Professional Documents

Culture Documents

Exelene Ldpe: Low Density Polyethylene Heavy Duty HMW-LDPE Blow Film Extrusion

Uploaded by

dianaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exelene Ldpe: Low Density Polyethylene Heavy Duty HMW-LDPE Blow Film Extrusion

Uploaded by

dianaCopyright:

Available Formats

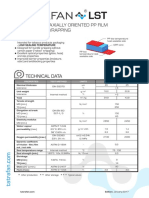

Exelene® LDPE

Product Data Sheet

Low Density Polyethylene

Heavy Duty HMW-LDPE1

0200

Blow Film Extrusion Melt Flow Rate 0,25

Density 0,919

Applications

■ Greenhouse Film, Industrial Shrink Film, 25kg Industrial Bags

■ Bags for re-packing powdered foods and grains such as rice, pulses, salt, sugar, flour and cereals

■ Bags for packing powdered substances for domestic or industrial use such as detergents, sand and gravel

Characteristics

The Exelene resin LDPE 0200 meets the requirements of section 177.1520, paragraph C, from chapter 21 denominated “Olefin

■

Polymers” from the Code of Federal Regulations of the FDA, to be utilized with direct food contact.

Properties ASTM Testing Units Values

Resin Properties

Melt Flow Rate MFI2 D 1238 (190°C; 2,16 kgf) g/10 min 0.25

Density D 792 (23°C) g/cm3 0.919

Melting Point DSC °C 110

Blow Film Properties with thickness of 2,0 mils = 50,8 mm y BUR = 2,5

MD psi 1,550

Tensile Strength @ yield (2) D 882A (20 in/min)

TD psi 1,430

MD psi 3,500

Tensile Strength @ break D 882A (20 in/min)

TD psi 3,000

MD % 250

Elongation @ break D 882A (20 in/min)

TD % 750

MD psi 22,000

Flexural Strength D 882A (0,2 in/min; 1%)

TD psi 28,000

MD gf 330

Elmendorf Tear Propagation D 1922 (23°C; 1.600 gf)

TD gf 120

Impact Resistance by the Free Falling Dart Method D 1709A (F50; 38 mm; 66 cm) gf 250

Opacity D 1003 % 20.5

(1) HMW-LDPE – Low Density Polyethylene with high molecular mass (MFI2 < 0,3 g/min) for Heavy Duty applications

(2) MD = Machine Direction and TD =Transversal Direction

http://www.montachem.com

Revision 1/15-12-2007

You might also like

- BE YLAA Scroll ChillerDocument68 pagesBE YLAA Scroll ChillerEnrique Mejia Gamarra100% (1)

- Technical Datasheet: LDPE 2101TN00WDocument16 pagesTechnical Datasheet: LDPE 2101TN00WjavadmohammadiNo ratings yet

- Aircraft Landing Gear Simulation and AnalysisDocument8 pagesAircraft Landing Gear Simulation and AnalysisStanciu MariusNo ratings yet

- DC Motors, Speed Controls, Servo Systems: An Engineering HandbookFrom EverandDC Motors, Speed Controls, Servo Systems: An Engineering HandbookRating: 5 out of 5 stars5/5 (3)

- Citrus National High School 2nd Quarter ExamDocument3 pagesCitrus National High School 2nd Quarter ExamCitrus National High School100% (1)

- Standards Overviews For ArrestersDocument5 pagesStandards Overviews For Arrestersrasheed313No ratings yet

- ROCHEM RO-Wasserbehandlung GMBH PDFDocument117 pagesROCHEM RO-Wasserbehandlung GMBH PDFhdf1788% (8)

- Uhde Brochures PDF en 18Document32 pagesUhde Brochures PDF en 18geocottonNo ratings yet

- Exelene Ldpe 0700Document1 pageExelene Ldpe 0700diana sarmientoNo ratings yet

- Exelene Hdpe 20000 2021Document1 pageExelene Hdpe 20000 2021diana sarmientoNo ratings yet

- Polietileno LDF 1925 - HMDocument1 pagePolietileno LDF 1925 - HMMariangela Nava0% (1)

- Product Data: Titanlene Ldf200GgDocument1 pageProduct Data: Titanlene Ldf200GgchinchotarngNo ratings yet

- Lldpe c4 - Llw1018f (Lf1020cc)Document1 pageLldpe c4 - Llw1018f (Lf1020cc)Guillermo CúmezNo ratings yet

- LF410 (영문)Document1 pageLF410 (영문)coordinador.comercialNo ratings yet

- Product Data: Titanlene Ldf250YzDocument1 pageProduct Data: Titanlene Ldf250YzchinchotarngNo ratings yet

- Ficha Tecnica Polietileno Chemium Hdpe 2285 (7000f)Document1 pageFicha Tecnica Polietileno Chemium Hdpe 2285 (7000f)Carlos SiuNo ratings yet

- Exelene Hdpe: HDPE Copolymer 1-Hexene High Density PolyethyleneDocument1 pageExelene Hdpe: HDPE Copolymer 1-Hexene High Density PolyethyleneGregorio Gaviria HernandezNo ratings yet

- LDF201FG R01Document1 pageLDF201FG R01Oscar Tan IIINo ratings yet

- Engineering Plastics Polybutylene Terephthalate Technical DataDocument2 pagesEngineering Plastics Polybutylene Terephthalate Technical Dataavinashchauhan2695No ratings yet

- Riblene FF20Document2 pagesRiblene FF20Stefan PopaNo ratings yet

- Technical Datasheet LF0190: 1) Product DescriptionDocument1 pageTechnical Datasheet LF0190: 1) Product DescriptionjavadmohammadiNo ratings yet

- Exelene Hdpe 5100MDocument1 pageExelene Hdpe 5100MAndres Quiroga JuarezNo ratings yet

- Durolon HFR 1910Document2 pagesDurolon HFR 1910elrolo3000No ratings yet

- GM5340PRK enUS ASTMDocument2 pagesGM5340PRK enUS ASTMDuongthithuydungNo ratings yet

- HDPE Pipe Ineos TUB121GNDocument2 pagesHDPE Pipe Ineos TUB121GNluisalbertolvNo ratings yet

- High Density Polyethylene GF4950: DescriptionDocument1 pageHigh Density Polyethylene GF4950: Descriptioncesar1scribdNo ratings yet

- SMS016R0Document1 pageSMS016R0PRASANTH PRASANTHNo ratings yet

- LL7420D Linear Low Density Polyethylene ResinDocument1 pageLL7420D Linear Low Density Polyethylene ResinFahad MohamedNo ratings yet

- LL0209 AA-shazand PDFDocument1 pageLL0209 AA-shazand PDFmohamad mostafaviNo ratings yet

- Product Data: Titanex Hf0961Document1 pageProduct Data: Titanex Hf0961chinchotarngNo ratings yet

- Novapol TF 0338 e NovaDocument2 pagesNovapol TF 0338 e NovaJulio GarcíaNo ratings yet

- Lldpe 22501aa22501kjDocument2 pagesLldpe 22501aa22501kj李万福No ratings yet

- BPC - BG HD 7000fDocument1 pageBPC - BG HD 7000fSLKM Engineering & ConsultantsNo ratings yet

- Technical Datasheet 2100TN00: 1) Product DescriptionDocument1 pageTechnical Datasheet 2100TN00: 1) Product DescriptionjavadmohammadiNo ratings yet

- Sabic Lldpe MG200024: PolymersDocument2 pagesSabic Lldpe MG200024: PolymersYoshie IwaiNo ratings yet

- Lldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalDocument2 pagesLldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalĐỗ Ngọc TúNo ratings yet

- Hdpe HHM TR 144Document1 pageHdpe HHM TR 144JagrutNo ratings yet

- Flexmetprotect C-CNM-M: Technical Data SheetDocument1 pageFlexmetprotect C-CNM-M: Technical Data Sheetminni choubeyNo ratings yet

- Exelene Hdpe: High Density Polyethylene HDPE Copolymer With MWD Thin Injection MoldingDocument1 pageExelene Hdpe: High Density Polyethylene HDPE Copolymer With MWD Thin Injection MoldingOctavio DavidNo ratings yet

- 1695012734-2058787459-h-t-nh-a-ldpe-hp0724nn-tdsDocument2 pages1695012734-2058787459-h-t-nh-a-ldpe-hp0724nn-tdsChu ChuNo ratings yet

- SABIC® LDPE - HP2023JN - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP2023JN - Global - Technical - Data - SheetSarvesh SinghNo ratings yet

- Datasheet LTM-2125 PDFDocument1 pageDatasheet LTM-2125 PDFjavadmohammadiNo ratings yet

- GTS 4002S Is T MatlDocument1 pageGTS 4002S Is T MatlDaniel VillaflorNo ratings yet

- ASTM FL7100U Eng 240223Document1 pageASTM FL7100U Eng 240223MERVENo ratings yet

- LDPE Resin for Thin Shrink Film BagsDocument1 pageLDPE Resin for Thin Shrink Film BagsjavadmohammadiNo ratings yet

- GEOTECHNICAL DRAINAGE LAYERDocument1 pageGEOTECHNICAL DRAINAGE LAYERAladinNo ratings yet

- LDPE 2102TX00 Technical Datasheet Low Density Polyethylene Film PropertiesDocument1 pageLDPE 2102TX00 Technical Datasheet Low Density Polyethylene Film PropertiesjavadmohammadiNo ratings yet

- Geomembrane HDPE Smooth Black PDFDocument1 pageGeomembrane HDPE Smooth Black PDFandriarisetiawan0% (1)

- LDPE-HP0723JNDocument2 pagesLDPE-HP0723JNChu ChuNo ratings yet

- 1705122228-156282372-h-t-nh-a-lldpe-1002en-tdsDocument1 page1705122228-156282372-h-t-nh-a-lldpe-1002en-tdsChu ChuNo ratings yet

- Datasheet 2420E PDFDocument1 pageDatasheet 2420E PDFjavadmohammadiNo ratings yet

- High Density Polyethylene: ASTM D 1505 G/CM 0.958-0.962 ASTM D 1238 G/10min 7.0-8.0Document1 pageHigh Density Polyethylene: ASTM D 1505 G/CM 0.958-0.962 ASTM D 1238 G/10min 7.0-8.0Luca Guadagno100% (1)

- VERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good SealabilityDocument1 pageVERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good Sealabilityseeralan_1986No ratings yet

- Exelene Ldpe 8000Document1 pageExelene Ldpe 8000diana sarmientoNo ratings yet

- Ptfe PDFDocument1 pagePtfe PDFXiwen CloudNo ratings yet

- Datasheet 2420K PDFDocument1 pageDatasheet 2420K PDFjavadmohammadiNo ratings yet

- LDPE L2102TN42 Technical Data SheetDocument1 pageLDPE L2102TN42 Technical Data SheetPhuoc TranNo ratings yet

- Coextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataDocument2 pagesCoextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataJan GawełNo ratings yet

- Linear Low Density Polyethylene Resin for General Purpose FilmDocument1 pageLinear Low Density Polyethylene Resin for General Purpose FilmNitin MaheshwariNo ratings yet

- 富特士80 Series silicone rubberDocument4 pages富特士80 Series silicone rubberzhang kiraNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- SABIC® LDPE - HP0323NN - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP0323NN - Global - Technical - Data - SheetRubenMurguiaNo ratings yet

- Bfi 345-196 LdpeDocument1 pageBfi 345-196 LdpeShaikhRizwanNo ratings yet

- Rotomolding LH05RUDocument1 pageRotomolding LH05RUdianaNo ratings yet

- Marpol LL6F 801: Linear Low Density PolyethyleneDocument1 pageMarpol LL6F 801: Linear Low Density PolyethylenedianaNo ratings yet

- b325.b328 Polimaxx 3340HDocument1 pageb325.b328 Polimaxx 3340HdianaNo ratings yet

- Certene L.A. LLBF-122D (Sustituto 11PG4) ActualizadaDocument1 pageCertene L.A. LLBF-122D (Sustituto 11PG4) ActualizadadianaNo ratings yet

- Bamberger Bapolene ® 2035 High Density Polyethylene, Blow Molding GradeDocument1 pageBamberger Bapolene ® 2035 High Density Polyethylene, Blow Molding GradedianaNo ratings yet

- Exxonmobil™ Lldpe LL 1001av Blown: Linear Low Density Polyethylene ResinDocument2 pagesExxonmobil™ Lldpe LL 1001av Blown: Linear Low Density Polyethylene ResindianaNo ratings yet

- Certene L.A. LLBF-122D (Sustituto 11PG4) ActualizadaDocument1 pageCertene L.A. LLBF-122D (Sustituto 11PG4) ActualizadadianaNo ratings yet

- HPB GGGGGGDocument1 pageHPB GGGGGGMarwin PilayNo ratings yet

- Channel Prime Alliance 5R2 Polypropylene Data SheetDocument1 pageChannel Prime Alliance 5R2 Polypropylene Data SheetdianaNo ratings yet

- Exxonmobil™ Lldpe LL 1001av Blown: Linear Low Density Polyethylene ResinDocument2 pagesExxonmobil™ Lldpe LL 1001av Blown: Linear Low Density Polyethylene ResindianaNo ratings yet

- HI863 IngDocument1 pageHI863 IngdianaNo ratings yet

- Exelene Ldpe: LDPE Good Clarity Low Density PolyethyleneDocument2 pagesExelene Ldpe: LDPE Good Clarity Low Density PolyethylenedianaNo ratings yet

- Certene L.A. LLBF-122D (Sustituto 11PG4) ActualizadaDocument1 pageCertene L.A. LLBF-122D (Sustituto 11PG4) ActualizadadianaNo ratings yet

- Larsen & Toubro Limited, Construction.: WOM Bill Annexure - EC578BIL0000026 DT:09 Apr 2020Document4 pagesLarsen & Toubro Limited, Construction.: WOM Bill Annexure - EC578BIL0000026 DT:09 Apr 2020Kannan GnanaprakasamNo ratings yet

- BS en 10222-1-2017Document28 pagesBS en 10222-1-2017rahul mehta100% (2)

- Ni触媒MSDS 英文Document4 pagesNi触媒MSDS 英文dil1717No ratings yet

- Especificaciones de Construcción de Trabajo para La Gestión de Las Actividades de SoldaduraDocument14 pagesEspecificaciones de Construcción de Trabajo para La Gestión de Las Actividades de SoldaduraMartin Morales RodriguezNo ratings yet

- Kit Turbo TTEDocument64 pagesKit Turbo TTENokxaNo ratings yet

- Plastic cluster CFC proposalDocument21 pagesPlastic cluster CFC proposalmeenakshi_ludNo ratings yet

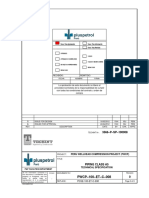

- PWCP-100-ET-C-008-0 - Piping Class A5Document10 pagesPWCP-100-ET-C-008-0 - Piping Class A5William ChipanaNo ratings yet

- Science 7 - First Periodical Test - T. Cha.Document4 pagesScience 7 - First Periodical Test - T. Cha.Ka KlasmeytNo ratings yet

- Bobbin Filters - Instructions and Operation ManualDocument37 pagesBobbin Filters - Instructions and Operation Manual8nqm4p3veNo ratings yet

- Rac NotesDocument16 pagesRac NotesJohnRay LominoqueNo ratings yet

- Production Engineering BFF3503: Assembly Line SetupDocument10 pagesProduction Engineering BFF3503: Assembly Line SetupMuhd ZackuanNo ratings yet

- Attock Cement MaintenanceDocument20 pagesAttock Cement Maintenancedanialme089No ratings yet

- DECK SLAB SPAN TABLESDocument1 pageDECK SLAB SPAN TABLESPhạm Tiến ĐạtNo ratings yet

- Product Testing PET Preform BottleDocument9 pagesProduct Testing PET Preform BottleShikha SinghNo ratings yet

- Seat Tracks and Anchor Plates CatalogDocument7 pagesSeat Tracks and Anchor Plates CatalogSergey FedorinovNo ratings yet

- SITRUST Brochure PDFDocument8 pagesSITRUST Brochure PDFÐôùxBébê Ðê MãmäñNo ratings yet

- Notes Chapter 3 Class 10 (Metallurgy)Document2 pagesNotes Chapter 3 Class 10 (Metallurgy)Yashmit SanwariaNo ratings yet

- Use of Vacuum Line - 17Document20 pagesUse of Vacuum Line - 17Sachin BokanNo ratings yet

- Design Practices - SVsDocument12 pagesDesign Practices - SVsagarwalashwin32No ratings yet

- Backfill NotesDocument1 pageBackfill NotesOscar Alberto Jáuregui AquinoNo ratings yet

- Filters Technical InformationDocument13 pagesFilters Technical InformationcartarNo ratings yet

- Electronics: A New Opportunity For Waste Prevention, Reuse, and RecyclingDocument4 pagesElectronics: A New Opportunity For Waste Prevention, Reuse, and RecyclingOmoloye SulaymanNo ratings yet

- Plexiglas GDocument2 pagesPlexiglas GMarco Ngawang KeelsenNo ratings yet

- Studer On-Air-1000 v403 InfoDocument164 pagesStuder On-Air-1000 v403 InfovaliblajovanNo ratings yet