Professional Documents

Culture Documents

Joint Gap Correction Procedure: Welding Sequence and Control To Be Done: 1-VT:100 %

Uploaded by

Houssem EttwilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Joint Gap Correction Procedure: Welding Sequence and Control To Be Done: 1-VT:100 %

Uploaded by

Houssem EttwilCopyright:

Available Formats

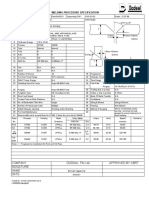

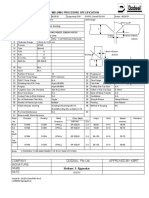

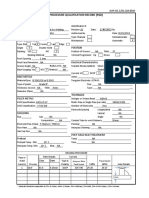

JOINT GAP CORRECTION PROCEDURE

Revision : 01 Page 1 de 1

Project : CHL1 Turnkey Cement Plant Erection Works Client :Fives FCB Site : Chlef

1 CTU-PR-003 Rev 0 Date 06/09/2016 Supporting PQR : NA

2 Reference Code AWS D 1.1

Welding addition in

3 Joint Design groove Butt Weld, Fillet Weld order to correct the

Gap

4 Joint Type All types (V,X,K…)

5 Baking Base Metal or Weld Metal

6 Base Metal Spec PN 1 Groupe 1 to any P N1

2‐3.2 mm

7 Base Metal Thickness All thickness

8 Max allowance of gap to be repaired Max :20 mm

9 Process SMAW 2nd

3rd

10 Type Manual

11 F . No 4

1st Layer

12 A . No 1

13 SFA No 5.1

2‐3.2 mm

14 AWS No E 7018

15 Flux NA

16 Welding Position ALL POSITION 24 Interpass Temp 150 °C

17 Position Groove : groove Butt 25 Pre-Heat Maintenance NA

18 Pre-Heat Temp Range NA 26 Time Range NA

19 Shielding Gas & % Comp NA 27 Methode of Gouging Grinding

20 Purging NA Drying & Baking of Welding Drying of low Hydrogene electrods

28

21 Number of Passes Multiple Electrodes at 250-350 °C During 2h

22 Initial / Interpass cleaning Grinding / Brushing 29 Weave Width 3x Core Dia of Electrode

23 Pre-Heat Maintenance NA

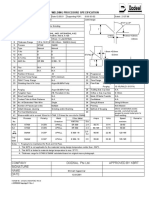

Welding sequence and control to be done:

1- VT :100 %

2- BUTTERING: (1st layer, 2nd, 3rd) welding layers addition according to the gap we have (Max:20 mm).

3- PT: 100% of buttering after grinding.

Layers sequence Process Polarity

Filler Metal

Amps Volts

Remarks

AWS No Dia

(mm)

1st SMAW DCEP E7018 2.5-3.2 75-100 22-24

2nd SMAW DCEP E7018 2.5-3.2 75-100 22-24

3rd SMAW DCEP E7018 2.5-3.2 75-100 22-24

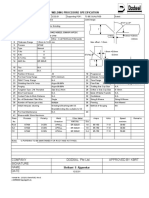

Validation of procedure

Approval : CTU ARESCO_EA Approval: Fives FCB

Name Younes ABDERRAHIM Name

Date 06/09/2016 Date

Signature Signature

Visa Visa

You might also like

- BBP SAP WM Implementation LuminousDocument33 pagesBBP SAP WM Implementation LuminousNaveen Kumar100% (6)

- Asme Ix - WPS - Gtaw Fcaw Gmaw PDFDocument1 pageAsme Ix - WPS - Gtaw Fcaw Gmaw PDFThe Welding Inspections CommunityNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- MMBD4148TW / BAS16TW: Surface Mount Fast Switching Diode Array FeaturesDocument3 pagesMMBD4148TW / BAS16TW: Surface Mount Fast Switching Diode Array Featuresقناة احترف بنفسكNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- 011 WPS ASME TOP F 2022 - Rev.0Document8 pages011 WPS ASME TOP F 2022 - Rev.0megantara maromNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Asmeix Wps Fcawgmaw 191019041529 PDFDocument1 pageAsmeix Wps Fcawgmaw 191019041529 PDFvinod100% (1)

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS Format For Asme Ix - Wps - Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- MKI-DS-J-001-A4 - Rev A Data Sheet PCVDocument60 pagesMKI-DS-J-001-A4 - Rev A Data Sheet PCVFIRMANSYAHNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- KBP2005G - KBP210G: 2.0A Glass Passivated Bridge RectifierDocument3 pagesKBP2005G - KBP210G: 2.0A Glass Passivated Bridge RectifierCZ ProduccionesNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- Hfy2 E1890 CPF1WT WLD SPC 0008Document3 pagesHfy2 E1890 CPF1WT WLD SPC 0008Firas AlbaweiNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS D1.3 RF 40Document8 pagesWPS D1.3 RF 40RodolfoNo ratings yet

- Limak - Sawaed WpsDocument1 pageLimak - Sawaed WpsAlam MD SazidNo ratings yet

- Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADocument1 pageUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNo ratings yet

- PWPS Vahali 26 - 136 PD - FWDocument1 pagePWPS Vahali 26 - 136 PD - FWVasiljka Đordan JelacaNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- Rubycon-25YXA2200MEFCCE12-5X25 C365705Document4 pagesRubycon-25YXA2200MEFCCE12-5X25 C365705Rajesh SuraNo ratings yet

- PALL FILTER - Process Data SheetDocument2 pagesPALL FILTER - Process Data SheetThirukkumaranBalasubramanianNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- Semiconducting III–V Compounds: International Series of Monographs on SemiconductorsFrom EverandSemiconducting III–V Compounds: International Series of Monographs on SemiconductorsNo ratings yet

- BV RulesDocument14 pagesBV RulesHoussem EttwilNo ratings yet

- PGS-JOBN-190582-P05-LS4-01-Plan de Contrôle QualitéDocument15 pagesPGS-JOBN-190582-P05-LS4-01-Plan de Contrôle QualitéHoussem Ettwil100% (1)

- Rapport Control Visuell Des Joints: Page 1 / 2Document2 pagesRapport Control Visuell Des Joints: Page 1 / 2Houssem EttwilNo ratings yet

- PT Repport: Cementrie de Chlef-Ligne de Production de 6000T/J de ClinkerDocument2 pagesPT Repport: Cementrie de Chlef-Ligne de Production de 6000T/J de ClinkerHoussem EttwilNo ratings yet

- Joint Visual Inspection Prior Welding DRW N°: CHL 1 M 19 Du 014 Item N°: 263 Du 02 L Mark I-Hrs (Left)Document6 pagesJoint Visual Inspection Prior Welding DRW N°: CHL 1 M 19 Du 014 Item N°: 263 Du 02 L Mark I-Hrs (Left)Houssem EttwilNo ratings yet

- Api Monetization: Unlock More Value From Your ApisDocument27 pagesApi Monetization: Unlock More Value From Your Apisserap topacNo ratings yet

- ENTREPDocument3 pagesENTREPChristian CabanelaNo ratings yet

- Ravindra Singh GangwarDocument87 pagesRavindra Singh Gangwarravi singhNo ratings yet

- Supply Chain Management in The Automotive Industry: Present by Narendra Singh Rathore Guide Name Miss. Mona Ma'amDocument15 pagesSupply Chain Management in The Automotive Industry: Present by Narendra Singh Rathore Guide Name Miss. Mona Ma'amNarendra Singh RathoreNo ratings yet

- Ome 664: Project Procurement and Contracting: Lecture Three: Warehouse ManagementDocument35 pagesOme 664: Project Procurement and Contracting: Lecture Three: Warehouse ManagementYonas Alemayehu100% (1)

- Job Description - Master Production SchedulerDocument3 pagesJob Description - Master Production SchedulerRicardo PirelaNo ratings yet

- Ooad Unit 5Document50 pagesOoad Unit 5Charveer “CHARVEERTV” tvNo ratings yet

- Tutorial 3 - SolutionsDocument11 pagesTutorial 3 - SolutionsLijing CheNo ratings yet

- IT-510 Module 3 Part OneDocument5 pagesIT-510 Module 3 Part Onepetetg5172No ratings yet

- Influencing Household Level Waste SortingDocument18 pagesInfluencing Household Level Waste SortingLucas CamposNo ratings yet

- Fit-Gap Analysis - OverviewDocument8 pagesFit-Gap Analysis - Overviewsoorya6969No ratings yet

- TOR001 Feb20 WebDocument76 pagesTOR001 Feb20 WebVarun KumarNo ratings yet

- Form PDFDocument4 pagesForm PDFطاروس وداسNo ratings yet

- Global E-Business & Collaboration Executive SummaryDocument3 pagesGlobal E-Business & Collaboration Executive SummaryAnonymous RYrN60No ratings yet

- Restaurant Balanced Scorecard ExampleDocument1 pageRestaurant Balanced Scorecard ExampleAiman AbousherNo ratings yet

- Week 2 - Module 1Document3 pagesWeek 2 - Module 1Kanton FernandezNo ratings yet

- Unit 2-Rural MarketingDocument23 pagesUnit 2-Rural MarketingAditya MohiteNo ratings yet

- Company Profile A4Document4 pagesCompany Profile A4William FranciscoNo ratings yet

- Global Supply Chain and Operations ManagementDocument9 pagesGlobal Supply Chain and Operations Managementsamer iqbalNo ratings yet

- BSBMKG414 Full Learner ResourceDocument76 pagesBSBMKG414 Full Learner ResourceStavros NathanailNo ratings yet

- AA Certificati ISO9001Document2 pagesAA Certificati ISO9001Haralambescu AndreiNo ratings yet

- Chapter 17Document26 pagesChapter 17Varsha ChotaliaNo ratings yet

- New Supplementary Notes of Mkt243 Chapter 1Document10 pagesNew Supplementary Notes of Mkt243 Chapter 1Ayu IbrahimNo ratings yet

- Group ADocument7 pagesGroup AJill MolinaNo ratings yet

- Marketing ReviewerDocument11 pagesMarketing ReviewerMikaela Shayne AguirreNo ratings yet

- Paper Mktg3-2 Group1Document49 pagesPaper Mktg3-2 Group1John johnNo ratings yet

- Customer Experience and Commitment in Retailing Does CustomerDocument9 pagesCustomer Experience and Commitment in Retailing Does Customerle mrNo ratings yet

- Operations Management 8 TH EditionDocument17 pagesOperations Management 8 TH EditionElmer John BallonNo ratings yet

- Group 1 Chapter 9Document2 pagesGroup 1 Chapter 9cecil cNo ratings yet