Professional Documents

Culture Documents

Welding detail of part B-1

Uploaded by

Ranjit Kumar ShahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding detail of part B-1

Uploaded by

Ranjit Kumar ShahCopyright:

Available Formats

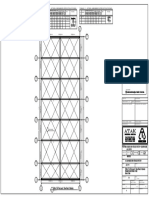

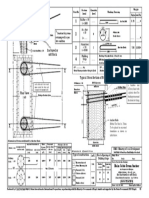

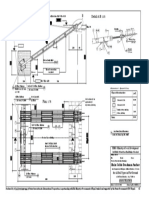

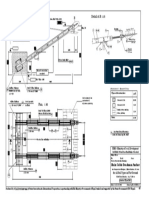

WELDING DETAIL OF PART B-1 (a-j)

FRONT ELEVATION SIDE ELEVATION VIEW - X

300 To obtain the shape as shown bend the angle at 400 B-2 B-3 B-4

the place where the flange is cut off and welded

after.

Plate 270 / 200 / 6

B-lc

Bend Inclined -5ο

Plate 338 / 60 / 6 B-lf

B-lf grind as required

Plate 240 / 150 / 6

B-lh

Plate 200 / 1975 / 6

B-ld

Rod φ 16 mm

B-l

Angle 65 / 65 / 6

B-la

Plate 250 / 1035 / 6

B-le

65 170 65 Plate 3345 / 150 / 12 C C

B-li

Tube φ 483 mm

B-lj

l = 150

B

Plate 75 / 58 / 6

B-lg

(Grind off as required)

TOP OF TOWER BASE

A PLATE. (on assembly)

NOTES :

1) To obtain uniformity, the use of templates and

jigs is mandatory for holing bending and

B 3345 Top of concrete level 106

welding of assembly.

383

2) All parts or bundles and packages with

SECTION B-B SECTION C-C

identical parts have to be bundled or marked

SECTION A-A with the respective part number by the

Rod φ 16 mm

B-lb 4

Angle 65 / 65 / 6 workshop.

4 l = 1461 B-la

4

4 Angle 65 / 65 / 6 HMG / Ministry of Local Development

B-la DoLIDAR / Short SpanTrail Bridge Standard

Plate 75 / 58 / 6 6

B-lg Bridge Name:

Tube φ 483 mm 6 Budhi Khola 1

6 B-lj No: Span: 52

l = 150

6 Plate 3345 / 150 / 12 Steel Drawing:

B-li

Plate 75 / 58 / 6 4 65

B-lg

(Grind off as required)

12 Rod φ 16 mm Base Element for

B-lb

Plate 3345 / 150 / 12 l = 1461 Tower No. 1,2,3 or 4

B-li

37 32 37

300 Assembly & Welding Details

383 106

Date : September 30, 2002 Drawing No. 100N

Produced by Nepal Swiss Association for International Cooperation, in partnership with His Majesty’s Government of Nepal, funded and supported by the Swiss Government (SDC Nepal). 25

You might also like

- IP 346-92 Determination of PAC in LubrificantsDocument6 pagesIP 346-92 Determination of PAC in LubrificantsMark Foster Jr.100% (1)

- DKD-R5-1-vol 2017 (Temp) PDFDocument35 pagesDKD-R5-1-vol 2017 (Temp) PDFAbdul wahid ButtNo ratings yet

- Spreadsheets To BS 8110: VK 14-Jan-2022 1 - 3271Document24 pagesSpreadsheets To BS 8110: VK 14-Jan-2022 1 - 3271christi SNo ratings yet

- Spreadsheets To BS 8110: Advisory Group ECBP Typical Floor To BS8110 RMW 11-Jun-2020 123 CHG - R68Document23 pagesSpreadsheets To BS 8110: Advisory Group ECBP Typical Floor To BS8110 RMW 11-Jun-2020 123 CHG - R68Hossen LeopoldNo ratings yet

- 101 Assembly DrawingDocument16 pages101 Assembly DrawingAshifurNo ratings yet

- 5M. Polygonal: Hot Dip Galvanized Pole Model: TUGDocument1 page5M. Polygonal: Hot Dip Galvanized Pole Model: TUGDumitrache IulianNo ratings yet

- Spreadsheets To BS 8110: The Concrete CentreDocument1 pageSpreadsheets To BS 8110: The Concrete CentremayphyoNo ratings yet

- CEA FINAL-converted Word FileDocument5 pagesCEA FINAL-converted Word FilePol OlmedillaNo ratings yet

- Detailed Estimate of A G-3 Building in Excel - Part 11 - Headroom & Lift Slab PDFDocument1 pageDetailed Estimate of A G-3 Building in Excel - Part 11 - Headroom & Lift Slab PDFmintu PatelNo ratings yet

- Mara DsDocument1 pageMara Dslix0123No ratings yet

- Matrita Injectat Pistol CU APADocument1 pageMatrita Injectat Pistol CU APAOvidiu StoianNo ratings yet

- RCC93 Flat Slabs (Tables)Document15 pagesRCC93 Flat Slabs (Tables)Cioabla BogdanNo ratings yet

- Crosby Western Tulsa, Okla HS-130-BDocument1 pageCrosby Western Tulsa, Okla HS-130-BNizam ShahNo ratings yet

- TCC53 Column Design 2002 2008Document24 pagesTCC53 Column Design 2002 2008get100% (1)

- CMB P DatabookDocument26 pagesCMB P DatabookDavid VaronaNo ratings yet

- Fan shroud assembly drawingDocument5 pagesFan shroud assembly drawingviniciusschwabNo ratings yet

- Column DesignDocument18 pagesColumn Designhala_azhari100% (1)

- 01.01. 100mm Dia. Water Meter Assembly. (Strainer)Document1 page01.01. 100mm Dia. Water Meter Assembly. (Strainer)Amadou MokshaNo ratings yet

- P1.3.R02 LBG Linear Bar Grille.A4Document6 pagesP1.3.R02 LBG Linear Bar Grille.A4ekahNo ratings yet

- UntitledDocument10 pagesUntitledBaatar ZorigtNo ratings yet

- Assy - Bottom Roller - Rev19112018Document1 pageAssy - Bottom Roller - Rev19112018Deny Bayu SaefudinNo ratings yet

- Precast Culvert DrawingDocument5 pagesPrecast Culvert Drawingraahul_nNo ratings yet

- Fluid Cooling Shell & Tube B / SB Series: Performance NotesDocument6 pagesFluid Cooling Shell & Tube B / SB Series: Performance NotesIynulF.OmarNo ratings yet

- Quick Sheet: ASME B16.34 Forged Steel Piston Check ValvesDocument2 pagesQuick Sheet: ASME B16.34 Forged Steel Piston Check ValvesMorteza AtarianNo ratings yet

- HN7T2BC x3Document2 pagesHN7T2BC x3jorgel.infantezNo ratings yet

- 07 Forged Cryogenic Gate GlobeDocument2 pages07 Forged Cryogenic Gate GlobeAndri AjaNo ratings yet

- Final Box Culvert Segment 4 RFI - Inspection of St. Dennis Box Culvert Rebar ArrangementDocument12 pagesFinal Box Culvert Segment 4 RFI - Inspection of St. Dennis Box Culvert Rebar Arrangementpeter njugunaNo ratings yet

- ST Paul-S1Document1 pageST Paul-S1fcdorupaNo ratings yet

- Haki Structural Talk 2018Document28 pagesHaki Structural Talk 2018sanjaya krisnaNo ratings yet

- Sumi E B.compressedDocument127 pagesSumi E B.compressedabelmil123No ratings yet

- Input: Spreadsheets To BS 8110 Advisory Group Edge Column B1 (Akin To D&D)Document8 pagesInput: Spreadsheets To BS 8110 Advisory Group Edge Column B1 (Akin To D&D)atuhe DavisNo ratings yet

- Industrial Steel Pipe Flanges DimensionsDocument86 pagesIndustrial Steel Pipe Flanges Dimensionsramarathinam .sNo ratings yet

- Installation Drawing Leap 21ao01050 TypicalDocument1 pageInstallation Drawing Leap 21ao01050 TypicalAnorld WalkerNo ratings yet

- Input: Spreadsheets To BS 8110 Advisory Group Edge Column B1 (Akin To D&D)Document11 pagesInput: Spreadsheets To BS 8110 Advisory Group Edge Column B1 (Akin To D&D)christi SNo ratings yet

- Input: Spreadsheets To BS 8110 Advisory Group Edge Column B1 (Akin To D&D)Document11 pagesInput: Spreadsheets To BS 8110 Advisory Group Edge Column B1 (Akin To D&D)ali billNo ratings yet

- TCC54 Circular Column DesignDocument93 pagesTCC54 Circular Column DesignMelinda Gordon100% (1)

- B PDFDocument127 pagesB PDFshri mayuramNo ratings yet

- Ref. SiloDocument8 pagesRef. Siloahmed aboyosefNo ratings yet

- Flat Slabs Design - EC - MPADocument1 pageFlat Slabs Design - EC - MPAmayphyoNo ratings yet

- E12004180 - Light Weight Lub Lower AssyDocument1 pageE12004180 - Light Weight Lub Lower Assysachin kadamNo ratings yet

- Gate Valve Class 1500Document1 pageGate Valve Class 1500Hamdi Al-sarooryNo ratings yet

- Wire Mesh Tray-DrawingDocument1 pageWire Mesh Tray-DrawingNithin AbrahamNo ratings yet

- Terminal 245kV TE PorcelanaDocument1 pageTerminal 245kV TE PorcelanaCarlos FernandezNo ratings yet

- Hydraulic membrane pump connections, dimensions and specificationsDocument1 pageHydraulic membrane pump connections, dimensions and specificationswesquiNo ratings yet

- H6136BDocument1 pageH6136Bchanleo168No ratings yet

- Double DeskDocument1 pageDouble DeskUpdates for upcoming KingNo ratings yet

- OHMNews 185-3 CcholderDocument2 pagesOHMNews 185-3 CcholdermotorciNo ratings yet

- Enerpac Press CatalogDocument2 pagesEnerpac Press CatalogTitanplyNo ratings yet

- Technical Specification and Materials of ConstructionDocument1 pageTechnical Specification and Materials of ConstructionAhmadNo ratings yet

- Steel beam specifications and profile detailsDocument1 pageSteel beam specifications and profile detailsAbid AyubNo ratings yet

- Continuous BeamDocument29 pagesContinuous BeamZakwan ZakariaNo ratings yet

- Projek Pertama - JJ2023 PDFDocument1 pageProjek Pertama - JJ2023 PDFDinie ArifNo ratings yet

- Purlin Data Sheet MEIDocument1 pagePurlin Data Sheet MEIKamal FayazNo ratings yet

- Calmark - Birtcher 44 5 10 LF L DatasheetDocument2 pagesCalmark - Birtcher 44 5 10 LF L DatasheetirinaNo ratings yet

- TCC52 Column Chart GenerationDocument9 pagesTCC52 Column Chart Generationhala_azhari100% (2)

- Gate Valve DrawingDocument2 pagesGate Valve Drawingpriyanka GNo ratings yet

- IP67 Diecast Aluminium EnclosureDocument7 pagesIP67 Diecast Aluminium EnclosureDAVID SALVADORNo ratings yet

- Buoyant-U8m12-8PoE - Installation DrawingDocument1 pageBuoyant-U8m12-8PoE - Installation DrawingkkNo ratings yet

- Dodge Fc-E-115rDocument2 pagesDodge Fc-E-115rJavierNo ratings yet

- Ficha Tecnica Bomba de Paletas T6CR VeljanDocument2 pagesFicha Tecnica Bomba de Paletas T6CR VeljanSergio Gustavo Herrera ArellanoNo ratings yet

- 230x255Dp BEAM GF01 (1971mm) 230x255Dp BEAM GF02 (3045mm)Document1 page230x255Dp BEAM GF01 (1971mm) 230x255Dp BEAM GF02 (3045mm)TerrenceNo ratings yet

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- EP 46 Rishikesh SBD CertfDocument1 pageEP 46 Rishikesh SBD CertfRanjit Kumar ShahNo ratings yet

- Syllabi Master of TechnologyDocument63 pagesSyllabi Master of TechnologyRanjit Kumar ShahNo ratings yet

- Morpho-Hydraulic Parameters and Existing Stability Condition of Nakhu River, Southern Kathmandu, Central NepalDocument22 pagesMorpho-Hydraulic Parameters and Existing Stability Condition of Nakhu River, Southern Kathmandu, Central NepalRanjit Kumar ShahNo ratings yet

- Reinforced Concrete Section PropertiesDocument10 pagesReinforced Concrete Section PropertiesJose MLNo ratings yet

- Design Standard Final 2067 PDFDocument6 pagesDesign Standard Final 2067 PDFHemraj RajNo ratings yet

- 4.ramramti PhotosDocument3 pages4.ramramti PhotosRanjit Kumar ShahNo ratings yet

- EP 46 Rishikesh SBD CertfDocument1 pageEP 46 Rishikesh SBD CertfRanjit Kumar ShahNo ratings yet

- 4.ramramti PhotosDocument3 pages4.ramramti PhotosRanjit Kumar ShahNo ratings yet

- Terms of ReferenceDocument9 pagesTerms of ReferenceRanjit Kumar ShahNo ratings yet

- 2.pokhariya Estimation FinalDocument152 pages2.pokhariya Estimation FinalRanjit Kumar ShahNo ratings yet

- EOI Detailed Bridge Maintenance Survey and Design of The Existing Motorable Bridges On SRNDocument12 pagesEOI Detailed Bridge Maintenance Survey and Design of The Existing Motorable Bridges On SRNRanjit Kumar ShahNo ratings yet

- Revise - Final Inception Report - PK-14 - 076-77Document59 pagesRevise - Final Inception Report - PK-14 - 076-77Ranjit Kumar ShahNo ratings yet

- Morpho-Hydraulic Parameters and Existing Stability Condition of Nakhu River, Southern Kathmandu, Central NepalDocument22 pagesMorpho-Hydraulic Parameters and Existing Stability Condition of Nakhu River, Southern Kathmandu, Central NepalRanjit Kumar ShahNo ratings yet

- Intermediate-Lanes Traffic, Simply Supported Span, 3 Web, Cast-in-SituDocument8 pagesIntermediate-Lanes Traffic, Simply Supported Span, 3 Web, Cast-in-SituRanjit Kumar ShahNo ratings yet

- Jhilke Khola Bridge Hydrological StudyDocument15 pagesJhilke Khola Bridge Hydrological StudyRanjit Kumar ShahNo ratings yet

- Cover Page Drawing A3Document1 pageCover Page Drawing A3Ranjit Kumar ShahNo ratings yet

- Final Field ReportDocument37 pagesFinal Field ReportRanjit Kumar ShahNo ratings yet

- 48 NconDocument1 page48 NconRanjit Kumar ShahNo ratings yet

- Section at A-A, 1:75: Part No Section (MM) Quantity (Nos) Working Drawing WeightDocument1 pageSection at A-A, 1:75: Part No Section (MM) Quantity (Nos) Working Drawing WeightRanjit Kumar ShahNo ratings yet

- 17 RFP Vol III Feasibility Report Part III PDFDocument97 pages17 RFP Vol III Feasibility Report Part III PDFSrinivas PNo ratings yet

- Standard Drawing CompleteDocument60 pagesStandard Drawing CompleteRakesh Sharma100% (1)

- Section A-A, 1:40: Part No Section (MM) Quantity (Nos) Working Drawing Weight KG/PC Total KGDocument1 pageSection A-A, 1:40: Part No Section (MM) Quantity (Nos) Working Drawing Weight KG/PC Total KGRanjit Kumar ShahNo ratings yet

- Bridge GuidelineDocument14 pagesBridge GuidelineRanjit Kumar ShahNo ratings yet

- Section at A-A, 1:75 Detail at B 1:15: Main Cable Deadman AnchorDocument1 pageSection at A-A, 1:75 Detail at B 1:15: Main Cable Deadman AnchorRanjit Kumar ShahNo ratings yet

- Section at A-A, 1:50: Part No Section (MM) Quantity (Nos) Working Drawing WeightDocument1 pageSection at A-A, 1:50: Part No Section (MM) Quantity (Nos) Working Drawing WeightRanjit Kumar ShahNo ratings yet

- Section at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorDocument1 pageSection at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorRanjit Kumar ShahNo ratings yet

- Section A-A, 1:40: Part No Section (MM) Quantity (Nos) Working Drawing Weight KG/PC Total KGDocument1 pageSection A-A, 1:40: Part No Section (MM) Quantity (Nos) Working Drawing Weight KG/PC Total KGRanjit Kumar ShahNo ratings yet

- Section A-A, 1:40: Part No Section (MM) Quantity (Nos) Working Drawing Weight KG/PC Total KGDocument1 pageSection A-A, 1:40: Part No Section (MM) Quantity (Nos) Working Drawing Weight KG/PC Total KGRanjit Kumar ShahNo ratings yet

- Section at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorDocument1 pageSection at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorRanjit Kumar ShahNo ratings yet

- Section at A-A, 1:50: No Section (MM) Quantity (Nos) Working Drawing WeightDocument1 pageSection at A-A, 1:50: No Section (MM) Quantity (Nos) Working Drawing WeightRanjit Kumar ShahNo ratings yet

- Woodcock Johnson Achievement ReportDocument4 pagesWoodcock Johnson Achievement Reportapi-254874994100% (2)

- Study Scheme & Syllabus Of: IK Gujral Punjab Technical UniversityDocument28 pagesStudy Scheme & Syllabus Of: IK Gujral Punjab Technical UniversityvijiNo ratings yet

- Introduction To PhytoconstituentsDocument124 pagesIntroduction To PhytoconstituentsSiddhant BanwatNo ratings yet

- Carbon and Its CompoundDocument6 pagesCarbon and Its CompoundKartik meenaNo ratings yet

- Introduction To Software ModulesDocument3 pagesIntroduction To Software ModulesArif SamoNo ratings yet

- Parts Catalogue '18 ZX1002 BJF (EU) Ninja H2 SXDocument103 pagesParts Catalogue '18 ZX1002 BJF (EU) Ninja H2 SX张连杉No ratings yet

- Reinforced Concrete WorksDocument5 pagesReinforced Concrete WorksRanjith EkanayakeNo ratings yet

- Sage Erp X3 V7: Development Part 1 Exercises Level 2Document21 pagesSage Erp X3 V7: Development Part 1 Exercises Level 2Yahya Chiguer100% (1)

- Maths - Sample Paper1Document5 pagesMaths - Sample Paper1Arnav SudhindraNo ratings yet

- 3-1/2Document1 page3-1/2Mohamed FikryNo ratings yet

- Operational ManagementDocument2 pagesOperational ManagementNur Amalienna SyaheraNo ratings yet

- Jawaban Soal BahlDocument2 pagesJawaban Soal Bahlayu irsalinaNo ratings yet

- The Brook - Poetic DevicesDocument3 pagesThe Brook - Poetic Devicesraaj67% (12)

- The Design of Reinforced Earth Walls DGS 28-11Document32 pagesThe Design of Reinforced Earth Walls DGS 28-11paulombatista100% (1)

- Project Financial AppraisalDocument78 pagesProject Financial Appraisal'babi MulugetaNo ratings yet

- Phase 2 p&ID - Google SearchDocument4 pagesPhase 2 p&ID - Google SearchAhmed Essam El-DinNo ratings yet

- SEPMDocument12 pagesSEPM154Soyal LonareNo ratings yet

- Parallels RAS GPU Accelerated Application PublishingDocument42 pagesParallels RAS GPU Accelerated Application PublishingRichardNo ratings yet

- Sultamicillin Tablets 375 MG IHSDocument14 pagesSultamicillin Tablets 375 MG IHSGiancarlo Alessandro VettorNo ratings yet

- Linear Forms in Logarithms and ApplicationsDocument242 pagesLinear Forms in Logarithms and ApplicationsTarun Patel100% (3)

- Human Vision: Jitendra Malik U.C. BerkeleyDocument45 pagesHuman Vision: Jitendra Malik U.C. BerkeleyElisée Ndjabu DHNo ratings yet

- LetDocument9 pagesLetDvy D. VargasNo ratings yet

- Coclia EyelidDocument5 pagesCoclia EyelidFaradila HakimNo ratings yet

- of ProjectDocument24 pagesof ProjectamarparimiNo ratings yet

- WebAccess - SCADA 8.2 - Final20161019111852Document3 pagesWebAccess - SCADA 8.2 - Final20161019111852imadz853No ratings yet

- Linear Algebra ReviewDocument13 pagesLinear Algebra ReviewYoumna ShatilaNo ratings yet

- Polishing Up On Finishing How To Stay Competitive Due To Optimized Surface FinishingDocument33 pagesPolishing Up On Finishing How To Stay Competitive Due To Optimized Surface Finishingชนพัทธ์ คงพ่วงNo ratings yet

- ALGEBRADocument5 pagesALGEBRAArc CansinoNo ratings yet