Professional Documents

Culture Documents

Design Input: TS DF

Uploaded by

Omar Wardeh0 ratings0% found this document useful (0 votes)

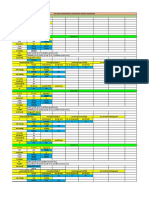

4 views2 pagesThe document contains specifications for designing two storage tanks, one for LPG and one for propane. The LPG tank has a design pressure of 12.65 bar, internal diameter of 3790 mm, and shell thickness of 20 mm carbon steel. The propane tank has a higher design pressure of 20.5 bar, requires 28 mm thick carbon steel for the shell, and 17.4 mm thick hemispherical dish end. Design calculations are shown for determining the minimum required shell thicknesses based on the material properties and internal pressures and diameters.

Original Description:

Original Title

NOTE

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document contains specifications for designing two storage tanks, one for LPG and one for propane. The LPG tank has a design pressure of 12.65 bar, internal diameter of 3790 mm, and shell thickness of 20 mm carbon steel. The propane tank has a higher design pressure of 20.5 bar, requires 28 mm thick carbon steel for the shell, and 17.4 mm thick hemispherical dish end. Design calculations are shown for determining the minimum required shell thicknesses based on the material properties and internal pressures and diameters.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pagesDesign Input: TS DF

Uploaded by

Omar WardehThe document contains specifications for designing two storage tanks, one for LPG and one for propane. The LPG tank has a design pressure of 12.65 bar, internal diameter of 3790 mm, and shell thickness of 20 mm carbon steel. The propane tank has a higher design pressure of 20.5 bar, requires 28 mm thick carbon steel for the shell, and 17.4 mm thick hemispherical dish end. Design calculations are shown for determining the minimum required shell thicknesses based on the material properties and internal pressures and diameters.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Design input

Content LPG

Design pressure bar 12.65

Temperature design °C 50

Material Carbon 20 mm th s275 jr cr

steel

Internal diameter mm 3790

length tangent to tangent mm 52800

Dish End Hemispherical

Material of dish end Carbon 15mm th-s275 jr

steel

Operating pressure (OP) = 11.5 bar

Design pressure (DP) DP=1.1 ×OP=1.1 ×11.5=12.65 ¯¿

Tensile strength (TS)-FOR MATERIAL SUPPLID = 480 Mpa

Design Factor (DF) = 3.5

TS 480

Allowable STress (S) = S= = =137.14 Mpa

DF 3.5

E joint efficiency = 1

Corrosion Allowance CR = 3 mm

P×R 12.65 ×0.1 ×1.895

Thickness of shell : t= +CR= +3=20 mm

( S . E−0.6 P) (137.14 ×1−0.6 ×1.265)

METHOD NO 2

THIKNESS REQUIRED FOR SHEEL 20MM

P×R 12.65 ×0.1 ×1895

t= +CR= +3=20.35 mm

( S . E+0.4 P) (137.14 ×1+0.4∗1.265)

SHEPHIRALE SHELLS

P×R 12.65 ×0.1 ×1895 2398

t= = = =8 .7 mm

(2 SE+ 0.8 P) (2 ×137.14 × 1+ 0.8 ×1.265) 275.28

METHOD NO 2

P×R 12.65 ×0.1 ×1895 2398

t= = = =8.7 mm

(2 SE+ 0.8 P) (2 ×137.14 × 1−0.2 ×1.265) 274.533

Design input

Content Propane

Design pressure bar 20.5

Temperature design °C 50

Material Carbon 28mm th s355 jr cr

steel

Internal diameter mm 3774

length tangent to tangent mm 52800

Dish End Hemispherical

Material of dish end Carbon 20mm th-s355 jr

steel

Operating pressure (OP) = 18.6 bar

Design pressure (DP) DP=1.1 ×OP=1.1 ×18.6=20.5 ¯¿

Tensile strength (TS)-FOR MATERIAL SUPPLID = 559 Mpa

Design Factor (DF) = 3.5

TS 559

Allowable press (S) = S= = =159.71 Mpa

DF 3.5

E joint efficiency = 1

Corrosion Allowance CR = 3 mm

P×R 20.5× 0.1× 1887

Thickness of shell : t= +CR= +3=27.44 mm

( S . E−0.6 P) (159.71× 1−0.6 × 2.05)

METHOD NO 2

THIKNESS REQUIRED FOR SHEEL 28MM

P×R 20.5× 0.1× 1887

t= +CR= +3=27.09 mm

( S . E+0.4 P) (159.71× 1+ 0.4∗2.05)

SHEPHIRALE SHELLS

P×R 20.5× 0.1 ×1887 3868.35

t= = = =12.2mm

(2 SE+ 0.8 P) (2 ×157.71 ×1+0.8 ×2.05) 317.06

METHOD NO 2

P×R 20.5 ×0.1 ×1887 3868.35

t= = = =12.28 mm

(2 SE+ 0.8 P) (2 ×157.51 ×1−0.2× 2.05) 315.01

You might also like

- Design of I C Engine Connecting RodDocument6 pagesDesign of I C Engine Connecting RodBinoy K BNo ratings yet

- Allowed Time: 60 Mins: Subject: Mechanical Design of Chemical Vessels Test #1 - Open Book - 11Document9 pagesAllowed Time: 60 Mins: Subject: Mechanical Design of Chemical Vessels Test #1 - Open Book - 11Hoàng Hữu QuốcNo ratings yet

- Calculation As Per Asme b31.3Document8 pagesCalculation As Per Asme b31.3Rajkumar ANo ratings yet

- Deign of PartsDocument11 pagesDeign of PartsMohamad Ahmed Hussein Abd elaalNo ratings yet

- Calculo de Recipientes A PresionDocument2 pagesCalculo de Recipientes A PresionCesar Augusto Castellar OrtegaNo ratings yet

- Informe TensionDocument4 pagesInforme TensionLuz Merlis Chávez SuárezNo ratings yet

- Exercises Problem On Spur Gear Nomenclatures: Module 2: Activity No. 2Document4 pagesExercises Problem On Spur Gear Nomenclatures: Module 2: Activity No. 2Leyzer MalumayNo ratings yet

- Operating Pressure 6.5 × N M N M × MM N MMDocument8 pagesOperating Pressure 6.5 × N M N M × MM N MMAZMINo ratings yet

- Div 2 THK CalcDocument10 pagesDiv 2 THK CalcelleNo ratings yet

- Inner Vessel Check Shell Thickness For Internal PressureDocument6 pagesInner Vessel Check Shell Thickness For Internal PressureSAMER OSMANNo ratings yet

- Calculation PSV and WeldDocument29 pagesCalculation PSV and WeldMuhammad Khoirul KhabibiNo ratings yet

- Manufactueing ProcessDocument7 pagesManufactueing ProcessZaw Min HtetNo ratings yet

- Allowable Stress SA 285 GR CDocument4 pagesAllowable Stress SA 285 GR Cdianita nurnandaNo ratings yet

- Structural EngineeringDocument6 pagesStructural EngineeringSammy SafoNo ratings yet

- Flange CouplingDocument16 pagesFlange CouplingARUN VNo ratings yet

- Efficycle 2016 Design Abstract FormatDocument16 pagesEfficycle 2016 Design Abstract FormatNABIL HUSSAINNo ratings yet

- Receiver Design StepsDocument3 pagesReceiver Design StepsSureshkannan VNo ratings yet

- Design of SplicingDocument13 pagesDesign of SplicingMc Tyler Reyes YuntingNo ratings yet

- AD 2000 Shell Under External PressureDocument3 pagesAD 2000 Shell Under External Pressuremechengg01100% (1)

- Design of Nozzle Thickness As Per Ug-45 of Asme Sec. Viii Div. 1 Nozzle MarkDocument1 pageDesign of Nozzle Thickness As Per Ug-45 of Asme Sec. Viii Div. 1 Nozzle MarkpratyaNo ratings yet

- Calculation AC-1 SunjinDocument3 pagesCalculation AC-1 SunjinJoulee NurimanNo ratings yet

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

- Flange Bolt LoadDocument3 pagesFlange Bolt LoadSAMER OSMANNo ratings yet

- Calc Wall Thickness B31.8Document1 pageCalc Wall Thickness B31.8panjiajinugroho23No ratings yet

- Baffle Design - by MossDocument6 pagesBaffle Design - by MossshaishavNo ratings yet

- 7 One Way SlabDocument4 pages7 One Way SlabPronay DhakNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Design of Worm GearsDocument5 pagesDesign of Worm GearsvenkateshNo ratings yet

- Allowable Soil Pressure: DL+RLL 150 KN/M DL+MLL 225 KN/MDocument19 pagesAllowable Soil Pressure: DL+RLL 150 KN/M DL+MLL 225 KN/MUno CasprowichNo ratings yet

- BALOKDocument9 pagesBALOKMuhammadTamNo ratings yet

- Perhitungan Kekuatan Konstruksi Bejana Tekanan: Ketebalan Minimal ShellDocument6 pagesPerhitungan Kekuatan Konstruksi Bejana Tekanan: Ketebalan Minimal Shellyafi hanifNo ratings yet

- Column Computation For Third Floor: A P G (Ag) A ADocument3 pagesColumn Computation For Third Floor: A P G (Ag) A AVergel Pabunan NogadasNo ratings yet

- Design of Stairs Design of Stairs From Ground To Landing Material PropertiesDocument3 pagesDesign of Stairs Design of Stairs From Ground To Landing Material PropertiesJohn Paul Hilary EspejoNo ratings yet

- Shell (S) : ASME Code VIII Div I 2010 Edition 2012 AddendaDocument1 pageShell (S) : ASME Code VIII Div I 2010 Edition 2012 AddendaPhát NguyễnNo ratings yet

- 5.1 Design Calculation of Vertical Pressure Vessel (MGF - ACF)Document2 pages5.1 Design Calculation of Vertical Pressure Vessel (MGF - ACF)shakib nazmus100% (2)

- حل بروبلمات مقاومه فصل ٧Document15 pagesحل بروبلمات مقاومه فصل ٧حسن صالح حسن المياحيNo ratings yet

- Piping Calculation Program For ASME B31 1 CodeDocument3 pagesPiping Calculation Program For ASME B31 1 CodeAMIT100% (2)

- Door OpeningDocument8 pagesDoor OpeningMd MohsinNo ratings yet

- Laporan Sistem Pemipaan: Program Studi Teknik Mesin S1 Fakultas Teknik Universitas Riau 2018Document5 pagesLaporan Sistem Pemipaan: Program Studi Teknik Mesin S1 Fakultas Teknik Universitas Riau 2018Domi NoxNo ratings yet

- AD 2000 Head Under Intenal PressureDocument3 pagesAD 2000 Head Under Intenal Pressuremechengg01No ratings yet

- Design For External Pressure-13022018Document14 pagesDesign For External Pressure-13022018Toni100% (1)

- Quality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodeDocument7 pagesQuality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodejunarkoNo ratings yet

- KKKKKKKKKKKKKKKKKNKJDocument5 pagesKKKKKKKKKKKKKKKKKNKJsksj cusjsNo ratings yet

- Problem SolvingDocument6 pagesProblem SolvingImran NoorNo ratings yet

- EJ CalculationDocument16 pagesEJ CalculationAmit NayakNo ratings yet

- Reactor & Flat Head ThicknessDocument2 pagesReactor & Flat Head ThicknessNUR AKMAL HISHAMNo ratings yet

- Design of ComponentsDocument10 pagesDesign of ComponentswabdushukurNo ratings yet

- Top Roof: Tank Tag No.: EG2-D-6306ADocument6 pagesTop Roof: Tank Tag No.: EG2-D-6306ASAMER OSMANNo ratings yet

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- Calculation Sheet: Act IDocument2 pagesCalculation Sheet: Act IFazri CMENo ratings yet

- Column ComputationDocument5 pagesColumn ComputationPoppy MooreNo ratings yet

- Asme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoDocument72 pagesAsme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoSivateja NallamothuNo ratings yet

- Design For External Pressure-13022018Document14 pagesDesign For External Pressure-13022018ToniNo ratings yet

- PerhitunganDocument5 pagesPerhitungansarah hadisuryaNo ratings yet

- Tugas Besar BetonDocument9 pagesTugas Besar BetonNatu IgasNo ratings yet

- Intze Tank 1 Moin 25-1-23Document17 pagesIntze Tank 1 Moin 25-1-23MOIN UDDINNo ratings yet

- Perancangan Pressure Vessel Water TankDocument6 pagesPerancangan Pressure Vessel Water TankAlda EricaNo ratings yet

- Shell and Tube HE CalculationDocument16 pagesShell and Tube HE CalculationPradip ShindeNo ratings yet

- Sample Projects: Societe Huiles Et DerivesDocument1 pageSample Projects: Societe Huiles Et DerivesOmar WardehNo ratings yet

- Sample Projects: Societe Huiles Et DerivesDocument1 pageSample Projects: Societe Huiles Et DerivesOmar WardehNo ratings yet

- Sample Projects: Sabbagh BuildingDocument1 pageSample Projects: Sabbagh BuildingOmar WardehNo ratings yet

- Final Catalog Design - Part13Document1 pageFinal Catalog Design - Part13Omar WardehNo ratings yet

- Sample Projects: Stairs Al Saha BeirutDocument1 pageSample Projects: Stairs Al Saha BeirutOmar WardehNo ratings yet

- Sample Projects: Brikama Power PlantDocument1 pageSample Projects: Brikama Power PlantOmar WardehNo ratings yet

- N CO H S C C C IC NC IC NC C Methyl Cyclo Pentane Benzene C Toluene C Ethyl Benzene M-Xylene P-Xylene O-Xylene C C C CDocument1 pageN CO H S C C C IC NC IC NC C Methyl Cyclo Pentane Benzene C Toluene C Ethyl Benzene M-Xylene P-Xylene O-Xylene C C C COmar WardehNo ratings yet

- Part 3Document1 pagePart 3Omar WardehNo ratings yet

- Capital Gas (209514) GPC Field (El Hamd, El Fanar, Gharib and Shoukeir Fields New - Part5 PDFDocument1 pageCapital Gas (209514) GPC Field (El Hamd, El Fanar, Gharib and Shoukeir Fields New - Part5 PDFOmar WardehNo ratings yet

- Sample Projects: The Gambia Conventional Mooring BuoysDocument1 pageSample Projects: The Gambia Conventional Mooring BuoysOmar WardehNo ratings yet

- Well: Various Fields Job Number EG/PVT/209514Document1 pageWell: Various Fields Job Number EG/PVT/209514Omar WardehNo ratings yet

- Company:: Capital Gas EgyptDocument1 pageCompany:: Capital Gas EgyptOmar WardehNo ratings yet

- Capital Gas Egypt,: Dear SirDocument1 pageCapital Gas Egypt,: Dear SirOmar WardehNo ratings yet

- T 8 S G C A W: e F C N: 5112Document1 pageT 8 S G C A W: e F C N: 5112Omar WardehNo ratings yet

- 209514Document1 page209514Omar WardehNo ratings yet

- Part 8Document1 pagePart 8Omar WardehNo ratings yet

- Part 11Document1 pagePart 11Omar WardehNo ratings yet

- Corex's: PVT Laboratory ServicesDocument1 pageCorex's: PVT Laboratory ServicesOmar WardehNo ratings yet

- Part 10Document1 pagePart 10Omar WardehNo ratings yet

- Part 9Document1 pagePart 9Omar WardehNo ratings yet

- Part 12Document1 pagePart 12Omar WardehNo ratings yet

- Technical Description Delta 2015.12.10 - Final Version - Part26Document1 pageTechnical Description Delta 2015.12.10 - Final Version - Part26Omar WardehNo ratings yet

- Technical Description Delta 2015.12.10 - Final Version - Part27Document1 pageTechnical Description Delta 2015.12.10 - Final Version - Part27Omar WardehNo ratings yet

- Corex: QualityDocument1 pageCorex: QualityOmar WardehNo ratings yet

- Technical Description Delta 2015.12.10 - Final Version - Part22Document1 pageTechnical Description Delta 2015.12.10 - Final Version - Part22Omar WardehNo ratings yet

- CoCom Lists - 1991 SeptDocument100 pagesCoCom Lists - 1991 SeptSamuel Evans100% (1)

- Hexweb - Honeycomb Attributes and Properties PDFDocument40 pagesHexweb - Honeycomb Attributes and Properties PDFkolle_sdestefaNo ratings yet

- C312-Assignment 3&4 CompileDocument35 pagesC312-Assignment 3&4 CompileDanica Joy AlfarNo ratings yet

- Bradt R C Munz D Sakai M White K W Fracture Mechanics of Cer PDFDocument608 pagesBradt R C Munz D Sakai M White K W Fracture Mechanics of Cer PDFГриг ГритNo ratings yet

- HumidificationDocument26 pagesHumidificationOky TresiaNo ratings yet

- Astm D 2583-95 R01Document4 pagesAstm D 2583-95 R01Felix Gonzalez BlancoNo ratings yet

- Oil Tubine DatasheetDocument2 pagesOil Tubine DatasheetHANIF AKBARNo ratings yet

- Horizontal Vessel Foundation Design FounDocument22 pagesHorizontal Vessel Foundation Design FounAllanNo ratings yet

- Code of Practice For Concrete Road Bridges Irc:112: ULS For Linear ElementsDocument6 pagesCode of Practice For Concrete Road Bridges Irc:112: ULS For Linear ElementsSony JsdNo ratings yet

- SLD GensetDocument1 pageSLD GensetIan Carlos AnchetaNo ratings yet

- How To Prepare Complete Piping Material SpecificationDocument2 pagesHow To Prepare Complete Piping Material SpecificationThet Naing TunNo ratings yet

- Sample BOQDocument93 pagesSample BOQkanishkaNo ratings yet

- Cast Irons: MSE 206-Materials Characterization I Lecture-6Document21 pagesCast Irons: MSE 206-Materials Characterization I Lecture-6Jose Luis Valin RiveraNo ratings yet

- The Optimum Coolant Temperature For Maruti 800 Engine Is Around 92 DegreesDocument3 pagesThe Optimum Coolant Temperature For Maruti 800 Engine Is Around 92 DegreesMohseen KarcheNo ratings yet

- Mbm-Italien EnuDocument285 pagesMbm-Italien EnuRadwan AL TrougNo ratings yet

- Compulsory Ethiopian Standard For Building Spatial Design CES 164Document67 pagesCompulsory Ethiopian Standard For Building Spatial Design CES 164BiniNo ratings yet

- "Torsion9" - Simplified Torsion Analysis For Steel Beams: Program DescriptionDocument13 pages"Torsion9" - Simplified Torsion Analysis For Steel Beams: Program DescriptionAmmar Nasiri AlrubaaiNo ratings yet

- Design of Counterfort Retaining WallDocument14 pagesDesign of Counterfort Retaining WallMonjit Gogoi100% (5)

- MC&TDDocument4 pagesMC&TDGopal Krishan0% (1)

- Ficha Técnica Stemgrass 50mm - Chile PastosDocument1 pageFicha Técnica Stemgrass 50mm - Chile PastosCarlosAlfonsoVasconcelloPeñaNo ratings yet

- Belzona Clear Cladding ConcentrateDocument2 pagesBelzona Clear Cladding ConcentrateBobby SatheesanNo ratings yet

- STA 449 F5 Jupiter en WebDocument16 pagesSTA 449 F5 Jupiter en WebMartín BenzoNo ratings yet

- Technical Bulletin For Kwik BoltDocument3 pagesTechnical Bulletin For Kwik BoltAbu Hena Mostofa KamalNo ratings yet

- Joule-Thomson Coefficient: Exercise 3Document4 pagesJoule-Thomson Coefficient: Exercise 3Ry NeutronNo ratings yet

- Design of SlabDocument7 pagesDesign of SlabAlam Mohammad Parvez SaifiNo ratings yet

- Strength and Chloride Ion Penetration Resistance of Ultra High Pe 2021 StrucDocument8 pagesStrength and Chloride Ion Penetration Resistance of Ultra High Pe 2021 StrucYoukhanna ZayiaNo ratings yet

- Ground Fault For Micrologic Trip UnitsDocument4 pagesGround Fault For Micrologic Trip UnitsLarry HaryNo ratings yet

- Dos 2 MCQ Unit 2, 3Document14 pagesDos 2 MCQ Unit 2, 3suresh kannanNo ratings yet

- Asco Valves Series T298Document2 pagesAsco Valves Series T298OceanexNo ratings yet

- Homework#6 F14 - M E 311Document1 pageHomework#6 F14 - M E 311Jeremy PriestNo ratings yet