesC653 and C653A Alternators: This Symbol Is Used To Indicate Presence of Hazards That Can Cause Minor Property DamageAyub SetiawanNo ratings yet

- BEKO K5 ChassisDocument46 pagesBEKO K5 Chassisf17439No ratings yet

- Complience ReportDocument1 pageComplience ReportHiren ParmarNo ratings yet

- OptimDocument16 pagesOptimCh Ll. Q.No ratings yet

- Safety Inspection Report 19 Aug 2022Document9 pagesSafety Inspection Report 19 Aug 2022Vincent VynilNo ratings yet

- Im 10Document2 pagesIm 10RafatNo ratings yet

- Service Manual: TX-21JT3PDocument19 pagesService Manual: TX-21JT3PFlorin CostinNo ratings yet

- Fire Water Motor Engine PMDocument5 pagesFire Water Motor Engine PMShamsuddin SoomroNo ratings yet

- Transformer Test Report SampleDocument10 pagesTransformer Test Report Samplej74926778No ratings yet

- Potential TransformerDocument8 pagesPotential TransformerSyed AbbasNo ratings yet

- Vertical Plug: BTB: Connect ConnectDocument7 pagesVertical Plug: BTB: Connect ConnectfredNo ratings yet

- Mod-Itp-Ll - 014 - Connection String InverterDocument1 pageMod-Itp-Ll - 014 - Connection String InverteralejandroNo ratings yet

- Schematic Diagram and Parts List for 65H80 ChassisDocument55 pagesSchematic Diagram and Parts List for 65H80 ChassisScool OleNo ratings yet

- Circular Threaded Coupling ConnectorsDocument2 pagesCircular Threaded Coupling Connectorsmohana6No ratings yet

- Technical Data Sheet for Circular Threaded ConnectorsDocument2 pagesTechnical Data Sheet for Circular Threaded Connectorsmohana6No ratings yet

- Kpt/Kpse: ConnectorsDocument31 pagesKpt/Kpse: ConnectorsFerdy Fer DNo ratings yet

- Operation and Maintenance Manual For Precision Adapters: 1. 4. PurposeDocument4 pagesOperation and Maintenance Manual For Precision Adapters: 1. 4. PurposeenticoNo ratings yet

- Service Manual: GR-D93US, GR-D94USDocument22 pagesService Manual: GR-D93US, GR-D94USsilictronicNo ratings yet

- Cordsets and Field Attachables: Technical DataDocument126 pagesCordsets and Field Attachables: Technical Datayoquins22No ratings yet

- ICTM602 CV 00Document2 pagesICTM602 CV 00Johnny Walker MartínezNo ratings yet

- Service Manual TX-29PS2Document28 pagesService Manual TX-29PS2tomgagNo ratings yet

- SR 5014Document2 pagesSR 5014Brandon CatronNo ratings yet

- Deepl Brouchure LatestDocument2 pagesDeepl Brouchure LatestSwamy ShanmukhaNo ratings yet

- Minitek PWR Cem-5 Pcie Connector System: Target MarketsDocument3 pagesMinitek PWR Cem-5 Pcie Connector System: Target MarketsŁukasz SrogaNo ratings yet

- Panasonic TX-21JT2P, TX-21JT2P-B (Chassis Z-M3L) (Service Manual) PDFDocument17 pagesPanasonic TX-21JT2P, TX-21JT2P-B (Chassis Z-M3L) (Service Manual) PDFpisy74No ratings yet

- Inductance Meter AdapterDocument3 pagesInductance Meter AdapterioanNo ratings yet

- PANASONIC TX-21AT2P (CP-521P) (WWW - Pieseelectronice.net)Document17 pagesPANASONIC TX-21AT2P (CP-521P) (WWW - Pieseelectronice.net)tipudelacablutvNo ratings yet

- Brosur Busduct NEWDocument29 pagesBrosur Busduct NEWTedi SNo ratings yet

- Construction Check Sheet Power & Auxilliary Transformer E-012ADocument2 pagesConstruction Check Sheet Power & Auxilliary Transformer E-012AhrimklimNo ratings yet

- Instruction E50 Single Pole Double Throw, Double Pole Double Throw Limit SwitchesDocument4 pagesInstruction E50 Single Pole Double Throw, Double Pole Double Throw Limit SwitchesAsif SharifNo ratings yet

- Sumpi FM ManDocument16 pagesSumpi FM ManFredericoNo ratings yet

- Colour TV Service ManualDocument25 pagesColour TV Service ManualSaigon8n8No ratings yet

- QC Series Connector1Document2 pagesQC Series Connector1Энхбаяр ДүгэрсүрэнNo ratings yet

- Panasonic TX-21JT2 Chassis ZM3LDocument17 pagesPanasonic TX-21JT2 Chassis ZM3LFlorin CostinNo ratings yet

- Inspection PDFDocument2 pagesInspection PDFdigyoNo ratings yet

- Digital Coriolis Mass Flowmeters Installation Guidelines and Quick Start - HARTDocument12 pagesDigital Coriolis Mass Flowmeters Installation Guidelines and Quick Start - HARTPhaniNo ratings yet

- 8.06.1 GTP - 33 KV Off-Load Isolator Without EarthDocument2 pages8.06.1 GTP - 33 KV Off-Load Isolator Without EarthkaranNo ratings yet

- CompEx Presentation PDF - Version 10 - Updated Jan 2020Document223 pagesCompEx Presentation PDF - Version 10 - Updated Jan 2020Aous HNo ratings yet

- Essential Requirement For OJT Training ProjectDocument4 pagesEssential Requirement For OJT Training ProjectAous HNo ratings yet

- Introduction To Control Valve & Its Main Components Rev.1Document30 pagesIntroduction To Control Valve & Its Main Components Rev.1Aous HNo ratings yet

- 1 System DynamicsDocument60 pages1 System DynamicsAous HNo ratings yet

- Testing of Power Transformers - Routine Tests - 240325 - 082449Document15 pagesTesting of Power Transformers - Routine Tests - 240325 - 082449Aous HNo ratings yet

- Electrical Breakdown Testing of Polymeric Materials Intended For Use in PV Modules IEC Standard Development and Progress Bernt Ake SultanDocument29 pagesElectrical Breakdown Testing of Polymeric Materials Intended For Use in PV Modules IEC Standard Development and Progress Bernt Ake SultanAous HNo ratings yet

- ZJA6BY Instuction ManualDocument22 pagesZJA6BY Instuction ManualAous H100% (1)

- Technical Specifications of YUNENG ZJA6KYDocument12 pagesTechnical Specifications of YUNENG ZJA6KYAous HNo ratings yet

- CT ExplanationDocument9 pagesCT ExplanationAous HNo ratings yet

- On Site Project Photos Transformer Oil Filtration PlantDocument10 pagesOn Site Project Photos Transformer Oil Filtration PlantAous HNo ratings yet

- Quotation For YUNENG ZJA6KY Transformer Oil Purificaiton Machine 2017.3.16Document1 pageQuotation For YUNENG ZJA6KY Transformer Oil Purificaiton Machine 2017.3.16Aous HNo ratings yet

- Leybold Vacuum Pump Instruction ManualDocument46 pagesLeybold Vacuum Pump Instruction ManualAous H0% (1)

- Gong Led Main Display LCD Main Display LCD Main Display: Touchscreen QmsDocument1 pageGong Led Main Display LCD Main Display LCD Main Display: Touchscreen QmsAous HNo ratings yet

- Cuiman Roots Pump Instruction Manual (Ver 2.1)Document12 pagesCuiman Roots Pump Instruction Manual (Ver 2.1)Aous HNo ratings yet

- Gong Led Main Display LCD Main Display LCD Main Display: Touchscreen QmsDocument1 pageGong Led Main Display LCD Main Display LCD Main Display: Touchscreen QmsAous HNo ratings yet

- Check List For Panels Function Test: Project NoDocument1 pageCheck List For Panels Function Test: Project NoAous HNo ratings yet

- Document transmittal for electrical rectification servicesDocument1 pageDocument transmittal for electrical rectification servicesAous HNo ratings yet

- Morley-IAS Catalogue 2020 UK 0120Document96 pagesMorley-IAS Catalogue 2020 UK 0120Aous HNo ratings yet

- 3003-FP110 Att.09 - TESTING OF DRY TYPE TRANSFORMERDocument1 page3003-FP110 Att.09 - TESTING OF DRY TYPE TRANSFORMERAous HNo ratings yet

- 3003-FP110 Att.04 Rev.0 - INSTALLATION AND TERMINATION of POWER CablesDocument1 page3003-FP110 Att.04 Rev.0 - INSTALLATION AND TERMINATION of POWER CablesAous HNo ratings yet

- Check List For Panels Function Test: Project NoDocument1 pageCheck List For Panels Function Test: Project NoAous HNo ratings yet

- Inspection Checklist for Panel Modification (KPC1901-0000-PRC-TP-027Document2 pagesInspection Checklist for Panel Modification (KPC1901-0000-PRC-TP-027Aous H100% (1)

- 3003-FP110 Att.06 - Installation LV-MV-HV CablesDocument2 pages3003-FP110 Att.06 - Installation LV-MV-HV CablesAous HNo ratings yet

- Kurdistan Crude Oil Pipeline Annunciator RectificationDocument2 pagesKurdistan Crude Oil Pipeline Annunciator RectificationAous HNo ratings yet

- Method Statement of Rectification of Defect No. E398Document13 pagesMethod Statement of Rectification of Defect No. E398Aous HNo ratings yet

- Tools & Instruments List: # I N D Q - (U)Document2 pagesTools & Instruments List: # I N D Q - (U)Aous H100% (1)

- Check List For Installation of Lighting SystemDocument1 pageCheck List For Installation of Lighting SystemAous HNo ratings yet

- KPC Electrical Instrumentation Contractor ChartDocument2 pagesKPC Electrical Instrumentation Contractor ChartAous HNo ratings yet

- Job Risk Assessment For Defect Item No. E398: Provision of Electrical & Instrument Rectification ServiceDocument5 pagesJob Risk Assessment For Defect Item No. E398: Provision of Electrical & Instrument Rectification ServiceAous HNo ratings yet

- Inspection Checklist for Panel Modification (KPC1901-0000-PRC-TP-027Document2 pagesInspection Checklist for Panel Modification (KPC1901-0000-PRC-TP-027Aous H100% (1)

- How To Use This ManualDocument4 pagesHow To Use This Manualariel avalosNo ratings yet

- 150 FX 4 ElectriDocument646 pages150 FX 4 ElectrilefontNo ratings yet

- Usulan Lkai 2020 - 10 S.D 15 April 2019Document350 pagesUsulan Lkai 2020 - 10 S.D 15 April 2019Dipa SuwidyaNo ratings yet

- Hand and Power Tool Safety English QuizDocument7 pagesHand and Power Tool Safety English Quizvibu vibasNo ratings yet

- Jura Burr ReplacementDocument11 pagesJura Burr ReplacementandrwsmthNo ratings yet

- JK-6380 Machine Arm and Bed Parts BookDocument21 pagesJK-6380 Machine Arm and Bed Parts BookRolando Gonzalez SibajaNo ratings yet

- Stellant DualDocument3 pagesStellant DualAlexandra JanicNo ratings yet

- GE A Series PanelsDocument6 pagesGE A Series PanelsccrtechNo ratings yet

- ROCHELLEDocument23 pagesROCHELLEHiezel G LandichoNo ratings yet

- Urc 7030Document20 pagesUrc 7030ump111No ratings yet

- Buckling AnalysisDocument9 pagesBuckling Analysischandravadiyaketan1504No ratings yet

- Me-1 To 10 Gf-PodiumDocument10 pagesMe-1 To 10 Gf-PodiumKristina OrmacidoNo ratings yet

- Progress ReportDocument3 pagesProgress Reportapi-610888061No ratings yet

- Recommended spare parts for H8800 Cone CrusherDocument3 pagesRecommended spare parts for H8800 Cone CrusherLmf DanielNo ratings yet

- 01 Acta Constitucion ProyectoDocument37 pages01 Acta Constitucion ProyectoMIGUELNo ratings yet

- Machining ShopDocument16 pagesMachining ShopOsii CNo ratings yet

- Well TechDocument38 pagesWell TechMax Lerouge33% (3)

- Dehumidifier: Owner'S ManualDocument32 pagesDehumidifier: Owner'S ManualWendy Lilian Gómez MonsivaisNo ratings yet

- INSTALL GUIDE: SAFETY UPGRADE KIT <40Document1 pageINSTALL GUIDE: SAFETY UPGRADE KIT <40Albert LugoNo ratings yet

- RTC89.7XX touch screen thermostat installationDocument2 pagesRTC89.7XX touch screen thermostat installationToni TalevskiNo ratings yet