Professional Documents

Culture Documents

Model NERO-2 Non-Elastomeric Sliding Sleeve: Descriptio

Uploaded by

felipeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model NERO-2 Non-Elastomeric Sliding Sleeve: Descriptio

Uploaded by

felipeCopyright:

Available Formats

Model NERO-2 Non-Elastomeric Sliding Sleeve

Assembly & Testing Technical Information

Part Number: (Various)

Description

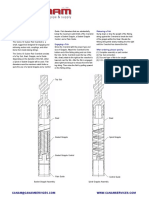

The NERO-2 Non-Elastomeric Sliding Sleeve is a communication device with a ported inner sleeve that can be opened or

closed using a shifting tool by standard slickline or coiled tubing methods. Equalizing holes in the inner sleeve provide

pressure equalization between the tubing and casing annulus as the sleeve is opened. The Sliding Sleeve is made up to

and forms part of the tubing string. The NERO-2 Sliding Sleeve is a shift-DOWN-to-open tool.

The NERO-2 Non-Elastomeric Sliding Sleeve uses common machined parts that allow the shift-open direction to be

changed from DOWN-to-open to UP-to-open by simply substituting different sub ends

The NERO-2 Non-Elastomeric Sliding Sleeve is designed for use in high pressure and high temperature wells to establish

a means of communication between the tubing string and the casing annulus for single-tubing or multiple-tubing string

completions. The NERO-2 Sliding Sleeve may be used for directing flow from the casing to the tubing in alternate or

selective completions. Other applications include killing a well, spot acidizing and fracturing, or equalizing pressure

between an isolated formation and the tubing string.

Features and Benefits

Proven non-elastomeric sealing design, that is cost effective and reliable, with a long operating life.

No o-rings or standard chevron style seals used.

Manufactured in 4140, 9Cr, 13Cr, S13Cr and Super Duplex materials.

GOR Selective Nipple Profile to land slickline tools. (Comparable to Halliburton's R® Landing Nipple Profile).

Available for 10,000psi & 12,000psi maximum working pressures.

Technical Numbers and Accessory Info

Maximum OD: API Coupling OD is standard, but OD can be larger, or smaller upon request.

Minimum ID: Seal Bores.

Opening Direction: UP

Drift Diameter: 0.0010” to 0.0015” smaller than seal bore Minimum ID.

Shifting Tools: Otis “B”, Otis “BO”, and DFAST

Separation Sleeve: GXS

Blanking Plug: GPX

Standing Valve: GVX

Sliding Sleeves-Landing Nipples-Blanking Plugs-Shifting Tools-On/Off Tools-Completion Packers

Flow Couplings/Blast Joints-Pup Joints-Crossover Subs-Jet Pumps-Anchor Catchers-Shear Out Safety Joints-Tubing

Drains-Much Much More.

Ph: 403-279-2015 Fax: 403-279-2019 www.giantoiltools.com sales@giantoiltools.com

Model NERO-2 Non-Elastomeric Sliding Sleeve

Assembly & Testing Technical Information

Part Number: (Various)

Testing

It is important that the sealing surfaces for the non-elastomeric seals are polished to a high finish to help load the seal

stack at low pressure, this is important to ensure successful testing and operation.

All NERO-2 Sliding Sleeves are pressure tested to 10,000 psi using internal seal bore seals that pressure test both the seal

stacks and the seal bores.

As previously noted, NERO-2 Sliding Sleeves are shifted with Otis type “B” shifting tools, for testing purposes, a shifting

tool dressed with self-releasing keys is used; shear to release keys can also be used.

Depending on the amount of squeeze applied to the V-Rings after assembling the sliding sleeve, the shifting force

required to open and close the sliding sleeve may vary, therefore a steel pin is used inside the shifting tool to stop

premature shearing of the pin before the sliding sleeve has been fully opened or closed.

1. After fully assembling the sliding sleeve, tighten it in a vise horizontally and shift the sliding sleeve closed-open-

closed, verifying that the sliding sleeve is fully closed and open each time.

2. Insert the test plugs into either end of the sliding sleeve; you will feel the seals grab the seal bores, confirming

location.

3. Fill the Sliding Sleeve with water or hydraulic fluid and apply pressure up to 500 psi.

4. Apply pressure in 1,000 psi increments, pausing every 1,000 psi for 5 seconds; up to 10,000 psi.

5. Hold at 10,000 psi for 10 minutes, ensure there are no leaks and drop in pressure, engrave the sliding sleeve

with a pressure test serial number and mark the pressure test chart with the same serial number.

6. Bleed off pressure, shift the sliding sleeve open-closed to ensure functionality and tighten sliding sleeve body

connections, wipe down and store.

Operating

When one or more NERO-2 Sliding Sleeves are run on the same production string, special slickline tool strings might be

required to selectively open or close the Sliding Sleeve depending on which Sliding Sleeve is to be opened or closed first.

In the NERO-2 Sliding Sleeve, there is an open, equalized, and closed position. The equalized position allows differential

pressure across the Sliding Sleeve to equalize prior to the final full open position and prevent the full force of the

differential pressure from acting on the v-seal stacks.

Sliding Sleeves-Landing Nipples-Blanking Plugs-Shifting Tools-On/Off Tools-Completion Packers

Flow Couplings/Blast Joints-Pup Joints-Crossover Subs-Jet Pumps-Anchor Catchers-Shear Out Safety Joints-Tubing

Drains-Much Much More.

Ph: 403-279-2015 Fax: 403-279-2019 www.giantoiltools.com sales@giantoiltools.com

Model NERO-2 Non-Elastomeric Sliding Sleeve

Assembly & Testing Technical Information

Part Number: (Various)

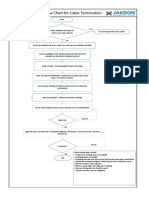

Opening an NERO-2 Sliding Sleeve

Important Note: When opening an NERO-2 Sliding Sleeve, it’s recommended that there is minimal to no differential

pressure across the Sliding Sleeve. Differential pressure across the Sliding Sleeve from the annulus to tubing or tubing to

annulus could cause damage to the seals of the sliding sleeve.

1. With the keys facing dwonward, attach the Otis “B” shifting tool to the slickline tool string. Lower the slickline

tool string in the tubing until above the Sliding Sleeve. Move the slickline tool string downward until the keys

engage in the Lower recess of the Inner Sleeve.

2. Jar downward until the pressure across the Sliding Sleeve starts to equalize.

3. Once the pressure across the Sliding Sleeve has equalized, continue to jar downward until the Inner Sleeve is

completely shifted, fully opening the Sliding Sleeve.

4. Continue jarring downward until the inclined shoulder of the Sliding Sleeve forces the keys inward, allowing the

shifting tool to pass through the sleeve.

5. Before returning the shifting tool to the surface, run it back through the Sliding Sleeve several times to ensure

the Inner Sleeve is in the open position.

Closing an NERO-2 Sliding Sleeve

1. With the keys facing upward, attach the Otis “B” shifting tool to the slickline tool string. Run the slickline tool

string in the tubing until below the Sliding Sleeve and them move upwards until the keys of the shifting tool lock

in the Upper recess of the Inner Sleeve.

2. Jar upward until the Inner Sleeve is completely shifted, placing the Sliding Sleeve in the closed position.

3. Continue jarring upward until the inclined shoulder of the Sliding Sleeve forces the keys of the shifting tool

inward, disengaging it from the recess of the Inner Sleeve, and allow the shifting tool to pass through the sliding

sleeve.

4. Before returning the shifting tool to the surface, run it back through the Sliding Sleeve several times to ensure

the Inner Sleeve is in the closed position.

Sliding Sleeves-Landing Nipples-Blanking Plugs-Shifting Tools-On/Off Tools-Completion Packers

Flow Couplings/Blast Joints-Pup Joints-Crossover Subs-Jet Pumps-Anchor Catchers-Shear Out Safety Joints-Tubing

Drains-Much Much More.

Ph: 403-279-2015 Fax: 403-279-2019 www.giantoiltools.com sales@giantoiltools.com

Model NERO-2 Non-Elastomeric Sliding Sleeve

Assembly & Testing Technical Information

Part Number: (Various)

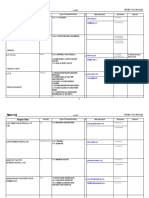

Giant Oil Tools Ltd., Model NERO-2 Sliding Sleeve

*Seal Bore ID Flow Area (Ports) Flow Area (Min ID) Max OD **Max

Standard

Shifting Working

Thread

in. mm. IN² CM² IN² CM² in. mm. Tool Pressure

Box x Pin

(psi)

1.710 43.43 2.295 14.806 1.710 “B”

1.781 45.23 4.73 30.516 2.489 16.058 3.063 77.80 2-3/8" EUE 1.781 “B”

1.875 47.62 2.759 17.799 1.875 “B”

2.125 53.97 3.544 22.864 2.125 “B”

2.188 55,57 6.16 39.741 3.758 24.245 3.750 95.25 2-7/8" EUE

2.312 “B”

2.312 58.26 4.199 27.09

2.562 65.07 5.156 33.264 2.562 “B” 10,000

2.750 69.30 6.389 41.219 5.940 38.322 4.500 114.30 3-1/2" EUE 2.750 “B”

2.813 71.45 6.211 40.070 2.812 “B”

3.437 87.29 9.273 59.825 3.312 “B”

3.688 93.67 14.280 92.128 10.677 68.883 5.500 139.70 4-1/2" EUE 3.688 “B”

3.813 96.85 11.413 73.632 3.813 “B”

4.562 115.87 21.140 136.38 16.337 105.40 6.975 172.60 5-1/2” LTC 4.562 “B”

*Seal Bore ID is also the Minimum ID of the Sliding Sleeve.

**High Pressure 12,000 psi options available.

Sliding Sleeves-Landing Nipples-Blanking Plugs-Shifting Tools-On/Off Tools-Completion Packers

Flow Couplings/Blast Joints-Pup Joints-Crossover Subs-Jet Pumps-Anchor Catchers-Shear Out Safety Joints-Tubing

Drains-Much Much More.

Ph: 403-279-2015 Fax: 403-279-2019 www.giantoiltools.com sales@giantoiltools.com

DO NOT SCALE DRAWING

OAL

"GOR" SELECTIVE HIGH PRESSURE PROFILE. A

(COMPARABLE TO HALLIBURTON's R® LANDING NIPPLE).

"B" SHIFTING "B" SHIFTING

TOOL PROFILE TOOL PROFILE

SEAL BORE INNER SLEEVE ID SEAL BORE

MAX OD

MIN ID MIN ID

BOX THREAD UP PIN THREAD DOWN

SECTION A-A

SCALE 1 : 4

ID BAND

INDICATES "UP"

MATERIAL UNLESS OTHERWISE SPECIFIED DRAWN DATE

-

TOLERANCES

.X = ± 0.030

SURFACE

FINISH GIANT -

APPROVED DATE

-

.XX = ± 0.015 125 OIL TOOLS - -

HEAT TREATMENT

.XXX = ± 0.005 DWG NO.

FRACTIONS = ± 1/64 -

ANGLES = ± 1/2

COATING DESCRIPTION

INSIDE CORNERS 0.015 R. MAX.

N/A ALL THREAD ENTRY AND EXIT ANGLES NERO-2 NON ELASTOMERIC SLIDING SLEEVE

SHIFT-DOWN-TO-OPEN TO BE 45 OFF AXIS OF THREAD

SHIFTING TOOL: B or DFAST

UPPER END REMOVE ALL BURRS AND SHARP CORNERS

Surface Area = sq. in.

LOWER END ALL THREADS-RIGHT HAND

ID = IDENTIFICATION UNITS INCHES

PROJECT -

SCALE SHT. OF PART REV. DWG REV. MASS

CONFIDENTIAL AND TRADE SECRET. DO NOT DISCLOSE, USE

OR REPRODUCE WITHOUT WRITTEN APPROVAL FROM G.O.T. NTS 1 1 A - - LB

DO NOT SCALE DRAWING Last modify : Tuesday, October 06, 2015 17:09:59

G:\Cad\CAD DATABASE\GIANT OIL TOOLS\FLOW CONTROL TOOLS\SLIDING SLEEVES\NONELASTOMERIC\NERO-2\2.560''\256NERO24140-CLIENT

You might also like

- TRDP - SSSVDocument23 pagesTRDP - SSSVsambhajiNo ratings yet

- 6" 6" 6" 6" WRDP WRDP WRDP WRDP - 2MP 2MP 2MP 2MP - NS Safety Valve NS Safety Valve NS Safety Valve NS Safety ValveDocument20 pages6" 6" 6" 6" WRDP WRDP WRDP WRDP - 2MP 2MP 2MP 2MP - NS Safety Valve NS Safety Valve NS Safety Valve NS Safety ValvePilar HernandezNo ratings yet

- Ad Blue Fault Codes PDFDocument6 pagesAd Blue Fault Codes PDFVincent Price100% (1)

- Cut82hr Manual Parts (Cr9b-) 130712siDocument43 pagesCut82hr Manual Parts (Cr9b-) 130712si2222222222222-242735No ratings yet

- ELMAR CatalogDocument62 pagesELMAR Catalogngueadoum93% (15)

- 1 Completion ComponentsDocument38 pages1 Completion ComponentsaliNo ratings yet

- Camisa Deslizable Modelo L para H2SDocument5 pagesCamisa Deslizable Modelo L para H2SCO BDNo ratings yet

- 4807Document7 pages4807Tamer Hesham AhmedNo ratings yet

- Model NERA-2 Non-Elastomeric Sliding Sleeve: DescriptioDocument5 pagesModel NERA-2 Non-Elastomeric Sliding Sleeve: DescriptiofelipeNo ratings yet

- Model NEFU-2 Non-Elastomeric Sliding Sleeve: DescriptioDocument6 pagesModel NEFU-2 Non-Elastomeric Sliding Sleeve: DescriptiofelipeNo ratings yet

- Model NEXO-2 Non-Elastomeric Sliding Sleeve: DescriptioDocument5 pagesModel NEXO-2 Non-Elastomeric Sliding Sleeve: DescriptiofelipeNo ratings yet

- Model NEXA-2 Non-Elastomeric Sliding Sleeve: DescriptioDocument5 pagesModel NEXA-2 Non-Elastomeric Sliding Sleeve: DescriptiofelipeNo ratings yet

- 2024 - 13.375 TST-2 Service PackerDocument15 pages2024 - 13.375 TST-2 Service PackerDhenny FarialNo ratings yet

- NEXO Sliding SleeveDocument3 pagesNEXO Sliding SleevetongsabaiNo ratings yet

- 2021 16.0 TST-2 Service PackerDocument15 pages2021 16.0 TST-2 Service PackerDhenny FarialNo ratings yet

- 2023 10.75 TST-2 Service PackerDocument15 pages2023 10.75 TST-2 Service PackerDhenny FarialNo ratings yet

- WBB Weatherproof Back Box Accessory: 3825 Ohio Avenue, St. Charles, Illinois 60174 1-800-SENSOR2, FAX: 630-377-6495Document1 pageWBB Weatherproof Back Box Accessory: 3825 Ohio Avenue, St. Charles, Illinois 60174 1-800-SENSOR2, FAX: 630-377-6495Carlos YepezNo ratings yet

- Service Manual: Leading Image Processing Technology We've Been There When You NeededDocument69 pagesService Manual: Leading Image Processing Technology We've Been There When You NeededOscar AbarcaNo ratings yet

- Product Information: Air Impact WrenchDocument12 pagesProduct Information: Air Impact WrenchPham Thien TruongNo ratings yet

- Golden Wheel 5900:5920Document23 pagesGolden Wheel 5900:5920birincimehmet34No ratings yet

- RDFALWN-CAM S Full en Us LetterDocument5 pagesRDFALWN-CAM S Full en Us LetterJustinNo ratings yet

- Mastercomlpetion11 15Document71 pagesMastercomlpetion11 15Mehrez AssidyNo ratings yet

- Pressure Roller Equipment: 307-713 Instructions-Parts ListDocument4 pagesPressure Roller Equipment: 307-713 Instructions-Parts ListLuis LugoNo ratings yet

- SPD Instructions 060120Document8 pagesSPD Instructions 060120jezfxrNo ratings yet

- JIH 455 Part3Document61 pagesJIH 455 Part3Michał JabłońskiNo ratings yet

- 3.20 On-Off - 27000Document13 pages3.20 On-Off - 27000Cuong TranNo ratings yet

- Uffy Liquid Level Controls With Electric Switches: Installation and Operating ManualDocument12 pagesUffy Liquid Level Controls With Electric Switches: Installation and Operating ManualSaeed VuNo ratings yet

- SM 133Document8 pagesSM 133gabriel90ccNo ratings yet

- FT7000 User 9510Document22 pagesFT7000 User 9510Son TonNo ratings yet

- Rebitadora Rivit Riv938ManualDocument48 pagesRebitadora Rivit Riv938ManualRobson LimeiraNo ratings yet

- Type 680 Hydraulic Stage CollarDocument6 pagesType 680 Hydraulic Stage Collar唐辉No ratings yet

- Appendices-V2Document76 pagesAppendices-V2Nikola AngjelkovskiNo ratings yet

- AppendicesDocument69 pagesAppendicesIvan CanoNo ratings yet

- 016-0190-086-A - SmarTrax - GVM Predator 8245 - Installation Manual PDFDocument20 pages016-0190-086-A - SmarTrax - GVM Predator 8245 - Installation Manual PDFJessé JoabeNo ratings yet

- Descriptio: Model GXA Sliding SleeveDocument4 pagesDescriptio: Model GXA Sliding SleevefelipeNo ratings yet

- YQK Series Hydraulic Crimping ToolDocument4 pagesYQK Series Hydraulic Crimping Toolbaolifeng100% (1)

- Engg 2Document8 pagesEngg 2ganesan 0011No ratings yet

- General Conversion Instructions For 3 X 4 In. (75 X 00 MM) Orbital SandersDocument2 pagesGeneral Conversion Instructions For 3 X 4 In. (75 X 00 MM) Orbital Sandersherysyam1980No ratings yet

- 78 36 00 410 040 BDocument5 pages78 36 00 410 040 BRohan SinghNo ratings yet

- Product InformationDocument56 pagesProduct InformationJose Enrique Mendoza RodriguezNo ratings yet

- 83-132550-000 Sa1 Ba - 55-107Document53 pages83-132550-000 Sa1 Ba - 55-107thiagoh179No ratings yet

- Cutter Instructions BookletDocument12 pagesCutter Instructions BookletgarduNo ratings yet

- FC 700E-3X-BO Product Page EnglishDocument4 pagesFC 700E-3X-BO Product Page EnglishLuis Alberto Serrano MesaNo ratings yet

- Application Example: Pneumatic 2-Finger Parallel GripperDocument35 pagesApplication Example: Pneumatic 2-Finger Parallel GripperBaltazar EspinosaNo ratings yet

- KS MNL ENG 04 01 (Retractable)Document13 pagesKS MNL ENG 04 01 (Retractable)chakrapani vagish chandra pandeyNo ratings yet

- K4-UT Operating ManualDocument51 pagesK4-UT Operating ManualCesar RiveroNo ratings yet

- CH 5 PDFDocument45 pagesCH 5 PDFAbderrazak BerrahalNo ratings yet

- RGFA Full en Metric LetterDocument4 pagesRGFA Full en Metric LetteressamNo ratings yet

- Manual SSW10Document31 pagesManual SSW10Victor RodriguezNo ratings yet

- NSB enDocument28 pagesNSB enPablo GonzalezNo ratings yet

- LG - KLINGER Transparent Glass InstallationDocument2 pagesLG - KLINGER Transparent Glass InstallationMazenNo ratings yet

- Technical Service BulletinDocument5 pagesTechnical Service BulletinMiguel AlmoraNo ratings yet

- 7.06 EC 10M SINGLE BOP manDocument20 pages7.06 EC 10M SINGLE BOP manRafael BolivarNo ratings yet

- LX8000T Preventative Maintenance & DiagnosticsDocument14 pagesLX8000T Preventative Maintenance & Diagnosticsjennifer murrishNo ratings yet

- BEP Marine TS1 Ultrasonic Sender User Manual enDocument12 pagesBEP Marine TS1 Ultrasonic Sender User Manual enfranciscoNo ratings yet

- BVH23, BVA23, BVP23, BVE23: Installation and Maintenance InstructionDocument2 pagesBVH23, BVA23, BVP23, BVE23: Installation and Maintenance InstructionMehedi HasanNo ratings yet

- DODGE® GRIP TIGHT Adapter Mount Ball BearingsDocument4 pagesDODGE® GRIP TIGHT Adapter Mount Ball BearingsDaNnIe09No ratings yet

- DBAFMCV924 Full en Metric LetterDocument6 pagesDBAFMCV924 Full en Metric LetterMechanical2022No ratings yet

- PEAK Sidewall Cutter Data ManualDocument13 pagesPEAK Sidewall Cutter Data ManualRizky WahyuNo ratings yet

- Neotech Hose Crimper NK 60 EngDocument1 pageNeotech Hose Crimper NK 60 EngAngel Cer RodNo ratings yet

- CDZ钻杆吊卡使用说明书(ZY)2013 03Document8 pagesCDZ钻杆吊卡使用说明书(ZY)2013 03WEI SHANGNo ratings yet

- Quinn's Sand Control Sliding Sleeve Optimizes ProductionDocument2 pagesQuinn's Sand Control Sliding Sleeve Optimizes ProductionfelipeNo ratings yet

- The Numbers: Riglock: Substantial Efficiency and Ebitda Benefits With An Improved Safety ProfileDocument1 pageThe Numbers: Riglock: Substantial Efficiency and Ebitda Benefits With An Improved Safety Profilefelipe100% (1)

- WL K - Netic Uni JarDocument2 pagesWL K - Netic Uni JarfelipeNo ratings yet

- WL K - Netic Uni JarDocument2 pagesWL K - Netic Uni JarfelipeNo ratings yet

- 209 - Slip Ring Combo Spec 2015-01-06Document4 pages209 - Slip Ring Combo Spec 2015-01-06baggo81No ratings yet

- Multi-Action Shear (MAS) HDPT - Multi-ReachDocument2 pagesMulti-Action Shear (MAS) HDPT - Multi-ReachfelipeNo ratings yet

- The A-2 Shock Absorber Is An Accessory Slickline ToolDocument1 pageThe A-2 Shock Absorber Is An Accessory Slickline ToolfelipeNo ratings yet

- Peak Gas Lift Straddle Pttep Gulf of Thailand Cs PDFDocument1 pagePeak Gas Lift Straddle Pttep Gulf of Thailand Cs PDFfelipeNo ratings yet

- Multi-Action Shear (MAS) HDPT - Multi-ReachDocument2 pagesMulti-Action Shear (MAS) HDPT - Multi-ReachfelipeNo ratings yet

- Open Circuit in An Electromechanical CableDocument3 pagesOpen Circuit in An Electromechanical CablefelipeNo ratings yet

- Case Study Multi Finger Caliper Tool and Gyro Tool Application PDFDocument2 pagesCase Study Multi Finger Caliper Tool and Gyro Tool Application PDFfelipeNo ratings yet

- Calculating The Pitting Resistance Equivalent Numbers (PREN)Document1 pageCalculating The Pitting Resistance Equivalent Numbers (PREN)felipeNo ratings yet

- Evolution Rotator Drive Systems Operating InstructionsDocument6 pagesEvolution Rotator Drive Systems Operating InstructionsfelipeNo ratings yet

- Recertification Form: For 14", 17", and 26" Rigging SheavesDocument1 pageRecertification Form: For 14", 17", and 26" Rigging SheavesfelipeNo ratings yet

- Packard International Products - Drop-In Check ValvesDocument2 pagesPackard International Products - Drop-In Check Valveskm1790No ratings yet

- 5b83dd5bb402392891138b3b - Datasheet - Adv Kick Over Tool - US - 1017Document2 pages5b83dd5bb402392891138b3b - Datasheet - Adv Kick Over Tool - US - 1017felipeNo ratings yet

- Series 10 Sucker Rod Overshots: Releasing A FishDocument4 pagesSeries 10 Sucker Rod Overshots: Releasing A Fishfelipe100% (1)

- Datasheet Glossary: WWW - Novametal.co - Uk Slickline@novametal - Co.ukDocument1 pageDatasheet Glossary: WWW - Novametal.co - Uk Slickline@novametal - Co.ukfelipeNo ratings yet

- Series 10 Sucker Rod Overshots: Releasing A FishDocument4 pagesSeries 10 Sucker Rod Overshots: Releasing A Fishfelipe100% (1)

- Slick-E-Line Coating Stripper: Part Number: A1204827Document1 pageSlick-E-Line Coating Stripper: Part Number: A1204827felipeNo ratings yet

- The A-2 Shock Absorber Is An Accessory Slickline ToolDocument1 pageThe A-2 Shock Absorber Is An Accessory Slickline ToolfelipeNo ratings yet

- K Netic Universal Calibration SubDocument2 pagesK Netic Universal Calibration SubfelipeNo ratings yet

- A Type Perf PDFDocument1 pageA Type Perf PDFJamel GasmiNo ratings yet

- CANAM - Hydraulic Release OvershotDocument2 pagesCANAM - Hydraulic Release OvershotfelipeNo ratings yet

- Credit Application FormDocument1 pageCredit Application FormfelipeNo ratings yet

- Slickline/E-Line InterventionDocument6 pagesSlickline/E-Line InterventionfelipeNo ratings yet

- Credit Application FormDocument1 pageCredit Application FormfelipeNo ratings yet

- 11116ej Ps PDFDocument1 page11116ej Ps PDFfelipeNo ratings yet

- Slick-E-Line Coating Stripper: Part Number: A1204827Document1 pageSlick-E-Line Coating Stripper: Part Number: A1204827felipeNo ratings yet

- Air Pak NIOSH Includes AP50i and AP75Document1 pageAir Pak NIOSH Includes AP50i and AP75Hector CachoNo ratings yet

- ZF-Synchroma-Gearbox Assembly, Maintenance and Operating InstructionsDocument38 pagesZF-Synchroma-Gearbox Assembly, Maintenance and Operating InstructionsLaura CingolaniNo ratings yet

- 10A) Brochure Bevel GearsDocument4 pages10A) Brochure Bevel GearsAnonymous srN69mFENo ratings yet

- Maintenance LogDocument5 pagesMaintenance LogAhmed OusamaNo ratings yet

- Reciprocating Compressor: Semi-HermeticDocument12 pagesReciprocating Compressor: Semi-HermeticGosai MohamedNo ratings yet

- Damcos BRCF: BRCF Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeDocument4 pagesDamcos BRCF: BRCF Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeLanceal TanNo ratings yet

- Yalesystems Katalog Jib PDFDocument12 pagesYalesystems Katalog Jib PDFcandratrikusumaNo ratings yet

- TBS299Document2 pagesTBS299harmonoNo ratings yet

- Eaton Xcomfort Selection Guide Technical Information Br005013en en UsDocument10 pagesEaton Xcomfort Selection Guide Technical Information Br005013en en UslegendraganNo ratings yet

- CP120B & CP160B: Portable X-Ray GeneratorsDocument2 pagesCP120B & CP160B: Portable X-Ray GeneratorsLale ZolfagharNo ratings yet

- One TouchclampsDocument76 pagesOne TouchclampsHector Serrano SantosNo ratings yet

- Jastine Ara B. Ognita March 11, 2015 3se - Bsece Engr - Alvin C. ManongsongDocument3 pagesJastine Ara B. Ognita March 11, 2015 3se - Bsece Engr - Alvin C. ManongsongJastineAraOgnitaNo ratings yet

- Flow Chart For Cable Termination: Not OkDocument1 pageFlow Chart For Cable Termination: Not Okpushpanath reddyNo ratings yet

- Ansul - Core O&imDocument64 pagesAnsul - Core O&imAmeen Hamed AlwseyNo ratings yet

- Predator bp120Document44 pagesPredator bp120byxpauloNo ratings yet

- A.v.L Based On Manufacturers - June2000Document490 pagesA.v.L Based On Manufacturers - June2000seetharaman k sNo ratings yet

- US Army C3 Service Manual InstructionsDocument6 pagesUS Army C3 Service Manual InstructionsRicardo Luis AbboudNo ratings yet

- Intech Isolated Auto Detecting Converter 2400 Is Installation GuideDocument12 pagesIntech Isolated Auto Detecting Converter 2400 Is Installation GuideSUMYPORT SASNo ratings yet

- PratikaDocument2 pagesPratikaAswy DeepakNo ratings yet

- Komatsu Wa600 3 Wa600 3d TBG Spec Wheel Loader Service Repair ManualDocument20 pagesKomatsu Wa600 3 Wa600 3d TBG Spec Wheel Loader Service Repair Manualedna100% (36)

- Pp2526 Intelligent Manual Call Point Issue 1 Locked - UnlockedDocument2 pagesPp2526 Intelligent Manual Call Point Issue 1 Locked - UnlockedbluesierNo ratings yet

- WA600-1 S/N 10001-UP (Overseas Version)Document2 pagesWA600-1 S/N 10001-UP (Overseas Version)Morteza BaratzadehNo ratings yet

- REI Taj 3 Setup ManualDocument1 pageREI Taj 3 Setup Manualaccountmailroom2253No ratings yet

- MK7 B V - CatalogDocument2 pagesMK7 B V - CatalogSteven WeiNo ratings yet

- Product Classification: SL110 Series Modular Jack, RJ45, Category 6, T568A/T568B, Unshielded, Without Dust Cover, BlackDocument2 pagesProduct Classification: SL110 Series Modular Jack, RJ45, Category 6, T568A/T568B, Unshielded, Without Dust Cover, BlackDWVIZCARRANo ratings yet

- Pce 28Document3 pagesPce 28Pop-Coman SimionNo ratings yet

- Ex200 Specs 1988 (db8)Document12 pagesEx200 Specs 1988 (db8)Jairo AcostaNo ratings yet

- BFV 300Document9 pagesBFV 300Adriana Agundiz RomeroNo ratings yet

- Philips MDK 900Document2 pagesPhilips MDK 900Heri MunirNo ratings yet