Professional Documents

Culture Documents

Problem: Solution:: Inadequate Air Pressure For Clamping A Pneumatic Booster

Uploaded by

Soro FoxOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Problem: Solution:: Inadequate Air Pressure For Clamping A Pneumatic Booster

Uploaded by

Soro FoxCopyright:

Available Formats

Problem: Inadequate Air Pressure for Clamping

Solution: A Pneumatic Booster

In this application air was the media. In addition to the

booster, a 5-gallon tank, a 3-way valve, two check valves, a

regulator and an extra pressure gauge were all that it took to

remedy the clamping problem.

The simple circuit shown below was "teed" into the existing

supply line to maintain the pressure required for reliable vise

operation.

Regulated Supply Controls

Final Output Pressure of Booster

System Supply 3-Way Control Valve

Check Valve Cycle On/Off Valve

The job at hand for this machine center was to pro- Output End Driving End

duce pneumatic valve bodies. The problem? Inad-

equate air pressure. Because of the extreme distance

away from the factory's main compressor, pressure at

the machine had dropped too low for its pneumatic

vise to hold parts securely during a vital thread mill- Check

Gage Valve

ing operation that was creating 1/4 NPT ports. System Supply

5 Gallon Tank BP Series Booster with

Inadequate clamping forces from the vise was putting Absorbs Pulses Option “ L” Limit Valves

valuable CNC tooling at risk and, of course, risked Boosted Pressure Output to Pneumatic Vise

damaging the workpieces at a late stage in their

production.

A Multi-Power® pressure booster provided a con- The booster chosen was a 2-1/2" bore, 2-piston unit having a

venient, low-cost solution that brought production power factor of 1.9. Adjusting the supply regulator to roughly

up to speed producing defect-free threads with no 74 psi produced the desired pressure of 140 psi in the reser-

rejected parts. voir tank assuring that the clamps would hold securely. Nice!

In general, the media input to a Multi-Power® Boost- Fabco-Air solves problems. Let us help.

er can be oil, other liquid, air or any compatible gas

up to 150 psi. Multiple pistons compress the media

in the output end of the booster raising the output

pressure to 500 psi max. Check valves insure the

direction of media flow. The output pressure of the

booster can be accurately set by regulating its supply

pressure, noting that (supply pressure) x (the booster's www.fabco-air.com

power factor) = (output pressure). service@fabco-air.com

You might also like

- Pressure Independent Valves For Terminal Unit Applications: Cost Effective Solution With Maximum Energy SavingsDocument8 pagesPressure Independent Valves For Terminal Unit Applications: Cost Effective Solution With Maximum Energy SavingsDaniel FigueiredoNo ratings yet

- Fluid Power ControlDocument40 pagesFluid Power ControlSonali DeyNo ratings yet

- 09 Pressure Sustaining Valve CPSVDocument2 pages09 Pressure Sustaining Valve CPSVCamilo AyalaNo ratings yet

- SM-800.40 FlexAirValve PDFDocument31 pagesSM-800.40 FlexAirValve PDFJIM CAMPBELLNo ratings yet

- Selecting Control and Balancing Valves in A Variable Flow System - ASHRAe Journal - Jun 1997Document10 pagesSelecting Control and Balancing Valves in A Variable Flow System - ASHRAe Journal - Jun 1997Vince DavidNo ratings yet

- Yarway Valve DesignDocument12 pagesYarway Valve DesignwaqashabibNo ratings yet

- Deluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataDocument16 pagesDeluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataNethajiNo ratings yet

- ABB Instrumentation: Pipeline Booster Station Control SystemsDocument6 pagesABB Instrumentation: Pipeline Booster Station Control SystemsPatricio AcuñaNo ratings yet

- Process Control Lab ManualDocument95 pagesProcess Control Lab ManualMangaiyarakarasi VenkatachalamNo ratings yet

- Deluge Valve Modelh5Document16 pagesDeluge Valve Modelh5Mariana HusainNo ratings yet

- Actuated Valve: Air Distribution Manifold (Instrument Air)Document45 pagesActuated Valve: Air Distribution Manifold (Instrument Air)Suguna moorthyNo ratings yet

- Back Pressure Regulators 101 Slides 2016 01Document32 pagesBack Pressure Regulators 101 Slides 2016 01Naseer HydenNo ratings yet

- Study and Testing of PRVDocument4 pagesStudy and Testing of PRVBhargava S PadmashaliNo ratings yet

- Mooney Flowgrid Brochure 8-12 FDocument8 pagesMooney Flowgrid Brochure 8-12 FmiltonNo ratings yet

- DSCV SaDocument19 pagesDSCV SaJuancho GuzmanNo ratings yet

- FIS123 Support Reservoir Install - 1Document8 pagesFIS123 Support Reservoir Install - 1DumitrescuNo ratings yet

- FIS168eng LTR REV 092018 PDFDocument8 pagesFIS168eng LTR REV 092018 PDFDumitrescuNo ratings yet

- Frese OPTIMA Design Guide SEP 12 PDFDocument16 pagesFrese OPTIMA Design Guide SEP 12 PDF윤병택No ratings yet

- Section 30 - Relief ValvesDocument17 pagesSection 30 - Relief ValveshammamiNo ratings yet

- Models A & B Automatic Pressure Maintenance DevicesDocument4 pagesModels A & B Automatic Pressure Maintenance DevicesSavy PhanethNo ratings yet

- Volume Booster, Qev and Fail Safe OperationDocument16 pagesVolume Booster, Qev and Fail Safe OperationharishcsharmaNo ratings yet

- Valves Deluge Valve Model h3Document16 pagesValves Deluge Valve Model h3Pedro Caminos BolanosNo ratings yet

- Spence - 6 - Safety Relief Valve Sizing - 2nd Edition PDFDocument24 pagesSpence - 6 - Safety Relief Valve Sizing - 2nd Edition PDFJorge DuranNo ratings yet

- Automatic Line Break ControlDocument2 pagesAutomatic Line Break Controlnizam17No ratings yet

- TSC 802 (A)Document2 pagesTSC 802 (A)KarmandeepBrarNo ratings yet

- AGV 10 - Gas Turbine Fuel ValveDocument4 pagesAGV 10 - Gas Turbine Fuel ValvewalidNo ratings yet

- Ebara Variable Speed and Constant Pressure BoosterDocument27 pagesEbara Variable Speed and Constant Pressure BoosternettomdNo ratings yet

- Variable Speed Pump PDFDocument73 pagesVariable Speed Pump PDFSenghy MaoNo ratings yet

- Kaltfrase - BM - 1000 - 1200 - 1300 - 30 - 2 - & - 2 - PB - BK HidraulicoDocument249 pagesKaltfrase - BM - 1000 - 1200 - 1300 - 30 - 2 - & - 2 - PB - BK Hidraulicosebastian blancoNo ratings yet

- HAZOP Worksheet: Node: 11 Type: Drawing: Design Conditions/parametersDocument3 pagesHAZOP Worksheet: Node: 11 Type: Drawing: Design Conditions/parametersAminNo ratings yet

- SCMS 7035Document5 pagesSCMS 7035Jose Manuel CastroNo ratings yet

- NLB Back Pressure Valves Brochure 032613Document9 pagesNLB Back Pressure Valves Brochure 032613EquilibarNo ratings yet

- Hose Pressure Test Pump (Air-Powered) : Part No DC27530Document2 pagesHose Pressure Test Pump (Air-Powered) : Part No DC27530omernoumanNo ratings yet

- CRDI TroubleshootingDocument16 pagesCRDI TroubleshootingRadu Soptea100% (1)

- Models A & B Automatic Pressure Maintenance DevicesDocument4 pagesModels A & B Automatic Pressure Maintenance DevicesHIDRUCOL SASNo ratings yet

- Valves Deluge Valve Model h3-bkp-03-04-2018Document16 pagesValves Deluge Valve Model h3-bkp-03-04-2018Benny Kurniawan LimNo ratings yet

- Valves Deluge Valve Model h3Document16 pagesValves Deluge Valve Model h3RaviNo ratings yet

- FlowCon PICV Write OutDocument17 pagesFlowCon PICV Write OutmajortayNo ratings yet

- Pressure RegulatorDocument4 pagesPressure RegulatorRICHIHOTS2No ratings yet

- TF500 22a - PV3 300 16Document6 pagesTF500 22a - PV3 300 16Jimmy HaddadNo ratings yet

- Connell ArticleDocument5 pagesConnell ArticleJames Harden100% (1)

- Pressure Independent Control ValveDocument12 pagesPressure Independent Control Valvekya_leyNo ratings yet

- Pressure Independent Control ValveDocument16 pagesPressure Independent Control ValverakamechNo ratings yet

- Regulador AxialDocument12 pagesRegulador Axialluis_d_mNo ratings yet

- Wet Pilot TypeDocument15 pagesWet Pilot TypeDipanjan ChakrabartiNo ratings yet

- Aircraft SystemDocument188 pagesAircraft SystemSamarth SNo ratings yet

- Prospekt-PSG - 20 - 12 10 - EnglischDocument22 pagesProspekt-PSG - 20 - 12 10 - EnglischMugeshNo ratings yet

- PRM FRDocument7 pagesPRM FRGelber Norberto Gutierrez PalaciosNo ratings yet

- Ig SystemDocument28 pagesIg SystemDamithaNo ratings yet

- Back Pressure Control On An Alternator Based System1Document3 pagesBack Pressure Control On An Alternator Based System1Anonymous xKEjITvij2No ratings yet

- Linde Synchron Control BrochureDocument24 pagesLinde Synchron Control BrochurethierrylindoNo ratings yet

- Pneumatic Actuator ElementsDocument49 pagesPneumatic Actuator Elementsdk.vermaNo ratings yet

- Valves Deluge Valve Model h3Document16 pagesValves Deluge Valve Model h3Peter Keith Vela RuizNo ratings yet

- Pressure ControlDocument12 pagesPressure ControlMohamed RashedNo ratings yet

- Operation and Maintenance Manual: AA-75CFDocument12 pagesOperation and Maintenance Manual: AA-75CFjcgm2209No ratings yet

- Double Solenoid Valve Combined Pressure Regulator and Safety Valves Servo Pressure Regulator MBC-... - SE DN 65 - DN 100Document8 pagesDouble Solenoid Valve Combined Pressure Regulator and Safety Valves Servo Pressure Regulator MBC-... - SE DN 65 - DN 100Adilson Melo de MouraNo ratings yet

- PRR Engineering, DataDocument4 pagesPRR Engineering, DataMauricio CamposNo ratings yet

- Automatic Recirculation Valve BrochureDocument12 pagesAutomatic Recirculation Valve BrochureYuvaraj NithyanandamNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- 3 Phase Hall Motor Driver Ic: FeaturesDocument12 pages3 Phase Hall Motor Driver Ic: FeaturesSoro FoxNo ratings yet

- Manual Pic18f4550 MicrochipDocument438 pagesManual Pic18f4550 MicrochipcacasecacacasecaNo ratings yet

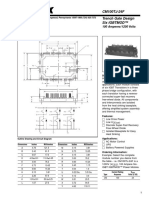

- CM100TJ-24F: 100 Amperes/1200 VoltsDocument4 pagesCM100TJ-24F: 100 Amperes/1200 VoltsSoro FoxNo ratings yet

- PIC24FJ128GA606 Microchip PDFDocument470 pagesPIC24FJ128GA606 Microchip PDFSoro FoxNo ratings yet

- CM400HU-24F MitsubishiElectricSemiconductorDocument4 pagesCM400HU-24F MitsubishiElectricSemiconductorSoro FoxNo ratings yet

- 18F4550 MicrochipTechnologyDocument6 pages18F4550 MicrochipTechnologySoro FoxNo ratings yet

- PIC16 F 627 ADocument180 pagesPIC16 F 627 AAlan Yair Hernandez GonzalezNo ratings yet

- Ip-7900-26 Ip-7700-26 Bog en 04 79365 PDFDocument134 pagesIp-7900-26 Ip-7700-26 Bog en 04 79365 PDFSoro FoxNo ratings yet

- APOGEE Prepress 8.0: Installation GuideDocument106 pagesAPOGEE Prepress 8.0: Installation GuidePhishing Withtom100% (1)

- TN PrintDrive Support and ReferenceDocument82 pagesTN PrintDrive Support and ReferenceSoro Fox67% (3)

- Reflective Photosensor (Photoreflector) : DatasheetDocument5 pagesReflective Photosensor (Photoreflector) : DatasheetSoro FoxNo ratings yet

- These Two Scripts (Xcalibur45Edgelefttestpqs and Stability of The Left and Right Edge DetectionDocument2 pagesThese Two Scripts (Xcalibur45Edgelefttestpqs and Stability of The Left and Right Edge DetectionSoro FoxNo ratings yet

- Equipment Maintenance Scheduler (EMS)Document11 pagesEquipment Maintenance Scheduler (EMS)Soro FoxNo ratings yet

- Galileo VXT - Auto Exposure Test On Plate: Technical NoteDocument2 pagesGalileo VXT - Auto Exposure Test On Plate: Technical NoteSoro FoxNo ratings yet

- TN PrintDrive Support and ReferenceDocument82 pagesTN PrintDrive Support and ReferenceSoro Fox67% (3)

- Fiery E100 Configuration and SetupDocument59 pagesFiery E100 Configuration and SetupSoro FoxNo ratings yet

- Avalon LF Site Survey Rev ADocument25 pagesAvalon LF Site Survey Rev ASoro FoxNo ratings yet

- CAYIBA Version 2Document4 pagesCAYIBA Version 2Soro FoxNo ratings yet

- Equipment Maintenance Scheduler (EMS)Document11 pagesEquipment Maintenance Scheduler (EMS)Soro FoxNo ratings yet

- Adding The Control, Rigidity and Power of Hydraulics To A Pneumatic MachineDocument5 pagesAdding The Control, Rigidity and Power of Hydraulics To A Pneumatic MachineSoro FoxNo ratings yet

- Merlin Chiller M33 Service ManualDocument78 pagesMerlin Chiller M33 Service ManualSoro FoxNo ratings yet

- CAYIBA Version 2Document4 pagesCAYIBA Version 2Soro FoxNo ratings yet

- TH - Auto-Aligning System ManualDocument10 pagesTH - Auto-Aligning System ManualSoro FoxNo ratings yet

- The Specification Information of The E3041 Hotel Door LockDocument2 pagesThe Specification Information of The E3041 Hotel Door LockSoro Fox0% (1)

- Orbita Hotel Lock Manual of CMifare-1.1Document22 pagesOrbita Hotel Lock Manual of CMifare-1.1Soro FoxNo ratings yet

- ORBITA Handset - Usual - Manual-1.1Document11 pagesORBITA Handset - Usual - Manual-1.1Soro FoxNo ratings yet

- Datasheet ULM2083 Relais DriverDocument9 pagesDatasheet ULM2083 Relais DriverArno StampsNo ratings yet

- A8 Operation Instruction-ZDocument70 pagesA8 Operation Instruction-ZSoro FoxNo ratings yet

- R260, R265, R270, R360, R380, R390Document150 pagesR260, R265, R270, R360, R380, R390Proffisional ShopinrioNo ratings yet

- Kit Installation Instruction: Siemens Industry, IncDocument12 pagesKit Installation Instruction: Siemens Industry, IncKiaraNo ratings yet

- Bright 6 CarDocument1 pageBright 6 CarToby HarrisNo ratings yet

- 652b33e4fd19962a336aa48c PamofakemagugoxavoDocument2 pages652b33e4fd19962a336aa48c Pamofakemagugoxavoericblackberry57No ratings yet

- Electro Motion Machine Tools Stock ListDocument13 pagesElectro Motion Machine Tools Stock ListElectro Motion UK (Export) LtdNo ratings yet

- LV Catalogue 2017Document132 pagesLV Catalogue 2017Ariel DimacaliNo ratings yet

- Power 6393: Power 6393, Modular Power SupplyDocument2 pagesPower 6393: Power 6393, Modular Power Supplyghhg ioiiNo ratings yet

- Aleph J ManualDocument6 pagesAleph J ManualasenmtNo ratings yet

- Mid Term Problem 3 SolvedDocument13 pagesMid Term Problem 3 Solveddougie109No ratings yet

- Tech Manual: Tech-5.12 10M Ec Combi Large SHRDocument260 pagesTech Manual: Tech-5.12 10M Ec Combi Large SHROvRrj AhmedNo ratings yet

- Inverter - Solaredge - Installation-Manual - SE3800A-US InstallationDocument7 pagesInverter - Solaredge - Installation-Manual - SE3800A-US InstallationAl0% (1)

- 501-12 Instrument Panel and Console PICKUP JMCDocument5 pages501-12 Instrument Panel and Console PICKUP JMCRusonegroNo ratings yet

- Sistem Pengoperasian PltuDocument21 pagesSistem Pengoperasian PltuNizar AlfianNo ratings yet

- CEWE Prometer: Precision MeteringDocument2 pagesCEWE Prometer: Precision MeteringEric DondebzangaNo ratings yet

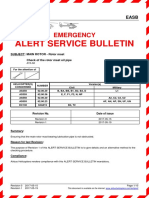

- Alert Service Bulletin: EmergencyDocument13 pagesAlert Service Bulletin: EmergencyRaymond ZamoraNo ratings yet

- Qy160v633 Opertaion ManualDocument299 pagesQy160v633 Opertaion ManualИванNo ratings yet

- Sheet Contents Revision Info RevisionDocument21 pagesSheet Contents Revision Info RevisionEber SoncoNo ratings yet

- AUTOMATIC RAILWAY GATE CONTROLLER-reportDocument57 pagesAUTOMATIC RAILWAY GATE CONTROLLER-reportAnarsinh Solanki75% (8)

- SEL-TBD-I-DS-021 - R0 - Data Sheet For MSAI Flow Transmitter - SignDocument4 pagesSEL-TBD-I-DS-021 - R0 - Data Sheet For MSAI Flow Transmitter - SignhadiNo ratings yet

- 03 - Statron Technical Datasheet - Item 3.0-DikonversiDocument16 pages03 - Statron Technical Datasheet - Item 3.0-DikonversiteleangNo ratings yet

- Fire Sprinkler System Testing FormDocument2 pagesFire Sprinkler System Testing FormDaniel Flores100% (1)

- Desmontar SalpicaderoDocument7 pagesDesmontar SalpicaderoGary BallNo ratings yet

- GSP600 Sub-Prime® Electric Submersible Dewatering Pumps: Features SpecificationsDocument2 pagesGSP600 Sub-Prime® Electric Submersible Dewatering Pumps: Features SpecificationsAbcehmu EgiNo ratings yet

- ATX Power Supply Pinout TablesDocument4 pagesATX Power Supply Pinout TablesElectrical EEENo ratings yet

- BK9105Document2 pagesBK9105joshi_ragsNo ratings yet

- ALFA 3K 5K ManualDocument46 pagesALFA 3K 5K ManualAamir TajNo ratings yet

- Compresor SanyoDocument14 pagesCompresor Sanyoroy_velasquez939No ratings yet

- MGL EFIS User Manual PDFDocument151 pagesMGL EFIS User Manual PDFPOUETNo ratings yet

- Ur3 Technical DetailsDocument1 pageUr3 Technical DetailszruscicNo ratings yet

- Signal Line 256 Gray Level 3 Channel Constant Current LED Driver ICDocument8 pagesSignal Line 256 Gray Level 3 Channel Constant Current LED Driver ICsteven MelgarejoNo ratings yet

- 2018 019 Lcac Dc-Inverter Air Conditioner Service Manual A++v1.4Document146 pages2018 019 Lcac Dc-Inverter Air Conditioner Service Manual A++v1.4Elson Dellinghausen Da CostaNo ratings yet