Professional Documents

Culture Documents

Maintenance Service Procedure Document For AMC: Scada &telecom System For Agcl Gas Pipeline Network

Uploaded by

anupamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance Service Procedure Document For AMC: Scada &telecom System For Agcl Gas Pipeline Network

Uploaded by

anupamCopyright:

Available Formats

This document is exclusive property of ABB Limited.

It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK .

Maintenance Service Procedure Document for AMC

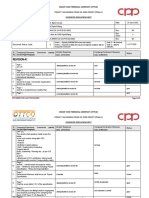

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 1

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

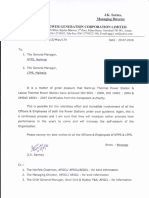

CSR:

With Ref to the comments vide

TE E-mail for AGCL _ Trial run punch points status Dated: 10.10.2019

ABB Document Identify: 3BYN496024-Txxx Dated: 27.09.2019

Doc Title: Maintenance Service Procedure Document for AMC Rev no. – 00

Our Reply/ Response is as follows:

Sl Comments from TE-IN/AGCL Response by

No ABB

1 ABB shall submit visit plan details in proper format with sign & stamp of project manager & concern engineer. This Noted &

shall be submitted in two sets of hard copies. Format should have following Format

1. hard copy in form of booklet. attached

2. add column- visit date, visitor sign, Problem identify, Problem attended and remark.

3. Format should have project no, PO no, logo of client, project name etc.

2 Noted &

Incorporated

Please refer

Cloud Mark,

TE Comments: This shall be within 48 Hrs as per AMC conditions Page no 9 of

19

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 2

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

3 Noted &

Incorporated

Please refer

Cloud Mark,

TE Comments: All the softwares up gradation of system shall be in ABB scope of work, refer AMC details Page no 6 of

19

4 Page 7 of 17 Noted &

Incorporated

Please refer

Cloud Mark,

Page no 9 of

TE Comments: this statement is not acceptable. ABB shall use spare but after repair of faulty hardware, same shall be 19

put back in service and used spare shall be once again kept in spare for future.

Table of content

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 3

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

1. Introduction.................................................................................................…….. 3

1.1 Project Introduction 3

1.2 Project Objective...............................................................................................................3

2. Introduction and Scope of maintenance Service......................................................4

2.1 Services Covered under scope of Maintenance service...............................................4

3. Preventive Maintenance Services……………………………………………………………………………5

3.1Half Yearly PM procedure for 74 TE, Major Consumer & PRS under New SCADA Scope…….6

3.2Half Yearly PM procedure for MCS…………………………………………………………………………………….6

3.3Tools & Testing equipment………………………………………………………………………………………………..6

4.Breakdown Maintenance Services……………………………………………………………………………..7

4.1 Breakdown Maintenance Procedure………………………………………………………………………………..7.

5. Report Submission during AMC……………………………………………………………………………………8

5.1 Monthly Report……………………………………………………………………………………………………………..8

5.2 Quarterly Report……………………………………………………………………………………………………………8

6. Exclusion……………………………………………………………………………………………………………………8

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 4

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

1. INTRODUCTION

1.1. Project Introduction

Assam Gas Company Ltd., Duliajan has been in the business of transporting high pressure and low pressure natural gas, through

its transmission and distribution network covering five districts of upper Assam, India to several key segments

The gas is collected presently from sources of OIL and ONGCL. However, gas from other producers may also be injected into

AGCL network as and when available, the compressed gas is transported by dedicated and common carriers lines to industries

such as Brahmaputra Valley Fertilizer Corporation Ltd (BVFCL), Assam Petrochemical Limited (APL), Namrup Thermal Power

Station (NTPS) and uncompressed natural gas to Lakwa thermal power station (LTPS) and Power Plant of NEEPCO. The company

also supplies low pressure natural gas to over 365 tea factories spread over five districts of Upper Assam.

Assam gas company Ltd. Duliajan is planning to build a supervisory control and data acquisition system (SCADA) and

Telecommunication system for acquiring, monitoring and controlling the process data from single location for existing Gas

pipeline network spread over five districts of upper Assam. Hereafter the project is called as "SCADA AND TELECOM SYSTEM

FOR AGCL GAS PIPELINE NETWORK”

TractebelEngineering Private Limited (TE-IN) has been appointed by AGCL for Consultancy service for setting up of SCADA and

Telecom system for gas pipeline network of AGCL

1.2. Project Objective

The objective of setting up a SCADA system is to monitor & control the gas flow to the tea factories as per agreed quantity &

also to permit the customers to withdraw more gas within 150% of the agreed quantity when there is excess gas available in the

network. In case of major consumer, SCADA system is to monitor the volume & pressure of the gas at receiver’s as well as

consumer’s end point.

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 5

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

2. Introduction and Scope of Maintenance Service

Entire network SCADA system will be under defects liability period for 1 year and thereafter will be under the scope of comprehensive

maintenance service for 4 years. As a part of Defects liability period + AMC, ABB will deploy teams that will carry out the Preventive

Maintenance Services & Breakdown Maintenance. Broadly the infrastructure consists of all hardware/software including field instrumentation,

RTUs, SCADA systems, servers, workstations, equipment, UPS System etc.

This will be a comprehensive AMC and will include replacement of defective parts / modules / cards / software/hardware, as part of main

contract, required for smooth operation of SCADA system at Various installations of Assam Gas Company Limited.

The procedures for each of the services offered are detailed in this document.

2.1Services Covered under scope of Maintenance service

Software Updates

Supply of software debugging/up gradation is covered during 4 years AMC period.

Server and network management activities

The activities related to the server will be carried out during the Preventive Maintenance Procedure in MCS.

Status and Performance Monitoring

The Status and Performance Monitoring of all the Servers provided under the project shall be performed.

Application of Patches/ Bug Fixes

The Application of Patches/Bug Fixes for current windows operating system software if available free of cost to ABB will be done after

taking prior approval for the same from Assam Gas Company Limited.

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 6

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

Implementing OS Hardening to enhance system security

All the required OS Hardening for security is already implemented. However, the same shall be ensured while replacing the faulty

hardware.

Network connectivity, routing /access control:

Network outages and routing issues will be communicated to and followed-up with Assam Gas Company Limited.

Back-up Management as per decided policy:

The Back-up of SCADA Database and Graphics will be taken on Half Yearly basis in the external Hard Disk.

Actions for Virus Protection:

The Anti-Virus software for all ABB supplied IT Hardware in SCADA project has been supplied by ABB India Ltd.

3. Preventive Maintenance Services

The preventive maintenance services will be carried out by ABB for the supplies made as per the contract. The schedule for the preventive

maintenance service, check list & report is part of this document.

During the maintenance visit ABB engineer shall co-ordinate with the SCADA I/C – Assam Gas Company Limited. discuss the details of the

activities carried out and the problem faced by him. The Preventive Maintenance (PM) shall be done half yearly basis.

ABB will conduct PM every half year through use of System/Field Instrument diagnostics and diagnostics information of the hardware

components of SCADA system.

Calibration of the instruments shall be undertaken on yearly basis or as recommended by OEM. In cases where there is a replacement of faulty

instrument the same shall calibrated before installation.

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 7

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

L;,ZThe PM procedure is classified in the following categories depending upon the location.

3.1 Half Yearly PM procedure for 74 TE, Major Consumer & PRS under New SCADA Scope

The preventive maintenance procedure for the facilities includes procedure for the RTU/Instrumentation /UPS as per applicability.

The PM at each of the installation shall be carried out as per the procedure indicated in Appendix - 1 (PM Procedure and Checklist for

respective Location). Upon Completion of the PM the checklist for the same is to be provided to AGCL SCADA I/C. In case preventive

maintenance cannot be carried out at a location in line with the schedule, same shall be brought out in the preventative maintenance checklist

and reports and same shall be rescheduled preferably within the same week.

3.2 Half Yearly PM procedure for MCS

The preventive maintenance procedure for MCS includes procedure for the SCADA Servers, GPS, HMIs & UPS, Battery bank. The PM at MCS is

to be carried out as per the procedure indicated in Appendix - 1 (Half Yearly PM Procedure and Checklist for MCS). Upon Completion of the

PM, the checklist for the same is to be provided to AGCL SCADA I/c. In case a successful Preventive maintenance cannot be carried out at MCS

same should be brought out in the PM checklist and reports. It should be rescheduled preferably with the same week or in next week.

3.3 Tools & Testing equipment

ABB engineers will have a set of required tools. For Break Down as well as for Preventative maintenance jobs they shall go along with these

tools. Relevant specialized / special tools shall be available with ABB engineer to perform the required maintenance task.

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 8

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

4. Breakdown Maintenance Services

The breakdown maintenance services are provided to ensure that the breakdown in any of the location is attended within 48 hours on the

receipt of such information from owner. The procedure to be followed for breakdown maintenance is explained below.

4.1 Breakdown Maintenance Procedure

The calls for the breakdown in any system are logged manually at the MCS, these calls are assigned to the maintenance engineer. ABB

engineers shall attend the calls and on completion the same shall be informed to the ASSAM GAS COMPANY LIMITED SCADA I/C. In case the

calls could not be attended or solved it will be informed to the ASSAM GAS COMPANY LIMITED SCADA I/C. In such cases the call is kept open till

the same is resolved.

The procedure for attending the breakdowns/equipment failures is based on the troubleshooting procedures mentioned in the OEM manuals.

The maintenance engineers will follow this document for trouble shooting of the failed device/ equipment. In general following are the steps

for the attending and resolving the breakdown/failure call.

The breakdown maintenance procedure primarily includes following steps:

Identify the problem

If problem is with the hardware, then attend & rectify the same

If the problem cannot be solved or concluded, then replace the hardware.

If the problem is with software, then record the problem and resolve the same by reinstalling or restoring from the backup as

applicable.

If the problem is related to the equipment/instrument not under ABB scope of maintenance service, then inform to the ASSAM GAS

COMPANY LIMITED SCADA I/C for rectification.

In case the failed devices are replaced with a spare, the faulty one will be sent for repair. Once it is repaired the same device shall be put back

in service and used spare shall be once again kept in spare for future.

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 9

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

5. Report Submission during AMC

5.1 Monthly Report

The monthly report will be submitted in the first week of every month as per the format in hardcopy. The report shall be submitted to the

SCADA I/c.

5.2 Quarterly Report

The quarterly report will be submitted in the first week of each quarter beginning as per the format in Hard Copy. The hardcopy will consist of

Quarterly Breakdown Report.

PM Completion Checklist.

The reports will be submitted by the ABB Maintenance Engineer.

6. Exclusions

The following shall remain out of scope of this contract.

a. Printer consumables like printer cartridges, paper after completion of defective liabilities period.

b. All cable: Repair, replacement need arising due to physical damage like cut, damage, and rupture due to reasons not attributable to ABB.

c. Damage on account of rodent /reptile entry.

d. Batteries of UPS after defect liability period, however scope covers maintenance of UPS.

e. Replacement of any equipment or part damaged or failed due to lightning, physical damages reasons not attributable to ABB, short circuit

and power surge from AGCL source.

f. Faulty/Non-working instruments due to change in process parameters as provided during engineering site survey and process parameters

are beyond the instrument range.

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 10

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

APPENDIX -I

PM PROCEDURE

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 11

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

PM PROCEDURE-MCS

Maintenance Activity Procedure Status (C/NC) Remarks

UPS:

1.Inspection (Physical + Clean the panel inside & outside

Cleanness)

2. Cooling Fan Check that the cooling fans are running smoothly & it is

not making noise.

3. Environment of UPS Check for environment in the UPS room. If AC is not

room workingin the UPS room immediately report to

concerned officials of AGCL

4. Mains Input Voltage (1 Check the input incoming voltage in Display unit of UPS

phase or 3 phase) in Volt and record it. It should be as per specifications.

5. Mains Input Current (1 Check the input incoming current in Display unit and

phase or 3 phase) in record it. It should be below the UPS rated current.

Amps

6. Check Auxiliary input Check the Auxiliary voltage in Display unit and record it.

voltage It should be as per specifications.

7. Check inverter Voltage Check the inverter voltage in Display unit of UPS and

record it. It should be as per specifications.

8. Check the UPS Output Check the output voltage in Display unit of UPS and

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 12

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

Voltage record it. It should be as per specifications.

9. Output Current in Check the output current in Display unit of UPS and

Amps record it. It should be as per specifications.

10. Battery Check the battery charging & discharging current in UPS

Charging/Discharging display and record it.

Current in Amps

11.Battery voltage and Check battery voltage & current with mains in off

current (when mains in condition in Display unit of UPS.

Off condition)

12. Battery voltage and Check battery voltage & current with mains in off

current (when mains in condition in Display unit of UPS and record it.

Off Condition)

13. Battery Voltage and Check battery voltage & current after putting back to

Current after putting mains input in Display unit of UPS and record it.

back to mains Input

Servers :

1. Cabinet health check a. Check the cabinets are free from dust and other

for Server cabinets foreign materials. Clean the Cabinets.

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 13

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

b. Press the door limit switch and check whether the fans

and lights are working properly.

2. Server Performance a. Open the task manager of the server and check for any

excess utilization in the server resources.

3. Unwanted software’s a. Go to Add/Remove programs in control panels and

check that unwanted software’s are not installed. If any

unwanted software is found, then same should be

bought out to ASSAM GAS COMPANY LIMITED. notice

and accordingly removed from the servers

4.Software / Archived a. Check the HDD space consumed by the history

Data Backup accumulated in the SCADA servers and identify the need

for the archiving. If needed, archive all the data to the

media and put an identification on the same with

a. Take periodic backup every 6 month as per the backup

5.Software / Archived procedure indicated in the user guides for the SCADA /

Data Backup RTU and other software’s as applicable.

6. Unwanted folders in

a. Check if unwanted folders are created in the desktop

Server or partitioned Drives. Delete the unwanted folder if

any.

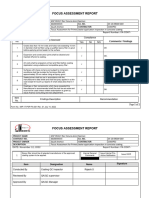

PM PROCEDURE-MAJOR CONSUMER LOCATION NAME: BVFCL DATE: 10.08.2020

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 14

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

FLOW COMPUTER AND MODEM

Flow Computer a. Check the Flow computer cabinet are free from dust

and other foreign materials. Clean the Cabinets. OK

b. Check the cable tightness of the Flow Computer OK

c. Check the incoming supply of the Flow computer 12VDC

d. Check the connection of the modem and its signal OK

strength

e. Need to take the program backup of the RTU and OK

need to be stored in the external HDD

g. Check the communication status of Flow computer OK

with SCADA

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 15

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

PM PROCEDURE – PRS (3NOS)

FILTARATION SKID

Manual valves at inlet header and at a.Check the tightness of the stud bolts

Filter’s inlet and outlet.

a. Smear a light coating of grease to

the sealing and mating faces for

protection from corrosion

Pressure Gauge at inlet header a. Clean the gauges exteriors and

housing with Lint free soft cloth.

Pressure control valve active a. Check the set point tuning

monitor

Slam shut valve and creep relief a. Check the set point tuning

valve

b. Inspect appearance for obvious

damage and external tightness.

c. clean parts such as diaphragm,

valve plug and O-ring. Other O-

rings

are needed to be checked

Filter Element a. Check the condition of filter

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 16

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

This document is exclusive property of ABB Limited. It is to be used only for the purpose which it is lent and must not be copied or used in anyway detrimental to the interest of this company and subject to return on demand.

element. Clean the filter and

remove the elements from the

case and bottom of the case

should be clean from all solids

and liquids.

Pressure regulator a. Ensure that there is no leakage

on the regulator and tubing

connections using soap solution.

b. Observe the outlet pressure

gauge to make sure that the

desired outlet pressure is

stabilized.

c..Clean the regulator and pilot and

check the seat, diaphragm, O-rings

and other soft parts.

d..Check the other parts of the

regulator to ensure that they are in

good working condition. Change the

worn out parts

e..Ensure the pipeline system is

clean and free of foreign materials.

Note : C means Completed/ NC means Not Completed

MAINTENANCE SERVICE PROCEDURE DOCUMENT

Project: SCADA &TELECOM SYSTEM FOR AGCL GAS PIPELINE NETWORK.

Title FOR AMC

Doc no. Lang: en Rev no. Page 17

ABB INDIA Limited 3BYN496024-JJBC Date: 14/10/19 01 Pages 17

You might also like

- Jisc 8715-2019 PDFDocument9 pagesJisc 8715-2019 PDFJocelinNo ratings yet

- QCP KOC-VME 1221006120-PART 1 Rev 2Document49 pagesQCP KOC-VME 1221006120-PART 1 Rev 2Alireza GolpesarNo ratings yet

- MK1 E51am017 00Document170 pagesMK1 E51am017 00Farshad MahmoudiNo ratings yet

- SMS - 67390 8jb0a - K2MCDocument21 pagesSMS - 67390 8jb0a - K2MCmani sNo ratings yet

- Hume Pipe Method StatementDocument2 pagesHume Pipe Method StatementDurgawati Mishra67% (3)

- Construction of New Integrated Passenger Terminal Electrical Services Method Statement ReviewDocument2 pagesConstruction of New Integrated Passenger Terminal Electrical Services Method Statement ReviewDurgawati MishraNo ratings yet

- Gc-32, New Gathering Centre For Sek Document Title: Construction Quality Plan For Mei Works in Osbl AreaDocument2 pagesGc-32, New Gathering Centre For Sek Document Title: Construction Quality Plan For Mei Works in Osbl AreaSreeju sreeNo ratings yet

- Revision-A1: Oman Tank Terminal Company (Ottco)Document5 pagesRevision-A1: Oman Tank Terminal Company (Ottco)ANIL PLAMOOTTILNo ratings yet

- Engineering Services for EPCC-1-AVU UnitDocument9 pagesEngineering Services for EPCC-1-AVU UnitajayNo ratings yet

- Data Sheets - Closed Circuit Television System For Lewpp-3ProjectDocument21 pagesData Sheets - Closed Circuit Television System For Lewpp-3ProjectCaptainNo ratings yet

- E.VAIN001-IE1-0001 Revisions: Oman Industrial Complex - Phase I Project Rules & Guideline Interface ConceptDocument14 pagesE.VAIN001-IE1-0001 Revisions: Oman Industrial Complex - Phase I Project Rules & Guideline Interface ConceptDxFxNo ratings yet

- Document Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. NumberDocument4 pagesDocument Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. Numberrajindo1No ratings yet

- 01-Engineering Specification Flare REV-01Document10 pages01-Engineering Specification Flare REV-01Bassem Balghouthi100% (1)

- Cylinder Liner - Production Recommendation 0742048 3Document17 pagesCylinder Liner - Production Recommendation 0742048 3thiha aungNo ratings yet

- Doc. No.: TitleDocument11 pagesDoc. No.: TitlePrakash RajNo ratings yet

- CORRIGENDUM - 1 (Query & Reply) : Agency-1Document62 pagesCORRIGENDUM - 1 (Query & Reply) : Agency-1John Son GNo ratings yet

- 14B. 2082-PM-ITP-7015 Rev.0 - SITE ITP TankageDocument10 pages14B. 2082-PM-ITP-7015 Rev.0 - SITE ITP TankageAmarKumarNo ratings yet

- 4000046273-PGCA-EA-C01-010 - C1 - 1 - Package InstrumentDocument4 pages4000046273-PGCA-EA-C01-010 - C1 - 1 - Package Instrumentrajindo1No ratings yet

- 19-20-330-340-PLC DWG-250MW-BIKANER-RAJ-As BuiltDocument41 pages19-20-330-340-PLC DWG-250MW-BIKANER-RAJ-As Builtpradeep.selvarajanNo ratings yet

- VD V220 BSL DWG 0015 - eDocument26 pagesVD V220 BSL DWG 0015 - eabdulNo ratings yet

- Crs - b390 Jnki056 PC DG 0618 - r0 (Zeeco Reply 20 Sep 22)Document1 pageCrs - b390 Jnki056 PC DG 0618 - r0 (Zeeco Reply 20 Sep 22)daniel perezNo ratings yet

- BRMY ARF 3448 19 - 29596 97 - ADocument45 pagesBRMY ARF 3448 19 - 29596 97 - Adarmaalikhwan747No ratings yet

- Construction Issue: 24 July 2019 Lake Mainit Hydropower Plant Project Lake Mainit - Powerhouse Agusan Power CorporationDocument1 pageConstruction Issue: 24 July 2019 Lake Mainit Hydropower Plant Project Lake Mainit - Powerhouse Agusan Power Corporationmr. oneNo ratings yet

- JKTD17025-0060.S-RFI-WP2-IX-19 B1 Beam Supporting Escalator and TravellatorDocument2 pagesJKTD17025-0060.S-RFI-WP2-IX-19 B1 Beam Supporting Escalator and TravellatormarklesterNo ratings yet

- sch-45852 CDocument13 pagessch-45852 CCatalin NeacsuNo ratings yet

- Ds EA2018 036 Standards and Customer Secondary Service EquipmentDocument111 pagesDs EA2018 036 Standards and Customer Secondary Service EquipmentK MahmoodNo ratings yet

- Uzair Appraisal Form JulyDocument2 pagesUzair Appraisal Form JulyUzair AmirNo ratings yet

- 3574.01-PDC-001 Process Design Criteria Rev GDocument10 pages3574.01-PDC-001 Process Design Criteria Rev GBUDI HARIANTONo ratings yet

- PLC3PS8221 & 8229 Rev.01Document7 pagesPLC3PS8221 & 8229 Rev.01isan.structural TjsvgalavanNo ratings yet

- Budgetary Commercial OfferDocument8 pagesBudgetary Commercial OfferISHA SINGHNo ratings yet

- Duct House Company ProfileDocument67 pagesDuct House Company ProfileMahmoud ElsadatNo ratings yet

- Presentation on IU (Group B_14_11_23)Document41 pagesPresentation on IU (Group B_14_11_23)Nazat AfrinNo ratings yet

- Comet Gland CatalogueDocument12 pagesComet Gland CataloguePrabhudatta KarNo ratings yet

- TCP 04 Form 01 Sub-Con Reg - R9Document9 pagesTCP 04 Form 01 Sub-Con Reg - R9SBW ReportingNo ratings yet

- Boq Oriental Plaza 01Document179 pagesBoq Oriental Plaza 01Zaki AduseNo ratings yet

- Substation Building - 318N - CNDocument133 pagesSubstation Building - 318N - CNDevesh GuptaNo ratings yet

- Vedanta Limited's SRP Project Dosing Skid GA DrawingsDocument21 pagesVedanta Limited's SRP Project Dosing Skid GA DrawingsBALASUBRAMANIAM MEGHANADHNo ratings yet

- Focus Assessment - Material ReceivingDocument2 pagesFocus Assessment - Material Receivingkousick sundararajanNo ratings yet

- IR Deck Q4 FY22Document27 pagesIR Deck Q4 FY22Gurvinder JunejaNo ratings yet

- ITP 07-2 3LPP CS Rev.4 E0660-P10361121-H03-2001-05 (CODE 1) PDFDocument29 pagesITP 07-2 3LPP CS Rev.4 E0660-P10361121-H03-2001-05 (CODE 1) PDFBlade ChannelTvNo ratings yet

- PDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia SeparatorDocument8 pagesPDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia Separatorhgag selimNo ratings yet

- Sub-Contractor Comments Response Sheet: Ain Tsila DevelopmentDocument27 pagesSub-Contractor Comments Response Sheet: Ain Tsila DevelopmentZaidiNo ratings yet

- 4000046273-PGCA-EA-C06-003 - C1 - 1 - Datasheet Lube Oil CoolerDocument5 pages4000046273-PGCA-EA-C06-003 - C1 - 1 - Datasheet Lube Oil Coolerrajindo1No ratings yet

- 4000046273-PGCA-EA-C01-002 - C1 - 1 - Liquied FuelDocument6 pages4000046273-PGCA-EA-C01-002 - C1 - 1 - Liquied Fuelrajindo1No ratings yet

- DBL 7381 2015-05Document17 pagesDBL 7381 2015-05cmorabitoNo ratings yet

- Gre Pipe Technical Documents PDFDocument64 pagesGre Pipe Technical Documents PDFSunriseNo ratings yet

- B-U00-A-MS-3010 - R01 Method Statement For Sealant Application & Repair Procedure - FC - RemovedDocument20 pagesB-U00-A-MS-3010 - R01 Method Statement For Sealant Application & Repair Procedure - FC - RemovedKarna Dikon ComuNo ratings yet

- Bi-bccp-00-Cem-157-Mg-0013 r1 Piping Isometric For Potable Water SystemDocument25 pagesBi-bccp-00-Cem-157-Mg-0013 r1 Piping Isometric For Potable Water SystemmizanNo ratings yet

- Reactor Boron System Operating ManualDocument51 pagesReactor Boron System Operating ManualvrajakisoriDasiNo ratings yet

- Attachment#2 - B224-FCC-LT-111-PP-SP-0007 - REV 01Document28 pagesAttachment#2 - B224-FCC-LT-111-PP-SP-0007 - REV 01Raju NaiduNo ratings yet

- Seal AIr Blowers To Burners and Observation PortsDocument5 pagesSeal AIr Blowers To Burners and Observation Portspedro13761No ratings yet

- Inhouse Standard: Coatings Powder Coating With Epoxy Resin and Polyester ResinDocument11 pagesInhouse Standard: Coatings Powder Coating With Epoxy Resin and Polyester ResinkapilNo ratings yet

- QCP KOC-VME 1221006120-PART 1 Rev 3Document49 pagesQCP KOC-VME 1221006120-PART 1 Rev 3Alireza Golpesar100% (1)

- Datasheet For Drum Scrubber of Line B & CDocument4 pagesDatasheet For Drum Scrubber of Line B & Clarbiaboumadi363No ratings yet

- CS 220802djpcme714 Exco00 13Document2 pagesCS 220802djpcme714 Exco00 13nimrod napituNo ratings yet

- Al-Babtain Contracting Co. Quality Manual QA/QC PlanDocument39 pagesAl-Babtain Contracting Co. Quality Manual QA/QC PlanRazi KhanNo ratings yet

- QAQC Procedure For Fabrication - Flare KOD Rev ADocument9 pagesQAQC Procedure For Fabrication - Flare KOD Rev ARajesh K Pillai100% (1)

- Process Pipes Bolt Tightening Procedure - 3 Additional SpheresDocument8 pagesProcess Pipes Bolt Tightening Procedure - 3 Additional Spheresqaqc.nimerlawzi1No ratings yet

- Hitachi: Registered OfficeDocument17 pagesHitachi: Registered OfficeShradha mamNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- DiabetisDocument12 pagesDiabetischandra9000No ratings yet

- UPI Presentation: An Introduction to Unified Payments InterfaceDocument13 pagesUPI Presentation: An Introduction to Unified Payments InterfaceanupamNo ratings yet

- Gas-Volume Conversion Device PTZ-BOX 3.0: Manual Specifications Technical Description Mounting Instructions ConfigurationDocument120 pagesGas-Volume Conversion Device PTZ-BOX 3.0: Manual Specifications Technical Description Mounting Instructions ConfigurationanupamNo ratings yet

- BVFCLDocument1 pageBVFCLanupamNo ratings yet

- Sub: Request For Gate Pass For Visiting of AGCL's Metering PointDocument1 pageSub: Request For Gate Pass For Visiting of AGCL's Metering Pointanupam50% (2)

- It A Trial To Send DataDocument1 pageIt A Trial To Send DataanupamNo ratings yet

- Mineral Industries of AssamDocument16 pagesMineral Industries of AssamnehaNo ratings yet

- Mutual Aid ERP for Hazardous IndustriesDocument30 pagesMutual Aid ERP for Hazardous IndustriesSuriya DasNo ratings yet

- 09 Aug 2016 184316203KN27MVMPAnnexure-Pre-FeasibilityReport (PFR) File PDFDocument43 pages09 Aug 2016 184316203KN27MVMPAnnexure-Pre-FeasibilityReport (PFR) File PDFAyman RiyadhNo ratings yet

- Assam Petro-Chemicals LTD.: Advt. No. APL/HR/Con/Adv-53 (PT-V) /62Document2 pagesAssam Petro-Chemicals LTD.: Advt. No. APL/HR/Con/Adv-53 (PT-V) /62Merupranta SaikiaNo ratings yet

- Work Commitment and Absenteeism Among The Industrial Workers: A Sociological Study of Two Industries of Namrup, AssamDocument6 pagesWork Commitment and Absenteeism Among The Industrial Workers: A Sociological Study of Two Industries of Namrup, AssamIJBSS,ISSN:2319-2968No ratings yet

- AGCL On-Site Emergency PlanDocument63 pagesAGCL On-Site Emergency PlanDasari VenkateshNo ratings yet

- Importance of Field Work in GeologyDocument19 pagesImportance of Field Work in GeologyDay 2 DayNo ratings yet

- ImgDocument8 pagesImgAnonymous Qoz6rhj5yXNo ratings yet

- Comparative Analysis of Financial Statement With The Help of Ratio Analysis TechniquesDocument85 pagesComparative Analysis of Financial Statement With The Help of Ratio Analysis TechniquesManish KumarNo ratings yet