Professional Documents

Culture Documents

355 PDF

355 PDF

Uploaded by

Chandru ChristurajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

355 PDF

355 PDF

Uploaded by

Chandru ChristurajCopyright:

Available Formats

ROBO CRIB TX750

A Breakthrough In Industrial Vending Technology

Incredible Bin Density Dispense Square Packages or Boxes

The system in its most dense (smallest) bin size configuration provides The RoboCrib® TX750 is the first machine that was specifically designed

for up to 987 bins in roughly the same footprint as our other equivalent to dispense square or rectangular boxes or packages. This practically

RoboCrib machines or other competing vending machines. Our patented

®

eliminates the need for repackaging items to fit in helix coil machines or

plastic bin shelf system, mated with the incredibly flexible tambour style door, carousels that use pie shaped bins. The dual tambour approach coupled

gives the machine the ability to virtually eliminate vertical bin “height” waste with a machine that utilizes square bins allows for an incredible amount of

that is common with fixed door machines. flexibility in bin sizes from 2” (5cm) height to 60” (152cm) height.

Dramatically Reduce Maintenance Costs Quickly Configure at the Customer Site

AutoCrib’s vast experience has found that reducing the number of moving The simple user interface takes maximum advantage of the bin density

parts significantly reduces maintenance. Utilizing a dual tambour eliminates and flexibility by simply sliding shelves into a rack. The machine walks you

over 15 separate sub-systems and greatly reduces maintenance costs. through a bin assignment process that is quick and easy. You can set up the

machine with little to no prep work as you perform the initial stock or load.

Automatic Adjusting Door Large 19” Display!

Dispense square/rectangular boxes, Stunning high-resolution 19” (48cm)

MRO items, and other oddly shaped touch display, the largest of any industrial

inventory items. It’s quick and easy to vending machine on the market.

load for restocking.

Intuitive Biometrics

Incredible Density

Sign in using barcodes, prox cards, smart

Increase capacity of your industrial

cards, and mag-stripe ID cards. For

vending machine by 30%, while adding

additional security, integrate fingerprint

incredible flexibility.

validation.

Configure On Site Reduce Maintenance Costs

Plastic shelves can be reconfigured in By reducing the number of moving

minutes without tools. parts, the machine is nearly

maintenance free.

SPECIFICATIONS SOFTWARE

• Patented plastic trays for easy reconfiguration of shelves • Over 200 standard reports!

• High-resolution 19” (48cm) touch display • AutoCrib.net or Client-Server - Cloud managed

• Configurations: Up to 987 SKUs (Unique Products) at 2” (5cm) bin services or secured internal network

height. • EDI - Advanced ship notices (ASN) via EDI

• Weight Capacity: 1,200 lbs (544kg) • ERP system support - Interface with many popular ERP

• Onboard PC: Intel Core i5 Processor systems (SAP, Prophet 21, JDE, Baan, etc…)

• Enclosure Dimensions: • Alerts - Get inventory alerts and email reports to any

-34.1”W (86.6cm) x 79.4”H (201.7cm) x 41.4”D (105.2cm) smartphone, tablet, or computer

-Requires just 9.8 square feet (0.9m ) of floor space!

2

• Seamlessly Connect - Use it with existing AutoCrib®

• Built-in slots for forklift (Optional: Heavy Duty Swivel Caster Wheels) systems or use it as a standalone system

• Power: 100-240VAC– 50/60HZ, 5A/2.5A MAX

• UPS Backup Battery

FEATURES

• 24-7 availability with accountability

• No repackaging required

• Quickly configure on-site

• Dispense square or rectangular boxes or packages

• No bulk stocking required. Use 100% of the machine’s space!

Stock as many or as few SKUs as you want.

• Issue delicate items without dropping

• Fast issue time 10 seconds or less!

• Automated purchase orders

• Control reconditioned items and force regrinds first

• Universal search - Find any item plant-wide!

• Gauge Management - Deny access to a gauge that has fallen out

of calibration

• User Access: Fingerprint, proximity cards, key fobs, mag-stripe

cards, barcodes, keypad/PINs. You can use your existing

employee badges!

• Optional: Caster wheels make it easy to relocate your machines

where you want them

HOW IT WORKS

1. Login – Sign in using your employee badge or employee number. For additional security, require

fingerprint validation.

2. Select Item – Select the item you want.

3. Dispense – The machine automatically finds the right item, opens the dual-tambour to dispense

the product, and unlocks the outside security door.

Optional: You may also track costing data like Department, Job, Machine, Assembly Line, Cost Center,

Customer Number, Tail Number, etc… You can customize the field names to match your needs.

(800)-671-6501 sales@autocrib.com

(714) 274-0400 www.autocrib.com

2882 Dow Avenue Tustin, CA 92780

You might also like

- Compal La-8951p r0.1 SchematicsDocument55 pagesCompal La-8951p r0.1 SchematicsPaulo AmaralNo ratings yet

- Daily Complete Network Administrator Checklist: Review Audit LogsDocument10 pagesDaily Complete Network Administrator Checklist: Review Audit Logshemachandran vNo ratings yet

- Ubuntu Server Essentials - Sample ChapterDocument26 pagesUbuntu Server Essentials - Sample ChapterPackt PublishingNo ratings yet

- Ishida ACP-700 Series Case Packer Brochure (6200)Document10 pagesIshida ACP-700 Series Case Packer Brochure (6200)Kundan KumarNo ratings yet

- Videojet 1880: Continuous InkjetDocument2 pagesVideojet 1880: Continuous InkjetchristopheNo ratings yet

- A20 PDFDocument8 pagesA20 PDFGuillermo Ramirez100% (2)

- Cutting Room Agility and ExcellenceDocument8 pagesCutting Room Agility and Excellenceperro perezNo ratings yet

- AML Monarch Data SheetDocument2 pagesAML Monarch Data SheetMandukotNo ratings yet

- Universal Lathe For Precise and Powerful CuttingDocument12 pagesUniversal Lathe For Precise and Powerful CuttingFabio OliveiraNo ratings yet

- HPlus 405Document16 pagesHPlus 405VishalNo ratings yet

- Brochure 3D AreasensorDocument5 pagesBrochure 3D AreasensorDhananjay gowdaNo ratings yet

- Vc80 Specification Sheet en UsDocument2 pagesVc80 Specification Sheet en UsEdwin BarahonaNo ratings yet

- Vulcan FC500 700datasheetDocument2 pagesVulcan FC500 700datasheetLullaby kalibongNo ratings yet

- Web-Fed Digital Solution For Embossed Hot Foiling and 2D/3D Spot Uv CoatingDocument4 pagesWeb-Fed Digital Solution For Embossed Hot Foiling and 2D/3D Spot Uv CoatingAlexutza StanNo ratings yet

- A-19-06092 WID WIDIA ToolBOSS 2019 Brochure EN HRDocument12 pagesA-19-06092 WID WIDIA ToolBOSS 2019 Brochure EN HRadamkrogulskiNo ratings yet

- VulcanDocument4 pagesVulcanUlisses DurãesNo ratings yet

- Do Cuma Teuk SmallDocument2 pagesDo Cuma Teuk Smalltroy2k0No ratings yet

- Konica Minolta AccurioPress C4080 BrochureDocument12 pagesKonica Minolta AccurioPress C4080 BrochurePablo Emilio Espoz MezaNo ratings yet

- Kt-4Gfxs: Biometric SolutionsDocument2 pagesKt-4Gfxs: Biometric Solutionsjuan carlosNo ratings yet

- Acp 700 SeriesDocument5 pagesAcp 700 SeriesM. Rionaldhie AfpriliansyahNo ratings yet

- LR-38/625S en JPN 16P M61 9 Mar.2016 02K MPDocument8 pagesLR-38/625S en JPN 16P M61 9 Mar.2016 02K MPLe Thanh HuyNo ratings yet

- Highcon Beam: Digital Cutting and Creasing For Mainstream ProductionDocument4 pagesHighcon Beam: Digital Cutting and Creasing For Mainstream ProductionshruthiNo ratings yet

- أكشاك المسار الذكية من SITA - وضع العلامات الذاتي لـ TS6Document2 pagesأكشاك المسار الذكية من SITA - وضع العلامات الذاتي لـ TS6khalid alkhudhirNo ratings yet

- Specifikacii DCS3500EDocument2 pagesSpecifikacii DCS3500EMiki MitevskiNo ratings yet

- SaintyCo Data-Sheet - Smart-Plus-Tablet-PressDocument6 pagesSaintyCo Data-Sheet - Smart-Plus-Tablet-PressJamall EllisNo ratings yet

- MGI JETvarnish 3D EvoDocument6 pagesMGI JETvarnish 3D EvoSusanta BhattacharyyaNo ratings yet

- UX Series BrochureDocument28 pagesUX Series BrochureNelson CofréNo ratings yet

- Videojet 1220Document2 pagesVideojet 1220Roking Kumar100% (1)

- TIJ Printer BrochureDocument8 pagesTIJ Printer BrochureSarat KumarNo ratings yet

- TIJ Printer Brochure PDFDocument8 pagesTIJ Printer Brochure PDFSarat KumarNo ratings yet

- SMII Scanmaster SorterDocument2 pagesSMII Scanmaster Sorterdan_alpa5No ratings yet

- 1 JetStreamII Brochure MegaDocument2 pages1 JetStreamII Brochure MegaMuhammad Imran Latif ChaudhryNo ratings yet

- DICO Capping BrochureDocument8 pagesDICO Capping BrochureStuart MelenNo ratings yet

- รวม Supplypoint ทุกรุ่น by PTSCDocument16 pagesรวม Supplypoint ทุกรุ่น by PTSCRenishaw-ThaiNo ratings yet

- Versity Data Sheet 2020Document2 pagesVersity Data Sheet 2020AdamNo ratings yet

- ICS685 Pick and Pack BrochureDocument4 pagesICS685 Pick and Pack BrochureSergeyNo ratings yet

- Videojet 1520: Continuous InkjetDocument2 pagesVideojet 1520: Continuous Inkjetsimohamed alaoui aziziNo ratings yet

- 4 Suspension BenchDocument5 pages4 Suspension BenchTecnicas Reunidas de AutomociónNo ratings yet

- Mercury: Fully Digital Servomotor Control For Presses Old and NewDocument4 pagesMercury: Fully Digital Servomotor Control For Presses Old and NewAndre ZapataNo ratings yet

- Mercury: Fully Digital Servomotor Control For Presses Old and NewDocument4 pagesMercury: Fully Digital Servomotor Control For Presses Old and NewAndre ZapataNo ratings yet

- Supply Point Flyers MODULO Lo-ResDocument2 pagesSupply Point Flyers MODULO Lo-RespolishegyptNo ratings yet

- C Series Brochure - PrintReadyDocument2 pagesC Series Brochure - PrintReadyLuis Carlos Rodrigo DalmauNo ratings yet

- Autofeed Digital Die Cutter: Authorised Distributor For IndiaDocument4 pagesAutofeed Digital Die Cutter: Authorised Distributor For IndiaParvez ChoudhariNo ratings yet

- DISAMATIC D3 - Brochure - 2020 - ENGDocument8 pagesDISAMATIC D3 - Brochure - 2020 - ENGSAMARTH GITENo ratings yet

- 2018 Applications Industry4Document123 pages2018 Applications Industry4Ridwan MerduNo ratings yet

- Sipitaly - Catalogue - 326H-SPV5D 2017Document2 pagesSipitaly - Catalogue - 326H-SPV5D 2017Fantastic DragonNo ratings yet

- V 1000lineDocument4 pagesV 1000lineHermelindo Samuel Rabanales CifuentesNo ratings yet

- KB818N Nurse Call System Manual-2Document19 pagesKB818N Nurse Call System Manual-2Tun Wai WinNo ratings yet

- CS92 en LRDocument8 pagesCS92 en LRAnderson AntunesNo ratings yet

- (Brochure) ViTrox V510i 3D AOI (REV00 - 03-21, ENG, H)Document11 pages(Brochure) ViTrox V510i 3D AOI (REV00 - 03-21, ENG, H)Heverton SantosNo ratings yet

- MGI Brochure JETvarnish 3D UK SDDocument6 pagesMGI Brochure JETvarnish 3D UK SDAnderson AntunesNo ratings yet

- Alpine E200ls enDocument20 pagesAlpine E200ls ensanaNo ratings yet

- Información Press Breake AccurlDocument16 pagesInformación Press Breake AccurlSebastian Pardo VillasecaNo ratings yet

- NeoHorizon 03ixDocument16 pagesNeoHorizon 03ixCezaryCezasNo ratings yet

- In-Line Surface Inspection SYS Tems: Automated Defect Detection For The Highest Quality ControlDocument8 pagesIn-Line Surface Inspection SYS Tems: Automated Defect Detection For The Highest Quality ControlKumbhar p.s.No ratings yet

- R 2000ib 100H Compact PalletizerDocument2 pagesR 2000ib 100H Compact Palletizertallest.l.sNo ratings yet

- KB Rapida 106 enDocument24 pagesKB Rapida 106 eny9dww6km7yNo ratings yet

- The Way To Make IT The Way To Make ITDocument16 pagesThe Way To Make IT The Way To Make ITMnasri Rami0% (1)

- YouQuanTex BD - ENDocument12 pagesYouQuanTex BD - ENAndy YouQuanTexNo ratings yet

- P&C Documento Unico DEF WebDocument2 pagesP&C Documento Unico DEF Webabdelaziz_ismail685662No ratings yet

- Carat 10,500 To 92,000 KN: Highest Value Creation For Sophisticated ApplicationsDocument46 pagesCarat 10,500 To 92,000 KN: Highest Value Creation For Sophisticated ApplicationsNagaraju MuruguduNo ratings yet

- Ricoh Pro C5100S/C5110S: Digital Full Colour Production PrinterDocument12 pagesRicoh Pro C5100S/C5110S: Digital Full Colour Production Printerramendra0857No ratings yet

- Design Acceptance Report FormatDocument3 pagesDesign Acceptance Report FormatChandru ChristurajNo ratings yet

- 4.1 LIST MBBS 2019 FinalDocument17 pages4.1 LIST MBBS 2019 FinalChandru ChristurajNo ratings yet

- DHL Overdue Account Notice - 3300673641Document2 pagesDHL Overdue Account Notice - 3300673641Chandru ChristurajNo ratings yet

- 1 CM-2600 Series, 2.6" OD BLDC Hollow Shaft Servo Motor/encoder Servomotor/encoderDocument3 pages1 CM-2600 Series, 2.6" OD BLDC Hollow Shaft Servo Motor/encoder Servomotor/encoderChandru ChristurajNo ratings yet

- Account Statement From 15 May 2019 To 17 May 2019Document2 pagesAccount Statement From 15 May 2019 To 17 May 2019Chandru ChristurajNo ratings yet

- QT125 ValeoDocument1 pageQT125 ValeoChandru ChristurajNo ratings yet

- Mod Forge Existing Layout U-Bolt AutomationDocument1 pageMod Forge Existing Layout U-Bolt AutomationChandru ChristurajNo ratings yet

- Form Form of Application For The Renewal of Driving (See Rule 18 (1) )Document4 pagesForm Form of Application For The Renewal of Driving (See Rule 18 (1) )Chandru ChristurajNo ratings yet

- C65MS1-L5 Spec Sheet - A - A4Document3 pagesC65MS1-L5 Spec Sheet - A - A4Chandru ChristurajNo ratings yet

- Iho1 Robot Spare: QuotationDocument3 pagesIho1 Robot Spare: QuotationChandru ChristurajNo ratings yet

- Calculation of Cycle Times: Methods For Calculating Cycle TimeDocument2 pagesCalculation of Cycle Times: Methods For Calculating Cycle TimeChandru ChristurajNo ratings yet

- C65P1 Spec Sheet - E - A4Document3 pagesC65P1 Spec Sheet - E - A4Chandru ChristurajNo ratings yet

- BASTAIN SOLUTION-250 KG SG EOT CRANE - 316Document10 pagesBASTAIN SOLUTION-250 KG SG EOT CRANE - 316Chandru ChristurajNo ratings yet

- Account Statement: Msatools N No 12 O No 18 Sowrastra Nagar 1St Street Choolaimedu Ambattur ChennaiDocument2 pagesAccount Statement: Msatools N No 12 O No 18 Sowrastra Nagar 1St Street Choolaimedu Ambattur ChennaiChandru ChristurajNo ratings yet

- Budget FormatDocument57 pagesBudget FormatChandru ChristurajNo ratings yet

- Design and Proposals Organogram: (Presently Vacant)Document8 pagesDesign and Proposals Organogram: (Presently Vacant)Chandru ChristurajNo ratings yet

- S34D01001Document2 pagesS34D01001Chandru ChristurajNo ratings yet

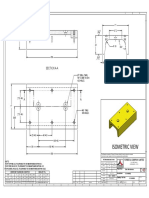

- 1.5 X 45° CH TYP: Isometric ViewDocument1 page1.5 X 45° CH TYP: Isometric ViewChandru ChristurajNo ratings yet

- Isometric View: 9.5 M6 Thru (02) HOLESDocument1 pageIsometric View: 9.5 M6 Thru (02) HOLESChandru ChristurajNo ratings yet

- FRB02A010102Document1 pageFRB02A010102Chandru ChristurajNo ratings yet

- C ChannelDocument1 pageC ChannelChandru ChristurajNo ratings yet

- Bale Lifting Tongs Standard Indentation Type:) QuickshipDocument1 pageBale Lifting Tongs Standard Indentation Type:) QuickshipChandru ChristurajNo ratings yet

- Sixth Sense Robotics and Automations PVT LTDDocument2 pagesSixth Sense Robotics and Automations PVT LTDChandru ChristurajNo ratings yet

- 700 C Vikash In-Charge Mechanical 1.ganesh Electrical Engr 2.mahendra Patil PLC 3.pratul Software 4.mayur Mechanical 5.sumit DesignDocument1 page700 C Vikash In-Charge Mechanical 1.ganesh Electrical Engr 2.mahendra Patil PLC 3.pratul Software 4.mayur Mechanical 5.sumit DesignChandru ChristurajNo ratings yet

- Dry-Running Vacuum Pumps EVE-TR XDocument1 pageDry-Running Vacuum Pumps EVE-TR XChandru ChristurajNo ratings yet

- Industrial Robot: Shortest Cycle TimesDocument4 pagesIndustrial Robot: Shortest Cycle TimesChandru ChristurajNo ratings yet

- List of Empanelled Vendor and Contact Details of T-03 MSKPY-1 PDFDocument2 pagesList of Empanelled Vendor and Contact Details of T-03 MSKPY-1 PDFChandru ChristurajNo ratings yet

- Burncycle - TutorialDocument12 pagesBurncycle - TutorialTony LeMesmerNo ratings yet

- Asus P5Q WS Qualified Vendor List Memory (09.02.25)Document14 pagesAsus P5Q WS Qualified Vendor List Memory (09.02.25)Patrick StivénNo ratings yet

- Operating System QuestionsDocument5 pagesOperating System QuestionsKande Archana K100% (1)

- ICT121 - JULY - 2017 - Exam PaperDocument8 pagesICT121 - JULY - 2017 - Exam PaperBenjamin TangNo ratings yet

- Phases: Covering Your Tracks: - Steganography - Event Logs AlterationDocument9 pagesPhases: Covering Your Tracks: - Steganography - Event Logs AlterationhiyuNo ratings yet

- Synopsis Employee Information System in C++Document13 pagesSynopsis Employee Information System in C++manjit100% (3)

- Ih dcc6526 6626 Uk Data PDFDocument354 pagesIh dcc6526 6626 Uk Data PDFرانا راشدNo ratings yet

- p85x HW SW GuideDocument123 pagesp85x HW SW GuideibrahimcakiciNo ratings yet

- Chapter 5 PDFDocument11 pagesChapter 5 PDFMd. Ayub KhanNo ratings yet

- Lab 3.2.1.4 - Configuring EtherChannelDocument34 pagesLab 3.2.1.4 - Configuring EtherChannelSamuelAbateSimmonsNo ratings yet

- ESDocument31 pagesESKummari NagaiahNo ratings yet

- First Ansible Playbook For BeginnersDocument8 pagesFirst Ansible Playbook For Beginnersxmywayx5316No ratings yet

- Msi MPG b550 Gaming PlusDocument68 pagesMsi MPG b550 Gaming PlusMarvelous WololoNo ratings yet

- Release Notes RobotStudio 5.61Document37 pagesRelease Notes RobotStudio 5.61Rafael BispoNo ratings yet

- MC403 Datasheet PDFDocument3 pagesMC403 Datasheet PDFHellen MontañaNo ratings yet

- Chapter 5 QsDocument4 pagesChapter 5 QsAadam AlmsNo ratings yet

- Ms Outlook: Features Available in OLDocument9 pagesMs Outlook: Features Available in OLHari Hara Ganesh KrishnanNo ratings yet

- Cyber SecurityDocument2 pagesCyber Securityahmed storage7No ratings yet

- Scadapack: 334 Hardware ManualDocument167 pagesScadapack: 334 Hardware ManualJuan BonetNo ratings yet

- UPGRADE GUIDE - Sap Enable Now 1Document5 pagesUPGRADE GUIDE - Sap Enable Now 1Carola SanchezNo ratings yet

- Catalyst 3560 Switch Software Configuration GuideDocument1,288 pagesCatalyst 3560 Switch Software Configuration GuideAbdullah KhanNo ratings yet

- Software Installation Manual: Computerboards, IncDocument16 pagesSoftware Installation Manual: Computerboards, IncDIPIN PNo ratings yet

- Exchange 2007 Edge Queue 4.7.5 Certificate Validation FailureDocument2 pagesExchange 2007 Edge Queue 4.7.5 Certificate Validation FailureBrahim BouaichaNo ratings yet

- OSPF PE-CE Routing Protocol Overview, Configuration and VerificationDocument47 pagesOSPF PE-CE Routing Protocol Overview, Configuration and VerificationJesus RosalesNo ratings yet

- DuplicateDocument29 pagesDuplicatesadan809No ratings yet

- CS8791 - Cloud Computing (Ripped From Amazon Kindle Ebooks by Sai Seena)Document352 pagesCS8791 - Cloud Computing (Ripped From Amazon Kindle Ebooks by Sai Seena)rhythm serviceNo ratings yet

- WeweDocument75 pagesWeweRalph EvanoNo ratings yet