Professional Documents

Culture Documents

Final Standard 6 Inch

Uploaded by

Raman KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Standard 6 Inch

Uploaded by

Raman KumarCopyright:

Available Formats

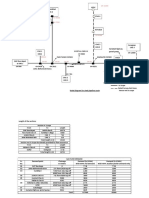

Doc. No.

: 1009-00-PP-CAL-2002 Rev :0

WALL THICKNESS CALCULATION FOR

Date : 26/01/20

NAMBOR-GOLAGHAT-NUMALIGARH GAS PIPELINE PROJECT

Page : 1 of 4

6″ NATURAL GAS PIPELINE

1. INPUT

Design Factor = 0.60 0.50 0.40

Design Code = ASME B 31.8 ASME B 31.8 ASME B 31.8

Fluid Transporated = GAS GAS GAS

Pipeline Installation = Buried Buried Buried

Internal Design pressure of pipeline P = 4.90 4.90 4.90 MPa

Pipeline Rating # = 300 300 300

Pipeline OD D = 168.30 168.30 168.30 mm

Corrosion Allowance CA = 0.50 0.50 0.50 mm

Pipe Manufacturing type = SMLS SMLS SMLS

Longitudinal Joint Factor E = 1.00 1.00 1.00 Table 841.1.7-1 of ASME B 31.8

Line Pipe Material = API 5L GR B API 5L GR B API 5L GR B

Specified Min. Yield Strength(SMYS) S = 245.00 245.00 245.00 MPa (for API 5L X70 Grade)

Location Class = Class-2 Class-3 Class-4

Temperature Derating Factor T = 1.00 1.00 1.00 Table 841.1.8-1 of ASME B 31.8

Modulus of elasticity of steel Es = 200000.00 200000.00 200000.00 MPa Table 832.5 of ASME B 31.8

Temperature at the time of installation T1 = 21.00 21.00 21.00 °C

Design Temperature T2 = 65.00 65.00 65.00 °C

Hydrotest Temperature T3 = 35.00 35.00 35.00 °C

Hydrotest Factor (based on SMYS) Fh = 0.95 0.95 0.95

Linear coefficient of thermal expansion a = 0.00001170 0.00001170 0.00001170 mm/mm/°C

Poisson's Ratio n = 0.30 0.30 0.30

Density of Water ρW = 1000.00 1000.00 1000.00 kg/m3

Maximum Water Depth Hw = 25.00 25.00 25.00 m

Acc. Due to gravity g = 9.81 9.81 9.81 m/s2

Collapse factor fP = 0.70 0.70 0.70 m/s2

Length of Pipe (For Tensile Criteria) L = 12.00 12.00 12.00 m

3LPE Coating Thickness Tc = 3.20 3.20 3.20 mm

Density of 3LPE Coating Thickness ρc = 1400.00 1400.00 1400.00 kg/m3

Density of Steel Pipe ρs = 7850.00 7850.00 7850.00 kg/m3

Static friction co-efficient (For tensile Load) fs = 0.60 0.60 0.60

Extenal Force R = 0.00 0.00 0.00 N

2. CALCULATION

2.1 WALL THICKNESS CALCULATION

Design Factor F = 0.60 0.50 0.40

Minimum Nominal Wall Thickness

tn =( P*D)/(2*S*E*F*T) tn = 2.81 3.37 4.21 mm (ASME B31.8, clause 841)

Wall Thickness after Adding

Corrosion Allowance tnc =tn+CA tnc = 3.31 3.87 4.71 mm

Selected Wall Thickness ts = 6.40 6.40 6.40 mm

Diameter/ Thickness Ratio (D/ts) = 26.30 26.30 26.30 mm

Diameter/ Thickness Ratio (D/ts) Check = PASS PASS PASS mm

(D/ts) <=100

2.2 STRESSESS CALCULATION (INTERNAL PRESSURE CRITERIA)

2.2.1 A) HOOP STRESS CALCULATION

Hoop Stress at Corroded Thickness

SH=PD/2 (ts-CA) SH = 69.89 69.89 69.89 MPa (ASME B31.8, clause 841)

% of Hoop Stress of SMYS = 28.53 28.53 28.53 %

Allowable Hoop Stress SHA = 147.00 122.50 98.00 MPa

SHA=F*E*T*S

Stress check, SH<=SHA = PASS PASS PASS

Doc. No.: 1009-00-PP-CAL-2002 Rev :0

TITLE: WALL THICKNESS CALCULATION FOR

Date : 26/01/20

DAHEJ-BHADBHUT PIPELINE PROJECT

Page : 2 of 4

6″ NATURAL GAS PIPELINE

2.2.2 B) LONGITUDINAL STRESS CALCULATION

2.2.2.1 Longitudinal Stress due to Internal Pressure SP = 20.97 20.97 20.97 MPa (ASME B31.8, clause 833.2)

SP=0.3*SH

2.2.2.2 Longitudinal Stress due to Thermal ExpansionST = -102.96 -102.96 -102.96 MPa (ASME B31.8, clause 833.2)

ST=E*α*(T1-T2)

2.2.2.3 Nominal Bending Stress for Straight Pipe SB = 0.00 0.00 0.00 MPa (ASME B31.8, clause 833.2)

SB=M/Z

Pipe Cross sectional Area Ac = 0.00 0.00 0.00 m2 (ASME B31.8, clause 833.2)

2.2.2.4 Axial Stress SX = 0.00 0.00 0.00 MPa (ASME B31.8, clause 833.2)

SX=R/AC

2.2.2.5 Net Longitudinal Stress SL = -81.99 -81.99 -81.99 MPa (ASME B31.8, clause 833.3)

SL=SP+ST+SB+SX

Calculated Longitudinal Stress (Absolute) SL = 81.99 81.99 81.99 MPa From Sr no 2.1 above

Allowable Longitudinal Stress SLA = 220.50 220.50 220.50 MPa

SLA=0.9*E*T*S

Code check, SL<=SLA = PASS PASS PASS

2.2.3 C) EQUILVALENT STRESS CALCULATION

2.2.3.1 Combined Stress (Von Mises Theory) SE1 = 131.67 131.67 131.67 MPa (ASME B31.8, clause 833.4)

SE1=(SL² - SL*SH + SH²)^0.5

2.2.3.2 Combined Stress (Max Shear Stress Theory) SE2 = 151.88 151.88 151.88 MPa (ASME B31.8, clause 833.4)

SE2= |SH-SL|

2.2.3.2 Maximum of Combined Stress (SE1 or SE2) SE = 151.88 151.88 151.88 MPa (ASME B31.8, clause 833.4)

SE= Max of SE1 & SE2

Allowable Equivalent Stress SEA = 220.50 220.50 220.50 MPa

SEA=0.9*E*T*S

Code Stress check, SE<=SEA = PASS PASS PASS

2.3 STRESSESS CALCULATION (HYDROTEST PRESSURE CRITERIA)

Flange Rating Pressure as per MSS SP 44 Pf = 5.10 5.10 5.10 MPa

A) Hydrostatic Test Pressure as per Ph1 = 7.65 7.65 7.65 MPa Value -1

Flange rating Ph1=1.5*Pf

B) Hydrostatic Test Factor (as per ASME B 31.8) Fhp = 1.25 1.50 1.50 MPa

(Based on Design Pressure )

Hydrostatic Test Pressure as per Ph2 = 6.13 7.35 7.35 MPa Value -2

ASME B 31.8, Ph2= Fhp *P

C) Hydrostatic Stength Test Pressure Ph3 = 17.70 17.70 17.70 MPa Value -3

Based on SMYS (Ph3= 2*ts*S*Fh*E*T/D)

D) Selected Hydrostatic Test Pressure Ph = 7.65 7.65 7.65 MPa

(Ph=Greater among Ph2 & Ph3 but not more than Ph1)

2.3.1 A) HOOP STRESS CALCULATION

Hoop Stress at Corroded Thickness

SHh=PhD/2 (ts-CA) SHh = 109.16 109.16 109.16 MPa (ASME B31.8, clause 841)

% of Hoop Stress of SMYS = 44.55 44.55 44.55 %

2.3.2 B) LONGITUDINAL STRESS CALCULATION

2.3.2.1 Longitudinal Stress due to Internal Pressure SPh = 32.75 32.75 32.75 MPa (ASME B31.8, clause 833.2)

SPh=0.3*SHh

2.3.2.2 Longitudinal Stress due to Thermal ExpansionSTh = -32.76 -32.76 -32.76 MPa (ASME B31.8, clause 833.2)

STh=E*α*(T1-T3)

Doc. No.: 1009-00-PP-CAL-2002 Rev :0

TITLE: WALL THICKNESS CALCULATION FOR

Date : 26/01/20

DAHEJ-BHADBHUT PIPELINE PROJECT

Page : 3 of 4

6″ NATURAL GAS PIPELINE

2.3.2.3 Nominal Bending Stress for Straight Pipe SBh = 0.00 0.00 0.00 MPa (ASME B31.8, clause 833.2)

SBh=M/Z

2.3.2.4 Pipe Cross sectional Area Ac = 0.00 0.00 0.00 m2 (ASME B31.8, clause 833.2)

Axial Stress SXh = 0.00 0.00 0.00 MPa (ASME B31.8, clause 833.2)

SXh=R/Ac

2.3.2.5 Net Longitudinal Stress SLh = -0.01 -0.01 -0.01 MPa (ASME B31.8, clause 833.3)

SLh=SPh+STh+SBh+SXh

Allowable Longitudinal Stress SLhA = 220.50 220.50 220.50 MPa

SLhA=0.9*E*T*S

Code check, SLh<=SLhA = PASS PASS PASS

2.3.3 C) EQUILVALENT STRESS CALCULATION

2.3.3.1 Combined Stress (Von Mises Theory) SEh1 = 109.16 109.16 109.16 MPa (ASME B31.8, clause 833.4)

SEh1=(SLh² - SLh*SHh + SHh²)^0.5

2.3.3.2 Combined Stress (Max Shear Stress Theory) SEh2 = 109.17 109.17 109.17 MPa (ASME B31.8, clause 833.4)

SEh2= |SHh-SLh|

2.3.3.2 Maximum of Combined Stress (SE1 or SE2) SEh = 109.17 109.17 109.17 MPa (ASME B31.8, clause 833.4)

SEh= Max of SEh1 & SEh2

Allowable Equivalent Stress SEhA = 220.50 220.50 220.50 MPa

SEhA=0.9*E*T*S

Code check, SEh<=SEhA = PASS PASS PASS

2.4 ELASTIC BEND RADIUS CALCULATION

2.4.1 Allowable Equivalent Stress SEA = 220.50 220.50 220.50 MPa

SEA=0.9 *E*T*S

2.4.1 Stress Available for Bending SBA = 68.62 68.62 68.62 MPa

SBA=SEA-SE

2.4.1 Min Bending Radius RB = 245.27 245.27 245.27 m

RB=D*ES/2*SBA

2.4.1 Selected Bending Radius RBs = 300.00 300.00 300.00 m

2.4 TENSILE LOAD CRITERIA

2.4.1 Inside Diameter of Pipe Di = 155.50 155.50 155.50 mm

Di=D-2*ts

2.4.1 Overall Outer Diameter of Pipe Do = 174.70 174.70 174.70 mm

Do=D+2*Tc

2.4.1 Area of Pipe Ap = 6.59 6.59 6.59 m2

Ap=Do*L* 3.14/1000

2.4.1 Weight per unit length W = 27.97 27.97 27.97 kg/m

W= (3.14/ 4)*[(D2-Di2)*ρs +(Do2-D2)*ρc]

2.4.1 Pulling Stress SPU = 0.0003 0.0003 0.0003 MPa

SPU=(fs*L*W)/Ap

2.4.1 Bending Stress Sb = 56.1000 56.1000 56.1000 MPa

Sb=Es*D*/ 2* RB

2.4.1 Combined Longitudinal Stress (Sc) SPU+Sb = 56.1003 56.1003 56.1003 MPa

Allowable Longitudinal Stress SLA = 220.50 220.50 220.50 MPa

SLA=0.9*E*T*S

Code check, SC<=SLA = PASS PASS PASS

Doc. No.: 1009-00-PP-CAL-2002 Rev :0

TITLE: WALL THICKNESS CALCULATION FOR

Date : 26/01/20

DAHEJ-BHADBHUT PIPELINE PROJECT

Page : 3 of 4

6″ NATURAL GAS PIPELINE

2.5 COLLASPE CRITERIA

2.5.1 External pressure at max. water depth PWO = 0.25 0.25 0.25 MPa

PWO=ρw *Hw * g

2.5.2 External collapse pressure on pipe PC2 = 0.35 0.35 0.35 MPa

PC2=(Pwo-Pi)/fp

2.5.3 Yield pressure at Collaspe Py = 18.63 18.63 18.63 MPa

Py=2*S/(D/t)

2.5.4 Elastic collapse pressure Pe = 24.17 24.17 24.17 MPa

Pe=2*Es*(ts/D)³/(1-ν²)

2.5.4 Collapse pressure of Pipe PC1 = 14.76 14.76 14.76 MPa

PC1=Py*Pe/(Py²+Pe²)½

Stress check, PC2<=PC1 = PASS PASS PASS

RESULT SUMMARY

DESIGN RATIO

DESCRIPTION TYPE OF CHECK CALCULATED ALLOWABLE

FACTOR CHECK

0.6 26.30 100 PASS

D/ts RATIO D/ts 0.5 26.30 100 PASS

0.4 26.30 100 PASS

DESIGN CALCULATED ALLOWABLE STRESS

DESCRIPTION TYPE OF CHECK

FACTOR (Mpa) (Mpa) CHECK

0.6 69.89 147.00 PASS

HOOP STRESS 0.5 69.89 122.50 PASS

0.4 69.89 98.00 PASS

0.6 81.99 220.50 PASS

INTERNAL PRESSURE TOTAL LONGITUDINAL

0.5 81.99 220.50 PASS

CRITERIA STRESS

0.4 81.99 220.50 PASS

0.6 151.88 220.50 PASS

EQUIVALENT STRESS 0.5 151.88 220.50 PASS

0.4 151.88 220.50 PASS

0.6 -0.01 220.50 PASS

TOTAL LONGITUDINAL

0.5 -0.01 220.50 PASS

STRESS

0.4 -0.01 220.50 PASS

HYDROTEST PRESSURE

CRITERIA

0.6 109.17 220.50 PASS

EQUIVALENT STRESS 0.5 109.17 220.50 PASS

0.4 109.17 220.50 PASS

0.6 56.10 220.50 PASS

TENSIL LOAD CRITERIA PULLING +BENDING STRESS 0.5 56.10 220.50 PASS

0.4 56.10 220.50 PASS

0.6 0.35 14.76 PASS

EXTERNAL COLLAPSE

COLLASPE CRITERIA 0.5 0.35 14.76 PASS

PRESSURE

0.4 0.35 14.76 PASS

You might also like

- Ethylene Oxide Production From EthyleneDocument1 pageEthylene Oxide Production From EthyleneBramJanssen76No ratings yet

- ISO 13623 pipe wall thickness calculation for Mahani-2 projectDocument6 pagesISO 13623 pipe wall thickness calculation for Mahani-2 projectRanjan KumarNo ratings yet

- Tugas 2 PPTKDocument5 pagesTugas 2 PPTKIlman Azhari NstNo ratings yet

- Piping Streess AnalysisDocument10 pagesPiping Streess AnalysisYosses Sang NahkodaNo ratings yet

- Wall Thickness Calculation Verification under StressDocument1 pageWall Thickness Calculation Verification under StresshhgjdfNo ratings yet

- Attachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)Document4 pagesAttachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)ISRAEL PORTILLONo ratings yet

- Ips G Pi 280Document23 pagesIps G Pi 280MahdiNo ratings yet

- ASME B31.4-Wall Thickness Calc For 6 InchDocument2 pagesASME B31.4-Wall Thickness Calc For 6 InchBagus Sukoco KocoNo ratings yet

- Solid Wall HDPE Pipe: NRCS NEH 636 Chap. 52 Buried Pipeline Design CalculationsDocument13 pagesSolid Wall HDPE Pipe: NRCS NEH 636 Chap. 52 Buried Pipeline Design CalculationsBalaji HariNo ratings yet

- Vortex Shedding Load On PipingDocument1 pageVortex Shedding Load On Pipingananyo_sengupta100% (1)

- IPS-E-PM-385(2) ForewordDocument25 pagesIPS-E-PM-385(2) ForewordmasoudNo ratings yet

- SEPA15014 MFSTF CV 00 SPC 004 - Specification For Grouting - Rev ADocument15 pagesSEPA15014 MFSTF CV 00 SPC 004 - Specification For Grouting - Rev APruthviraj JuniNo ratings yet

- Hydraulic Fracture Design and Post Fracture Analysis inDocument21 pagesHydraulic Fracture Design and Post Fracture Analysis inBilal IjazNo ratings yet

- Formula for buried pipeline anchor stress and forceDocument4 pagesFormula for buried pipeline anchor stress and forcePriyam KmNo ratings yet

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 pagesHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNo ratings yet

- Stress analysis of buried cross-country pipingDocument3 pagesStress analysis of buried cross-country pipingSharon LambertNo ratings yet

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536No ratings yet

- Correlation table for two-phase flow modelsDocument4 pagesCorrelation table for two-phase flow modelssouthliNo ratings yet

- Calculation of Air Content (P/V Plot)Document2 pagesCalculation of Air Content (P/V Plot)Vimin PrakashNo ratings yet

- American SteelBook 2Document454 pagesAmerican SteelBook 2JesusNo ratings yet

- Tender227 VOL II PDFDocument945 pagesTender227 VOL II PDFrasnowmah2012No ratings yet

- CCC1Document5 pagesCCC1Uok RitchieNo ratings yet

- Under Re - Attachment (Elastic Bend)Document4 pagesUnder Re - Attachment (Elastic Bend)ISRAEL PORTILLONo ratings yet

- Discharge Nozzle Load Analysis for Fire Water Pump P-05ADocument22 pagesDischarge Nozzle Load Analysis for Fire Water Pump P-05ASeptian FirdausNo ratings yet

- Piepline Thickness CalculationDocument6 pagesPiepline Thickness CalculationAneeq NaufalNo ratings yet

- CW Pipe Thickness Calculation - 80% Vacuum - With RCCDocument39 pagesCW Pipe Thickness Calculation - 80% Vacuum - With RCCAshitava Sen0% (1)

- Buried Pipe Design for Deep Rock Petroleum TerminalDocument12 pagesBuried Pipe Design for Deep Rock Petroleum TerminalMichael J. BaneNo ratings yet

- Pipe wall thickness calculation sheet for high pressure natural gas lineDocument1 pagePipe wall thickness calculation sheet for high pressure natural gas lineAris KancilNo ratings yet

- Pipeline Design For Onshore Pipelines: STD.4600 Engineering Standards and Specifications PipelineDocument23 pagesPipeline Design For Onshore Pipelines: STD.4600 Engineering Standards and Specifications PipelineEzequiel Guillermo Trejo NavasNo ratings yet

- Pipeline Virtual Anchor Length Calculations: VariablesDocument3 pagesPipeline Virtual Anchor Length Calculations: Variablesromvos8469No ratings yet

- 2009 02 M HD 319 0Document5 pages2009 02 M HD 319 0ZoebairNo ratings yet

- EPM-GL-PI-CLC-0004 - Rev 0 - Slug Flow Force CalculationDocument4 pagesEPM-GL-PI-CLC-0004 - Rev 0 - Slug Flow Force CalculationHernán DazaNo ratings yet

- Offshore Intake Velocity Cap Structure DesignDocument1 pageOffshore Intake Velocity Cap Structure Designpreeti kumariNo ratings yet

- Casing Pipe THK - 24 InchDocument6 pagesCasing Pipe THK - 24 InchAnupam MehraNo ratings yet

- Upheavel Buckling CalculationDocument8 pagesUpheavel Buckling Calculationsaravanakkumar boominahtanNo ratings yet

- Mss sp-71 1997 PDFDocument10 pagesMss sp-71 1997 PDFChotiwan RattanasatienNo ratings yet

- Perhitungan Kekuatan PipelineDocument9 pagesPerhitungan Kekuatan PipelineRAHMAN HakimNo ratings yet

- Calculation of maximum pressure rise and surge pressure in water pipelineDocument7 pagesCalculation of maximum pressure rise and surge pressure in water pipelineSameer MinhajNo ratings yet

- Pipe Size Flange Rating Operating Condition: E F SFDocument4 pagesPipe Size Flange Rating Operating Condition: E F SFvivekpec100% (1)

- G Me 160 PDFDocument70 pagesG Me 160 PDFHamid AbbasiNo ratings yet

- Pipeline Size CalculationDocument6 pagesPipeline Size CalculationharyjbiNo ratings yet

- Inputs Required For FIV & AIV StudyDocument1 pageInputs Required For FIV & AIV StudyRonak MotaNo ratings yet

- Mechanical Engineering: Merger Turns To Collaboration - COADE Remains IndependentDocument24 pagesMechanical Engineering: Merger Turns To Collaboration - COADE Remains IndependentfileseekerNo ratings yet

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocument8 pages8 AS4041 ASME B31 3 Pipe Wall ThicknessĐinh Thiện SỹNo ratings yet

- Wall thickness calculation for 36-inch gas pipelineDocument1 pageWall thickness calculation for 36-inch gas pipelinetitir bagchiNo ratings yet

- Vortex Excitation of Metal BellowsDocument8 pagesVortex Excitation of Metal BellowsMourad BenabderrahmaneNo ratings yet

- Format - Pipe Rack Load CalculationDocument2 pagesFormat - Pipe Rack Load CalculationManeesh DwivediNo ratings yet

- ... Go To Air Volume Calculation Prepared by MD - Zafar ... Go To Strength & Leak TestDocument4 pages... Go To Air Volume Calculation Prepared by MD - Zafar ... Go To Strength & Leak TestJatin PatelNo ratings yet

- Mathcad - ASME I I VIII I Thickness Cylindrical ShellDocument3 pagesMathcad - ASME I I VIII I Thickness Cylindrical ShellkurcekNo ratings yet

- Combined Stress Calc Rev. 2Document12 pagesCombined Stress Calc Rev. 2babu75% (4)

- Calcs 4Document19 pagesCalcs 4Syariful Maliki NejstaršíNo ratings yet

- Upheaval Buckling PipelineDocument11 pagesUpheaval Buckling PipelineRYZKI EFENDI SIMANULANGNo ratings yet

- 6208734-I-Rfq-001 PLC RFQ R1Document26 pages6208734-I-Rfq-001 PLC RFQ R1KarthikeyanNo ratings yet

- Surge DiverterDocument2 pagesSurge DiverterKa TranNo ratings yet

- NozzlePRO PDFDocument185 pagesNozzlePRO PDFIan CarrNo ratings yet

- HDD Design Calculation for Sonamura GGS Pipeline ProjectDocument22 pagesHDD Design Calculation for Sonamura GGS Pipeline ProjectPer Bagus HandokoNo ratings yet

- Piping Stress Analysis Report for Relocation ProjectDocument13 pagesPiping Stress Analysis Report for Relocation ProjectPer Bagus Handoko100% (1)

- V.4_wall Thickness & Bend Thin 6 InchDocument15 pagesV.4_wall Thickness & Bend Thin 6 InchSuaib VCSNo ratings yet

- Pdesign: 100 Barg Line Pipe Material: API Grade X60Document64 pagesPdesign: 100 Barg Line Pipe Material: API Grade X60Luong NgoNo ratings yet

- Square Blind Flange With Stiffener ULDocument5 pagesSquare Blind Flange With Stiffener ULjoeriji100% (1)

- DESIGN OF FLOOR SLAB (0.15m Thick)Document9 pagesDESIGN OF FLOOR SLAB (0.15m Thick)Living Life100% (1)

- Slab DesignDocument9 pagesSlab Designsuleiman.ahNo ratings yet

- PMC-Cross Country PipelinesDocument4 pagesPMC-Cross Country PipelinesRaman KumarNo ratings yet

- PMC-O&MDocument7 pagesPMC-O&MRaman KumarNo ratings yet

- eoi-dfrDocument12 pageseoi-dfrRaman KumarNo ratings yet

- VPC-QD-PP-002 APPROVAL MATRIX New Rev LatestDocument5 pagesVPC-QD-PP-002 APPROVAL MATRIX New Rev LatestRaman KumarNo ratings yet

- VPC-QD-PP-035 Escalation QuantitiesDocument7 pagesVPC-QD-PP-035 Escalation QuantitiesRaman KumarNo ratings yet

- EN - 206 Work Demarcation MatrixDocument5 pagesEN - 206 Work Demarcation MatrixRaman KumarNo ratings yet

- VPC-QD-PP-036 Check List LogDocument10 pagesVPC-QD-PP-036 Check List LogRaman KumarNo ratings yet

- EN-208 Engineering Item ListDocument4 pagesEN-208 Engineering Item ListRaman KumarNo ratings yet

- List of Recommended TPIADocument1 pageList of Recommended TPIARaman KumarNo ratings yet

- VPC-QD-PP-004 Idc Check MatrixDocument3 pagesVPC-QD-PP-004 Idc Check MatrixRaman KumarNo ratings yet

- 1009 00 PP Ten 2024 - c1 Control ValveDocument161 pages1009 00 PP Ten 2024 - c1 Control ValveRaman KumarNo ratings yet

- Node diagram for steel pipeline routeDocument2 pagesNode diagram for steel pipeline routeRaman KumarNo ratings yet

- Aisi 340 Info PDFDocument3 pagesAisi 340 Info PDFAn DikaNo ratings yet

- FORM A - CHECK LIST OkDocument1 pageFORM A - CHECK LIST OkRaman KumarNo ratings yet

- Sordehradunweb 20191018 160256Document17 pagesSordehradunweb 20191018 160256Raman KumarNo ratings yet

- Voliweb 20191018 155439Document307 pagesVoliweb 20191018 155439Raman KumarNo ratings yet

- City Gas Distribution Project of Kota Ga, RajasthanDocument4 pagesCity Gas Distribution Project of Kota Ga, RajasthanRaman KumarNo ratings yet

- Route Map Pani Tanki Chowk To Kumhari VillageDocument1 pageRoute Map Pani Tanki Chowk To Kumhari VillageRaman KumarNo ratings yet

- Node diagram for steel pipeline routeDocument2 pagesNode diagram for steel pipeline routeRaman KumarNo ratings yet

- Factor of Safety Against Sliding Refresher CourseDocument3 pagesFactor of Safety Against Sliding Refresher CourseKim Ryan PomarNo ratings yet

- Piping Handbook GuideDocument52 pagesPiping Handbook Guideafzal khan100% (3)

- 5 Material and Traceability RecordDocument6 pages5 Material and Traceability RecordEdha Ali100% (1)

- EIMCO-K.C.P. installations around the worldDocument16 pagesEIMCO-K.C.P. installations around the worldsatishNo ratings yet

- Design of Sand FilterDocument5 pagesDesign of Sand FilterAbhay ThakurNo ratings yet

- DIIPA Lecture-1C Columns 07042020Document16 pagesDIIPA Lecture-1C Columns 07042020amul ghimireNo ratings yet

- FM - Chap5 - Water Usage in The Lodging Industry - FinalDocument45 pagesFM - Chap5 - Water Usage in The Lodging Industry - FinalMarcus VoNo ratings yet

- Unit: Pltu Bolok Area: UNIT #1 Equipment Standard Measurement Point Unit Minggu 1 Minggu 2 Minggu 3 Minggu 4 StatusDocument18 pagesUnit: Pltu Bolok Area: UNIT #1 Equipment Standard Measurement Point Unit Minggu 1 Minggu 2 Minggu 3 Minggu 4 StatusAchmad Zaki MubarokNo ratings yet

- Thickener-Booklet NA Imperial Digital-FileDocument4 pagesThickener-Booklet NA Imperial Digital-Fileharishram12345650% (2)

- خواص صخور المكمن رقم 6Document31 pagesخواص صخور المكمن رقم 6maamoun ramyNo ratings yet

- Saving lives through fire protection system licensing and inspectionDocument1 pageSaving lives through fire protection system licensing and inspectionBING_DING_RINGNo ratings yet

- Flow Sensor Technical Guide BookDocument20 pagesFlow Sensor Technical Guide Books12originalNo ratings yet

- System PracticesDocument27 pagesSystem PracticesMechanicalNo ratings yet

- Past BoardDocument19 pagesPast BoardMarco Sarmiento100% (1)

- Interpretation of geometrical effects in CFD and integral modelsDocument113 pagesInterpretation of geometrical effects in CFD and integral modelsAiman LatifNo ratings yet

- Charlotte DWVDocument68 pagesCharlotte DWVFrancisco MartinezNo ratings yet

- Waste Water Treatment Using Electrocoagulation TechnologyDocument4 pagesWaste Water Treatment Using Electrocoagulation TechnologyKetan V. JoshiNo ratings yet

- Suction BellmouthsDocument4 pagesSuction BellmouthsAnonymous Kr13NEB100% (1)

- PVC Pipes - Friction Loss and Flow Velocities Schedule 40Document9 pagesPVC Pipes - Friction Loss and Flow Velocities Schedule 40VitrophoenicsNo ratings yet

- Super Precision Tapered Roller Bearings: Rotating Centres Ballscrew Support Cartridge UnitsDocument72 pagesSuper Precision Tapered Roller Bearings: Rotating Centres Ballscrew Support Cartridge UnitsCaranovic StefanNo ratings yet

- Impact of Single and Dual Pressure Butt-Welding Procedures On The Reliability of PE 100 Pipe WeldsDocument7 pagesImpact of Single and Dual Pressure Butt-Welding Procedures On The Reliability of PE 100 Pipe WeldsThouraya HbsNo ratings yet

- Enggcyclopedia Process Design GuideDocument6 pagesEnggcyclopedia Process Design GuidemshadabkNo ratings yet

- CFD analysis airfoil flow using FluentDocument6 pagesCFD analysis airfoil flow using FluentsrinathcfdNo ratings yet

- Applications of Microreactors in Renewable EnergyDocument21 pagesApplications of Microreactors in Renewable EnergyGodofredoNo ratings yet

- Experimental Determination of Fouling Factor On Plate Heat Exchangers in District Heating System PDFDocument8 pagesExperimental Determination of Fouling Factor On Plate Heat Exchangers in District Heating System PDFarianaseriNo ratings yet

- The C3MR Liquefaction CycleDocument14 pagesThe C3MR Liquefaction Cyclekamran5426No ratings yet

- 9080 Optimass 7300 Flowmeter ManualDocument146 pages9080 Optimass 7300 Flowmeter ManualMaruti HuleNo ratings yet