Professional Documents

Culture Documents

Method Statement of Jack-In Pile - Rev.1 PDF

Uploaded by

AMIR ASYRAF ZAINUDINOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement of Jack-In Pile - Rev.1 PDF

Uploaded by

AMIR ASYRAF ZAINUDINCopyright:

Available Formats

METHOD STATEMENT OF JACK-IN PILE

Scope

To define and establish the method statement for Jack-In Precast Concrete RC Pile to

ground and set.

Material

- RC Pile size 150mm x 150mm

- RC Pile size 200mm x 200mm

Equipment

1. Pile Jack-in plant complete with crane

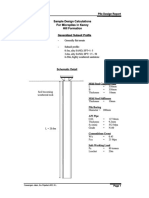

The “ZYC120B-B1” Injection machine with the capacity of 120 tonne complete with

crane shall be used. The equipment is using “grip” system and hydraulically injects

the pile into the ground.

2. Welding machine

A welding machine shall be used to welding the joint.

3. Diamond cutter

A diamond cutter shall be used to cut the pile if the installed piles restrict the jack-in

equipment movement. The pile shall be cut flush the ground level.

4. Steel plate

Proper steel plate shall be used if the Jack-in machine could not avoid to cross the

installed pile.

Setting Out

Based on the approved Pre-computation plan, the positions of the piles are set out on

site and pegs installed by a competent surveyor.

Handling and Storage

The method and sequence of lifting, handling, transporting and storing piles shall be

such that piles are not damaged. Only the designed lifting and support points shall be

placed on adequate to supports located under the lifting points of the piles.

Pitching

1. Piles shall be pitched accurately in the positions as shown on the Drawings. At all

stages during installation and until the pile has set, all exposed piles shall be cut off to

the ground level (provided is minimum 1 meter above cut off level) by means of

hydraulic breaker.

2. All cutting of pile to the cut off level shall be by diamond cutter. All cut off piles shall

be prevented from damage and deviated out of position.

JNH BINA SDN. BHD.

Driving Method

1. Mobilization and set up hydraulic Jack-in machine at site.

2. For unloading and shifting the piles, it must be lifted at the designated points.

3. Each pile shall be clearly marked at 300mm intervals along it length to enable the

Jack-in pressure / force to be recorder at every 250mm depth of pile penetration. The

interval may be larger if the penetration rate is fast due to soft ground.

4. Shifting the hydraulic Jack-in machine to the pile point position. The jacking

machine shall be couple with calibrated pressure gauge report.

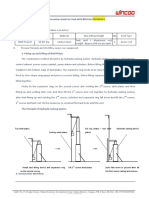

5. For pitching of pile into Jack-in plant, it would be lifted at one end near the upper

lifting eyes and slowly lift it up to vertical position. Then insert into the grip of the

jack-in plant.

6. Apply hydraulic pressure on the “grip” component, which will hold firmly and

evently on surface of the pile.

7. After the pile is gripped, verticality check shall be carried out by spirit level and

adjusting by mean 4 nos. Hydraulic stabilizer.

8. Jack-in force shall be gradually apply up to the required pressure. The Jack-in

forced shall be determined by the corresponding hydraulic pressure at the pressure

gauge. Except jointing, each pile shall be jack-in continuously until required resistance

or penetration is reached.

9. When the top of the pile is too low for the reach of grip component, a steel dolly

shall be lifted up by crane and placed on the top of pile head and apply hydraulic

pressure on the grip component which will grip firmly on the steel dolly and above

jacking sequence shall be repeat until pile achieved its bearing capacity or the top of

the initial pile head reached the existing ground level to receive the extension pile.

10. After the initial pile is installed and if an extension pile is required,it shall be

extended by means of butt weld the steel plates on the pile heads. On completion of

welding, the slag will be chipped off end wire brushed to receive a coat of anti-rust

paint or equivalent. Jacking shall the recommence not less than fifteen (15) minutes

after welding at the joint is completed.

Set Criteria

The maintained time for “set” should be 60 seconds.

The pile termination criteria shall be as follows:-

i. When it is noticed that the penetration is appreciably reduced, full pressure is

applied and unloaded to zero repeatedly. When instructed by Engineer that “set” can

be taken, full pressure is applied and maintained for at least 60 seconds before it is

released to zero. The pile settlement recorded when the full pressure was maintained

is recorded as “set”.

JNH BINA SDN. BHD.

ii. If the settlement measured exceeds 1mm, full pressure is again applied and

maintained for at least 60 seconds before being released. The “set” is then measured

again. The operation is repeated until the “set” is reduced to 1mm or less.

iii. A minimum of three (3) continuous readings of “set” (< 1mm) shall be taken

(measured by dial gauge and graph paper). Pile jacking may only be terminated when

the “sets” are in the acceptable range.

JNH BINA SDN. BHD.

You might also like

- Case 580k SMDocument1,303 pagesCase 580k SMgrebnesor100% (8)

- 01) Jack-In Pile SubmissionDocument47 pages01) Jack-In Pile Submissionalfredo100% (2)

- Erection of DPC Clinker Silo Extraction-2Document7 pagesErection of DPC Clinker Silo Extraction-2RajuNo ratings yet

- Set Calculation For Hammer Driven Piles Using Modofoed HILLEY's FormulaDocument2 pagesSet Calculation For Hammer Driven Piles Using Modofoed HILLEY's Formulaqoci5ko89% (9)

- MBE900 Nozzle Holder PDFDocument5 pagesMBE900 Nozzle Holder PDFJosue Alvarez VegaNo ratings yet

- Milling MachineDocument80 pagesMilling Machineravi upadhyayNo ratings yet

- Kessler Transfer Case PDFDocument27 pagesKessler Transfer Case PDFazamen100% (1)

- Method Statement For GunitingDocument2 pagesMethod Statement For GunitingAlsonChin100% (1)

- Methodology For Pile Foundation 08-09Document4 pagesMethodology For Pile Foundation 08-09Jeremy Jenkins86% (7)

- Method Statement of HACKING WORKS ON CONCRETE WALL FOR LIFTDocument3 pagesMethod Statement of HACKING WORKS ON CONCRETE WALL FOR LIFTfaizbukhari100% (2)

- Method Statement of Hoarding PDFDocument1 pageMethod Statement of Hoarding PDFAMIR ASYRAF ZAINUDINNo ratings yet

- Marudi-Wms003 - Piling Work - RC Square PileDocument31 pagesMarudi-Wms003 - Piling Work - RC Square PileKelvin LauNo ratings yet

- Pile Head Treatment Method StatementDocument12 pagesPile Head Treatment Method StatementĐặng Quang Huy100% (1)

- 012 Piling WorkDocument17 pages012 Piling WorkFara Atika Bha Ney100% (3)

- METHOD OF STATEMENT-Mackintosh Probe TestDocument3 pagesMETHOD OF STATEMENT-Mackintosh Probe TestAzmi SabriNo ratings yet

- Method Statement For PILINGDocument7 pagesMethod Statement For PILINGcworld86% (7)

- The Rise Resort Skim Coating ProjectDocument10 pagesThe Rise Resort Skim Coating ProjectMin Luo100% (1)

- Itp V2 2015 PDFDocument218 pagesItp V2 2015 PDFLynn Mail100% (1)

- Pile Set CriteriaDocument3 pagesPile Set CriteriaAnonymous O404LiV4CNo ratings yet

- Example Method Statement For DrainageDocument3 pagesExample Method Statement For DrainageLynn Mail100% (8)

- METHOD STATEMENt Retaining WallDocument3 pagesMETHOD STATEMENt Retaining WallKamal Ismail50% (8)

- JKR Geotechnical SpecificationDocument9 pagesJKR Geotechnical SpecificationSousei No Keroberos100% (1)

- 08-02 ManholeTestingDocument3 pages08-02 ManholeTestingelcivilengNo ratings yet

- 773EDocument31 pages773EWilliams ArayaNo ratings yet

- Calculation of Pile Set Using Hiley FormulaDocument14 pagesCalculation of Pile Set Using Hiley FormulahauzhiNo ratings yet

- Test Method MP JKR PROBEDocument2 pagesTest Method MP JKR PROBENedyHortetl100% (1)

- Method Statement For PilecapDocument6 pagesMethod Statement For PilecapMohd Nizamuddin Mohamad Noor100% (2)

- RC Piling Method for Elevated Water TankDocument6 pagesRC Piling Method for Elevated Water TankPUI CHEE KHIAN100% (3)

- Construction of Tanks Using Caisson Sinking MethodDocument3 pagesConstruction of Tanks Using Caisson Sinking MethodPilingHammerNo ratings yet

- Example Method Statement Jack in-PPCDocument4 pagesExample Method Statement Jack in-PPCLatifi AmirNo ratings yet

- Pile Set CalculationDocument2 pagesPile Set Calculationqoci5ko100% (1)

- MS 145 2006Document20 pagesMS 145 2006Tank LanNo ratings yet

- Work Method Statement FOR Laying of Pipe Culvert and Concrete Sump at Existing DrainDocument3 pagesWork Method Statement FOR Laying of Pipe Culvert and Concrete Sump at Existing DrainLynn Mail100% (1)

- Method Statement For Micropiling Works-Jbt. Kedua Sg. YongDocument2 pagesMethod Statement For Micropiling Works-Jbt. Kedua Sg. YongKelvin LauNo ratings yet

- Method Statement - Preboring - R1Document5 pagesMethod Statement - Preboring - R1Dionisius Sapto100% (1)

- Method Statement of Jack-In Pile - Rev.1 PDFDocument3 pagesMethod Statement of Jack-In Pile - Rev.1 PDFAMIR ASYRAF ZAINUDIN100% (1)

- Method Statement For The Rectification Hacked Staircase 1 Landing at Level 31Document2 pagesMethod Statement For The Rectification Hacked Staircase 1 Landing at Level 31Bunga Teratai50% (4)

- Method Statement Rectification of Insufficient Lapping Length 45 Dia. For Column Starter BarDocument2 pagesMethod Statement Rectification of Insufficient Lapping Length 45 Dia. For Column Starter BarMohd Hafizul Hj Tanalol100% (1)

- API 6A, 16A, BX Ring Gaskets, BX Ring Gasket DimensionsDocument1 pageAPI 6A, 16A, BX Ring Gaskets, BX Ring Gasket DimensionsKaleem UllahNo ratings yet

- Method Statement of Jack-In Pile PDFDocument3 pagesMethod Statement of Jack-In Pile PDFAMIR ASYRAF ZAINUDIN100% (1)

- Method Statement for Driven Spun Piles InstallationDocument5 pagesMethod Statement for Driven Spun Piles InstallationTinesh K RamanNo ratings yet

- 3 Propulsion and Fuel SystemsDocument39 pages3 Propulsion and Fuel SystemsFanhang ZhangNo ratings yet

- Mackintosh/JKR Probe Test Determines Soil Bearing CapacityDocument4 pagesMackintosh/JKR Probe Test Determines Soil Bearing CapacityDeraman AbdullahNo ratings yet

- Lecture 4 - Jack-In PileDocument52 pagesLecture 4 - Jack-In PileAyingaran Thevathasan100% (3)

- Metals Classification and Properties GuideDocument40 pagesMetals Classification and Properties Guideaman sudiNo ratings yet

- Apd Catalog PDFDocument28 pagesApd Catalog PDFsoo RenNo ratings yet

- 1701-Drainage Method StatementDocument3 pages1701-Drainage Method StatementMisz_10_ScorpioNo ratings yet

- Damage Stability: Principles of Naval Architecture The Management of Merchant Ship Stability, Trim & StrengthDocument28 pagesDamage Stability: Principles of Naval Architecture The Management of Merchant Ship Stability, Trim & StrengthAnwarul Shafiq AwalludinNo ratings yet

- Syabas DWG LatestDocument1 pageSyabas DWG LatestThoong Yew ChanNo ratings yet

- Sunway Spun Pile PDFDocument2 pagesSunway Spun Pile PDFLim Cheng Zhou100% (1)

- MS JKR Road Work SpecDocument6 pagesMS JKR Road Work SpecDarren WanNo ratings yet

- Bakau Pile SpecificationDocument1 pageBakau Pile SpecificationHoo Yen How100% (6)

- Method Statement Pressure GroutingDocument2 pagesMethod Statement Pressure GroutingStephen David Gozun100% (5)

- MSCL Pipe Rev2Document9 pagesMSCL Pipe Rev2Ahmad Zakwan AsmadNo ratings yet

- Procedure For Spun Pile at Vac 1 (CH 155.55)Document11 pagesProcedure For Spun Pile at Vac 1 (CH 155.55)Ami ShafiNo ratings yet

- MS1314 2004 Pile SpecificattionDocument28 pagesMS1314 2004 Pile SpecificattionmaNo ratings yet

- Method Statement For Installation of Soil Nails SK Kauluan, Ranau .Document9 pagesMethod Statement For Installation of Soil Nails SK Kauluan, Ranau .Asdia Aseffah FathiyaNo ratings yet

- Method Statement For Piling WorksDocument2 pagesMethod Statement For Piling Worksshahul_hamid_277% (22)

- Method Statement Bored PileDocument9 pagesMethod Statement Bored PileAsma Farah100% (3)

- Appendix 5 D Method Statement For Construction ActivitiesDocument48 pagesAppendix 5 D Method Statement For Construction ActivitiesNajmul QamarNo ratings yet

- Method Statement of Floor HardenedDocument2 pagesMethod Statement of Floor HardenedTaqiuddinHarith100% (1)

- Micropile Design Calculations for Kenny Hill FormationDocument89 pagesMicropile Design Calculations for Kenny Hill Formationmatt n100% (1)

- PILE CAPACITY CALCULATORDocument7 pagesPILE CAPACITY CALCULATORAdrian DorhatNo ratings yet

- Cadangan Pembaikan Cerun Dan Kerja-Kerja Berkaitan Di SK Kauluan Ranau, SabahDocument6 pagesCadangan Pembaikan Cerun Dan Kerja-Kerja Berkaitan Di SK Kauluan Ranau, SabahAsdia Aseffah Fathiya100% (1)

- 37 - Method Statement For Windsor Probe TestDocument8 pages37 - Method Statement For Windsor Probe TestNaj Nasir100% (1)

- Gabion construction proceduresDocument6 pagesGabion construction proceduresHakim HuriNo ratings yet

- Caisson Method Statement For Pipe JackingDocument2 pagesCaisson Method Statement For Pipe JackingTeddy TP100% (1)

- Piling Works WMSDocument8 pagesPiling Works WMSRufahniyah LizhaNo ratings yet

- CM For Pile Cap Formwork Revise RE 12 Maret 2007 (Submitted)Document45 pagesCM For Pile Cap Formwork Revise RE 12 Maret 2007 (Submitted)Gangsar Lukmanjaya100% (1)

- 02 Construction Guide For TankDocument16 pages02 Construction Guide For TankARABONo ratings yet

- Mill Wright 1Document56 pagesMill Wright 1balamuruganNo ratings yet

- Erection of Reciprocating CompressorsDocument21 pagesErection of Reciprocating Compressorsahmed meselhyNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Method Statement - PILE CAPS PDFDocument8 pagesMethod Statement - PILE CAPS PDFAMIR ASYRAF ZAINUDINNo ratings yet

- Work Program SpiceDocument4 pagesWork Program SpiceAMIR ASYRAF ZAINUDINNo ratings yet

- Work Program SpiceDocument4 pagesWork Program SpiceAMIR ASYRAF ZAINUDINNo ratings yet

- MS PVD 1 PDFDocument4 pagesMS PVD 1 PDFAMIR ASYRAF ZAINUDINNo ratings yet

- Method Statement EarthworksDocument7 pagesMethod Statement EarthworksAMIR ASYRAF ZAINUDINNo ratings yet

- 512 Army Base WorkshopDocument8 pages512 Army Base WorkshopSinZahoNo ratings yet

- Compact LPG injection system for small vehiclesDocument2 pagesCompact LPG injection system for small vehiclesMayamayar GreenmotorsNo ratings yet

- Natural Convection Heat Transfer From A Long Heated Vertical Cylinder To An Adjacent Air Gap of Concentric and Eccentric ConditionsDocument6 pagesNatural Convection Heat Transfer From A Long Heated Vertical Cylinder To An Adjacent Air Gap of Concentric and Eccentric ConditionskarthikeyanNo ratings yet

- Lecture 36 - Phase Change Heat ExchangersDocument19 pagesLecture 36 - Phase Change Heat ExchangersVidvendu GuptaNo ratings yet

- Power Supply and Ground ComponentsDocument41 pagesPower Supply and Ground Componentsscott glackenNo ratings yet

- Getting The Flow of MAF Sensors PDFDocument4 pagesGetting The Flow of MAF Sensors PDFFabricio LimaNo ratings yet

- XF Series 1-1.8t Mast Parts Catalog 2022.10Document102 pagesXF Series 1-1.8t Mast Parts Catalog 2022.10santiago medinaNo ratings yet

- Mini Stepper Shaft Design: INME 4011 Machine Component Design 1, 2007-IDocument27 pagesMini Stepper Shaft Design: INME 4011 Machine Component Design 1, 2007-IjudarangocaNo ratings yet

- AMD Tutorial Stress StrainDocument3 pagesAMD Tutorial Stress Strainrip111176No ratings yet

- ACI 421.1R-99: Reported by Joint ACI-ASCE Committee 421Document15 pagesACI 421.1R-99: Reported by Joint ACI-ASCE Committee 421Fred PrzNo ratings yet

- MIT physics problem solutionsDocument5 pagesMIT physics problem solutionsJake AJNo ratings yet

- EagleBurgmann - E110801 - E1 - High-Pressure Seals For ESPO Pipeline Pumps - 10.11 PDFDocument2 pagesEagleBurgmann - E110801 - E1 - High-Pressure Seals For ESPO Pipeline Pumps - 10.11 PDFkztro066No ratings yet

- Cascade Boiler Rooms: Catalogue of ComponentsDocument40 pagesCascade Boiler Rooms: Catalogue of Componentsabu7omar-1No ratings yet

- Drill Pipe Flow Chart PDFDocument1 pageDrill Pipe Flow Chart PDFairlinemembershipNo ratings yet

- PropertiesDocument26 pagesPropertiesafaq ahmad khanNo ratings yet

- 5 6327711652896571694Document168 pages5 6327711652896571694Anant SaggamNo ratings yet

- Unit V - Rocket PropulsionDocument5 pagesUnit V - Rocket PropulsionKeerthi VarmanNo ratings yet

- SR Catalog of WBCUDocument23 pagesSR Catalog of WBCUEdgar GomezNo ratings yet

- Kushal Kushal Tractors TractorsDocument12 pagesKushal Kushal Tractors TractorsMourya kanthNo ratings yet