Professional Documents

Culture Documents

Weld Visual Report Rev.0 PDF

Weld Visual Report Rev.0 PDF

Uploaded by

John Terry0 ratings0% found this document useful (0 votes)

17 views1 pageOriginal Title

Weld Visual report Rev.0.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 pageWeld Visual Report Rev.0 PDF

Weld Visual Report Rev.0 PDF

Uploaded by

John TerryCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

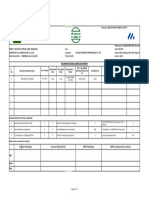

FORM NO: SCM-VI-001 REV.

WELD VISUAL INSPECTION REPORT

PROJECT : REPORT NO. :

PRINCIPAL/CLIENT : INSPECTION DATE :

JOB NO. : PHASE OF FABRICATION :-

SHOP DWG REG. LIST :

1. Element 2. Sub-Assembly 3. Assembly

ASSEMBLY NO. :

PWR REPORT NO. : 4. Block 5. Final Erection

PWR REV. :

Quality Standard QCI QAI

Item Check Item (Visual Examination Procedure & Remark

Weld Metal and Base Metal Repair Procedure) ACC REJ ACC REJ

1 Weld Profile and Details • IFC Shop Drawing

• Slightly Concave, Flat or Slightly

2 Fillet Weld Contour Convex

• Required Throat & Leg Size

3 Weld Type, Size and Length • IFC Shop Drawing

Piping or Other Porosity Open to

4 • Not accepted

Surface

• Allowed Maximum :

- Zone 1 - 0.25 mm

5 Undercut

- Zone 2 - 0.25 mm

- Zone 3 - 1 mm

6 Cracks, Weld Craters and Overlap • Not permitted

7 Arc Strikes Outside Weld Bevel • Not permitted

Complete Fusion Between Weld

8 Passes and Between Weld Metal and • Required

Base Metal

• Allowed Maximum :

- Zone 1 - 3 mm, Re-entrant Angle

9 Butt Weld Reinforcement > 135 Degrees

- Zone 2 & 3 - 5 mm, Transition to

Base Metal with No Overlap

Misalignment of Minimum Plate - Buttweld - 0.1T, Max 3 mm

10

Thickness - Cruciform - 0.25T, Max 6 mm

11 Weld Face Surface Finish • IFC Shop Drawing

12 Missing Members • IFC Shop Drawing

• Ground Flush, Max Reinforcement

13 Weld Tab Removed

3 mm

• Slag Removed

14 Cleaning of Completed Welds

• Spatter Removed

COMMENTS :

REVIEWED BY :

PRODUCTION QC SCM QA Shell Vito Class

Signature

Name

Date

Result Accept / Reject Accept // Reject

Reject

Accept / Reject Accept Accept / Reject

You might also like

- Solucionário Exercícios FlambagemDocument31 pagesSolucionário Exercícios FlambagemMarcos MaiaNo ratings yet

- Welding Consumables Control RegisterDocument5 pagesWelding Consumables Control RegisterAli Mhaskar100% (2)

- Welding Traceability Record 1Document1 pageWelding Traceability Record 1Alfian Imaduddin100% (1)

- Work Instructions For Rolling of PlatesDocument3 pagesWork Instructions For Rolling of PlatesPravin Patil100% (1)

- Basic Fabrication Process FlowchartDocument2 pagesBasic Fabrication Process FlowchartGodwin A.udo-akan100% (1)

- Procedure D'inspectionDocument9 pagesProcedure D'inspectionsalahjallali100% (2)

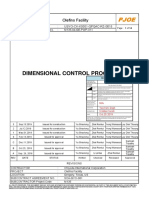

- Dimensional-Control Procedure PDFDocument57 pagesDimensional-Control Procedure PDFJohn Terry100% (2)

- Yuchai YC4D120-20 D1008 PDFDocument75 pagesYuchai YC4D120-20 D1008 PDFAbel Gheller100% (1)

- Level 1 Pneumatics Answers For ExercisesDocument22 pagesLevel 1 Pneumatics Answers For ExercisesSamantha AshmanNo ratings yet

- Weld Repair ReportDocument1 pageWeld Repair Reportkerons100% (1)

- Welding Quality Control and Inspection FormDocument1 pageWelding Quality Control and Inspection FormJuli Agus100% (2)

- Stage Wise Inspection ReportDocument2 pagesStage Wise Inspection ReportKarthi Keyan100% (2)

- FIT UP ReportDocument2 pagesFIT UP Reportsiva8000No ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFNatarajan Raja100% (2)

- NR-37 - Dez 2018 - ENGDocument46 pagesNR-37 - Dez 2018 - ENGJohn TerryNo ratings yet

- WOODWARD ACTUOTOR CATALOGE PDF 1 PDFDocument78 pagesWOODWARD ACTUOTOR CATALOGE PDF 1 PDFHendra M100% (3)

- Welder Qualification Procedure PDFDocument13 pagesWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- Ins-P-021, Long Seam Set UpDocument4 pagesIns-P-021, Long Seam Set UpDeepak100% (1)

- Visual Inspection FormatDocument2 pagesVisual Inspection Formattuan mai vanNo ratings yet

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarNo ratings yet

- Attachment 22 - (SECL-PIP026) Welding Consumable Issue SlipDocument5 pagesAttachment 22 - (SECL-PIP026) Welding Consumable Issue SlipRjeb mohamedNo ratings yet

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- Plate Inspection ReportDocument1 pagePlate Inspection ReportlalitaliNo ratings yet

- Welding TracebillityDocument15 pagesWelding TracebillityDeby Agung PratamaNo ratings yet

- Magnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiDocument1 pageMagnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiMurugan Raja100% (1)

- Incoming Material Inspection Report: Date of ReceiptDocument1 pageIncoming Material Inspection Report: Date of ReceiptRaj MNo ratings yet

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Document2 pagesVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- Material Traceability ProcedureDocument12 pagesMaterial Traceability Procedureqamar qateebNo ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- Weld RepairDocument2 pagesWeld RepairAnurag YadavNo ratings yet

- MPT Report FormatDocument1 pageMPT Report FormatRoshan Thomas100% (1)

- Preparation and Control of WeldingDocument3 pagesPreparation and Control of Weldingbalakumar rajaramNo ratings yet

- Inspection report-GRVE BlankDocument2 pagesInspection report-GRVE BlankJoseph Perez100% (1)

- Welding Control ProcedureDocument4 pagesWelding Control Procedurevenkatesh100% (2)

- Welder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationDocument1 pageWelder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationPerminder Singh100% (1)

- Duties Before WeldingDocument1 pageDuties Before WeldingMuhammed ThanzeelNo ratings yet

- Liquid Penetrant Examination Report: PO No.&Document2 pagesLiquid Penetrant Examination Report: PO No.&Samir Chaudhary100% (2)

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDocument1 pageField Welding Inspection Checklist: Wisconsin Department of Transportationandreafaith biatingoNo ratings yet

- Welding Parameters Control PipelineDocument1 pageWelding Parameters Control PipelinemusheerNo ratings yet

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Flame StraighteningDocument3 pagesFlame StraighteningAvishek Gupta100% (1)

- Welding Visual Inspection FormatDocument2 pagesWelding Visual Inspection Formatgst ajah100% (3)

- Visual and Dimensional Insp Report FORMATDocument9 pagesVisual and Dimensional Insp Report FORMATiftekhar ahmedNo ratings yet

- Welding Report For PipingDocument1 pageWelding Report For PipingRifki HasyaNo ratings yet

- Sample Heat Treatment ProcedureDocument13 pagesSample Heat Treatment ProcedureAnonymous uXdS9Y7100% (1)

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- Visual Inspection ReportDocument2 pagesVisual Inspection ReportAlfian ImaduddinNo ratings yet

- Form Attchment - RFI PICTURE-2Document2 pagesForm Attchment - RFI PICTURE-2Echik Kici100% (1)

- Welding Consumable Baking Register PDFDocument1 pageWelding Consumable Baking Register PDFKandula Raju100% (1)

- Fit Up & Weld VisualDocument2 pagesFit Up & Weld VisualBhanu Pratap ChoudhuryNo ratings yet

- Weld Repair Rate - MFJO542Document2 pagesWeld Repair Rate - MFJO542Salahuddin Farooqui100% (1)

- PBI-CCP-QA-0001 QA Welding Consumable Control ProcedureDocument15 pagesPBI-CCP-QA-0001 QA Welding Consumable Control ProcedureTadaya KasaharaNo ratings yet

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouNo ratings yet

- MNT - QC - BP - 001 Blasting & Painting ReportDocument1 pageMNT - QC - BP - 001 Blasting & Painting Reportsivagnanam sNo ratings yet

- STD-InSP-0006 (Flange Inspection Procedure)Document3 pagesSTD-InSP-0006 (Flange Inspection Procedure)airbroom100% (1)

- Daily Fit-Up/Welding Inspection ReportDocument7 pagesDaily Fit-Up/Welding Inspection ReportRichard PeriyanayagamNo ratings yet

- Welding Control ProcedureDocument9 pagesWelding Control ProcedureRomi Abdul RahmanNo ratings yet

- Work Instructions - FabricationDocument3 pagesWork Instructions - Fabricationvivek suresh0% (1)

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDocument3 pagesSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNo ratings yet

- Welding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotDocument3 pagesWelding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotRicardo LourençoNo ratings yet

- JNK Heaters Co - LTD: Ferrite Test ReportDocument1 pageJNK Heaters Co - LTD: Ferrite Test ReportUzorNo ratings yet

- Op-3-65. Checklist For Jack-In-Pile Supervision: Work Instructions For EngineersDocument4 pagesOp-3-65. Checklist For Jack-In-Pile Supervision: Work Instructions For Engineersjinwook75No ratings yet

- Visual Inspection Acceptance CriteriaDocument2 pagesVisual Inspection Acceptance CriteriaJohn TerryNo ratings yet

- Usyo CK k0001 Qpqac RZ 0015 - Rev.03 - Code1 PDFDocument18 pagesUsyo CK k0001 Qpqac RZ 0015 - Rev.03 - Code1 PDFJohn TerryNo ratings yet

- Certificado de Teste de Instrumentação Teste de Multicabo: Instrument Test Certification Multi-Cable TestDocument1 pageCertificado de Teste de Instrumentação Teste de Multicabo: Instrument Test Certification Multi-Cable TestJohn TerryNo ratings yet

- Fabrication SupervisorDocument1 pageFabrication SupervisorJohn TerryNo ratings yet

- GENERAL About Welder Qualification Follow ASME IXDocument2 pagesGENERAL About Welder Qualification Follow ASME IXJohn TerryNo ratings yet

- P68 M13 Painting Documents PDFDocument708 pagesP68 M13 Painting Documents PDFJohn TerryNo ratings yet

- NR10【2016】Safety in Electrical Installations and ServicesDocument7 pagesNR10【2016】Safety in Electrical Installations and ServicesJohn TerryNo ratings yet

- AWS-Pre-During-Post-Weld-Inspections ChecksheetDocument4 pagesAWS-Pre-During-Post-Weld-Inspections ChecksheetJohn TerryNo ratings yet

- NR10【2016】Safety in Electrical Installations and ServicesDocument7 pagesNR10【2016】Safety in Electrical Installations and ServicesJohn TerryNo ratings yet

- (Sample) Joint Audit ScheduleDocument1 page(Sample) Joint Audit ScheduleJohn TerryNo ratings yet

- FX Family - Training Manual (Positioning Control) 214562-B (08.12) PDFDocument116 pagesFX Family - Training Manual (Positioning Control) 214562-B (08.12) PDFftsebeek6164No ratings yet

- 06 ARO103 - Jet - Engine - Laboratory - Spring - 2010-Rev1xDocument16 pages06 ARO103 - Jet - Engine - Laboratory - Spring - 2010-Rev1xNatallia NatalliaNo ratings yet

- Chassis DynamometerDocument6 pagesChassis DynamometervanessaNo ratings yet

- DIN 7991 ISO 10642: Flat Countersunk Head Socket Cap ScrewsDocument3 pagesDIN 7991 ISO 10642: Flat Countersunk Head Socket Cap Screwsdilnair99No ratings yet

- 2015-TPC-0930 Reel-Lay Method To Allow For Direct Tie-In of Pipelines - DRAFTLDocument11 pages2015-TPC-0930 Reel-Lay Method To Allow For Direct Tie-In of Pipelines - DRAFTLnicholas_j_vaughanNo ratings yet

- Lockout / Tag Out Program: Presented by DOSHTIDocument21 pagesLockout / Tag Out Program: Presented by DOSHTIKanupriya100% (1)

- PCT 3189927Document5 pagesPCT 3189927Flávio GarboNo ratings yet

- Multi V IV Trouble Shooting 2016 PDFDocument167 pagesMulti V IV Trouble Shooting 2016 PDFJorge Dovale100% (2)

- Pruebas y Ajustes r1300GDocument21 pagesPruebas y Ajustes r1300GYersonNo ratings yet

- 1 Logarthmic - DecrementDocument5 pages1 Logarthmic - DecrementAnup PatilNo ratings yet

- Installation Systems - PDF - PBDocument38 pagesInstallation Systems - PDF - PBKUMAARRRNo ratings yet

- Fabrication CalculationDocument40 pagesFabrication CalculationRamesh mudunuri100% (1)

- Floor Vibration and The Electronic Office - Thomas MurrayDocument4 pagesFloor Vibration and The Electronic Office - Thomas MurrayDesert1997No ratings yet

- Kubota 05 Series d1305 E3b SpecificationsDocument2 pagesKubota 05 Series d1305 E3b SpecificationsVol VasylkevychNo ratings yet

- T 202 ACETONE COLUMN DESIGN - v2Document7 pagesT 202 ACETONE COLUMN DESIGN - v2Jewls HatudNo ratings yet

- Atmospheric Pressure Sensor PDFDocument4 pagesAtmospheric Pressure Sensor PDFMijaelNo ratings yet

- Om YorkDocument36 pagesOm YorkMuhhamad JunaidNo ratings yet

- Centrifugal Pump Manual 620 MCDocument35 pagesCentrifugal Pump Manual 620 MCstrainstress20006715No ratings yet

- 7.1 Moments-Cie Ial Physics-Theory QPDocument11 pages7.1 Moments-Cie Ial Physics-Theory QPAhmed HunainNo ratings yet

- Buried Pipe Analysis PDFDocument6 pagesBuried Pipe Analysis PDFDivesh rahul50% (2)

- Deluxe DB75 and 75V ManualDocument48 pagesDeluxe DB75 and 75V ManualMaxwell MandikumbaNo ratings yet

- Direct Numerical SimulationDocument38 pagesDirect Numerical SimulationddqylxgNo ratings yet

- CE637A-Pactice Question - 1Document2 pagesCE637A-Pactice Question - 1Sanchita PaulNo ratings yet

- Dynaweld 12Document16 pagesDynaweld 12Riverland Welding and Tool SuppliesNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- T Beam Design: Step 1: Given DataDocument7 pagesT Beam Design: Step 1: Given DataKARTHIK SGNo ratings yet