Professional Documents

Culture Documents

Adding The Control, Rigidity and Power of Hydraulics To A Pneumatic Machine

Uploaded by

Soro FoxOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adding The Control, Rigidity and Power of Hydraulics To A Pneumatic Machine

Uploaded by

Soro FoxCopyright:

Available Formats

Series: hydraulic-type control in pneumatic machinery

Adding

Adding the

the control,

control, rigidity

rigidity and

and power

power

of

of hydraulics

hydraulics to

to aa pneumatic

pneumatic machine

machine

FABCO-AIR – www.fabco-air.com – phone 1-352-373-3578

Control with Air-Oil Tanks Three (3) pistons are simultaneously pressurized

for the power stroke; one (1) drives the retract

Air-Oil tanks provide a nice alternative to hydraulic

stroke. At 90 psi, the three piston thrust will be

systems when precise cylinder motion is required.

over 5,000 pounds. More than enough for the job

They cost less and take up far less space. No pumps.

at hand.

No noisy motors. No relief valves or the like. And

of course, installation is a lot simpler too.

In combination with off-the-shelf air valves, air-oil

tanks enable precise, smooth cylinder motion with

absolute control using basic shop air pressure.

Baffles separate

Fabco-Air’s Air-Oil tanks are available in single the three pistons

tank and space-saving double tank versions with and have vents

bore (I.D.) sizes of 1-1/4”, 2” and 4” to suit most to atmosphere

applications.

F55 Series Press shown with customer tooling

Controlling speed and shock-

As you know, we must make accommodations for

the inertial and impact forces that will be released

when our tooling breaks through the work piece.

To capture these potentially destructive forces,

Fabco-Air Air-Oil Tanks: 2” Bore x 9” high and prevent damage to the power cylinder and

tooling, an air-over-oil tank is incorporated in the

Single Tank Units - circuit between the directional control valve and

Single tanks are used when hydraulic control of the the cylinder return port.

cylinder is required in one direction only. If there is any

Air Supply

question as to the integrity of the piston seal, a double

tank is recommended. Single Tank Units are also used as Muffler

fluid storage tanks for boosters, hydraulic shock options,

Directional Control

and other applications. Double Tank Units are used when 4-Way Air Valve

hydraulic control of the cylinder is required in both direc-

tions. The one-piece heads that hold both tanks simplify

mounting and save space. Single Tank

Air-over- Oil

Using a single Air-Oil Tank with

the power cylinder on an air press

Flow Control Valve

Let’s assume we want to punch holes in a stack of

laminations. We’ll use one of Fabco-Air’s Multi-

Power Cylinder

Power® air presses in this example. The power unit

of the press is a 5” bore, force-multiplying air cyl-

inder with three pistons.

Figure 1. Air-over-oil shock control circuit

FABCO-AIR, Inc. • www.fabco-air.com • service@fabco-air.com

Series: hydraulic-type control in pneumatic machinery

FABCO-AIR – www.fabco-air.com – phone 1-352-373-3578

How it works– Tips for using Air-Oil Systems -

Fluid in the tank is used for the cylinder’s return 1 The best control is achieved by installing the speed

media only. (Reference Figure 1, previous page.) control valves so that the fluid being forced out of the

Fluid flow and cylinder speed can be controlled by cylinder is being controlled.

a needle or flow control valve. In our example we 2 The piping between the cylinder and the speed

have chosen a flow control valve because we want to controlling valve should be rigid enough to maintain

control the speed of the “work” stroke while allowing the required rigidity of the system.

a full speed retract stroke. When the material shears

and the cylinder tries to complete the stroke, the 3 It is best to mount the tanks so that the bottoms of

non-compressible fluid resists rapid movement. It the tanks are higher than the cylinder. Cylinder ports

“catches” the built-up forces, dissipating them before should be up with piping running as straight as pos-

the cylinder can bottom out. Thus the piston won’t sible to the tanks. This aids in purging the cylinder of

“pound” on the piston stop. air, by allowing the air to rise through the piping and

into the tank where it will dissipate.

Two-Speed work stroke with shock control - Monitoring fluid through the translucent fiberglass

With a slight modification to the circuit in Figure 1, 1 The highest fluid level should be kept reasonably

using a sequence valve, a needle valve and a shut-off near the top baffle to avoid excessive air usage, provid-

valve, our single air/oil tank provides us with 2-speed ing the quickest cycle reversal, and to allow for possible

work stroke operation shown in Figure 2 below. fluid loss.

2 If the fluid levels in the tanks become unbalanced,

the fluid is bypassing the cylinder’s piston seal. This

Muffler can occur in a new cylinder with U-Cups designed

for air service or side loading on the piston rod. In old

systems the bypass can be a result of seal and cylinder

wear, seal shrinkage, or other reasons. A crossover

valve can allow for tank balancing. (See Figure 4.)

3. Fluid aeration and foaming can reduce intended

cylinder control and make its operation “mushy.”

Properly designed air-oil tanks have special baffling

top and bottom which eliminates such disturbance.

(Figure 3.)

Fill Flow Port

Port

Translucent Custom molded

fiberglass Buna-N tube

tube seal

Baffles force fluid or

air to sides of tank, Usable

eliminating surface Oil

Figure 2. Two-Speed work stroke with shock control disturbance, Capacity

aeration & foaming

Quiet zone

below baffle Brass baffle

The sequence is as follows: plate for plates, tube, &

sediment to spacers, top &

1. Rapid “extend” stroke to approach the work. settle out bottom

2. Automatic switch to controlled rate when resistance

is met and pressure builds up to the point where a

Fabco-Air RV “Sequence Valve” actuates the 2-way Drain Flow

Port

shut-off valve forcing fluidflow through the speed Port

controlling needle valve. (See page 5 for RV info)

3. Fluid catches the cylinder motion, thus controlling Figure 3. Fabco-Air Single tank construction

the shock that could otherwise occur. highlighting the engineered baffle system

4. Automatic return to rapid rate on the “Cylinder

Retract” stroke.

Page 2

Series: hydraulic-type control in pneumatic machinery

FABCO-AIR – www.fabco-air.com – phone 1-352-373-3578

Double Air-Oil Tanks - Now... Add hydraulic power

Earlier we discussed controlling cylinder speed in

one direction only. When control is required in both

with a pneumatic booster

directions, two air-oil tanks are needed. As you can Combining an Air-Oil Tank with a pressure booster

see from the circuit shown below, double Air-Oil provides a convenient, low cost way of adding the

Tanks used in conjunction with two flow control control, rigidity, and power of hydraulics to an air

valves enables hydraulic control with one speed in powered machine. Fabco-Air Multi-Power® Boosters

each direction. use basic shop air to raise the pressure of another gas

or liquid. They are compact and versatile finding use

Air Supply

in numerous applications such as clamping, shearing,

Muffler pressing, crimping, bending, testing, and many more.

Directional Control Two considerations-

Valve 4-Way – Air

(1) When relatively small volumes of high-pressure

fluid are called for intermittently, boosters show obvi-

Double

Air - Oil

ous advantages over continuously running hydraulic

Tanks systems.

(2) For applications where high pressure must be

Crossover

and shut off maintained for prolonged times, boosters are ideal.

provide easy After the booster strokes, there is no further energy

Flow balancing of input required and no heat build up.

Control tank levels

A booster can be mounted in almost any convenient

Cylinder

location, and most of its control valves are installed in

the low-pressure circuit where lower cost components

Figure 4.Controlling speed in two (2) directions save costs over hydraulics.

How they work -

The input is shop air, or any compatible gas, up to 150

Bi-Directional, Two-Speed Stop & Hold

psi; the output can be oil, liquid, air, or gas pressurized

Here’s another helpful circuit showing double Air- to 500 psi maximum. Multiple pistons compress the

Oil Tanks used with shut-off valves & needle valves oil or fluid in the output end of the booster. Check

to provide: valves insure the direction of fluid flow.

(1) Stop & hold in either direction at any point in

cylinder travel.

(2) Choice of rapid or control rate in either di- Gravity Feed Oil or Fluid

Atmospheric Pressure: Air or Gas

Air into Multiple

rection at any point of cylinder travel. Check Valve

Not Furnished Air into Single Pistons for Power

Piston for Reset Stroke.

Piston Center Stroke 30 psi

Shaft Minimum

Input

Cap End

Plug

Output Driving

End End

Nut

Tube

Seal Pilot

Washer

Piston

Piston Baffle Baffle Piston

Seals Seal Stop

Check Valve

Not Furnished

High (Boosted) Pressure Output 500 psi Maximum

Figure 6. Function of 2-stage Pressure Booster

In Figure 6 above we show only two (2) pistons. But

Fabco-Air boosters can have as many as five (5) pistons

Figure 5. Bi-directional, 2-speed, stop & hold driving the output.

Page 3

Series: hydraulic-type control in pneumatic machinery

FABCO-AIR – www.fabco-air.com – phone 1-352-373-3578

Sizing boosters - Booster becomes a Pump

By selecting the proper combination of bore size, Adding a magnet piston enables position sensing.

stroke, power factor (determined by number of pis- Electronic sensors can then control a 4-way solenoid

tons) and regulating the input air pressure, the exact valve causing the booster pistons to reciprocate and

output pressure and required volume can be achieved pump high pressure liquid. Exhaust liquid is returned

and maintained. to the tank’s top port from the driven device.

Available sizes: 2-1/2” and 4”bores

Outputs: 4.9 or 12.5 cu. in. per inch of stroke.

Strokes 1” to 12”.

Atmosphere Regulated Supply Controls Final

Fabco-Air BA Series 2-stage Output Pressure of Booster

Pressure Booster

see more info on boosters

Air/Oil Tank

Versatility - 4 Way Control Valve

Since it is a basic booster without controls built-in, Check Valve

it can be adapted and controlled to perform a wide

variety of applications. Fabco-Air boosters are not Output End Driving End

limited to cylinder applications. They may be used

wherever a small volume of high-pressure media is

required.

BA Series

The BA Series is built for use on systems in which Booster with

Option E

the input to the booster will be gravity fed (no pres- Check Valve Magnetic Piston

sure) fluid or atmospheric pressure gas. It requires a Sensors for Piston

Gage Position Sensing

4-way air valve for operation. Porting is provided on

the booster for the multiple piston power stroke and Figure 7. BA Booster used as pump

single piston reset stroke. with Air-Oil tank reservoir

One-shot Holding Cycle

Here a single tank air-to-oil booster feeds two (2)

clamping cylinders. The clamp-off position of the

4-way pneumatic control releases the clamp cylinders

Booster benefits

and simultaneously opens the pilot-operated check

valve allowing oil to flow back into the tank. • Low initial cost: Boosters can eliminate

the need for costly hydraulic systems.

Atmosphere Regulated Supply Controls Final

Output Pressure of Booster • Low energy cost: Boosters hold pressure

Air/Oil indefinitely without energy loss.

Tank

• Save space: Boosters can usually be

4 Way Control Valve mounted directly on the machine

unlike pumping units which are large

Pilot Operated

Check Valve and bulky.

BA Series Booster • Smooth power: Boosters give a cylinder

the rigid, smooth, controlled motion of

Output End Driving End hydraulics.

• Safe: Boosters can be completely air

operated to function safely in a

potentially hazardous environment.

Gage

Work

Cylinders

Figure 7. BA Booster one-shot holding circuit

Page 4

Series: hydraulic-type control in pneumatic machinery

FABCO-AIR – www.fabco-air.com – phone 1-352-373-3578

Nice to know - Also nice -

When you don’t need hydraulic control, but just need The sequence valve used back on page 2, Figure 2,

to bump up your air pressure, the BP Series air boosters is our RV pressure sensing valve. We find it in use

will do the trick with pressure outputs up to 500 psi! in all sorts of applications, providing pilot signals

from adjustable setpoints. Available in 1/8” and 1/4”

Pressurized Input to Booster

NPT sizes.

and to Reset (30 psi Minimum)

Air into Multiple

Check Valve Pistons for Power

Not Furnished

Stroke.

Piston Center Atmospheric 30 psi

Shaft Vent Minimum

Input

Cap End

Plug

Output Driving

End End

Nut Cut-away view of a Fabco-Air

Tube

Seal

RV Sequence Valve

Pilot

Washer

Piston Read more about it in either of these white papers

Piston Baffle Piston

Seals Seal Baffle Stop on our website www.fabco-air.com

Check Valve

Not Furnished

High (Boosted) Pressure Output 500 psi Maximum

Maintaining exact forces for best

Figure 7. BP Series Booster construction results with a pneumatic press.

This series is built for use on systems in which the Controlling cylinder forces with a

input to the booster will be pressurized fluid or gas. pressure sensing valve.

It requires a 3-way air valve for operation. Porting is

provided on the unit for the power stroke only. When

power stroke air is removed, the pressurized booster ❖

input will reset the pistons.

about FABCO-AIR

since 1958

With operations housed in 61,000 sq. ft. in Gainesville, Florida,

Fabco is dedicated to developing and providing advanced fluid

power technology to give our customers the competitive edge

One of Fabco-Air's 24/7 lights-out machining centers they need in their field.

24/7 lights-out precision machining centers drive production,

assure product quality and enable reliable delivery.

Fabco has all the popular off-the-shelf pneumatic components you

want, ready for immediate shipment. Yet almost half of our business

comes from helping customers solve design problems with special

pneumatic solutions. We can design, prototype and deliver custom

samples within 72 hours! Fabco-Air solves problems. Let us help!

Fabco-Air, Inc. • 3716 NE 49th Ave. •Gainesville, FL 32609-1699

Page 5

You might also like

- Volvo L350F Manual PDFDocument251 pagesVolvo L350F Manual PDFAdmin Test100% (2)

- Emd-Mi1144 Compresor WBO WBGDocument27 pagesEmd-Mi1144 Compresor WBO WBGVictor Raul Tobosque Muñoz100% (3)

- Hydraulic Ram SlideshowDocument26 pagesHydraulic Ram SlideshowAbhishek Patil100% (1)

- MA-4 Carb ManualDocument34 pagesMA-4 Carb Manualayazkhan797100% (1)

- Structure and FunctionDocument88 pagesStructure and FunctionEko Sunaryo100% (2)

- Steam Turbine ValvesDocument16 pagesSteam Turbine ValvesBradley Nelson100% (5)

- Aircraft Systems CourseDocument57 pagesAircraft Systems CourseAttakaththi DineshNo ratings yet

- Orbita Hotel Lock Manual of CMifare-1.1Document22 pagesOrbita Hotel Lock Manual of CMifare-1.1Soro FoxNo ratings yet

- RT-96 - Exhaust Valve Spindle LubricationDocument6 pagesRT-96 - Exhaust Valve Spindle LubricationGeorgios MariolisNo ratings yet

- Introduction To Gas Removal Systems and Liquid Ring Vacuum PumpsDocument3 pagesIntroduction To Gas Removal Systems and Liquid Ring Vacuum PumpsDheeraj ShuklaNo ratings yet

- Hidrl1 PDFDocument7 pagesHidrl1 PDFRajesh Kumar100% (1)

- Service Instructions: Oilgear Type "PVV 540" Open Loop PumpsDocument14 pagesService Instructions: Oilgear Type "PVV 540" Open Loop PumpsAxel LetonaNo ratings yet

- Ip-7900-26 Ip-7700-26 Bog en 04 79365 PDFDocument134 pagesIp-7900-26 Ip-7700-26 Bog en 04 79365 PDFSoro FoxNo ratings yet

- Chapter 5 - Basic Fluid Power SystemsDocument11 pagesChapter 5 - Basic Fluid Power SystemsDedi SetionoNo ratings yet

- Yarway Valve DesignDocument12 pagesYarway Valve DesignwaqashabibNo ratings yet

- Hibon Blover Genel KatalogDocument40 pagesHibon Blover Genel KatalogRudy Rere Simamora100% (2)

- TN PrintDrive Support and ReferenceDocument82 pagesTN PrintDrive Support and ReferenceSoro Fox67% (3)

- TN PrintDrive Support and ReferenceDocument82 pagesTN PrintDrive Support and ReferenceSoro Fox67% (3)

- Valve Actuator Torque CurvesDocument4 pagesValve Actuator Torque CurvesyogitatanavadeNo ratings yet

- Wet Pipe Sprinkler System Spec - 072314Document7 pagesWet Pipe Sprinkler System Spec - 072314Hai PhamNo ratings yet

- Understanding Valve & Their FunctionsDocument30 pagesUnderstanding Valve & Their FunctionsMan ThiNo ratings yet

- Librito de Partes WatersDocument312 pagesLibrito de Partes WatersJonathanCubillosSerratoNo ratings yet

- Pneumatic Design 101Document6 pagesPneumatic Design 101azrockclimberNo ratings yet

- Air Box DrainsDocument12 pagesAir Box DrainsLuwīsi Karikamo RomaniNo ratings yet

- Selecting Motorized Valves: For HVAC ControlDocument4 pagesSelecting Motorized Valves: For HVAC ControlNATHANNo ratings yet

- Pump Minimum Flow Protection Using Automatic Recirculation ValvesDocument6 pagesPump Minimum Flow Protection Using Automatic Recirculation ValvesJose Rodrigo Salguero DuranNo ratings yet

- Research Paper On Aircraft Hydraulic SystemDocument6 pagesResearch Paper On Aircraft Hydraulic Systemgw32pesz100% (1)

- TW HeatlssDocument12 pagesTW Heatlssherysyam1980No ratings yet

- Air Release Valve Sizing Chart - How To Choose The Right ValveDocument6 pagesAir Release Valve Sizing Chart - How To Choose The Right ValveopetakyNo ratings yet

- AirValveforFireProtection - 6 1 18Document6 pagesAirValveforFireProtection - 6 1 18AhmAd GhAziNo ratings yet

- Cag I Air Compressor HPDocument5 pagesCag I Air Compressor HPsudarwantoNo ratings yet

- Final Control Elements Performance CharacteristicsDocument16 pagesFinal Control Elements Performance CharacteristicsSanchit KhannaNo ratings yet

- U11 Fluid Power DevicesDocument6 pagesU11 Fluid Power Devicesmaitham100No ratings yet

- Aeroplanes 2 (Essay)Document13 pagesAeroplanes 2 (Essay)Kishan YashwardeoNo ratings yet

- Ngineering ATA: Fan Damper SelectionDocument4 pagesNgineering ATA: Fan Damper SelectionMohamed TahounNo ratings yet

- CHW Plant Design Guide SummaryDocument6 pagesCHW Plant Design Guide SummaryMarc KennethNo ratings yet

- Pneumatic Systems: 5-1. Schematic Drawing of A Hydraulic Circuit, and Physical Drawing of The Components in The CircuitDocument8 pagesPneumatic Systems: 5-1. Schematic Drawing of A Hydraulic Circuit, and Physical Drawing of The Components in The Circuitmuhd_danialNo ratings yet

- About Control ValvesDocument17 pagesAbout Control ValvesSaurabh BarangeNo ratings yet

- Twintower, Heatless, Regenerative Compressed Air Dryers - 8-75 CFM Models (PDF, 913KB)Document4 pagesTwintower, Heatless, Regenerative Compressed Air Dryers - 8-75 CFM Models (PDF, 913KB)Sudar MyshaNo ratings yet

- Operating a Single Acting Pneumatic CylinderDocument8 pagesOperating a Single Acting Pneumatic CylinderAliyu omeiza YusufNo ratings yet

- LIT VS Series VS01EDocument11 pagesLIT VS Series VS01EManuel Flores100% (1)

- Criterios de VA y VD AWWA M11Document3 pagesCriterios de VA y VD AWWA M11nicolas3000No ratings yet

- PRR Engineering, DataDocument4 pagesPRR Engineering, DataMauricio CamposNo ratings yet

- Boiler Auxiliaries: Safety and Relief ValvesDocument24 pagesBoiler Auxiliaries: Safety and Relief Valvesnelson escuderoNo ratings yet

- MCT 2Document3 pagesMCT 2Sylesh SreehariNo ratings yet

- .Fabrication of Air Hybrid TricycleDocument4 pages.Fabrication of Air Hybrid TricycleRishikesh GunjalNo ratings yet

- 0802 B GeneratorsDocument77 pages0802 B GeneratorsAI Sari DewiNo ratings yet

- Fan Damper Selection Fe 2600Document4 pagesFan Damper Selection Fe 2600Guilherme AugustoNo ratings yet

- Brake Systems Used by IRDocument46 pagesBrake Systems Used by IRSagar BhaiNo ratings yet

- Cf-Fa12-Dpt 154 2227 12261194719Document125 pagesCf-Fa12-Dpt 154 2227 12261194719اشرينكيل مسونكيلNo ratings yet

- Reliableb1acc 1Document6 pagesReliableb1acc 1salajeanuNo ratings yet

- Trans DLDocument3 pagesTrans DLAlaaNo ratings yet

- Air Brake RDSO Report 0159 Rev - 0 Jan - 2013Document149 pagesAir Brake RDSO Report 0159 Rev - 0 Jan - 2013Niking Thomsan0% (1)

- Im 306Document10 pagesIm 306Iwan SetiawanNo ratings yet

- F51 450 FP AccessoriesDocument4 pagesF51 450 FP AccessoriesFayez Al-ahmadiNo ratings yet

- Case Study Bonus Project Ahmed ShammaDocument10 pagesCase Study Bonus Project Ahmed ShammaAhmed ShammaNo ratings yet

- IR Ower LossaryDocument7 pagesIR Ower LossaryiconoclasticjarheadNo ratings yet

- Compressor Types and SelectionDocument14 pagesCompressor Types and SelectionweirdwolfvortexNo ratings yet

- MiniVac OIM ManualDocument10 pagesMiniVac OIM ManualGiorgiana RosuNo ratings yet

- Datos Tecnicos Quemador OVENPAK 400 PDFDocument8 pagesDatos Tecnicos Quemador OVENPAK 400 PDFIsaias de la CruzNo ratings yet

- OVENPAK® 400 Gas Burners: Instruction ManualDocument8 pagesOVENPAK® 400 Gas Burners: Instruction ManualIsaias de la CruzNo ratings yet

- Fuel System Components 1. Fuel TanksDocument6 pagesFuel System Components 1. Fuel TanksRebecca Lepon LegaspiNo ratings yet

- Fuel System Components 1. Fuel TanksDocument6 pagesFuel System Components 1. Fuel TanksRebecca Lepon LegaspiNo ratings yet

- Submarine Main Propulsion Diesels - Chapter 6Document11 pagesSubmarine Main Propulsion Diesels - Chapter 6Michael ChungNo ratings yet

- Convair New Tanker Operation & Maintenance Manual Nov 2010Document24 pagesConvair New Tanker Operation & Maintenance Manual Nov 2010franktreviNo ratings yet

- Air Brake SystemsDocument48 pagesAir Brake SystemsBaD BoYNo ratings yet

- ISO 9001 Maintenance Guide for Cooling TowersDocument9 pagesISO 9001 Maintenance Guide for Cooling TowersShanooziya KhanNo ratings yet

- AVK Air Release ValvesDocument12 pagesAVK Air Release ValvesAr JunNo ratings yet

- What Is The True Cost of Static PressureDocument8 pagesWhat Is The True Cost of Static PressuremarcalpiNo ratings yet

- Boiler FixtureDocument10 pagesBoiler FixtureMohd ZafreNo ratings yet

- 3 Phase Hall Motor Driver Ic: FeaturesDocument12 pages3 Phase Hall Motor Driver Ic: FeaturesSoro FoxNo ratings yet

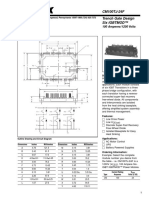

- CM100TJ-24F: 100 Amperes/1200 VoltsDocument4 pagesCM100TJ-24F: 100 Amperes/1200 VoltsSoro FoxNo ratings yet

- PIC16 F 627 ADocument180 pagesPIC16 F 627 AAlan Yair Hernandez GonzalezNo ratings yet

- PIC24FJ128GA606 Microchip PDFDocument470 pagesPIC24FJ128GA606 Microchip PDFSoro FoxNo ratings yet

- CM400HU-24F MitsubishiElectricSemiconductorDocument4 pagesCM400HU-24F MitsubishiElectricSemiconductorSoro FoxNo ratings yet

- Manual Pic18f4550 MicrochipDocument438 pagesManual Pic18f4550 MicrochipcacasecacacasecaNo ratings yet

- 18F4550 MicrochipTechnologyDocument6 pages18F4550 MicrochipTechnologySoro FoxNo ratings yet

- Equipment Maintenance Scheduler (EMS) ConfigurationDocument11 pagesEquipment Maintenance Scheduler (EMS) ConfigurationSoro FoxNo ratings yet

- Galileo VXT - Auto Exposure Test On Plate: Technical NoteDocument2 pagesGalileo VXT - Auto Exposure Test On Plate: Technical NoteSoro FoxNo ratings yet

- These Two Scripts (Xcalibur45Edgelefttestpqs and Stability of The Left and Right Edge DetectionDocument2 pagesThese Two Scripts (Xcalibur45Edgelefttestpqs and Stability of The Left and Right Edge DetectionSoro FoxNo ratings yet

- APOGEE Prepress 8.0: Installation GuideDocument106 pagesAPOGEE Prepress 8.0: Installation GuidePhishing Withtom100% (1)

- Merlin Chiller M33 Service ManualDocument78 pagesMerlin Chiller M33 Service ManualSoro FoxNo ratings yet

- Reflective Photosensor (Photoreflector) : DatasheetDocument5 pagesReflective Photosensor (Photoreflector) : DatasheetSoro FoxNo ratings yet

- Avalon LF Site Survey Rev ADocument25 pagesAvalon LF Site Survey Rev ASoro FoxNo ratings yet

- Problem: Solution:: Inadequate Air Pressure For Clamping A Pneumatic BoosterDocument1 pageProblem: Solution:: Inadequate Air Pressure For Clamping A Pneumatic BoosterSoro FoxNo ratings yet

- CAYIBA Version 2Document4 pagesCAYIBA Version 2Soro FoxNo ratings yet

- Equipment Maintenance Scheduler (EMS) ConfigurationDocument11 pagesEquipment Maintenance Scheduler (EMS) ConfigurationSoro FoxNo ratings yet

- CAYIBA Version 2Document4 pagesCAYIBA Version 2Soro FoxNo ratings yet

- The Specification Information of The E3041 Hotel Door LockDocument2 pagesThe Specification Information of The E3041 Hotel Door LockSoro Fox0% (1)

- TH - Auto-Aligning System ManualDocument10 pagesTH - Auto-Aligning System ManualSoro FoxNo ratings yet

- ORBITA Handset - Usual - Manual-1.1Document11 pagesORBITA Handset - Usual - Manual-1.1Soro FoxNo ratings yet

- A8 Operation Instruction-ZDocument70 pagesA8 Operation Instruction-ZSoro FoxNo ratings yet

- Fiery E100 Configuration and SetupDocument59 pagesFiery E100 Configuration and SetupSoro FoxNo ratings yet

- Eight Darlington Arrays for Multiple Logic TypesDocument9 pagesEight Darlington Arrays for Multiple Logic TypesArno StampsNo ratings yet

- R260, R265, R270, R360, R380, R390Document150 pagesR260, R265, R270, R360, R380, R390Proffisional ShopinrioNo ratings yet

- Castel Check ValveDocument9 pagesCastel Check Valveamin2shahinNo ratings yet

- Gfps System Specification Progef Standard PP en PDFDocument29 pagesGfps System Specification Progef Standard PP en PDFTitus FelixNo ratings yet

- Calculations of Hydraulic CamDocument2 pagesCalculations of Hydraulic CamIago SalvadorNo ratings yet

- VS7 6 8 EuDocument36 pagesVS7 6 8 Eumtc smelterNo ratings yet

- 1009 Bronze Vertical Check Valve (Screwed) : Salient FeaturesDocument28 pages1009 Bronze Vertical Check Valve (Screwed) : Salient FeaturesVignesh NadimuthuNo ratings yet

- Catpump 993330E GUD System DesignDocument20 pagesCatpump 993330E GUD System Designhidrastar123No ratings yet

- In-Line Check Valves: SpecificationsDocument2 pagesIn-Line Check Valves: SpecificationsyorisfmNo ratings yet

- 12 400E 2MC FinalDocument4 pages12 400E 2MC FinalthadanivishalNo ratings yet

- Hydraulic Power Supply System MNT Manual (Curso)Document28 pagesHydraulic Power Supply System MNT Manual (Curso)William Jaldin CorralesNo ratings yet

- Air Driven Hydraulic PumpsDocument32 pagesAir Driven Hydraulic Pumpsdejanr111No ratings yet

- SuperLift Pump ManualDocument9 pagesSuperLift Pump ManualRubenNo ratings yet

- Fundamentals of Piping System PDFDocument24 pagesFundamentals of Piping System PDFravi00098No ratings yet

- Modeling Reference - Hydropneumatic TanksDocument19 pagesModeling Reference - Hydropneumatic Tankspca97No ratings yet

- HuhuDocument18 pagesHuhuMasturah RahmanNo ratings yet

- Methven Nefa Pressure Reducing Valves ReferenceDocument36 pagesMethven Nefa Pressure Reducing Valves ReferenceLen Salisbury100% (1)

- Dry Gas Seal System StandarDocument8 pagesDry Gas Seal System StandarRonny AjaNo ratings yet

- Mechanical Seals For Mixers and Specialty EquipmentDocument16 pagesMechanical Seals For Mixers and Specialty EquipmentHarshal BendaleNo ratings yet

- Maintenance Operating and Service ManualDocument16 pagesMaintenance Operating and Service ManualsaritasohamNo ratings yet

- Technical Specification For ValvesDocument11 pagesTechnical Specification For ValvesSANDESHNo ratings yet

- Application of ValvesDocument4 pagesApplication of ValvesRevathy Kannan100% (1)

- Check TycoDocument6 pagesCheck TycoJosé Ricardo Salinas VillacísNo ratings yet

- English Catalogue POLIXDocument97 pagesEnglish Catalogue POLIXMilos Stojanovic100% (1)