Professional Documents

Culture Documents

Final Gear Calculator

Uploaded by

John Ross0 ratings0% found this document useful (0 votes)

31 views12 pagesOriginal Title

Final_Gear_Calculator.xlsx

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views12 pagesFinal Gear Calculator

Uploaded by

John RossCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 12

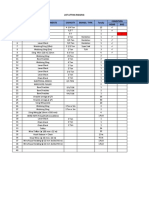

Inputs Gear Symbol Value Pinion Symbol Value

Outside Diameter in inches DoG= 3.2 DoP= 2.2

Number of Teeth NG= 30 NP= 20

Pitch Diameter in inches DG= 3 DP= 2

Fixed Constants Gear Symbol Value Pinion Symbol Value

Pressure Angle in degrees φ= 20 φ= 20

Outputs Gear Symbol Value

Diametral Pitch P= 10.0000

Base Diameter in inches DbG= 2.8191

Root Diameter in inches DRG= 2.7560

Whole Depth in inches htG= 0.2220

Addendum in inches aG= 0.1000

Dedendum in inches bG= 0.0220

Auxiliary Angle in degrees φAG= 31.3213

Interval of Contact in inches uG= 0.2298

Roll Angle at Theoretical Limit Radius in Degrees ϵlG= 11.3616

Theoretical Limit Radius in inches rlG= 1.4377

Form Diameter in inches dfG= 2.8753

Circular Tooth Thickness in inches t= 0.1571

Fillet Radius in inches rfG= 0.0300

All formulas are from the Boston Gear Ca

Values in formulas that have bars around the

pinion value if you are calculating for the gear a

Pinion Symbol Value Formula

P= 10.0000 N/D

DbP= 1.8794 Dcosφ

DRP= 1.7560 Do-2ht

htP= 0.2220 2.2/P + .002

aP= 0.1000 1/P

bP= 0.0220 ht - 2a

φAP= 28.2414 cos-1((|Db|/2)/((|D|/2)+|a|))

uP= 0.2441 ((|D|/2)+a)*sin(φA)-(|D|/2)*sin(φ)

ϵlP= 5.9508 tan-1(((D/2)sin(φ) - u)/(Db/2))

rlP= 0.9448 (Db/2)/cos(ϵl)

dfP= 1.8846 2(rl - .025*(.025/P))

t= 0.1571 Pi/2*P

rfP= 0.0300 .3/P

m the Boston Gear Catalog

have bars around them use the

ulating for the gear and vice versa

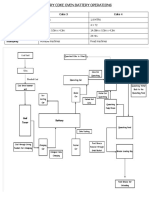

Parameter Gear Symbol Value Pinion Symbol Value

Number of Teeth NG= 78 NP= 31

Diametral Pitch Pd= 12 Pd= 12

Shaft Angle (in degrees) Σ= 90 Σ= 90

Is There a Full Set of Inputs? Yes Yes

Fixed Constants Gear Symbol Value Pinion Symbol Value

Pressure Angle (in Degrees) φ= 20 φ= 20

The gears produced by this spread sheet have no crowning

and always have a pressure angle of 20 degrees

Outputs Gear Symbol Value Pinion Symbol Value

Ratio mG= 2.516 mG= 2.516

Pitch Diameter DG= 6.500 DP= 2.583

Pitch Angle (in degrees) Γ= 68.325 ϒ= 21.675

Outer Cone Distance Ao= 3.497 Ao= 3.497

Face Width F= 0.833 F= 0.833

Equivalent 90° Ratio m90= Err:509 m90= 2.516

Working Depth hk= 0.167 hk= 0.167

Addendum (at heel of tooth) aoG= 0.051 aoP= 0.116

Whole Depth ht= 0.184 ht= 0.184

Dedendum (at heel of tooth) boG= 0.133 boP= 0.069

Dedendum Angle (In Degrees) δG= 2.182 δP= 1.126

Face Angle (in Degrees) Γo= 69.451 ϒo= 23.857

Outside Diameter DoG= 6.538 DoP= 2.798

Pitch Cone Apex to Crown XoG= 1.244 XoP= 3.207

Circular Pitch p= 0.262 p= 0.262

Root Angle (in Degrees) ΓR= 66.143 ϒR= 20.549

Back-Angle Distance No Symbol 3.497 No Symbol 3.497

All Formulas Come From table 5-22 of the Gea

Handbook

Formulas

mG=NG/NP

DG=NG/Pd and DP=NP/Pd

Γ=Σ-ϒ and If Σ=90: ϒ=tan-1(NG/NP) If Σ<90: ϒ=tan-1(sin(Σ)/(mG+cos(Σ)) If Σ>90: ϒ=tan-1(sin(180-Σ)/(mG-cos(180-Σ)))

If Σ=90: Ao=1/2(DP2+DG2)1/2, If Σ≠90: Ao=DG/(2*sin(Γ))

F=Ao/3 or F=10/Pd (use the smaller value)

If Σ=90: m90=mG, If Σ≠90: m90=(mG(cos(ϒ)/cos(Γ)))1/2

hk=2.0/Pd

aoG=(.54/Pd)+(.460/Pd*m902) and aoP=hk-aoG

ht=2.188/Pd+.002

boG=ht-aoG and boP=ht-aoP

δG=tan-1(boG/Ao) and δP=tan-1(boP/Ao)

Γo=Γ+δG and ϒo=ϒ+δP

DoG=DG+2aoG*cos(Γ) and DoP=DP+2aoP*cos(ϒ)

If Σ=90: XoG=DP/2-aoG*sin(Γ) and XoP=DG/2-aoP*sin(ϒ), If Σ≠90: XoG=Ao*cos(Γ)-aoG*sin(Γ) and XoP=Ao*cos(ϒ)-aoP*sin(ϒ)

p=π/Pd

ΓR=Γ-δG and ϒR=ϒ-δP

Back-Angle Distance = Ao

table 5-22 of the Gear Manufacturer's

Handbook

Parameter Gear Symbol Value Pinion Symbol Value

Number of Teeth NG= 78 NP= 31

Diametral Pitch Pd= 12 Pd= 12

Shaft Angle (in degrees) Σ= 90 Σ= 90

Is There a Full Set of Inputs? Yes Yes

Fixed Constants Gear Symbol Value Pinion Symbol Value

Pressure Angle (in Degrees) φ= 20 φ= 20

The gears produced by this spread sheet have no crowning

and always have a pressure angle of 20 degrees

Outputs Gear Symbol Value Pinion Symbol Value

Ratio mG= 2.516 mG= 2.516

Pitch Diameter DG= 6.500 DP= 2.583

Pitch Angle (in degrees) Γ= 68.325 ϒ= 21.675

Outer Cone Distance Ao= 3.497 Ao= 3.497

Face Width F= 0.833 F= 0.833

Equivalent 90° Ratio m90= Err:509 m90= 2.516

Working Depth hk= 0.142 hk= 0.142

Addendum (at heel of tooth) aoG= 0.043 aoP= 0.098

Whole Depth ht= 0.157 ht= 0.157

Dedendum (at heel of tooth) boG= 0.114 boP= 0.059

Dedendum Angle (In Degrees) δG= 1.865 δP= 0.969

Face Angle (in Degrees) Γo= 69.294 ϒo= 23.539

Outside Diameter DoG= 6.532 DoP= 2.766

Pitch Cone Apex to Crown XoG= 1.251 XoP= 3.214

Circular Pitch p= 0.262 p= 0.262

Root Angle (in Degrees) ΓR= 66.461 ϒR= 20.706

Back-Angle Distance No Symbol 3.497 No Symbol 3.497

All Formulas Come From table 5-22 of the Gea

Handbook

Formulas

mG=NG/NP

DG=NG/Pd and DP=NP/Pd

Γ=Σ-ϒ and If Σ=90: ϒ=tan-1(NG/NP) If Σ<90: ϒ=tan-1(sin(Σ)/(mG+cos(Σ)) If Σ>90: ϒ=tan-1(sin(180-Σ)/(mG-cos(180-Σ)))

If Σ=90: Ao=1/2(DP2+DG2)1/2, If Σ≠90: Ao=DG/(2*sin(Γ))

F=Ao/3 or F=10/Pd (use the smaller value)

If Σ=90: m90=mG, If Σ≠90: m90=(mG(cos(ϒ)/cos(Γ)))1/2

hk=1.70/Pd

aoG=(.46/Pd)+(.390/Pd*mG2) and aoP=hk-aoG

ht=1.888/Pd

boG=ht-aoG and boP=ht-aoP

δG=tan-1(boG/Ao) and δP=tan-1(boP/Ao)

Γo=Γ+δG and ϒo=ϒ+δP

DoG=DG+2aoG*cos(Γ) and DoP=DP+2aoP*cos(ϒ)

If Σ=90: XoG=DP/2-aoG*sin(Γ) and XoP=DG/2-aoP*sin(ϒ), If Σ≠90: XoG=Ao*cos(Γ)-aoG*sin(Γ) and XoP=Ao*cos(ϒ)-aoP*sin(ϒ)

p=π/Pd

ΓR=Γ-δG and ϒR=ϒ-δP

Back-Angle Distance = Ao

table 5-22 of the Gear Manufacturer's

Handbook

Horse Power Required for Desired Application Shaft Sizes (in inches)

1 1/2

RPM Required for Desired Application 5/8

20 3/4

Min. Shaft Diameter for Desired Application (in inches)

1.732

Suitable?

Not Suitable

Not Suitable

Not Suitable

You might also like

- Final Gear CalculatorDocument15 pagesFinal Gear CalculatorJennifer Nicky ShakerNo ratings yet

- Piñon y Engranaje RectosDocument39 pagesPiñon y Engranaje RectosJosue E. HernandezNo ratings yet

- Safari - May 16, 2022 at 9:00 PMDocument1 pageSafari - May 16, 2022 at 9:00 PMDagneNo ratings yet

- Fdocuments - Ec Hoja de Calculo para Engranajes RectosDocument6 pagesFdocuments - Ec Hoja de Calculo para Engranajes Rectosag cnc & wedm machining shopNo ratings yet

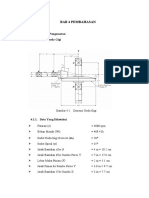

- Bab 4 Pembahasan: 4.1. Data Hasil Pengamatan 4.1.1 Dimensi Roda GigiDocument7 pagesBab 4 Pembahasan: 4.1. Data Hasil Pengamatan 4.1.1 Dimensi Roda GigiKurniadi SabdaNo ratings yet

- Meshing Spur GearsDocument25 pagesMeshing Spur GearsCherrydhelNo ratings yet

- Spur GearDocument33 pagesSpur GearMau100% (1)

- UAQ Facultad de Ingeniería Diseño Mecánico AvanzadoDocument12 pagesUAQ Facultad de Ingeniería Diseño Mecánico AvanzadoSalvador Vega MancillaNo ratings yet

- Lecture 2 Sample Problems WordDocument9 pagesLecture 2 Sample Problems Wordjake luis matthewNo ratings yet

- Module 2 Activity No. 2 Spur Gear ProblemDocument4 pagesModule 2 Activity No. 2 Spur Gear ProblemLeyzer MalumayNo ratings yet

- Top Roof: Tank Tag No.: EG2-D-6306ADocument6 pagesTop Roof: Tank Tag No.: EG2-D-6306ASAMER OSMANNo ratings yet

- Tedata: Programm Benutzer Datum Kunde Proj. NRDocument3 pagesTedata: Programm Benutzer Datum Kunde Proj. NRJason CanoNo ratings yet

- Shi20396 ch13 OCTAVADocument27 pagesShi20396 ch13 OCTAVARSNo ratings yet

- Helical Gearing Design Calculations and Stress AnalysisDocument3 pagesHelical Gearing Design Calculations and Stress AnalysisJason CanoNo ratings yet

- Gear Calculation Final ReportDocument2 pagesGear Calculation Final ReportNaman HumaneNo ratings yet

- Dim. ReportDocument4 pagesDim. Reportrajit kumarNo ratings yet

- Horizontal Curves SuperelevationDocument18 pagesHorizontal Curves SuperelevationagusherlyNo ratings yet

- Structural Computation: Prepared byDocument7 pagesStructural Computation: Prepared byJing JingNo ratings yet

- SolutionDocument35 pagesSolutionMariel MirafloresNo ratings yet

- How To Draw Involute Bevel GearDocument2 pagesHow To Draw Involute Bevel GearMatija RepincNo ratings yet

- Perhitungan Tugas 1 Perancangan HEDocument3 pagesPerhitungan Tugas 1 Perancangan HELuthfanNo ratings yet

- MMB411 Tutorial - Gears01 Fundamentals PDFDocument29 pagesMMB411 Tutorial - Gears01 Fundamentals PDFNdivhuwo NdivhuwoNo ratings yet

- Tugas Pap Kel3Document9 pagesTugas Pap Kel316-125 Ruth Ria RistaNo ratings yet

- Project SampleDocument8 pagesProject SampleRamji RaoNo ratings yet

- Calculation of DavitDocument2 pagesCalculation of DavitpiziyuNo ratings yet

- First Worm Finding Number of Teeth and Gear Diameter: DW+DG 2 1.5 in +4.7 in 2Document4 pagesFirst Worm Finding Number of Teeth and Gear Diameter: DW+DG 2 1.5 in +4.7 in 2mitha07No ratings yet

- Bevel CalcuDocument5 pagesBevel Calcupalani powerNo ratings yet

- Perancangan Alat CekDocument19 pagesPerancangan Alat CekLilyNo ratings yet

- Budynas SM ch13Document24 pagesBudynas SM ch13Terence LamNo ratings yet

- 2-1 Elliptical DISH DEVLOPMENTDocument1 page2-1 Elliptical DISH DEVLOPMENTpkolNo ratings yet

- FWEFJLNIY4QKLQXDocument13 pagesFWEFJLNIY4QKLQXSoldan MihaiNo ratings yet

- Design and Analysis of CranesDocument14 pagesDesign and Analysis of Cranesrip111176No ratings yet

- Bearing Capacity Calculation: Description of StrataDocument8 pagesBearing Capacity Calculation: Description of StrataDadi YashwantNo ratings yet

- How To Draw Involute Bevel GearDocument2 pagesHow To Draw Involute Bevel GeardimtecNo ratings yet

- Isolated Footing P & MDocument8 pagesIsolated Footing P & Mمحمد حاج اسماعيلNo ratings yet

- Roda Gigi KerucutDocument4 pagesRoda Gigi KerucutOkky RachmadillaNo ratings yet

- Design of SlabDocument14 pagesDesign of Slabابراهيم المبيضينNo ratings yet

- Basic Data:: Calculation of Gust Effect FactorDocument1 pageBasic Data:: Calculation of Gust Effect FactorYaser ShabasyNo ratings yet

- Roof Tank Stiffener CalculationsDocument6 pagesRoof Tank Stiffener CalculationsSAMER OSMANNo ratings yet

- Not For Commercial Use: TedataDocument2 pagesNot For Commercial Use: Tedatawilly rojas zeballosNo ratings yet

- interference-split-[42-42]-20231105100344Document1 pageinterference-split-[42-42]-20231105100344primeanshumalikashyapNo ratings yet

- Pipe Friction + Fitting (Type 2)Document3 pagesPipe Friction + Fitting (Type 2)AmroKashtNo ratings yet

- Base Plate, Pedestal and FootingDocument8 pagesBase Plate, Pedestal and FootingRai RiveraNo ratings yet

- SteelDocument78 pagesSteelzulsyamNo ratings yet

- Design Calculation of Gearbox: ST ND RD TH THDocument50 pagesDesign Calculation of Gearbox: ST ND RD TH THKaung KhantNo ratings yet

- Flange Bolt LoadDocument3 pagesFlange Bolt LoadSAMER OSMANNo ratings yet

- FootingDocument4 pagesFootingrudolfNo ratings yet

- Baja Denny (Tipe 1)Document13 pagesBaja Denny (Tipe 1)zulsyamNo ratings yet

- Dimensions of Sprocket: Single-Strand Double-Strand Quadrup-StrandDocument1 pageDimensions of Sprocket: Single-Strand Double-Strand Quadrup-Strandวิทวัส นิเทียนNo ratings yet

- Lab data gear calculationsDocument7 pagesLab data gear calculationsMuhammad Hammad AsgharNo ratings yet

- Designing a Speed ReducerDocument12 pagesDesigning a Speed ReducerHannahNo ratings yet

- BlindDocument3 pagesBlindSajal KulshresthaNo ratings yet

- Calculo de Areas VariosDocument106 pagesCalculo de Areas Variosjuan cordovaNo ratings yet

- Symbol Formula Pitch PDocument5 pagesSymbol Formula Pitch PdhaNo ratings yet

- Appendix B-9 Design of Support Pier:: Force (N) X-Component Y-ComponentDocument5 pagesAppendix B-9 Design of Support Pier:: Force (N) X-Component Y-ComponentkkgbkjNo ratings yet

- Details of GearsDocument88 pagesDetails of Gearsramchandra rao deshpandeNo ratings yet

- Asentamientos Elasticos WordDocument6 pagesAsentamientos Elasticos WordMonica PintoNo ratings yet

- Pre Heater Design CalculationsDocument4 pagesPre Heater Design CalculationsFahad KhokharNo ratings yet

- 6-49370NA Service Book PDFDocument182 pages6-49370NA Service Book PDFJohn RossNo ratings yet

- IRAMX16UP60ADocument18 pagesIRAMX16UP60Atheylor1990No ratings yet

- 6 43052na-Schematic PDFDocument6 pages6 43052na-Schematic PDFJohn RossNo ratings yet

- 6 42965NAR0 Transmission PDFDocument1,064 pages6 42965NAR0 Transmission PDFJohn RossNo ratings yet

- Bevel Gear Formula - MasterDocument191 pagesBevel Gear Formula - Masterer_winwibowo100% (1)

- Bevel GearsDocument3 pagesBevel GearsJohn RossNo ratings yet

- Read Me!!!Document1 pageRead Me!!!John RossNo ratings yet

- Vdocuments - MX - Bevel Gears 565dba8eb5fd9Document4 pagesVdocuments - MX - Bevel Gears 565dba8eb5fd9John RossNo ratings yet

- Gear Calculations Rev3Document5 pagesGear Calculations Rev3ghostghost123No ratings yet

- This Is A Blank DocumentDocument1 pageThis Is A Blank DocumentJohn RossNo ratings yet

- Number of Teeth Diametral Pitch Pressure AngleDocument2 pagesNumber of Teeth Diametral Pitch Pressure AngleroderiqueNo ratings yet

- FWEFJLNIY4QKLQXDocument13 pagesFWEFJLNIY4QKLQXSoldan MihaiNo ratings yet

- List Lifting RiggingDocument2 pagesList Lifting RiggingrezaNo ratings yet

- ASTM A307 Bolts ASTM A325 BoltsDocument21 pagesASTM A307 Bolts ASTM A325 BoltsprimasukmayuanaNo ratings yet

- 46551237-EN-07-13-New HB Regulator InstallDocument3 pages46551237-EN-07-13-New HB Regulator Installsu30mkii83gmail.comNo ratings yet

- Antar20074border 730Document1 pageAntar20074border 730FAOUZINo ratings yet

- Heavy Hex Nut, ASTM A194/A194M and ASME SA194/SA194M, Grade 2H, ZincDocument2 pagesHeavy Hex Nut, ASTM A194/A194M and ASME SA194/SA194M, Grade 2H, ZincJ.GuerhardNo ratings yet

- 160m Hyd TroubleshootDocument8 pages160m Hyd TroubleshootDaniel Rhasty-ghee AhmanorNo ratings yet

- Operation Base Layout: Griffon Hovercraft LTDDocument6 pagesOperation Base Layout: Griffon Hovercraft LTDJESÚS DAVID DÍAZ CORTÉSNo ratings yet

- B31.3, Process Piping 1Document1 pageB31.3, Process Piping 1Jason FlowersNo ratings yet

- GRAPADORADocument36 pagesGRAPADORARafaelChochoaNo ratings yet

- Putzmeister Stationary PumpDocument11 pagesPutzmeister Stationary PumpAbdallah Tarek100% (1)

- STEALTH 2 Torque Conversion ChartDocument2 pagesSTEALTH 2 Torque Conversion Chartluisantoniojimenezperez31No ratings yet

- Ersatzteilliste SD20 Bis SD185 enDocument5 pagesErsatzteilliste SD20 Bis SD185 enAswin AntonyNo ratings yet

- Table of Specification: Caraga State UniversityDocument2 pagesTable of Specification: Caraga State UniversityJsy LangNo ratings yet

- Up5 11, Up5 15, Up5 18, Up5 22 Parts Manual Rev. DDocument92 pagesUp5 11, Up5 15, Up5 18, Up5 22 Parts Manual Rev. Djorgereinaldo78% (9)

- Metric Bolt Torque Chart for Strength Grades 8.8, 10.9 & 12.9Document1 pageMetric Bolt Torque Chart for Strength Grades 8.8, 10.9 & 12.9mithun7557No ratings yet

- JSW Recovery Coke OvenDocument20 pagesJSW Recovery Coke OvenStarluck shine75% (4)

- Pumps Motors Cyl SteeringDocument155 pagesPumps Motors Cyl Steeringgerardo floresNo ratings yet

- Ted 221 - Machine Shop Practice 1Document34 pagesTed 221 - Machine Shop Practice 1Mr. MushahidNo ratings yet

- 962g Trans Clutch CalibrateDocument8 pages962g Trans Clutch Calibrateluis eduardo corzo enriquez100% (1)

- Under Water WeldingDocument11 pagesUnder Water Weldinglegendiam443No ratings yet

- Iec 60287-2-1 2001-08Document77 pagesIec 60287-2-1 2001-08Luis ÁtilaNo ratings yet

- Outlet Relief Valve For Torque Converter: EspecificacionesDocument2 pagesOutlet Relief Valve For Torque Converter: EspecificacionesJose PichinteNo ratings yet

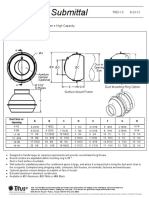

- TND-AA SubmittalDocument1 pageTND-AA Submittalhector tosarNo ratings yet

- Discontinuous Mounting On ConcreteDocument4 pagesDiscontinuous Mounting On ConcreteEricNo ratings yet

- Cal Am Manufacturing Digital CatalogDocument42 pagesCal Am Manufacturing Digital CatalogeasyxcessNo ratings yet

- Katalog Pesawat #Rev3Document13 pagesKatalog Pesawat #Rev3Wataru Ardhy MizunoNo ratings yet

- Pressure Relief ValueDocument7 pagesPressure Relief ValueVictor Torres100% (1)

- Ist KatalogDocument29 pagesIst Katalogmajmor-1No ratings yet

- Other Projects - Ut3Document7 pagesOther Projects - Ut3api-261139685No ratings yet

- Welded ConnectionsDocument10 pagesWelded ConnectionsminaNo ratings yet

![interference-split-[42-42]-20231105100344](https://imgv2-1-f.scribdassets.com/img/document/721373287/149x198/5d90bd4cbd/1712639930?v=1)