Professional Documents

Culture Documents

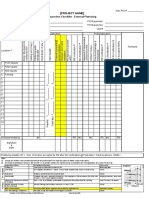

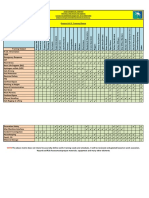

(Project Name) : Inspection Checklist - Tiling (Floor & Wall)

Uploaded by

Mohd TameziOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Project Name) : Inspection Checklist - Tiling (Floor & Wall)

Uploaded by

Mohd TameziCopyright:

Available Formats

Insp. Ref.

#: _____________

[PROJECT NAME]

Inspection Checklist - Tiling (Floor & Wall)

Main Contractor (MC): PIC/Supervisor:

Sub-Contractor: PIC/Supervisor:

Resident Staff (RS): Unit #:

Inspection criteria (2) Pre & Post Screeding Post-Installation of Floor & Wall Tiles

Hollow, Holes at Joints

completed and tested.

Consistency of Colour

RS Re-Verification (3)

Gradient at Wet Area)

Gradient at Wet Area)

Positioning of Fixings

RS Accepted Works

Water Ponding Test

Free from Damage,

CWP Pressure test

Floor Flatness (2%

Floor Flatness (2%

MC Rectification (3)

MC Rectification (3)

RS Verification (3)

RS Verification (3)

Floor Level Pegs

Tile Setting Out

RS Approval to

Wall Alignment

Water proofing

proceed works

Remarks

Tones & Sizes

completed

Location (1)

1 Living, Dining N/A NA NA

2 Bedroom 4 N/A NA NA

3 Bathroom 4

NA

4 Kitchen N/A NA

5 Staircase N/A NA NA

6 Family Hall N/A NA NA

7 Master

N/A

Bedroom NA NA

8 Bathroom 1

9 Bedroom 2 N/A NA NA

10 Bathroom 2

11 Bedroom 3 N/A NA NA

12 Bathroom 3

13

Checked/Verified by: MC RS MC RS MC RS MC RS

Signature

&

Date

Tiling Quality KPI = Nos. of location accepted by RS after Re-Verification @ Post-Inst. / Total locations x 100% =

Notes:

(1) Change the location in this checklist according to the product layout. For high-rise project, to attach a copy of the layout.

(2) See below for acceptance tolerance. MC to mark 'a' in respective location only if workmanship is acceptable (NA if not applicable), then inform RS to verify.

Inspection stage Inspection criteria Acceptance tolerance Tools used

Pre-Screeding Floor level pegs 1 along the wall, intermediate at < 1600mm interval Measuring

Wall alignment (base plaster) 3mm / 1.2m for verticality, horizontality & squareness tape

Cross line

Water ponding testing completed 24hrs Water ponding test passed before proceed with floor screeding. laser

Visual

Post Screeding Floor flatness (2% gradient at wet area) 3mm / 1.2m for flatness Spirit level

Tiles setting out At every 1 to 3 columns & rows Cross line

Post Installation of Floor & Wall Floor flatness (2% gradient at wet area) 3mm / 1.2m for flatness. No warpage laser

Spirit level

Tiles Consistency of colour tone & sizes No butting; Joint size: 2-4mm or otherwise stated by SO; Consistent colour of infill, preferably light Visual.

grey at wet area Measuring

tape

Free from damage, hollow, holes at joints No hollow sound when tapped; No crack & chip edges of tiles; Proper infill at tile joints: no holes; Ball bearing

Flat bedding at 5' wall tile termination rod. Visual

Positioning of fittings At required height & position = drawing & Plumbing & Sanitary Work Checklist Visual

Water ponding test ( for bathrooms) Test for 24 hours after completion of floor tiling Visual

(3) RS to mark 'a' if acceptable, 'x' if reject (& circle the respective item) or '-' if not check (not for Post-Installation). MC to rectify if any reject & RS to re-verify.

Filename: Q:\QA\TQM\cm_iso\Insp_CL\502195398.xls Version amended on 28/06/06

You might also like

- (Project Name) : Inspection Checklist - External PlasteringDocument2 pages(Project Name) : Inspection Checklist - External PlasteringMohd TameziNo ratings yet

- (Project Name) : Inspection Checklist - Stone FinishesDocument1 page(Project Name) : Inspection Checklist - Stone FinishesMohd TameziNo ratings yet

- Brickworks InspectionDocument1 pageBrickworks InspectionMohd TameziNo ratings yet

- Plumbing, SanitaryDocument2 pagesPlumbing, Sanitarykumarakash122392No ratings yet

- As Shown: Client: SI ContractorDocument6 pagesAs Shown: Client: SI ContractornurNo ratings yet

- (Project Name) : Inspection Checklist - Waterproofing SystemDocument1 page(Project Name) : Inspection Checklist - Waterproofing SystemMohd TameziNo ratings yet

- Daily Report (The Walk)Document1 pageDaily Report (The Walk)muzaffaralhashmimaazmuzaffarNo ratings yet

- PMMC Phase 01 Master Shop Drawing Submission SummaryDocument1 pagePMMC Phase 01 Master Shop Drawing Submission SummaryAMMAR MAWNo ratings yet

- Mechanical CommentDocument2 pagesMechanical CommentMdAzadAnsariNo ratings yet

- ITP Format - Excel GEP 1120Document22 pagesITP Format - Excel GEP 1120raghuvarma100% (1)

- Small Boat Harbours Project: Inspection and Test Plan For Casting of Concrete Quay Wall BlocksDocument4 pagesSmall Boat Harbours Project: Inspection and Test Plan For Casting of Concrete Quay Wall BlockseleanorNo ratings yet

- GM 1927 30 BIQS Supplier SelfAssessment Rev. 15.0 2020Document17 pagesGM 1927 30 BIQS Supplier SelfAssessment Rev. 15.0 2020Juan Carlos Murillo Larrota100% (1)

- 2016-11-17 RRAA MS Construction of Pre-Cast Fence - Rev C (Arup)Document1 page2016-11-17 RRAA MS Construction of Pre-Cast Fence - Rev C (Arup)gregNo ratings yet

- CLR FM 002 Calibration PlanDocument1 pageCLR FM 002 Calibration Planchemist_tmaNo ratings yet

- M1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerDocument63 pagesM1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerAnandu AshokanNo ratings yet

- (Project Name) : Inspection Checklist - External Works Within Lot BoundaryDocument1 page(Project Name) : Inspection Checklist - External Works Within Lot BoundaryMohd TameziNo ratings yet

- Detail Engineering Design: Pembangunan Proyek - Vihara Sakyamula Pematang SiantarDocument4 pagesDetail Engineering Design: Pembangunan Proyek - Vihara Sakyamula Pematang SiantarLouis UdinNo ratings yet

- 2021-10-13 Project Quality Plan Rev. ADocument1 page2021-10-13 Project Quality Plan Rev. AjaymarNo ratings yet

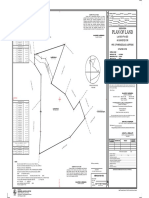

- Plan of Land: Lot 6824, Pls-823Document1 pagePlan of Land: Lot 6824, Pls-823John Rey Montemor100% (1)

- StevenCookCONST 160 TransmittalDocument2 pagesStevenCookCONST 160 TransmittalSteven CookNo ratings yet

- Transmittal Form for Teluride Home ProjectDocument2 pagesTransmittal Form for Teluride Home ProjectSteven CookNo ratings yet

- Paintng ReportDocument1 pagePaintng Reportibrahim hegazyNo ratings yet

- Plan of Land: Lot 10339-A-2, Psd-07-103358Document1 pagePlan of Land: Lot 10339-A-2, Psd-07-103358John Rey MontemorNo ratings yet

- Ontonagon Architectural PlansDocument35 pagesOntonagon Architectural PlanstbarradasNo ratings yet

- Optional Working For Airport ProjectDocument9 pagesOptional Working For Airport ProjectSatish KapoorNo ratings yet

- BH05 LB Si JPS SG GalingDocument1 pageBH05 LB Si JPS SG GalingFNo ratings yet

- For PresentationDocument5 pagesFor PresentationZaki AnwerNo ratings yet

- Social Aspect Impact RegisterDocument1 pageSocial Aspect Impact RegisterAbderrahmene SaciNo ratings yet

- Geotech Report SummaryDocument13 pagesGeotech Report SummarySM ConsultantsNo ratings yet

- For Construction: Mesh Detall Side ElevationDocument1 pageFor Construction: Mesh Detall Side ElevationllNo ratings yet

- GM 1927 30 BIQS Assessment Self Assessment 2019Document20 pagesGM 1927 30 BIQS Assessment Self Assessment 2019sahil sagarNo ratings yet

- O&m Log SheetDocument41 pagesO&m Log SheetMohamed MousaNo ratings yet

- Software Requisition - Form - NitinDocument4 pagesSoftware Requisition - Form - NitinlavakerreddyNo ratings yet

- Training MatrixDocument2 pagesTraining MatrixAmeerHamzaWarraichNo ratings yet

- 2023-02-08 MAR-080 IMC Pipes and Fittings (Smartube) - ANAKO Philippines Corporation RRAADocument1 page2023-02-08 MAR-080 IMC Pipes and Fittings (Smartube) - ANAKO Philippines Corporation RRAAjaymarNo ratings yet

- 1.RFI COVER-combinedDocument3 pages1.RFI COVER-combinednatamas systemsNo ratings yet

- 3D Visual Architecture 1: Approval Drawing - LOD 200Document6 pages3D Visual Architecture 1: Approval Drawing - LOD 200Ali AsnanNo ratings yet

- RRAA Review of Concrete Mix DesignDocument1 pageRRAA Review of Concrete Mix DesignjaymarNo ratings yet

- Daily Wo 17 Februari 2024Document1 pageDaily Wo 17 Februari 2024agusNo ratings yet

- Core Sector 19-20 PDW Bill Barobisa 1Document3 pagesCore Sector 19-20 PDW Bill Barobisa 1asovvokuttaNo ratings yet

- Tangga 2Document1 pageTangga 2Valenza TanjayaNo ratings yet

- RFI Summary (April 30 2018) Rev 01Document1 pageRFI Summary (April 30 2018) Rev 01zahid1078No ratings yet

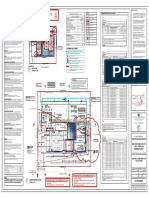

- Me-2001b (3) - 231004-Basement 2 Layout Plan Sheet BDocument1 pageMe-2001b (3) - 231004-Basement 2 Layout Plan Sheet BhumcanopNo ratings yet

- Bhds 3534Document2 pagesBhds 3534Neeraj SharmaNo ratings yet

- Petrovietnam Fertilizer and Chemicals Corporation (Pvfcco) Ammonia Plant Revamp ProjectDocument10 pagesPetrovietnam Fertilizer and Chemicals Corporation (Pvfcco) Ammonia Plant Revamp ProjectNcTungNo ratings yet

- TransmittalForm-CM16 - 10-7-20 - v508 - 101420 Submittals For NPSDocument2 pagesTransmittalForm-CM16 - 10-7-20 - v508 - 101420 Submittals For NPSLiliana PatiñoNo ratings yet

- Scaled PlanDocument6 pagesScaled PlanDillion BradleyNo ratings yet

- 2021-10-05 Proposed Concrete Design Mix For General Structure Rev.a RRAADocument4 pages2021-10-05 Proposed Concrete Design Mix For General Structure Rev.a RRAAjaymarNo ratings yet

- Typical - Package ITPDocument23 pagesTypical - Package ITPrandyNo ratings yet

- Rfi Log 24.12.2020Document67 pagesRfi Log 24.12.2020Deepu CNo ratings yet

- WestDocument1 pageWestValenza TanjayaNo ratings yet

- Mist-Spray System Log BookDocument3 pagesMist-Spray System Log BookAartiNo ratings yet

- Road Plan_Ricarte SurDocument10 pagesRoad Plan_Ricarte SurCyrene EstelaNo ratings yet

- Me-2001a (3) - 231004-Basement 2 Layout Plan Sheet ADocument1 pageMe-2001a (3) - 231004-Basement 2 Layout Plan Sheet AhumcanopNo ratings yet

- Daily site report template for construction project updatesDocument1 pageDaily site report template for construction project updatesShaaban NoamanNo ratings yet

- 01 - General Tracker-1Document4 pages01 - General Tracker-1MAGED ELSADIGNo ratings yet

- Sp3 MB A WPF Det - Typ 004-Rev A (Not in Use)Document1 pageSp3 MB A WPF Det - Typ 004-Rev A (Not in Use)Renaldo BunaidiNo ratings yet

- Invoice for roofing project servicesDocument1 pageInvoice for roofing project servicesGokula Krishnan.DNo ratings yet

- (Project Name) : Inspection Checklist - External Works Within Lot BoundaryDocument1 page(Project Name) : Inspection Checklist - External Works Within Lot BoundaryMohd TameziNo ratings yet

- (Project Name) : Inspection Checklist - Timber / Metal Door FrameDocument1 page(Project Name) : Inspection Checklist - Timber / Metal Door FrameMohd TameziNo ratings yet

- (Project Name) : Inspection Checklist - Waterproofing SystemDocument1 page(Project Name) : Inspection Checklist - Waterproofing SystemMohd TameziNo ratings yet

- Inspection Checklist - Aluminium Works - Sliding Doors /windowsDocument2 pagesInspection Checklist - Aluminium Works - Sliding Doors /windowsMohd Tamezi100% (2)

- 3.Q-Cat Door Frame Vol.1Document19 pages3.Q-Cat Door Frame Vol.1Mohd TameziNo ratings yet

- 4..Q-Cat For Door Vol .2Document18 pages4..Q-Cat For Door Vol .2Mohd TameziNo ratings yet

- 1.Q-Cat RC Safety and SequanceDocument67 pages1.Q-Cat RC Safety and SequanceMohd TameziNo ratings yet

- Quality Conformance Awareness Training: For Brick - WorkDocument29 pagesQuality Conformance Awareness Training: For Brick - WorkMohd TameziNo ratings yet

- 2.Q-Cat Aluminium - GlazingDocument26 pages2.Q-Cat Aluminium - GlazingMohd TameziNo ratings yet

- Autocad ShortcutsDocument13 pagesAutocad ShortcutsKriscel CaraanNo ratings yet

- SPYTL - Anti TermiteDocument6 pagesSPYTL - Anti TermiteMohd TameziNo ratings yet

- CAD Tutorial Fangfang 110227Document42 pagesCAD Tutorial Fangfang 110227Mohd TameziNo ratings yet

- Gabion retaining wall notesDocument1 pageGabion retaining wall notesLee WhiteheadNo ratings yet

- Genset Pad Plan Genset Pad Section: Client Designer Drawn Reuse of Documents SEB CSCDocument4 pagesGenset Pad Plan Genset Pad Section: Client Designer Drawn Reuse of Documents SEB CSCMark Genesis VelonzaNo ratings yet

- As Sarrar Substation Saudi Arabia - Profile - 080222Document7 pagesAs Sarrar Substation Saudi Arabia - Profile - 080222salman KhanNo ratings yet

- 4 Training AK0303001 Delta P-C01 IOM - Rev3Document22 pages4 Training AK0303001 Delta P-C01 IOM - Rev3Nad DaniNo ratings yet

- NBC - Fire SafetyDocument200 pagesNBC - Fire Safetyvenkin84507486% (7)

- Ahsptmk 2021-Rab Ged, Buah MerahDocument117 pagesAhsptmk 2021-Rab Ged, Buah MerahNATSIR LEWANo ratings yet

- PWD SR Rate of Belagavi 2015-16 PDFDocument483 pagesPWD SR Rate of Belagavi 2015-16 PDFRavindra67% (3)

- Structural MembersDocument37 pagesStructural Membersmario gadianoNo ratings yet

- Rough HardwareDocument26 pagesRough HardwarePaulo AmorosoNo ratings yet

- 5 KL GLSR: SchemeDocument12 pages5 KL GLSR: SchemeVenkata Bhaskar DameraNo ratings yet

- DIN - ISO - EN Crossover Chart - Fuller Fasteners - Fuller FastenersDocument6 pagesDIN - ISO - EN Crossover Chart - Fuller Fasteners - Fuller FastenersRicardoNo ratings yet

- 2BEE BRO 55 RLNG OUTRGR MANUAL - ROB5x5Document20 pages2BEE BRO 55 RLNG OUTRGR MANUAL - ROB5x5jimmycarter87No ratings yet

- HVAC B.O.Q Cost Breakdown Master Sheet For Construction ProjectsDocument6 pagesHVAC B.O.Q Cost Breakdown Master Sheet For Construction ProjectsSanjeevan KrishnasamyNo ratings yet

- KA022 Installation Manual - 1Document95 pagesKA022 Installation Manual - 1matt peacockNo ratings yet

- Waterproofing - Estokote Grey - Data Sheet - 100106Document2 pagesWaterproofing - Estokote Grey - Data Sheet - 100106Azizy YusofNo ratings yet

- CPE 524 PLATE NO. 6 Theory 1 & Structural Design 1Document3 pagesCPE 524 PLATE NO. 6 Theory 1 & Structural Design 1mike reyesNo ratings yet

- Merante Resident Notification LetterDocument1 pageMerante Resident Notification LetterEmeka IgweNo ratings yet

- Method Statement For Brickworks: Pembinaan Infra E&J SDN BHDDocument5 pagesMethod Statement For Brickworks: Pembinaan Infra E&J SDN BHDChezy629No ratings yet

- Repairs and Rehabilitation of Bridges PDFDocument9 pagesRepairs and Rehabilitation of Bridges PDFSourabh NegiNo ratings yet

- Dragline ExcavatorDocument5 pagesDragline ExcavatorusouvNo ratings yet

- SOP QC-101 ASME B31.9 Shop and Field Inspection - Supervisor Intro RFS - Rev. 1Document36 pagesSOP QC-101 ASME B31.9 Shop and Field Inspection - Supervisor Intro RFS - Rev. 1iplaruffNo ratings yet

- AGPT04L-09 Guide To Pavement Technology Part 4L Stabilising BindersDocument27 pagesAGPT04L-09 Guide To Pavement Technology Part 4L Stabilising BindersFábio LibórioNo ratings yet

- Experiment No. 6 - Bitumen Extraction Test: ObjectiveDocument4 pagesExperiment No. 6 - Bitumen Extraction Test: ObjectiveKanishka Sarkar83% (6)

- Aci 214-77Document14 pagesAci 214-77Gael Valles100% (1)

- House SpecDocument6 pagesHouse SpecJuan CarlosNo ratings yet

- Session 4 EWDocument31 pagesSession 4 EWYasichalew sefinehNo ratings yet

- Application of Time Buffers To Construction (Ok)Document10 pagesApplication of Time Buffers To Construction (Ok)N'diLn-goNo ratings yet

- Specs Part 1 of 2Document146 pagesSpecs Part 1 of 2Haseeb RazviNo ratings yet

- Section 04 - GmaDocument6 pagesSection 04 - GmaHunterNo ratings yet

- Boat DesignDocument5 pagesBoat Designthrashmetalhead100% (3)