Professional Documents

Culture Documents

120-10788 Isir Rep

Uploaded by

Mechtek LabOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

120-10788 Isir Rep

Uploaded by

Mechtek LabCopyright:

Available Formats

Page 2 of 3 Pages

Note: IF A DIMENSION IS OUT OF SPEC., DO NOT SUBMIT PPAP. FIX THE DISCRAPANCY AND CONTACT EATON ASAP

Production Part Approval / Dimensional Test Results CQD-113.28; Rev 1; 01/15/15 SCM Form-73 (Rev. 1, 2016)

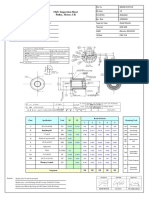

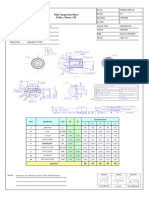

Supplier JAKAP Part Number 120-10788

Submission First Time submission Part Name LOCK NUT - 08 QCAB

Layout (Full / Partial) Full Revision A / 09.27.05

Space for up-to 5 parts measurement results by supplier Space for up-to 5 parts measurement results by Eaton (Optional)

Item Dimension / Specification Specification / Limits Test Date Qty. Measurement Method

Tested Part 1 Part 2 Part 3 Part 4 Part 5 OK Not OK Part 1 Part 2 Part 3 Part 4 Part 5 OK Not OK

1 Total Length 0.280 ± 0.010 17.03.20 5 Vernier Caliper 0.280 0.281 0.281 0.280 0.281 ok -

2

Perpendicular ˔ 0.005 w.r.t A 17.03.20 2 Profile Projector 0.0005 0.0001 - - - ok -

3 Angle 45º ± 1º 17.03.20 1 Profile Projector 45º Destructive Test ok -

4 Dia. 0.880 - 0.895 17.03.20 5 Profile Projector 0.886 0.888 0.889 0.887 0.889 ok -

5 Chamfer to 1" Dia 10º ± 1º 17.03.20 5 Profile Projector 10º 10º 10º 10º 10º ok -

7/8-14 UNF-2B ( P.D

6 Thread 17.03.20 5 TPG ok ok ok ok ok ok -

0.8286 - 0.8356 )

7 Thread Min Mod 0.7980 - 0.8068 17.03.20 5 Profile Projector 0.800 0.802 0.801 0.800 0.802 ok -

8 Parallel ǁ 0.005 w.r.t B 17.03.20 2 Profile Projector 0.0001 0.0005 - - - ok -

9 Hex 1.0000 17.03.20 5 Vernier Caliper 1.000 0.996 0.998 0.997 0.998 ok -

10 Stamp Trade mark per ES 70 17.03.20 5 Visual ok ok ok ok ok ok -

11 Material 1" Hex Brass C36000 17.03.20 5 MTC ok ok ok ok ok ok -

Break Shap Edges 0.005 /0.010 and

12 17.03.20 5 Visual ok ok ok ok ok ok -

Remove all burrs

Thread Dimensions and designations as per

13 17.03.20 5 - ok ok ok ok ok ok -

Federal Handbook H-28

All machined surfaces 125 MU. IN. MAX.

14 17.03.20 5 - ok ok ok ok ok ok -

Weatherhead Std D-1000

Blanket statements of conformance are unacceptable for any test results.

Signature Title Title Title Title Title Date

QC Inspector QC

Mr. Hitesh QC Inspector Inspector QC Inspector QC Inspector 17.03.20

Mr. Amit QC

QC Manager QC Manager Manager QC Manager QC Manager 17.03.20

Mr. QA

QA Manager QA Manager Manager QA Manager QA Manager 17.03.20

March CFG-1003 2006

Jakap Lace Pvt. Ltd.

MATERIAL TEST CERTIFICATE Form No: JM/QA/F/22

Rev No & Date: 001/01.11.2017

Purchaser:- Order Number: TC No: 30325

Date: 02.03.2020

Part No: 120-10788 Quantity/WTG:- 7.450 KG. Rod Size: HEX 1" Grade: CDA 360

Mechanical Tests

yield Hardness Forgi

Heat # Cu% Pb% Fe% Al% Sn% Mn% Ni% Si% Cd% Zn (Rem) Total Imp U.T.S.Kgf EL% Fracture MN Test

strength (HRB) Bility

min

60.00- Min 44000

2.5-3.0 0.35 Max. --- --- --- --- --- --- Remainder 0.50 Max. 15 Min. 25000 45 - 70 --- --- ---

63.00 psi

in PSI

A43-166 57.60% 3.00% 0.25% 0.37% 66166.993 22.46 28816.4 63-64

Signed: Signed:

Name : PATAL SANDIP. Name : 'Premnath Kushwaha'

Post : QC Incharge, Ext.Dept. Post : Works Manager (Ext. Plant)

You might also like

- 0 400 866 208 TestPlanDocument2 pages0 400 866 208 TestPlanคุณชายธวัชชัย เจริญสุข100% (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Oral MedicationDocument30 pagesOral MedicationPetit NacarioNo ratings yet

- Color Coding of Pipeline and Piping IdentificationDocument3 pagesColor Coding of Pipeline and Piping IdentificationLisa Malone50% (2)

- VLSI Micro-Project Report Group A PDFDocument14 pagesVLSI Micro-Project Report Group A PDFganesh SawantNo ratings yet

- A Compendium of Ground Modification TechniquesDocument371 pagesA Compendium of Ground Modification Techniquesminhhuan0101No ratings yet

- ASTM C-1305 - Standard Test Method For Crack Bridging Ability of Liquid Applied Waterproofing Membrane PDFDocument3 pagesASTM C-1305 - Standard Test Method For Crack Bridging Ability of Liquid Applied Waterproofing Membrane PDFLeonardo Otto CoutinhoNo ratings yet

- OQC Inspection Sheet Pulley, Motor, CR: OK OK OK OK OKDocument1 pageOQC Inspection Sheet Pulley, Motor, CR: OK OK OK OK OKadi meliNo ratings yet

- OQC Inspection Sheet Pulley, Motor, CR: OK OK OK OK OKDocument1 pageOQC Inspection Sheet Pulley, Motor, CR: OK OK OK OK OKadi meliNo ratings yet

- 00904B-B00104 Isir RepDocument7 pages00904B-B00104 Isir RepMechtek LabNo ratings yet

- SLM360 Clamp BoltDocument1 pageSLM360 Clamp BoltTony CeNo ratings yet

- OQC Inspection Sheet Pulley, Motor, CRDocument1 pageOQC Inspection Sheet Pulley, Motor, CRadi meliNo ratings yet

- Cross Piece BayonetDocument2 pagesCross Piece BayonetVilasNo ratings yet

- PommelDocument3 pagesPommelVilasNo ratings yet

- TRDR 300204825BDocument2 pagesTRDR 300204825BVidya SheeshNo ratings yet

- 10 MM AS0480104Document1 page10 MM AS0480104mamdouhNo ratings yet

- Layout Inspection Report: M/s Pricol LTDDocument35 pagesLayout Inspection Report: M/s Pricol LTDPrakash kumarTripathiNo ratings yet

- Sizing CalculationDocument4 pagesSizing Calculationsachin2712No ratings yet

- OIR - Top Hook BracketDocument1 pageOIR - Top Hook BracketHafizi HassanNo ratings yet

- DS AddPak Injection Block R08Document4 pagesDS AddPak Injection Block R08eka pramudia santosoNo ratings yet

- OQC Inspection Sheet Spur Gear 3.6: Rohs FreeDocument1 pageOQC Inspection Sheet Spur Gear 3.6: Rohs Freeadi meliNo ratings yet

- SKH Process Report1Document8 pagesSKH Process Report1Mohan KumarNo ratings yet

- Hardness Test Report: ITP For Piping Installation QCR: 6000-011Document4 pagesHardness Test Report: ITP For Piping Installation QCR: 6000-011tranvando1986No ratings yet

- AQUI-InfoPLC TX-TEP-0001 MP Interpretacion de Planos ElectricosDocument4 pagesAQUI-InfoPLC TX-TEP-0001 MP Interpretacion de Planos Electricosmarco antoniomegreteNo ratings yet

- FINAL INSPECTION CHECK SHEET Maru A 01-02-2021Document6 pagesFINAL INSPECTION CHECK SHEET Maru A 01-02-2021Ulfsaar KhanNo ratings yet

- Material Specification: Astm A 193 Gr. B7: Ed-2021Document2 pagesMaterial Specification: Astm A 193 Gr. B7: Ed-2021Precision EngineeringNo ratings yet

- Test Report Only For Information: Echaar Equipments PVT - Ltd. (UNIT-I)Document2 pagesTest Report Only For Information: Echaar Equipments PVT - Ltd. (UNIT-I)ananda_beloshe75No ratings yet

- 7.5 Kva BomDocument2 pages7.5 Kva BomDinesh MNo ratings yet

- 10CDCF LM-1600406 (PFGD)Document2 pages10CDCF LM-1600406 (PFGD)Sohaib AhmadNo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- Product Audit: Volkswagen AgDocument2 pagesProduct Audit: Volkswagen Agcong daNo ratings yet

- 991500591020-AA-DE CARDA TC11 (Conductos)Document1 page991500591020-AA-DE CARDA TC11 (Conductos)Soraire LucasNo ratings yet

- Collar 9.5X10Document1 pageCollar 9.5X10Preetam KumarNo ratings yet

- Plate CutterDocument3 pagesPlate CutterVilasNo ratings yet

- MICROJDocument12 pagesMICROJalexanderNo ratings yet

- Ventosa de Contacto Norgren m58400Document1 pageVentosa de Contacto Norgren m58400Base SistemasNo ratings yet

- Collar Cam Chain Guide Roller PdirDocument1 pageCollar Cam Chain Guide Roller PdirPreetam KumarNo ratings yet

- ET-SGM37FE-1222 (20170810003-H16035) ModelDocument1 pageET-SGM37FE-1222 (20170810003-H16035) Modelruta0405No ratings yet

- Bohler E 8010 4,0mm 2142568 PDFDocument1 pageBohler E 8010 4,0mm 2142568 PDFJack KomboyNo ratings yet

- Spare Part Drawings Polymore Mini 10-2,4Document8 pagesSpare Part Drawings Polymore Mini 10-2,4Jessica Perez BallesterosNo ratings yet

- BladeDocument3 pagesBladeVilasNo ratings yet

- Examination Data Sheet: Walter TostoDocument3 pagesExamination Data Sheet: Walter TostoasdasdasdasdNo ratings yet

- Zppg-Aico-Sas-Rt-0698 - 21-10-2018 (Pew)Document1 pageZppg-Aico-Sas-Rt-0698 - 21-10-2018 (Pew)Ahmed ThaerNo ratings yet

- RS 002 July 2014 (Welder Test Run Sheet Asep W)Document1 pageRS 002 July 2014 (Welder Test Run Sheet Asep W)Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Technical Review: (Minimum Score Required 75%)Document4 pagesTechnical Review: (Minimum Score Required 75%)Deepak HoleNo ratings yet

- Kon D000Document1 pageKon D000MohitNo ratings yet

- Function ListDocument7 pagesFunction ListAipsa AipsaNo ratings yet

- Control Plan-StampingDocument2 pagesControl Plan-StampingVipin Jangra100% (1)

- Material and Perform 3037Document4 pagesMaterial and Perform 3037Hương DươngNo ratings yet

- Verified Analog Parts - LNKDocument3 pagesVerified Analog Parts - LNKAnonymous BW9mIv22NNo ratings yet

- Collar Muff ProtectorDocument1 pageCollar Muff ProtectorPreetam KumarNo ratings yet

- 160 Kva Factory Joint Test Report InternalDocument2 pages160 Kva Factory Joint Test Report InternalDebdulal DuttaNo ratings yet

- Pushover Curve - FEMA 440 Equivalent Linearization: ETABS 2016 16.0.2 License # 1XE56Y53VR7VRLBDocument2 pagesPushover Curve - FEMA 440 Equivalent Linearization: ETABS 2016 16.0.2 License # 1XE56Y53VR7VRLBAdam JrNo ratings yet

- CCL 1Document1 pageCCL 1prabu cNo ratings yet

- M215HW01 V0 AuoDocument27 pagesM215HW01 V0 Auocoloane85UNo ratings yet

- P06300493-A Mantenimiento Motores HTDocument36 pagesP06300493-A Mantenimiento Motores HToperacion.ocensaNo ratings yet

- Examination Data Sheet: Walter TostoDocument3 pagesExamination Data Sheet: Walter TostoasdasdasdasdNo ratings yet

- Relay Settings TablesDocument29 pagesRelay Settings Tablesgirishprabhu1984No ratings yet

- Zppg-Aico-Sas-Rt-0611 - 02-07-2018 (Pew)Document1 pageZppg-Aico-Sas-Rt-0611 - 02-07-2018 (Pew)Ahmed ThaerNo ratings yet

- TC - ASTM 517 GR FDocument1 pageTC - ASTM 517 GR FPremnath YadavNo ratings yet

- Axle Push Lever - BK-7Document1 pageAxle Push Lever - BK-7Preetam KumarNo ratings yet

- Technical Specification PTP Ennore Part2-2024-02!19!06!07!41Document239 pagesTechnical Specification PTP Ennore Part2-2024-02!19!06!07!41trilokNo ratings yet

- Technical Specifications: Enviropol Engineers Pvt. LTDDocument17 pagesTechnical Specifications: Enviropol Engineers Pvt. LTDArvind KumarNo ratings yet

- Hardness Test Report: ITP For Piping Installation QCR: 6000-011Document4 pagesHardness Test Report: ITP For Piping Installation QCR: 6000-011tranvando1986No ratings yet

- Book 1Document1 pageBook 1Mechtek LabNo ratings yet

- Jakap Lace Pvt. LTD.: Material Test CertificateDocument1 pageJakap Lace Pvt. LTD.: Material Test CertificateMechtek LabNo ratings yet

- Jakap Lace Pvt. LTD.: Material Test CertificateDocument1 pageJakap Lace Pvt. LTD.: Material Test CertificateMechtek LabNo ratings yet

- Jakap Lace Pvt. LTD.: Material Test CertificateDocument1 pageJakap Lace Pvt. LTD.: Material Test CertificateMechtek LabNo ratings yet

- Jakap Lace Pvt. LTD.: Material Test CertificateDocument1 pageJakap Lace Pvt. LTD.: Material Test CertificateMechtek LabNo ratings yet

- Mechtek Laboratory: Document No. F/MKT/03 Page No. 2 of 2 Issue No. 01 Rev. No. 01 Issue Date 01-08-19 Rev. Date 02-02-20Document6 pagesMechtek Laboratory: Document No. F/MKT/03 Page No. 2 of 2 Issue No. 01 Rev. No. 01 Issue Date 01-08-19 Rev. Date 02-02-20Mechtek LabNo ratings yet

- Net Weight (Brass) : Drawing Number 9000439 Round WeightDocument8 pagesNet Weight (Brass) : Drawing Number 9000439 Round WeightMechtek LabNo ratings yet

- Customer Name and Symbol Removed in DrawingDocument1 pageCustomer Name and Symbol Removed in DrawingMechtek LabNo ratings yet

- Jakap Lace Pvt. LTD.: Material Test CertificateDocument1 pageJakap Lace Pvt. LTD.: Material Test CertificateMechtek LabNo ratings yet

- Mechtek Laboratory: Raw Data Sheet For Vernier CaliperDocument3 pagesMechtek Laboratory: Raw Data Sheet For Vernier CaliperMechtek LabNo ratings yet

- Mechtek Laboratory: Raw Data Sheet For Vernier CaliperDocument1 pageMechtek Laboratory: Raw Data Sheet For Vernier CaliperMechtek LabNo ratings yet

- En Ratio Calculation For Internal Quality Check Calibration Point A B Unc A Unc B en Ratio 10.2108Document1 pageEn Ratio Calculation For Internal Quality Check Calibration Point A B Unc A Unc B en Ratio 10.2108Mechtek LabNo ratings yet

- Qa ItDocument277 pagesQa ItMechtek LabNo ratings yet

- FF - 01 - Vernier CaliperDocument2 pagesFF - 01 - Vernier CaliperMechtek LabNo ratings yet

- GWDocument1 pageGWMechtek LabNo ratings yet

- More About Mechtek Calibration LaboratoryDocument2 pagesMore About Mechtek Calibration LaboratoryMechtek LabNo ratings yet

- Jakap Lace Pvt. LTD.: Material Test CertificateDocument1 pageJakap Lace Pvt. LTD.: Material Test CertificateMechtek LabNo ratings yet

- Jakap Lace Pvt. LTD.: Material Test CertificateDocument1 pageJakap Lace Pvt. LTD.: Material Test CertificateMechtek LabNo ratings yet

- Net Weight (Brass) : Drawing Number 9000439 Round WeightDocument5 pagesNet Weight (Brass) : Drawing Number 9000439 Round WeightMechtek LabNo ratings yet

- F-QC-01 Schedule For QC CheckDocument2 pagesF-QC-01 Schedule For QC CheckMechtek LabNo ratings yet

- En Ratio Calculation For Internal Quality Check Calibration Point A B Unc A Unc B en Ratio 0Document1 pageEn Ratio Calculation For Internal Quality Check Calibration Point A B Unc A Unc B en Ratio 0Mechtek LabNo ratings yet

- Jakap Lace Pvt. LTD.: Material Test CertificateDocument1 pageJakap Lace Pvt. LTD.: Material Test CertificateMechtek LabNo ratings yet

- Delhi MumbaiDocument2 pagesDelhi MumbaiSahanaNo ratings yet

- 144 - Harsh NewDocument4 pages144 - Harsh NewMechtek LabNo ratings yet

- 178-Vishal Bhatti-11Document3 pages178-Vishal Bhatti-11Mechtek LabNo ratings yet

- 143 - HardikDocument3 pages143 - HardikMechtek LabNo ratings yet

- Book 1Document3 pagesBook 1sojitra raviNo ratings yet

- Machine RM Status Qty No - of Day Start End DateDocument5 pagesMachine RM Status Qty No - of Day Start End DateMechtek LabNo ratings yet

- 150 - Rathod Manoj CVDocument2 pages150 - Rathod Manoj CVMechtek LabNo ratings yet

- 150 - Rathod Manoj CV PDFDocument2 pages150 - Rathod Manoj CV PDFMechtek LabNo ratings yet

- Experiment No. 2 "Test of Fineness of Cement by Sieve Method"Document4 pagesExperiment No. 2 "Test of Fineness of Cement by Sieve Method"KOBENo ratings yet

- PDFDocument228 pagesPDFhayderlin navaNo ratings yet

- Digestion and Absorption of CarbohydratesDocument25 pagesDigestion and Absorption of CarbohydrateskhadijaNo ratings yet

- Metode Antioksidan AEACDocument7 pagesMetode Antioksidan AEACFira KuswandariNo ratings yet

- Savana Mining TrommelsDocument2 pagesSavana Mining TrommelsWyattYeagerNo ratings yet

- Introduction To Cotton FibreDocument8 pagesIntroduction To Cotton FibreDebasish GhoshNo ratings yet

- Assignment Week 10Document5 pagesAssignment Week 10Shikha SinghNo ratings yet

- 8 DenitrificationDocument50 pages8 DenitrificationArjun RanabhatNo ratings yet

- HD 35-04 Provisions For The Use of Secondary and Recycled Materials (Nov 2004)Document16 pagesHD 35-04 Provisions For The Use of Secondary and Recycled Materials (Nov 2004)sandycastleNo ratings yet

- TDS - 3765 - Texotile Spray-On - Euk - GB PDFDocument3 pagesTDS - 3765 - Texotile Spray-On - Euk - GB PDFSomanith KoumNo ratings yet

- CHM3201 Lab Report S2 2019-2020Document42 pagesCHM3201 Lab Report S2 2019-2020Halimatun MustafaNo ratings yet

- Final Mechanics Quiz PPT 21 1 .11.09Document68 pagesFinal Mechanics Quiz PPT 21 1 .11.09Abhilash DayaNo ratings yet

- CH 3. Mass Relations in Chemistry - StoichiometryDocument12 pagesCH 3. Mass Relations in Chemistry - Stoichiometryewewwe weweweweNo ratings yet

- ALERT - MCC CENTRALINA - BO0349675320 - SIDOC PLANTA 2 ACERIAS - VALVULA DESLIZANTE 3 - 1 - en - EsDocument2 pagesALERT - MCC CENTRALINA - BO0349675320 - SIDOC PLANTA 2 ACERIAS - VALVULA DESLIZANTE 3 - 1 - en - EsLuis CortesNo ratings yet

- GroutingDocument4 pagesGroutingDrPadipat ChaemmangkangNo ratings yet

- Vanders Human Physiology The Mechanisms of Body Function 14th Edition Widmaier Solutions ManualDocument26 pagesVanders Human Physiology The Mechanisms of Body Function 14th Edition Widmaier Solutions Manualconsignedurylic75hi100% (24)

- Whitening NineShadeChangebyLaser-AssistedTeethWhiteningDocument4 pagesWhitening NineShadeChangebyLaser-AssistedTeethWhiteningruxandrafitaNo ratings yet

- MSDS 108 Sigma M 460 Air Compressor Fluid Tcm9 8533Document10 pagesMSDS 108 Sigma M 460 Air Compressor Fluid Tcm9 8533Anonymous xJahbl2WZNo ratings yet

- Vaccum Dehydrator 1Document7 pagesVaccum Dehydrator 1Simbu ArasanNo ratings yet

- Ashima JMLDocument11 pagesAshima JMLPrachi PatnaikNo ratings yet

- A Study On Sand Filtration: Submitted byDocument15 pagesA Study On Sand Filtration: Submitted byNIRMALKUMAR.KNo ratings yet

- V. Mosfet PDFDocument33 pagesV. Mosfet PDFleeminho_janxiNo ratings yet

- Water Treatment GEDocument283 pagesWater Treatment GEJorge Mauricio Justiniano Helbingen100% (1)

- Tencile StrengthDocument11 pagesTencile StrengthYdzel Jay Dela TorreNo ratings yet

- Specification For Dual-Layer FBEDocument19 pagesSpecification For Dual-Layer FBEali saidNo ratings yet