Professional Documents

Culture Documents

HEMP-006 Operation of Wood Cutting & Grooving Machine Rev.1 PDF

HEMP-006 Operation of Wood Cutting & Grooving Machine Rev.1 PDF

Uploaded by

saravana.bOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HEMP-006 Operation of Wood Cutting & Grooving Machine Rev.1 PDF

HEMP-006 Operation of Wood Cutting & Grooving Machine Rev.1 PDF

Uploaded by

saravana.bCopyright:

Available Formats

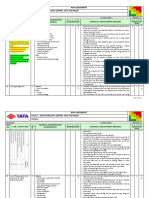

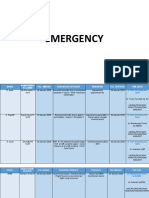

HAZARDS AND EFFECTS MANAGEMENT PROCESS (HEMP)

CONSEQUENCE

CONSEQUENCE

OPERATION OF WOOD CUTTING

PROBABILITY

PROBABILITY

RISK RATING

RECOVERY

MEASURES

RESIDUAL

(A,B,C,D,E)

(A,B,C,D,E)

(0,1,2,3,4,5)

(0,1,2,3,4,5)

RATING

/ GROOVING MACHINE (FIXED)

RISK

CONTROL MEASURES

SIGNIFICANT HSE

EFFECT

HAZARD

Improper machine Health

setting / posture

Upper limbs 2 C M Adequate work space for machine operation 1 C L Medical Aid

disorder /ergonomic considerations.

M.S. Disorder The cutting blade shall be of correct size to fit

Noise with the machine - rating (RPM) shall be at

least more than the no-load RPM of the

machine.

Proper tightening of blade - the blade shall

have correct sized hole to fit snugly on the

spindle without any slack or applying force.

Inspection of blade prior to use.

Do not modify the machine to suit site

requirements, against the manufacturer

specifications.

Noise measurements and use of suitable

hearing protection.

Machine shall be held firmly for proper control

Periodic rest breaks / stretch-outs

Safety

Tool damage 3 C M Adequate work space to be provided for safe 1 C L Emergency

Injury to persons operation / manoeuvre. response

Do not modify the machine to suit site

requirements, against the manufacturer

specifications.

The cutting blade shall be of correct size to fit

with the machine - rating (RPM) shall be at

least more than the no-load RPM of the

machine.

Revision No. Date Document No. Page

1 01.08.2014 HSE-HEMP-000-006 2 of 7

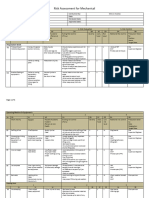

HAZARDS AND EFFECTS MANAGEMENT PROCESS (HEMP)

CONSEQUENCE

CONSEQUENCE

OPERATION OF WOOD CUTTING

PROBABILITY

PROBABILITY

RISK RATING

RECOVERY

MEASURES

RESIDUAL

(A,B,C,D,E)

(A,B,C,D,E)

(0,1,2,3,4,5)

(0,1,2,3,4,5)

RATING

/ GROOVING MACHINE (FIXED)

RISK

CONTROL MEASURES

SIGNIFICANT HSE

EFFECT

HAZARD

Proper tightening of blade - the blade shall

have correct sized hole to fit snugly on the

spindle without any slack or applying force.

Inspection of blade prior to use.

The machine shall be operated in right speed to

suit the specific application.

Secure the machine firmly to avoid vibrations /

kickbacks.

Cutting blade shall be covered with a guard to

protect personnel from getting injured.

Switch off the machine and remove plugs from

the socket before changing / adjusting /

replacing the cutting blade.

All machine controls, cutting blade, power

drives, etc., should be inspected daily and at

each new set up.

Use of suitable PPE - Helmet, safety boots,

safety goggles, gloves, ear plug / muff, aprons

as required.

Environment -NA- NA -NA-

-NA-

Defective electric Health -NA- NA -NA-

connections

-NA-

Safety

3 C M Electrical rating should be in accordance with 1 C L Emergency

Injury manufacturer specification and applicable local response

Asset damage standards.

Revision No. Date Document No. Page

1 01.08.2014 HSE-HEMP-000-006 3 of 7

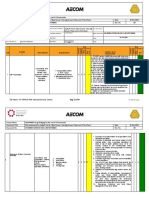

HAZARDS AND EFFECTS MANAGEMENT PROCESS (HEMP)

CONSEQUENCE

CONSEQUENCE

OPERATION OF WOOD CUTTING

PROBABILITY

PROBABILITY

RISK RATING

RECOVERY

MEASURES

RESIDUAL

(A,B,C,D,E)

(A,B,C,D,E)

(0,1,2,3,4,5)

(0,1,2,3,4,5)

RATING

/ GROOVING MACHINE (FIXED)

RISK

CONTROL MEASURES

SIGNIFICANT HSE

EFFECT

HAZARD

Electric Shock Provide independent grounding conductor to

prevent electric shocks.

Provide independent circuit breaker apart from

any switchgear on the equipment itself, to

electrically isolate the equipment in the event

of failure, or for routine repairs or preventive

maintenance.

Inspection of Electrical connections & cables

prior to every use and prompt repairs.

Use of suitable PPE - Helmet, safety boots,

safety goggles, gloves, ear plug / muff, aprons

as required.

Environment -NA- NA -NA-

-NA-

Flying particles / Health 2 C M Restrict access only to authorized personnel in 1 C L Medical Aid

saw dust the work area.

Respiratory track / Proper ventilation / exhaust arrangement.

Lung disorders Provide warning sign boards.

Eye irritation Use appropriate PPE- respiratory mask,

coverall, apron, safety boots, helmet &

goggles.

Safety 3 C M Restrict access only to authorized personnel in 1 C L Emergency

the work area. response

Personal injury Adequate protection to cutting blade to prevent

Fire operator or others nearby from getting injured

by flying particles.

Proper ventilation / exhaust arrangement to

Revision No. Date Document No. Page

1 01.08.2014 HSE-HEMP-000-006 4 of 7

HAZARDS AND EFFECTS MANAGEMENT PROCESS (HEMP)

CONSEQUENCE

CONSEQUENCE

OPERATION OF WOOD CUTTING

PROBABILITY

PROBABILITY

RISK RATING

RECOVERY

MEASURES

RESIDUAL

(A,B,C,D,E)

(A,B,C,D,E)

(0,1,2,3,4,5)

(0,1,2,3,4,5)

RATING

/ GROOVING MACHINE (FIXED)

RISK

CONTROL MEASURES

SIGNIFICANT HSE

EFFECT

HAZARD

prevent build up of flammable atmosphere.

Keep the surrounding clear of any flammable

or combustible material / activity.

Protect the area from naked flames / smoking.

Provide warning sign boards.

Ensure availability of suitable fire

extinguishers nearby.

Use appropriate PPE- coverall, apron, safety

boots, helmet & suitable face shield to protect

all the sides or a combination of face shield

with goggles.

Environment 2 E M Prompt collection & storage 1 D L Collection

Peruse possibility of re-use. & Disposal

Solid Non- Disposal as per waste management procedure.

hazardous waste

Contact with moving Health -NA- NA -NA-

/ rotating parts

-NA-

Safety 3 C M Provide guards to all moving / rotating parts of 1 C L Emergency

the machine. response

Personal injury Circular saws shall be fitted with both a fixed

guard over the upper half and a movable guard

over the lower part. Both guards shall, at all

times, be operative.

Restrict access only to authorized personnel.

Do not wear loose clothing, gloves and

jewellery that can get entangled in moving /

rotating machinery.

Avoid touching the cutting blade for any

Revision No. Date Document No. Page

1 01.08.2014 HSE-HEMP-000-006 5 of 7

HAZARDS AND EFFECTS MANAGEMENT PROCESS (HEMP)

CONSEQUENCE

CONSEQUENCE

OPERATION OF WOOD CUTTING

PROBABILITY

PROBABILITY

RISK RATING

RECOVERY

MEASURES

RESIDUAL

(A,B,C,D,E)

(A,B,C,D,E)

(0,1,2,3,4,5)

(0,1,2,3,4,5)

RATING

/ GROOVING MACHINE (FIXED)

RISK

CONTROL MEASURES

SIGNIFICANT HSE

EFFECT

HAZARD

reason till the rotation stops fully.

Switch off the machine and remove plugs from

the socket before changing / adjusting /

replacing the cutting blade.

Use guide bars / push sticks to guide the piece

instead of exposing fingers.

Environment -NA- NA -NA-

-NA-

Improper use of Health -NA- NA -NA-

machine

-NA-

Safety 3 C M Machine should be inspected daily and before 1 C L Emergency

every use. response

- Personal injury Machine shall not be left unattended when

- Asset Damage ‘On’.

Switch off and keep the machine controls

secured, when not in use to avoid unauthorised

operation.

Display the identity of trained & authorised

operators, prominently.

Job pieces shall be held firmly such that it

doesn’t kick back and injure the operator.

Personnel shall not stand in line with cutting

blade till the blade reaches full speed due to

the possibility of kickback / throw of job piece.

Machine shall be used only for its authorised

purpose as per manufacturer specification.

Machine and the work surfaces should be

cleaned with a long-handled brush and not

Revision No. Date Document No. Page

1 01.08.2014 HSE-HEMP-000-006 6 of 7

HAZARDS AND EFFECTS MANAGEMENT PROCESS (HEMP)

CONSEQUENCE

CONSEQUENCE

OPERATION OF WOOD CUTTING

PROBABILITY

PROBABILITY

RISK RATING

RECOVERY

MEASURES

RESIDUAL

(A,B,C,D,E)

(A,B,C,D,E)

(0,1,2,3,4,5)

(0,1,2,3,4,5)

RATING

/ GROOVING MACHINE (FIXED)

RISK

CONTROL MEASURES

SIGNIFICANT HSE

EFFECT

HAZARD

with their hands or air nozzles, after the

equipment has stopped.

Do not operate without authorisation and

without necessary PPE.

Environment -NA- NA -NA-

-NA-

Revision No. Date Document No. Page

1 01.08.2014 HSE-HEMP-000-006 7 of 7

You might also like

- RISK ASSESSMENT REPORT - George Municipality - Tender ENG0042016 Installation of Perimeter Concrete Palisade FeDocument10 pagesRISK ASSESSMENT REPORT - George Municipality - Tender ENG0042016 Installation of Perimeter Concrete Palisade FeemmyNo ratings yet

- Contractor Ehs Risk Assessment For NDT TestingDocument6 pagesContractor Ehs Risk Assessment For NDT TestingBernard PenuliarNo ratings yet

- 675Document2 pages675Rameese MuhammedNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- The Cardiovascular System: Lecture Presentation by Patty Bostwick-Taylor Florence-Darlington Technical CollegeDocument124 pagesThe Cardiovascular System: Lecture Presentation by Patty Bostwick-Taylor Florence-Darlington Technical Collegelourd nabNo ratings yet

- ARA - For Emergency Diesel GeneratorDocument4 pagesARA - For Emergency Diesel GeneratorShaikh AftabNo ratings yet

- RA Pump TemoraryDocument11 pagesRA Pump TemoraryCarlos ImmanuelNo ratings yet

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocument5 pagesJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyNo ratings yet

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformandreNo ratings yet

- Crane-Hydra-deployment For Lifting-Lowering-Risk AssessmentDocument4 pagesCrane-Hydra-deployment For Lifting-Lowering-Risk AssessmentAhmed El-sherpiniNo ratings yet

- Master Hira - 01Document4 pagesMaster Hira - 01Angw BasumataryNo ratings yet

- RA Excavation For Trial TrenchDocument9 pagesRA Excavation For Trial TrenchSasi KumarNo ratings yet

- 9 - Risk Assessment - PaintingDocument8 pages9 - Risk Assessment - Paintingmahmoud nadaNo ratings yet

- Jsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.Document67 pagesJsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.jafar mohdNo ratings yet

- 01 PTW For Work at Height (MEWP) - DailyDocument6 pages01 PTW For Work at Height (MEWP) - DailyIgnatius TanNo ratings yet

- Lifting OperationDocument8 pagesLifting OperationFILE 1131No ratings yet

- 7.OHS-PR-09-03-F02 HIRA - 30 Hydro Testing of Gas PipelineDocument5 pages7.OHS-PR-09-03-F02 HIRA - 30 Hydro Testing of Gas PipelineabbasNo ratings yet

- Stand Operating For Maintenance of HOUSE KEEPING AND CLEANING Sop No.-Kpo / BND / Sinter Plant / Sop - 00Document3 pagesStand Operating For Maintenance of HOUSE KEEPING AND CLEANING Sop No.-Kpo / BND / Sinter Plant / Sop - 00Dwitikrushna Rout100% (1)

- Mobile Equipment Hazards-ADocument25 pagesMobile Equipment Hazards-ALuis PallerosNo ratings yet

- Risk Assessment For Coring WorksDocument5 pagesRisk Assessment For Coring WorksFaizan Tanveer100% (1)

- Risk Assessment of Trees MaintenanceDocument9 pagesRisk Assessment of Trees Maintenanceطارق رضوان100% (1)

- EFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of SignagesDocument2 pagesEFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of Signagesmohammed ayazNo ratings yet

- SWP CHECKLISTS - Works at HeightsDocument2 pagesSWP CHECKLISTS - Works at HeightsSrinivas Dumpala HSENo ratings yet

- Jha Clarke Engine PumpDocument4 pagesJha Clarke Engine Pumpperquino oasanNo ratings yet

- DOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerDocument4 pagesDOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerProfessional TrustNo ratings yet

- SS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksDocument6 pagesSS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksFarhat SetharNo ratings yet

- Procedure For Spill ControlDocument1 pageProcedure For Spill ControlMind HealerNo ratings yet

- RA Flushing &Hydro-TestingDocument8 pagesRA Flushing &Hydro-Testingalla malikNo ratings yet

- JSA EmployeesDocument2 pagesJSA EmployeesburhanNo ratings yet

- Risk Assessment - House and Office CleaningDocument6 pagesRisk Assessment - House and Office CleaningVimal Thomas100% (1)

- SOP 4 - Coal Bed Leveling in PGPDocument18 pagesSOP 4 - Coal Bed Leveling in PGPfaraz ahmedNo ratings yet

- Environmental Register: Electrical Power Distribution & Maintenance of 33Kv Transformer A 1Document2 pagesEnvironmental Register: Electrical Power Distribution & Maintenance of 33Kv Transformer A 1Pandu Birumakovela100% (1)

- Lock Out Tag Out-Permit To Work Process Flow Chart: EPC Sub-ContractorDocument1 pageLock Out Tag Out-Permit To Work Process Flow Chart: EPC Sub-ContractorShailendraNo ratings yet

- Al Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentDocument9 pagesAl Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentSujan AugustinNo ratings yet

- EFS-SLB-SRA-006 Risk Assessment For General Waste CollectionDocument2 pagesEFS-SLB-SRA-006 Risk Assessment For General Waste Collectionmohammed ayazNo ratings yet

- Risk Assessment For Mechanical: Preparation WorkDocument3 pagesRisk Assessment For Mechanical: Preparation Workahmedalderbi801No ratings yet

- Lifting Plan Mobie Crane Unloading RebarDocument3 pagesLifting Plan Mobie Crane Unloading Rebarlutfi100% (1)

- SOP 10 - Limestone Shifting Form YardDocument9 pagesSOP 10 - Limestone Shifting Form Yardfaraz ahmedNo ratings yet

- Risk Assessment For Installation of Drainage Pipes PDF FreeDocument17 pagesRisk Assessment For Installation of Drainage Pipes PDF FreeMalik RizwanNo ratings yet

- RISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Document1 pageRISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Sijo Rajan100% (1)

- PlasteringDocument1 pagePlasteringAnna Marie AranaydoNo ratings yet

- Plant and Equipment Risk Assessment Fgoc - NewDocument13 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- RA - Block Work RevisedDocument14 pagesRA - Block Work RevisedCarlus RieraNo ratings yet

- Health, Safety and Environment Policy ManualDocument3 pagesHealth, Safety and Environment Policy ManualVikas SinghNo ratings yet

- Shailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentDocument21 pagesShailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentNandini RajNo ratings yet

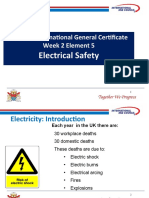

- NEBOSH International General Certificate Week 2 Element 5: Electrical SafetyDocument32 pagesNEBOSH International General Certificate Week 2 Element 5: Electrical SafetyJaballa AliNo ratings yet

- JSA #19 - Heavy Lifting in Hazardous AreaDocument1 pageJSA #19 - Heavy Lifting in Hazardous AreaMock ProjectNo ratings yet

- Pipe Nitrogen Testing in Non Confined SpaceDocument4 pagesPipe Nitrogen Testing in Non Confined SpaceKannan KamalNo ratings yet

- 2.8c Risk AssessmentDocument40 pages2.8c Risk AssessmentSn AhsanNo ratings yet

- Use of Stepladders 05Document1 pageUse of Stepladders 05cardyNo ratings yet

- Work at Height ChecklistDocument4 pagesWork at Height ChecklistSanil KuriakoseNo ratings yet

- RA - 10 - For Suspended & Slab On Grade ConstructionDocument26 pagesRA - 10 - For Suspended & Slab On Grade ConstructionIbrahim Esmat100% (1)

- OHS-PR-09-03-F02 HIRA - 011 Excavation Work Using Equipment Rev. 2021Document6 pagesOHS-PR-09-03-F02 HIRA - 011 Excavation Work Using Equipment Rev. 2021MUHAMMAD AHMADNo ratings yet

- 03a-306a3 - Pilling Machine ChecklistDocument2 pages03a-306a3 - Pilling Machine ChecklisttanoycometNo ratings yet

- RAMS For Roof Maintenance@AgbaraDocument7 pagesRAMS For Roof Maintenance@AgbaratrendyNo ratings yet

- Job Safety Analysis (Jsa) N2.Document5 pagesJob Safety Analysis (Jsa) N2.Joseph Paul IlaganNo ratings yet

- OHS-PR-09-03-F02 HIRA - 004 Soil Investigation For Plain AreaDocument6 pagesOHS-PR-09-03-F02 HIRA - 004 Soil Investigation For Plain AreaJaafar LagayanNo ratings yet

- 1.1 Buildings and FloorsDocument4 pages1.1 Buildings and FloorsMohamed Mouner100% (1)

- EHSS Risk Management System - DraftDocument17 pagesEHSS Risk Management System - DraftMd Rafat ArefinNo ratings yet

- Bar Bending Checklist: Contractor NameDocument1 pageBar Bending Checklist: Contractor NameAfroz AlamNo ratings yet

- 6620 Crane Manual 700 20013Document108 pages6620 Crane Manual 700 20013desgnhpNo ratings yet

- Fasciotomy of Compartment SyndromeDocument19 pagesFasciotomy of Compartment Syndromeansuh22No ratings yet

- ACE Group Fitness Instructor University Curriculum: Chapter 9: Emergency ProceduresDocument15 pagesACE Group Fitness Instructor University Curriculum: Chapter 9: Emergency ProceduresLouis TrầnNo ratings yet

- Orthopedic Emergency EnglishDocument64 pagesOrthopedic Emergency EnglishmegaNo ratings yet

- Yato Impact WrenchDocument64 pagesYato Impact WrenchMateusz KnafelNo ratings yet

- Basic Surgical Instruments: Rhoda Grace Estioco-Ruelos, Man, RN LecturerDocument84 pagesBasic Surgical Instruments: Rhoda Grace Estioco-Ruelos, Man, RN LecturerClaire LimosNo ratings yet

- NeurolocalizationDocument79 pagesNeurolocalizationNigussie Mersha100% (3)

- Differences in Muscle Shoulder External Rotation in Open Kinetic Chain and Closed Kinetic Chain Exercises PDFDocument3 pagesDifferences in Muscle Shoulder External Rotation in Open Kinetic Chain and Closed Kinetic Chain Exercises PDFLeonardiniNo ratings yet

- Laporan Emergency 2 FebDocument8 pagesLaporan Emergency 2 FebbisturisevenNo ratings yet

- RCL Pre-Employment Medical Exam FormsDocument5 pagesRCL Pre-Employment Medical Exam FormsScias84No ratings yet

- Approach and Management of Traumatic Retroperitoneal InjuriesDocument13 pagesApproach and Management of Traumatic Retroperitoneal InjuriesGrace TeweNo ratings yet

- Thesis PDF 1Document61 pagesThesis PDF 1NisaNo ratings yet

- 6 Law 6Document11 pages6 Law 6api-590317895No ratings yet

- DahliaDocument2 pagesDahliaespinosaisabella220No ratings yet

- 14Document10 pages14Juliana ObandoNo ratings yet

- LAW OF TORTS NegligenceDocument19 pagesLAW OF TORTS NegligenceSandy Sad100% (1)

- Post Test - Neuro - Dr. Arreglo (SC)Document2 pagesPost Test - Neuro - Dr. Arreglo (SC)Kristen FajilanNo ratings yet

- Webster 2019Document13 pagesWebster 2019sebakinesico-1No ratings yet

- Brain WorksheetDocument2 pagesBrain WorksheetiamruthannNo ratings yet

- Pre Inter Unit 3Document13 pagesPre Inter Unit 3Mariia BarnaNo ratings yet

- Crim Pe 3 (First Aid and Water Safety)Document32 pagesCrim Pe 3 (First Aid and Water Safety)Marc Daryl FelipeNo ratings yet

- Onesmus Mutungu - Njoroge - 103127005 - WallDocument2 pagesOnesmus Mutungu - Njoroge - 103127005 - Wallbit0090180No ratings yet

- 1998 Musculosketal Disorders in Newspapers and Commercial Printing PDF enDocument71 pages1998 Musculosketal Disorders in Newspapers and Commercial Printing PDF enDura EbrahimNo ratings yet

- DEN 015L - General Anatomy 1 Student'S Activity Sheet Dentistry / First YearDocument20 pagesDEN 015L - General Anatomy 1 Student'S Activity Sheet Dentistry / First YearMhdv Ndn McmNo ratings yet

- Oxford Partial Knee: Microplasty InstrumentationDocument56 pagesOxford Partial Knee: Microplasty InstrumentationBrian Vicky FaridyanNo ratings yet

- Fire Alarm Incident Report 02 April 2024Document3 pagesFire Alarm Incident Report 02 April 2024Mohsin RazaNo ratings yet

- Elbow JointDocument12 pagesElbow Jointbpt2No ratings yet

- Instrumental DeliveryDocument25 pagesInstrumental DeliveryAhmed ElmohandesNo ratings yet

- Shoulder Roll PDFDocument2 pagesShoulder Roll PDFMichele GranadaNo ratings yet