Professional Documents

Culture Documents

F S - F U: Ormula Heet Ield Nits

Uploaded by

Barbare RenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F S - F U: Ormula Heet Ield Nits

Uploaded by

Barbare RenCopyright:

Available Formats

FORMULA SHEET—FIELD UNITS

Acronyms used in the following formulas are defined in the WellSharp Acronyms document, available on the secure Provider Resources webpage. For instructions on

rounding numbers when making calculations, refer to the following rounding rules and recommendations. Carry the rounded values forward into subsequent

calculations.

ROUNDING RULES

• When calculating Kill Mud Weight, ROUND UP to one decimal place (for example: round up 10.73 ppg to 10.8 ppg; round up 11.03 ppg to 11.1 ppg).

• When calculating Leak Off Test Equivalent Mud Weight, ROUND DOWN to one decimal place (for example: round down 11.76 ppg to 11.7 ppg; round down 13.89

ppg to 13.8 ppg).

• When calculating Pressure Reduction Schedule, ROUND DOWN to a whole number (for example: round down 21.6 psi/100 stks to 21 psi/100 stks).

• If the Kill Mud Weight or Leak Off values are to be used in subsequent calculations, use the rounded value in the future calculation. Do not use the unrounded

calculated value.

ROUNDING RECOMMENDATIONS ROUNDING and

MEASUREMENT UNITS

ANSWER FORMAT

See Table to right where: Depth feet X

Pressure psi X

X= Whole number

X.XXXX = Number with 4 decimal places Pressure Gradient psi/foot X.XXXX

Mud Weight ppg X.X

Volume bbls X.X

Capacity and Displacement bbls/foot X.XXXX

Pump Speed in strokes per minute SPM X

Strokes stk or stks X

Speed in feet per hour feet/hour X

Area in2 X.XXXX

Force lbs X

Buoyancy Factor Unitless X.XXXX

psi/100 stks

Wait and Weight Pressure Reduction Schedule or X

* 10 steps = Surface to Bit strokes divided by 10. psi/10 steps*

Revision 3 07 May 2018 Page 1 of 6

1. FORCE (lbs) = Pressurepsi x Diameter2 x 0.7854 (Diameter in inches)

2. PRESSURE (psi) = Forcelbs Diameter2 0.7854

3. RECTANGULAR TANK VOLUME (bbls) = (Lengthft x Widthft x Heightft) 5.615

4. RECTANGULAR TANK CAPACITY (bbls/ft) = Lengthft x Widthft x 0.178

5. RECTANGULAR TANK CAPACITY (bbls/in) = Lengthft x Widthft x 0.0148

6. VERTICAL CYINDRICAL TANK VOLUME (bbls) = Capacitybbls/ft x Heightft

7. VERTICAL CYINDRICAL TANK CAPACITY(bbls/ft) = Tank diameterft2 7.148

8. TUBULAR CAPACITY (bbls/ft) = ID2 1029.4 (ID = Internal Diameter of Tubular)

9. ANNULAR CAPACITY (bbls/ft) = (D2 - d2) 1029.4 (D = Hole Diameter or Casing ID, d = Outside Diameter of Tubular)

10. HEIGHT OF FLUID IN A PIPE OR ANNULUS (ft) = Kick Volumebbls Annular Capacitybbls/ft or Pipe Capacitybbls/ft

11. HYDROSTATIC PRESSURE (psi) = Mud Weightppg x 0.052 x TVDft

12. HYDROSTATIC PRESSURE GRADIENT (psi/ft) = Mud Weightppg x 0.052

13. FORMATION PRESSURE (psi) = Hydrostatic Pressure in Drill Stringpsi + SIDPPpsi

(also referred to as Bottomhole Pressure at Shut In)

14. MUD WEIGHT (ppg) = Pressure Gradientpsi/ft 0.052 or Pressurepsi TVDft 0.052

Revision 3 07 May 2018 Page 2 of 6

15. EQUIVALENT MUD WEIGHT (ppg) = Pressurepsi 0.052 TVDft or (Surface Pressurepsi TVDft 0.052) + Mud Weightppg

16. EQUIVALENT CIRCULATING DENSITY (ppg) = [Annular Pressure Losspsi 0.052 TVDft] + Original Mud Weightppg

17. KILL MUD WEIGHT (ppg) = [SIDPPpsi 0.052 TVDft] + Original Mud Weightppg

18. INITIAL CIRCULATING PRESSURE (psi) = Slow Circulating Rate Pressurepsi + SIDPPpsi

19. FINAL CIRCULATING PRESSURE (psi) = Slow Circulating Rate Pressurepsi x [Kill Mud Weightppg Original Mud Weightppg]

20. NEW PUMP PRESSURE WITH NEW SPM (psi) = Current Pressurepsi x [New SPM Old SPM]2 (only approximate!)

21. NEW PUMP PRESSURE WITH NEW MUD WEIGHT (psi) = Current Pressurepsi x [New Mud Weight Old Mud Weight] (only approximate!)

22. MAXIMUM ALLOWABLE MUD WEIGHT (ppg) = [Surface Leak Offpsi 0.052 Shoe TVDft] + Test Mud Weightppg

(Fracture Mud Weight)

23. MAASP or MACP (psi) = [Maximum Allowable Mud Weightppg - Current Mud Weightppg] x 0.052 x Shoe TVDft

24. NEW MAASP AFTER KILL (psi) = [Maximum Allowable Mud Weightppg - Kill Mud Weightppg] x 0.052 x Shoe TVDft

25. ADDITIONAL MUD RETURNED BY SLUG (bbls) = [(Slug Weightppg Mud Weightppg) – 1] x Slug Volumebbls

26. TOTAL MUD RETURNED BY SLUG (bbls) = (Slug Weightppg Mud Weightppg) x Slug Volumebbls

27. LEVEL DROP AFTER PUMPING A SLUG (ft) = [(Slug Weightppg Mud Weightppg) – 1] x Slug Volumebbls Drill Pipe Capacitybbls/ft

28. RISER MARGIN (ppg) = [(Riser Mud Hydrostaticpsi – Seawater Hydrostaticpsi) 0.052] (Well TVDft - Water Depthft – Air Gapft)

Revision 3 07 May 2018 Page 3 of 6

29. CASING (or CHOKE) PRESSURE AFTER SUBSEA START-UP (psi) = Shut In Casing Pressurepsi – Choke Line Friction Losspsi

30. BOYLES LAW FORMULAE P1 x V1 = P2 x V2 P2 = P1 x V1 V2 = P1 x V1 Atmospheric Pressure. = 14.7psi

V2 P2 P = Pressure: V = Volume

31. GAS MIGRATION RATE (ft/hr) = Shut-In Pressure Increasepsi/hr Mud Gradientpsi/ft (can use SIDPP or SICP)

(Increase over last hour)

32. VOLUME TO BLEED DUE TO GAS MIGRATION (bbls) = (Working Pressure to Bleedpsi Mud Gradientpsi/ft) x Annular Capacitybbls/ft

(For Volumetric Method)

33. LENGTH OF WET PIPE PULLED BEFORE FILL-UP FOR DESIRED PRESSURE DROP ΔP (Lengthft)

= (ΔPpsi x Annulus Capbbl/ft) [0.052 x MW ppg x (DP Capbbl/ft + DP Displbbl/ft)]

34. LENGTH OF DRY PIPE PULLED BEFORE FILL-UP FOR DESIRED PRESSURE DROP ΔP (Lengthft)

= [ΔPpsi x (Annulus Capbbl/ft + DP Capbbl/ft)] 0.052 x MW ppg x DP Displbbl/ft

35. HYDROSTATIC PRESSURE DROP PER FOOT (ΔPpsi/ft) WHEN PULLING WET PIPE

= 0.052 x MW ppg x [(DP Capbbl/ft + DP Displbbl/ft) Annulus Capbbl/ft]

36. USABLE FLUID VOLUME PER BOTTLE

= (Precharge Pressure Minimum Operating Press) - (Precharge Pressure Maximum Operating pressure) x Bottle Volume

37. CONVERSION OF API GRAVITY (oAPI) TO SPECIFIC GRAVITY (SG) = 141.5 (oAPI + 131.5)

38. CONVERSION OF SPECIFIC GRAVITY (SG) TO PPG = 8.33 x SG

Revision 3 07 May 2018 Page 4 of 6

WELL COMPLETION/WORKOVER FORMULA SHEET—FIELD UNITS

1. KILL FLUID WEIGHT (ppg) = [SITPpsi 0.052 Top Perfs TVDft] + Original Fluid Weightppg

2. KILL FLUID WEIGHT (ppg) = BHPpsi 0.052 TVDft

3. BUOYANCY FACTOR (BF) = (65.4 – Fluid weightppg) 65.4

4. PIPE WEIGHT BUOYED–OPEN ENDED PIPE (lbs/ft)

= Weightair, (lbs ft) x Buoyancy Factor

5. BUOYED WEIGHT OF TUBULARS (CLOSED ENDED & NO FLUID IN PIPE) (lbs/ft)

= Weightair, (lbs ft) – [(Pipe OD2in x Fluid weightppg) 24.5]

6. BUOYED WEIGHT OF TUBULARS (DIFFERENT FLUID IN PIPE AND ANNULUS) (lbs/ft)

= Weightair, (lbs ft) + [(Pipe ID2in x Fluid weighttbg) 24.5] - [(Pipe OD2in x Fluid weightAnnulus) 24.5]

BULLHEADING FORMULAE

7. FORMATION FRACTURE PRESSURE (psi) = Formation Fracture Gradientpsi/ft x Top Perforations TVDft

8. INITIAL HYDROSTATIC PRESSURE (psi) = Formation Pressurepsi - SITPpsi

9. INITIAL AVERAGE FLUID DENSITY (ppg) = Initial Hydrostatic Pressurepsi Top Perforations TVDft 0.052

10. MAX INITIAL SURFACE PRESSURE (psi) = Formation Fracture Pressurepsi - Initial Hydrostatic Pressurepsi

11. MAX FINAL SURFACE PRESSURE (psi) = Formation Fracture Pressurepsi – (Kill Fluid Weightppg x 0.052 x Top Perforations TVDft)

12. VOLUME TO BULLHEAD (bbls) = Surface Linesbbls + Surface to EOTbbls + EOT to Top Perfsbbls + Top Perfs to Bottom Perfsbbls

{EOT = End of Tubing Perfs = Perforations}

13. BULLHEAD SPM TO EXCEED GAS MIGRATION = (Gas Migration Rateft/hr 60) x Tubing Capacitybbls/ft Pump Outputbbls/stroke

Revision 3 07 May 2018 Page 5 of 6

TEMPERATURE CORRECTION FORMULA FOR BRINES

14. FLUID DENSITY TO MIX (ppg) = Fluid Density at Avg. Tempppg + [(Avg. TempF - Surface TempF) x Weight Lossppg/OF]

{Avg = Average F = degrees Fahrenheit}

Example Weight Loss Chart Brine weight (ppg) Weight loss (ppg/°F)

(Note: Values will vary based on type 8.4 – 9.0 0.0017

of fluid and other factors.)

9.1 – 11.0 0.0025

11.1 – 14.5 0.0033

14.6 – 17.0 0.0040

17.1 – 19.2 0.0048

Revision 3 07 May 2018 Page 6 of 6

You might also like

- Well Control Formula SheetDocument5 pagesWell Control Formula Sheettanolucascribd0% (1)

- WellSharp Formula SI UnitsDocument4 pagesWellSharp Formula SI UnitstanolucascribdNo ratings yet

- Drilling Formula SheetDocument4 pagesDrilling Formula SheetPavin PiromNo ratings yet

- Section 2. Calculation Formula.: Drilling - English Metric (Constant 10.2) Formula SheetDocument4 pagesSection 2. Calculation Formula.: Drilling - English Metric (Constant 10.2) Formula SheetMn AnaNo ratings yet

- Assignment 1 Kill SheetDocument4 pagesAssignment 1 Kill SheetPrateekNo ratings yet

- Volume and StrokeDocument39 pagesVolume and StrokeHarpreetSinghNo ratings yet

- Assignment-2 Kill SheetDocument13 pagesAssignment-2 Kill SheetPrateekNo ratings yet

- QA-RD7AE-V8 English API Formula SheetDocument4 pagesQA-RD7AE-V8 English API Formula Sheetadvantage025No ratings yet

- IADC Formula Sheet: X X X + + ÷ X + X - ÷ XDocument5 pagesIADC Formula Sheet: X X X + + ÷ X + X - ÷ XMarwa ElghifaryNo ratings yet

- Hydraulics Work Sheet: Well DataDocument1 pageHydraulics Work Sheet: Well DataMohamed ElkumatiNo ratings yet

- Kill Sheet Formula GuideDocument4 pagesKill Sheet Formula GuideAwani Kester100% (1)

- Páginas DesdeFormulas Calculations Drilling Production WorkoverDocument8 pagesPáginas DesdeFormulas Calculations Drilling Production WorkoverDahize Moyna MendozaNo ratings yet

- Gate in Petroleum - Important Formulas: Abbreviations Used in This DocumentDocument4 pagesGate in Petroleum - Important Formulas: Abbreviations Used in This DocumentSHUBHAM SINGHNo ratings yet

- Module 01 - Basic PressureDocument13 pagesModule 01 - Basic PressureLismi LismiNo ratings yet

- Common Rig MathDocument17 pagesCommon Rig MathSanjay Mishra86% (7)

- QA-RD7A Formula Sheet Rev 3 - 2006Document4 pagesQA-RD7A Formula Sheet Rev 3 - 2006wandersaquaNo ratings yet

- EX-0035 Drilling - English API Forumla SheetDocument4 pagesEX-0035 Drilling - English API Forumla Sheetmohamed abbasNo ratings yet

- Formula Sheet - MetricDocument4 pagesFormula Sheet - MetricAlexander KlmNo ratings yet

- AD 0026 Surface Vertical Kill Sheet English API 1Document5 pagesAD 0026 Surface Vertical Kill Sheet English API 1Abdo OnhymNo ratings yet

- قوانين الحفرDocument4 pagesقوانين الحفرibrahim familyNo ratings yet

- Basic HydDocument89 pagesBasic HydThang TongNo ratings yet

- Note On Kick ToleranceDocument4 pagesNote On Kick TolerancePrasad100% (1)

- WELL CONTROL EQUATIONS CHARTS & TABLESDocument13 pagesWELL CONTROL EQUATIONS CHARTS & TABLESShaho Abdulqader Mohamedali100% (1)

- EX 0036 Drilling English Metric 0.0981 Formula SheetDocument4 pagesEX 0036 Drilling English Metric 0.0981 Formula Sheetorso brunoNo ratings yet

- Lecture-3 Drilling EngineeringDocument11 pagesLecture-3 Drilling Engineeringحيدر بادي - Haider BadiNo ratings yet

- Pounds Per Square Inch: Navigation SearchDocument7 pagesPounds Per Square Inch: Navigation SearchdsmnnangNo ratings yet

- Conversions Formulas: Visit Our Web SiteDocument1 pageConversions Formulas: Visit Our Web SiteKuttappa I GNo ratings yet

- Well Control Pre-Kick Sheet CalculationsDocument4 pagesWell Control Pre-Kick Sheet CalculationsElrohirPendragonNo ratings yet

- Light Pole Footing AASHTO Broms MethodDocument6 pagesLight Pole Footing AASHTO Broms MethodSaul ShapiroNo ratings yet

- PUMPFDNDocument9 pagesPUMPFDNSebastian Ramos GrilliNo ratings yet

- Guidance DDR PetroGas RigDocument11 pagesGuidance DDR PetroGas RigIda UranNo ratings yet

- 00 - Downhole Hydraulic II - UTC VersionDocument44 pages00 - Downhole Hydraulic II - UTC VersionaungwinnaingNo ratings yet

- Machining Center Paint Booth Hydraulic TrainingDocument104 pagesMachining Center Paint Booth Hydraulic TrainingPetr Kos100% (1)

- Drilling Formula SheetDocument4 pagesDrilling Formula Sheetamri hutabaratNo ratings yet

- Surface BOP Kill SheetDocument12 pagesSurface BOP Kill Sheetzouke2002No ratings yet

- Well Control FormulasDocument5 pagesWell Control FormulasAugustin DumitriuNo ratings yet

- Report MAT3D 1Document19 pagesReport MAT3D 1sysyphus01No ratings yet

- Kick Tolerance CalculationDocument6 pagesKick Tolerance Calculationsaffarzadeh100% (1)

- Kick Tolerance PDFDocument6 pagesKick Tolerance PDFsaffarzadehNo ratings yet

- Kick Tolerance CalculationDocument6 pagesKick Tolerance CalculationAliNo ratings yet

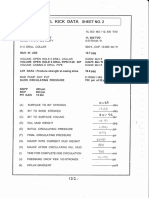

- Kill Sheet #4Document2 pagesKill Sheet #4Ad AwsdNo ratings yet

- Rumus untuk Well ControlDocument9 pagesRumus untuk Well Controlnawar mhlwNo ratings yet

- 14b-Kill Sheet PreparationDocument10 pages14b-Kill Sheet PreparationLorenaStămulescuNo ratings yet

- Wastewater Math FormulasDocument17 pagesWastewater Math FormulasRamon CardonaNo ratings yet

- Book 3Document6 pagesBook 3Sasikumar Jothi100% (1)

- 3 PressureConceptsDocument26 pages3 PressureConceptssahaya freedonNo ratings yet

- Exercise 4 AnswersDocument12 pagesExercise 4 AnswersadeelsnNo ratings yet

- Basic Hyd PDFDocument89 pagesBasic Hyd PDFThang TongNo ratings yet

- Practical Class 1Document26 pagesPractical Class 1asel.muratttNo ratings yet

- Kick Tolerance CalculationDocument5 pagesKick Tolerance Calculationi oNo ratings yet

- Conversions of PressureDocument1 pageConversions of Pressurelinkin_slayerNo ratings yet

- Lifting Lug Calculation - Concrete BucketDocument3 pagesLifting Lug Calculation - Concrete Bucketali akbarNo ratings yet

- Well Kick: Sidpp Sicp Gain (A) (B) (C) (D) (E) (F) (G) (H) (L) (J) (K)Document1 pageWell Kick: Sidpp Sicp Gain (A) (B) (C) (D) (E) (F) (G) (H) (L) (J) (K)andrewNo ratings yet

- Operation Department - Abbreviations ListDocument7 pagesOperation Department - Abbreviations ListBarbare RenNo ratings yet

- (IADC) JRC Rig Move Warranty Survey Revision 2.0 16 October 2014 Aligned With ISO SNAMEDocument20 pages(IADC) JRC Rig Move Warranty Survey Revision 2.0 16 October 2014 Aligned With ISO SNAMEpaoloNo ratings yet

- F S - F U: Ormula Heet Ield NitsDocument6 pagesF S - F U: Ormula Heet Ield NitsBarbare RenNo ratings yet

- Supervisor Pro: Advanced Wellsharp DrillingDocument2 pagesSupervisor Pro: Advanced Wellsharp DrillingBarbare RenNo ratings yet

- IADC Incident StatisticsDocument15 pagesIADC Incident StatisticsAnisBelhajAissaNo ratings yet

- Review of Wellsharp Test Question: Instructor Submitting The RequestDocument2 pagesReview of Wellsharp Test Question: Instructor Submitting The RequestBarbare RenNo ratings yet

- Supervisor Pro: Advanced Wellsharp DrillingDocument2 pagesSupervisor Pro: Advanced Wellsharp DrillingBarbare RenNo ratings yet

- WSP-01 Handbook-SecondEd Rev5 PDFDocument95 pagesWSP-01 Handbook-SecondEd Rev5 PDFBarbare Ren100% (1)

- Wellsharp Definitions Reference DocumentDocument15 pagesWellsharp Definitions Reference DocumentBarbare RenNo ratings yet

- Eigenvalues, Eigenvectors, and Eigenspaces of Linear Operators Math 130 Linear AlgebraDocument3 pagesEigenvalues, Eigenvectors, and Eigenspaces of Linear Operators Math 130 Linear AlgebraSani DanjumaNo ratings yet

- Galleon II 3P BrochureDocument2 pagesGalleon II 3P BrochureChong Kum ChunNo ratings yet

- Ieee Guide For Evaluating The Effect of Solar Radiation On OutdoDocument25 pagesIeee Guide For Evaluating The Effect of Solar Radiation On OutdoIbrahim EspinozaNo ratings yet

- MCQs Question of Surveying 1Document9 pagesMCQs Question of Surveying 1jamil ahmedNo ratings yet

- Sand Replacement Lab ReportDocument16 pagesSand Replacement Lab Reportimran shakirNo ratings yet

- Integrated Science 7Th Edition Bill W Tillery full chapterDocument51 pagesIntegrated Science 7Th Edition Bill W Tillery full chapterwilliam.berry830100% (5)

- SMD Assembly SE Mech - ADocument4 pagesSMD Assembly SE Mech - APrashantNo ratings yet

- Crystal Field Stabilisation Energies of Octahedral Complexes (CFSEsDocument2 pagesCrystal Field Stabilisation Energies of Octahedral Complexes (CFSEsAyushi JoshyaNo ratings yet

- Product Line Up 2018: World Class ComfortDocument41 pagesProduct Line Up 2018: World Class ComfortHashirama tobiramaNo ratings yet

- Zoomlion TC7030B Tower Crane Technical SpecsDocument13 pagesZoomlion TC7030B Tower Crane Technical SpecsfiarNo ratings yet

- Experimentno.4 Uniform Motion I. ObjectivesDocument6 pagesExperimentno.4 Uniform Motion I. ObjectivesStephanie AzucenaNo ratings yet

- 20NC60VD STMicroelectronicsDocument11 pages20NC60VD STMicroelectronicscristianNo ratings yet

- Roof Mounted Smoke Extraction FanDocument7 pagesRoof Mounted Smoke Extraction FanIgor SpirovNo ratings yet

- 1.9 Flyback Converter in DCM: Output PowerDocument4 pages1.9 Flyback Converter in DCM: Output PowerRakesh SutharNo ratings yet

- Physics Multiple Choice QuestionsDocument8 pagesPhysics Multiple Choice QuestionsPranav AgrawalNo ratings yet

- Galileoscope Optics Guide 1.1Document46 pagesGalileoscope Optics Guide 1.1Fernando P Mancebo CampilloNo ratings yet

- Concentration of SolutionsDocument42 pagesConcentration of SolutionsAien RonquilloNo ratings yet

- Design of Beam Slide ShareDocument26 pagesDesign of Beam Slide ShareVRKVRK10No ratings yet

- Quadrant+SystemDocument34 pagesQuadrant+SystemVM ViKasNo ratings yet

- PLU Civil Engineering Department Midterm Exam ReviewDocument7 pagesPLU Civil Engineering Department Midterm Exam ReviewhaniiramosNo ratings yet

- Designing Forming Fabrics for Optimum Papermaking PerformanceDocument6 pagesDesigning Forming Fabrics for Optimum Papermaking PerformanceLev BNo ratings yet

- Simbawa Oliver Task 2 Reading Report Calculus and Its Application To PhysicsDocument3 pagesSimbawa Oliver Task 2 Reading Report Calculus and Its Application To PhysicsOliver SimbawaNo ratings yet

- Various Power Generation TechnologiesDocument2 pagesVarious Power Generation TechnologiesPhoon Hee YauNo ratings yet

- Section 7 - Separation EquipmentDocument9 pagesSection 7 - Separation Equipmentlulis171No ratings yet

- Iso 1183 2 2004Document16 pagesIso 1183 2 2004luciana :D100% (1)

- Quick Start Guide: FeaturesDocument2 pagesQuick Start Guide: FeaturescwchowNo ratings yet

- Physics Laboratory Report On Simple PendulumDocument9 pagesPhysics Laboratory Report On Simple PendulumTesfamichael AbathunNo ratings yet

- SunscreenDocument44 pagesSunscreenArtyom FreemanNo ratings yet

- Astm A135Document9 pagesAstm A135banglvhNo ratings yet

- Experimental Study On The Influence of Draft Relative Due To Wave Transmission Energy Coefficient On Hanging Sheet Pile BreakwaterDocument9 pagesExperimental Study On The Influence of Draft Relative Due To Wave Transmission Energy Coefficient On Hanging Sheet Pile BreakwaterChairul PaotonanNo ratings yet