Professional Documents

Culture Documents

Corriculum Design - Electronic Products Assembly and Servicing Ncii - Distance - Face To Face

Uploaded by

nicelyn baisaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Corriculum Design - Electronic Products Assembly and Servicing Ncii - Distance - Face To Face

Uploaded by

nicelyn baisaCopyright:

Available Formats

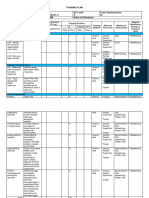

CURRICULUM DESIGN

Combination Distance Learning and Face to Face Mode

Course Title: Electronic Products Assembly and Servicing NC Level: NC II

Nominal Training Duration: 40 hrs – Basic Competencies

80 hrs – Common Competencies

140 hrs – Core Competencies

-------------------------------------------------

260 hrs – TOTAL

Course Description:

This course is designed to develop & enhance the knowledge, skills, & attitudes of an

Electronic Products Technician, in accordance with industry standards. It covers the basic and

common competencies in addition to the core competencies such as assembling electronic

products, fabricating PCB modules and installing and servicing consumer and industrial

electronic products and systems.

BASIC COMPETENCIES

Unit of Assessment Duration

Learning Outcome Methodology

Competency Approach

1. Participate in 1.1 Obtain and convey Distance Distance 40 hrs

workplace workplace information. Written exam

1.2 Complete relevant work Self-paced (8 hrs –

communication learning/Modular Face to Face

related documents. Face to

1.3 Participate in workplace Interview/ Face

meeting and discussion. Questioning

Face to Face

Demonstration 32 hrs –

& questioning Distance /

2.1 Describe and identify team Distance Module )

2. Work in a team Distance

environment role and responsibility in a Written exam

team. Self-paced

2.2 Describe work as a team learning/Modular Face to Face

member. Face to Face Interview/

Questioning

Demonstration &

questioning

3. Practice career 3.1 Integrate personal objectives Distance Distance

professionalis with organizational goals. Written exam

3.2 Set and meet work priorities. Self-paced

m learning/Modular Face to Face

3.3 Maintain professional growth

and development. Face to Face Interview/

Questioning

Demonstration

& questioning

4. Practice 4.1 Identify hazards and risks. Distance Distance

occupational 4.2 Evaluate hazard and risks Written exam

4.3 Control hazards and risks Self-paced

health & safety learning/Modular Face to Face

4.4 Maintain occupational health

and safety awareness Face to Face Interview/

Questioning

Demonstration

& questioning

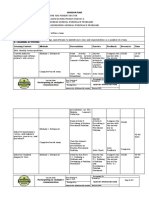

COMMON COMPETENCIES

Unit of Assessment Duration

Learning Outcomes Methodology

Competency Approach

1 Apply Quality 1.1 Assess quality of Distance Distance 80 hrs

. Standards received materials Written exam

1.2 Assess own work Self-paced (40 hrs –

1.3 Engage in learning /Modular Face to Face Face to

quality Demonstration Face

improvemen Face to Face & questioning

t Demonstration & Observation & 40 hrs –

questioning questioning Distance /

Module )

2. Perform 2.1 Plan and prepare for Distance Distance

Computer task to be undertaken Written exam

Operation 2.2 Input data into computer Self-paced

2.3 Access information learning /Modular Face to Face

using computer Demonstration

2.4 Produce output/data Face to Face & questioning

using computer Demonstration & Observation &

system questioning questioning

2.5 Use basic functions of a

web browser to locate

information

2.6 Maintain computer

equipment and

systems

3 Use Hand 3.1 Plan and prepare for Distance Distance

. Tools task to be undertaken Written exam

3.2 Prepare hand tools Self-paced

3.3 Use appropriate hand learning /Modular Face to Face

tools and equipment Demonstration

3.4 Maintain hand tools Face to Face & questioning

Demonstration & Observation &

questioning questioning

4 Perform 4.1 Select measuring Distance Distance

. Mensuration instruments Written exam

and 4.2 Carry out measurement Self-paced

Calculation and calculation learning /Modular Face to Face

4.3 Maintain Demonstration

measuring Face to Face & questioning

instruments Demonstration & Observation &

questioning questioning

5 Prepare and 5.1 Identify different Distance Distance

. Interpret kinds of technical Written exam

Technical drawings Self-paced

Drawings 5.2 Interpret technical drawing learning /Modular Face to Face

5.3 Prepare/make Demonstration

changes on Face to Face & questioning

electrical/electronic Demonstration & Observation &

schematic and questioning questioning

drawings

5.4 Store technical drawings

and equipment/

instruments

Unit of Assessment Duration

Learning Outcomes Methodology

Competency Approach

6. Terminate 6.1 Plan and prepare for Distance Distance

and Connect termination/connectio Written exam

Electrical n of electrical Self-paced

wiring and wiring/electronic learning /Modular Face to Face

Electronic circuits Demonstration

Circuits 6.2 Terminate/connect Face to Face & questioning

electrical Demonstration & Observation &

wiring/electronic circuits questioning questioning

6.3 Test termination/

connection of electrical

wiring

/electronics circuits

7. Test electronic 7.1 Determine criteria for Distance Distance

components testing electronics Written exam

components Self-paced

7.2 Plan an approach learning /Modular Face to Face

for component Demonstration

testing Face to Face & questioning

7.3 Test components Demonstration & Observation &

7.4 Evaluate the testing questioning questioning

process

CORE COMPETENCIES

140 hrs

Unit of Learning Outcomes Methodology Assessment Duration

Competency Approach

1. Assemble 1.1 Prepare to Distance Learning Distance 140 hrs

Electronic assemble Lectures/Modular Learning

Products electronics Self-paced Written exam (104 hrs –

products Learning Portfolio Face to

1.2 Prepare/ Make Film Viewing Face

PCB modules Face to Face

1.3 Mount and solder Face to Face Practical exam 36 hrs –

electronic components Hands on Practice Observation in

Distance /

1.4 Assemble workplace

Actual Demonstration

Module )

electronic

products Demonstration

1.5 Test and inspect And Discussion

assembled electronic

products Project Making

2. Service 2.1 Prepare unit, tools Distance Learning Distance

consumer and workplace for Lectures/Modular Learning

electronic installation and Self-paced Written exam

products and service Learning Portfolio

systems 2.2 Install consumer Film Viewing

electronic products and Face to Face

systems Face to Face Practical exam

2.3 Diagnose faults and Hands on Practice Observation in

defects consumer workplace

electronic products and Actual Demonstration

systems Demonstration

2.4 Maintain/Repair And Discussion

consumer electronic

products Project Making

2.5 Re-assemble and

test repaired

consumer

electronic products

3. Service 3.1 Prepare unit, tools Distance Learning Distance

industrial and workplace for Lectures/Modular Learning

electronic installation and Self-paced Written exam

modules, service Learning Portfolio

products and 3.2 Install industrial Film Viewing

systems electronic Face to Face

modules/products/syste Face to Face Practical exam

ms Hands on Practice Observation in

3.3 Diagnose faults and workplace

defects of industrial Actual Demonstration

electronic Demonstration

modules/systems/produc And Discussion

ts

3.4 Maintain/Repair Project Making

industrial electronic

products

3.5 Re-assemble and

test repaired

industrial

electronics

products

TRAINING DELIVERY

The delivery of training should adhere to the design of the curriculum. Delivery

should be guided by the 10 basic principles of the competency-based TVET.

The training is based on curriculum developed from the competency

standards;

Learning is modular in its structure;

Training delivery is individualized and self-paced;

Training is based on work that must be performed;

Training materials are directly related to the competency standards and

the curriculum modules;

Assessment is based in the collection of evidence of the performance of

work to the industry required standard;

Training is based both on and off-the-job components;

Allows for recognition of prior learning (RPL) or current competencies;

Training allows for multiple entry and exit; and

Approved training programs are nationally accredited.

The competency-based TVET system recognizes various types of delivery

modes, such as Face to Face and Distance Learning as long as the learning is

based on competency standards specified on the Training Regulations. The following

training modalities may be adopted when designing training programs:

Modular/self-paced learning is a competency-based training modality

wherein the trainee is allowed to progress at his own pace.

Distance learning is a formal education process in which majority of the

instruction occurs when the students and instructors are not in the same

place. Distance learning may employ correspondence study, or audio,

video or computer technologies.

TRAINEE ENTRY REQUIREMENTS

The trainees who wish to enter the course should possess the following

requirements:

Must have completed at least 10 yrs. basic education or an ALS

grade 10 certificate of rating holder

Can communicate in oral and written language

Can perform basic mathematical computations

This list does not include specific institutional requirements such as

educational attainment, appropriate work experience and others that may be

required from the trainees by the school or training center delivering the TVET

program.

LIST OF TOOLS, EQUIPMENT AND MATERIALS (Institution-based)

Recommended list of tools, equipment and materials required in every workstation

for Electronic Products Assembly and Servicing NC II:

TOOLS EQUIPMENT MATERIAL

Qty. Description Qty. Description Qty. Description

1 set Pliers assorted, 1

unit

Multimeter

(analog/digital)

1

spool Soldering wire

Long nose, Side

cutter

1 set Screw driver 1 set Workshop table 50 ml SMD soldering paste

assorted,

Phillips, slotted

1 set Desoldering tools 1 set High grade 500 SMD soldering flux

magnifying ml

glass with lamp

1 set Wrenches 1 Variable power 1 pc. Cleaning brush

assorted unit supply

1 set Allen wrench/key 1 Variable 1 Thinner/alcohol

unit transformer bottle

1 pc Utility 5ml Thermal paste

knife/stripper

1 set Test jigs 1 Hot air soldering 1 Ferric chloride

unit station bottle

1 pc Wire stripper 1 Oscilloscope, 5 Pale or water bucket

unit digital units

1 pc Digital micrometer 1 Signal generator 5m Stranded/solid/ hook-up

unit wires

1 pc Anti-static strap 1 Function 10m wire stranded, #22, red

unit generator

1 pc Anti-static brush 1 Electronically- 10m wire stranded, #22,

unit controlled black

soldering station

1pc Anti-static mat 10m wire stranded, #22,

white

Recommended

1 set Bread boards equipment (Optional): 10m wire stranded, #22,

blue

1 Table top reflow 10m wire stranded, #22,

unit oven yellow

Lead-free

1 soldering system 10m wire stranded, #22,

unit green

ESD free work 10m Solid wires, assorted

color

1 set bench with

mirror back-to-

back/one-sided 1 set Assorted electronic

components

50 resistors (different

pcs values)

50 capacitors (different

pcs values)

Note: Tools, Equipment & Materials are on a per-workstation basis

TRAINING FACILITIES

Recommended space requirements for the various teaching/learning areas are as

follows:

TEACHING/LEARNING/ SIZE IN QTY TOTAL AREA IN

FACILITIES AREAS METERS SQ. METERS

Lecture Area* 5x5 1 25

Workshop Area** 5x5/ 5 workstations / 25 /

(2trainees per Workstations) 9x5 10 workstations 45

1.5m x 2m

Learning Resource Area 4x5 1 20

Tool Room/Storage Area 4x4 1 16

Wash ,Toilet & Locker Room 2x3 2 12

Sub- Total 98 /

118

Facilities / Equipment / 30 /

Circulation*** 36

Total Area 5 workstations / 128 /

10 workstations 154

* Optional (good for minimum of 10 trainees)

** For the workshop area (maximum of 20 trainees)

***Area requirement is equivalent to 30% of the total teaching/learning areas

TRAINERS QUALIFICATIONS

Electronic Products Assembly and Servicing

NC II Trainer’s Qualification TMI

Holder of National TVET Trainer’s Certificate (NTTC) Level 1

* Must have at least 2-years relevant industry experience.

* Optional: Only when required by the hiring institution.

INSTITUTIONAL ASSESSMENT

Institutional assessment is undertaken by trainees to determine their

achievement of units of competency. A certificate of achievement is issued

for each unit of competency.

As a matter of policy, graduates of programs registered with TESDA

under these training regulations are required to undergo mandatory national

competency assessment upon completion of the program.

You might also like

- Delivering Time Management for IT Professionals: A Trainer's Manual: Tools, methods, and strategies for delivering effective time management trainingFrom EverandDelivering Time Management for IT Professionals: A Trainer's Manual: Tools, methods, and strategies for delivering effective time management trainingRating: 4 out of 5 stars4/5 (1)

- Corriculum Design - Electronic Products Assembly and Servicing Ncii - Distance - Face To Face-MtpDocument7 pagesCorriculum Design - Electronic Products Assembly and Servicing Ncii - Distance - Face To Face-Mtpnicelyn baisaNo ratings yet

- Corriculum Design - Electronic Products Assembly and Servicing Ncii - Distance - Face To Face - MTPDocument7 pagesCorriculum Design - Electronic Products Assembly and Servicing Ncii - Distance - Face To Face - MTPnicelyn baisaNo ratings yet

- Corriculum Design - Dressmaking Ncii - Distance - Face To FaceDocument6 pagesCorriculum Design - Dressmaking Ncii - Distance - Face To Facenicelyn baisaNo ratings yet

- Corriculum Design - Smaw Nci - Distance - Face To FaceDocument6 pagesCorriculum Design - Smaw Nci - Distance - Face To Facenicelyn baisaNo ratings yet

- Barista CBCDocument81 pagesBarista CBCNewlyn Everly Laroco50% (2)

- Training Plan EIMDocument4 pagesTraining Plan EIMRhyan Paul MontesNo ratings yet

- Css CBC InstallDocument11 pagesCss CBC InstallYuriiNo ratings yet

- CBC Css NC II-migratedDocument67 pagesCBC Css NC II-migratedRita Andrea Almonte94% (32)

- Session Plan: Basic Competencies (62 Hours)Document5 pagesSession Plan: Basic Competencies (62 Hours)Elonah Jean ConstantinoNo ratings yet

- CBC Organic AgriDocument14 pagesCBC Organic AgriYuriiNo ratings yet

- CBLM Basic CompetencyDocument90 pagesCBLM Basic CompetencyGemalyn ToledanoNo ratings yet

- Eng 210Document7 pagesEng 210ندى البلويNo ratings yet

- Curricular Competencies - BartendingDocument5 pagesCurricular Competencies - BartendingLegal DepartmentNo ratings yet

- Core - Training Plan OapDocument4 pagesCore - Training Plan OapMERLY DAYAONo ratings yet

- CBC FBS DiningDocument13 pagesCBC FBS DiningJIMBOY SAN DIEGONo ratings yet

- COMPETENCYDocument81 pagesCOMPETENCYKristine Ferrer De ValeNo ratings yet

- CBC 2019 EimDocument40 pagesCBC 2019 EimMae D. Saliring100% (6)

- TMC CBCDocument113 pagesTMC CBCRoselie BelgiraNo ratings yet

- MODULES OF INSTRUCTION Basicsmawnc1Document17 pagesMODULES OF INSTRUCTION Basicsmawnc1KaJong JaclaNo ratings yet

- Session Plan: Basic Competencies (18 Hours)Document6 pagesSession Plan: Basic Competencies (18 Hours)Richie S. Dequiña100% (1)

- 2CBC AutoDocument143 pages2CBC AutoMark MarasiganNo ratings yet

- Norcel Romero Session Plan Module1 NciiDocument9 pagesNorcel Romero Session Plan Module1 NciiArjan ElegadoNo ratings yet

- Detailed Lesson Plan (DLP) FormatDocument4 pagesDetailed Lesson Plan (DLP) FormatMaria Darve Gudito100% (1)

- Intended Learning OutcomeDocument6 pagesIntended Learning OutcomeCydrick cordovaNo ratings yet

- Training Plan Local Guiding Services Ncii 1Document3 pagesTraining Plan Local Guiding Services Ncii 1John Rhino SantosNo ratings yet

- BE1401-2 Course Outline Jan 2022Document11 pagesBE1401-2 Course Outline Jan 2022Joelle LimNo ratings yet

- New Form Course Structure-EPASDocument104 pagesNew Form Course Structure-EPASMicah Maulit RamosNo ratings yet

- CBC Elect Install and Maint NC II 2017Document63 pagesCBC Elect Install and Maint NC II 2017ralphNo ratings yet

- CBC TM I Trainers Methodology Level 1Document102 pagesCBC TM I Trainers Methodology Level 1ralph100% (1)

- F. Training Plan in Dressmaking NC IIDocument8 pagesF. Training Plan in Dressmaking NC IIRYDENNo ratings yet

- CBC-TM 2 Develop Competency Assessment ToolsDocument76 pagesCBC-TM 2 Develop Competency Assessment ToolsRushan Zenisni BellenNo ratings yet

- Common Competencies: No - Unit Code Unit of Competenc y Learning Outcome Methodology Assessment Approach DurationDocument3 pagesCommon Competencies: No - Unit Code Unit of Competenc y Learning Outcome Methodology Assessment Approach DurationJeru MacNo ratings yet

- Learning Module (Template)Document5 pagesLearning Module (Template)YOHANIS YADETANo ratings yet

- Competency-Based Curriculum A. Course Design Electrical Installation and MaintenanceDocument6 pagesCompetency-Based Curriculum A. Course Design Electrical Installation and MaintenanceFe Marie JisonNo ratings yet

- 2.curricular RequirementsDocument301 pages2.curricular RequirementsRogelio AlvarezNo ratings yet

- First Activity As A Would-Be Teacher: Learning TaskDocument6 pagesFirst Activity As A Would-Be Teacher: Learning TaskcrisdayNo ratings yet

- Carpentry CBC NEWDocument43 pagesCarpentry CBC NEWRichard Duran100% (1)

- CBC of Basic CompetencyDocument20 pagesCBC of Basic Competencyrommel esperidaNo ratings yet

- BE1401 Course OutlineDocument11 pagesBE1401 Course OutlineDeathrixNo ratings yet

- Competency-Based Curriculum: Masonry NC IiDocument8 pagesCompetency-Based Curriculum: Masonry NC IiMa Joan Aguilar RodriguezNo ratings yet

- Eim CBC NewDocument78 pagesEim CBC NewRalfh Pescadero De Guzman71% (14)

- Business Communication 10 3 22 04042022 113953amDocument7 pagesBusiness Communication 10 3 22 04042022 113953amsikander jalalNo ratings yet

- IT Learning Plan TemplateDocument21 pagesIT Learning Plan TemplateJefersonNo ratings yet

- Basic and Common Session PlanDocument4 pagesBasic and Common Session PlanGlandale Sentasas67% (3)

- Training Plan (SIL)Document3 pagesTraining Plan (SIL)robelyn veranoNo ratings yet

- Lo3. Solving and AddressingDocument8 pagesLo3. Solving and Addressingrobelyn veranoNo ratings yet

- Task2.2.6 Determining The Assessment MethodDocument57 pagesTask2.2.6 Determining The Assessment MethodRommel Angeles PeronaNo ratings yet

- Course Title Front Office Service Nominal Duration of The Program Qualification LevelDocument29 pagesCourse Title Front Office Service Nominal Duration of The Program Qualification LevelAmy Amper Pelenio-LofrancoNo ratings yet

- CBC FINAL Update June 23 2022Document111 pagesCBC FINAL Update June 23 2022Chester Allan F. Bautista100% (1)

- CBC-TM 2 Design and Develop Maintenance SystemsDocument79 pagesCBC-TM 2 Design and Develop Maintenance Systemsjaman mostofa0% (1)

- Competency-Based Curriculum A. Course Design Computer System Servicing 280 HRS NC IiDocument99 pagesCompetency-Based Curriculum A. Course Design Computer System Servicing 280 HRS NC IiChester Allan F. Bautista100% (2)

- CBLM Unit 3Document48 pagesCBLM Unit 3Andrea Nicole Erispe BronNo ratings yet

- Session Plan - Observe Procedures, Specifications and Manuals of Instruction - JAR & LMN - v1.1Document4 pagesSession Plan - Observe Procedures, Specifications and Manuals of Instruction - JAR & LMN - v1.1Edward RaagasNo ratings yet

- MIT4203 Core: Total Learning Hour (TLH) : 120Document5 pagesMIT4203 Core: Total Learning Hour (TLH) : 120Dr S B GoyalNo ratings yet

- CBC TM I Triners Methodology Level 1Document102 pagesCBC TM I Triners Methodology Level 1mftechnicalvocationalschoolNo ratings yet

- Course Design Dressmaking NCIIDocument81 pagesCourse Design Dressmaking NCIIRYDENNo ratings yet

- CSS 21st CenturyDocument62 pagesCSS 21st Centuryirish ragasa100% (1)

- Syllabus in COMP2 - Business ApplicationDocument3 pagesSyllabus in COMP2 - Business ApplicationPogs M. de LunaNo ratings yet

- Training Plan - APP - Updated 21stDocument20 pagesTraining Plan - APP - Updated 21strobelyn veranoNo ratings yet

- EPAS - Training Plan Basic Competency - MTPDocument5 pagesEPAS - Training Plan Basic Competency - MTPnicelyn baisaNo ratings yet

- Covid-19 Contingency Plan and Update: Current Advice On Self-IsolationDocument1 pageCovid-19 Contingency Plan and Update: Current Advice On Self-Isolationnicelyn baisaNo ratings yet

- TR - Dressmaking NC IIDocument61 pagesTR - Dressmaking NC IInicelyn baisaNo ratings yet

- Corriculum Design - Heo - Backhoe Loader Ncii - Distance - Face To FaceDocument6 pagesCorriculum Design - Heo - Backhoe Loader Ncii - Distance - Face To Facenicelyn baisaNo ratings yet

- EPAS - Training Plan Common Competency - MTPDocument12 pagesEPAS - Training Plan Common Competency - MTPnicelyn baisaNo ratings yet

- Corriculum Design - Heo - Backhoe Loader Ncii - Distance - Face To FaceDocument6 pagesCorriculum Design - Heo - Backhoe Loader Ncii - Distance - Face To Facenicelyn baisaNo ratings yet

- Corriculum Design - Electronic Products Assembly and Servicing Ncii - Distance - Face To FaceDocument7 pagesCorriculum Design - Electronic Products Assembly and Servicing Ncii - Distance - Face To Facenicelyn baisaNo ratings yet

- TR-Electronic Products Assembly and Servicing NC IIDocument77 pagesTR-Electronic Products Assembly and Servicing NC IInicelyn baisaNo ratings yet

- TR - Smaw NC IiDocument61 pagesTR - Smaw NC Iinicelyn baisaNo ratings yet

- Corriculum Design - Smaw Ncii - Distance - Face To FaceDocument7 pagesCorriculum Design - Smaw Ncii - Distance - Face To Facenicelyn baisaNo ratings yet

- TR - Smaw NC IDocument59 pagesTR - Smaw NC Inicelyn baisaNo ratings yet

- TR - Smaw NC IDocument59 pagesTR - Smaw NC Inicelyn baisaNo ratings yet

- Weldsteelpipein6gusingsmaw 150218104435 Conversion Gate02 PDFDocument41 pagesWeldsteelpipein6gusingsmaw 150218104435 Conversion Gate02 PDFRey SombreroNo ratings yet

- TR - Backhoe Loader NC IiDocument84 pagesTR - Backhoe Loader NC Iinicelyn baisaNo ratings yet

- TR - Smaw NC IiDocument61 pagesTR - Smaw NC Iinicelyn baisaNo ratings yet

- CBLM OhsDocument107 pagesCBLM Ohsnicelyn baisaNo ratings yet

- TR - Backhoe Loader NC IiDocument84 pagesTR - Backhoe Loader NC Iinicelyn baisaNo ratings yet

- TR - Backhoe Loader NC IiDocument84 pagesTR - Backhoe Loader NC Iinicelyn baisaNo ratings yet

- SOCIAL MEDIA DEBATE ScriptDocument3 pagesSOCIAL MEDIA DEBATE Scriptchristine baraNo ratings yet

- A 138Document1 pageA 138pooja g pNo ratings yet

- Hannah Mancoll - Research Paper Template - 3071692Document14 pagesHannah Mancoll - Research Paper Template - 3071692api-538205445No ratings yet

- Just in Time and TQMDocument8 pagesJust in Time and TQMBhramadhathNo ratings yet

- Iec Codes PDFDocument257 pagesIec Codes PDFAkhil AnumandlaNo ratings yet

- Days Papers 2001Document341 pagesDays Papers 2001jorgefeitoza_hotmailNo ratings yet

- Honda IzyDocument16 pagesHonda IzyTerry FordNo ratings yet

- Resistance & Resistivity: Question Paper 1Document15 pagesResistance & Resistivity: Question Paper 1leon19730% (1)

- Unbound DNS Server Tutorial at CalomelDocument25 pagesUnbound DNS Server Tutorial at CalomelPradyumna Singh RathoreNo ratings yet

- Duo Interpretation Class PresentationDocument31 pagesDuo Interpretation Class PresentationPlanetSparkNo ratings yet

- International Freight 01Document5 pagesInternational Freight 01mature.ones1043No ratings yet

- Sermon Manuscript Galatians 5:16-26Document9 pagesSermon Manuscript Galatians 5:16-26Nathaniel ParkerNo ratings yet

- Introduction To Password Cracking Part 1Document8 pagesIntroduction To Password Cracking Part 1Tibyan MuhammedNo ratings yet

- Lesser Known Homoeopathic Medicines of Alopecia Areata.20200718115446Document9 pagesLesser Known Homoeopathic Medicines of Alopecia Areata.20200718115446BruntNo ratings yet

- Operations Management Interim ProjectDocument4 pagesOperations Management Interim ProjectABAYANKAR SRIRAM (RA1931201020042)No ratings yet

- Aribah Ahmed CertificateDocument2 pagesAribah Ahmed CertificateBahadur AliNo ratings yet

- DAA UNIT 1 - FinalDocument38 pagesDAA UNIT 1 - FinalkarthickamsecNo ratings yet

- IMDSI22Document82 pagesIMDSI22Dang JinlongNo ratings yet

- Backwards Design - Jessica W Maddison CDocument20 pagesBackwards Design - Jessica W Maddison Capi-451306299100% (1)

- First - Second and Third Class Levers in The Body - Movement Analysis in Sport - Eduqas - Gcse Physical Education Revision - Eduqas - BBC BitesizeDocument2 pagesFirst - Second and Third Class Levers in The Body - Movement Analysis in Sport - Eduqas - Gcse Physical Education Revision - Eduqas - BBC BitesizeyoyoyoNo ratings yet

- Truss-Design 18mDocument6 pagesTruss-Design 18mARSENo ratings yet

- Philhis 1blm Group 6 ReportDocument19 pagesPhilhis 1blm Group 6 Reporttaehyung trashNo ratings yet

- CCDocument5 pagesCCnazmulNo ratings yet

- A Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyDocument11 pagesA Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyNova Ariston100% (2)

- Marketing Micro and Macro EnvironmentDocument8 pagesMarketing Micro and Macro EnvironmentSumit Acharya100% (1)

- Week - 2 Lab - 1 - Part I Lab Aim: Basic Programming Concepts, Python InstallationDocument13 pagesWeek - 2 Lab - 1 - Part I Lab Aim: Basic Programming Concepts, Python InstallationSahil Shah100% (1)

- I Pmtea 2020 HandoutDocument94 pagesI Pmtea 2020 HandoutAbhijeet Dutta100% (1)

- G1000 Us 1014 PDFDocument820 pagesG1000 Us 1014 PDFLuís Miguel RomãoNo ratings yet

- Inventions Over The Last 100 YearsDocument3 pagesInventions Over The Last 100 YearsHombreMorado GamerYTNo ratings yet

- Manual de Operacion y MantenimientoDocument236 pagesManual de Operacion y MantenimientoalexNo ratings yet