Professional Documents

Culture Documents

Section 2: Error Codes Rev.3 July 2008

Uploaded by

GeorgeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 2: Error Codes Rev.3 July 2008

Uploaded by

GeorgeCopyright:

Available Formats

GMM

Section 2: Error codes rev.3 July 2008

-

1. Error codes 1

1. Error codes

When one of the following codes is present, the watch-dog activates automatically, a power

drooping occurs and the control panel visualizes the number identifying the kind of alarm: it will be

therefore necessary to reset the equipment.

CODE TRANSMISSION CAUSE

001 Tilting Potentiometer

002 Operation unit protection

003 Motor+dynamo/DAC inverted

004 Motor reversibility

011 Elevation Potentiometer

012 Operation gear protection

013 Motor+dynamo/DAC inverted

014 Motor reversibility

015 Missing synchronism with the tilting

021 Stand Potentiometer

022’ Operation gear protection

023 Stand in Mobile Area

024 Stand in angle

025 Stand in tomography

026 Stand in Mobile Area+ contemporary angle

027 Motor reversibility

028 Angle > 440

031 SFD Potentiometer

032 Operation gear protection

033 SFD in Mobile Area

034 SFD in angle

035 SFD in tomography

036 SFD in Mobile Area+contemporary angle

037 Motor reversibility

041 FD Zero input alarm

042 Fault operation

051 Parallel collimator Potentiometer

052 Motor

061 Orthogonal collimator Potentiometer

062 Motor

071 Iris collimator Potentiometer

072 Motor

081 Parallel diaphragm Zero input alarm

082 Fault operation

Section 2: Error codes rev.3 July 2008 page

- - 1/3

I

OPERA T Adjustment Manual

-

GMM

1 If the tabletop longitudinal displacement is available, the alarm code 022 may intervene also in case of damage on the tabletop’s

circuit.

091 Crossed-diaphragm Zero input alarm

092 Fault operation

101 Parallel jaws Potentiometer

111 Perpendicular jaws Potentiometer

121 Longitudinal cassette Zero input alarm

122 Fault operation

131 Transversal cassette Zero input alarm

132 Fault operation

133 Central input alarm

141 1.1. Zero input alarm

142 Fault operation

143 Low Li input alarm

151 Grid Zero input alarm

152 Fault operation

161 Longitudinal tabletop Potentiometer

163 Motor+dynamo/DAC inverted

164 Motor reversibility

171 Filters Collimator Potentiometer

172 Motor

096 CPU battery in discharge

097 Movement control at the equipment start up

098 Broken fiber optic / wrong transmission

099 Stand-by

189÷196 System error

197 Assi board error

198 Transmissiion error on RS232 during installation

199 Transmission error type on R5232

200 PROM not present / broken

2

E

201 Virgin E

PROM

2

202 Alarm error not managed

Iii

Forfurther explanations on the error codes and the relevantfault

research, please make reference to the “Opera T Fault research” —

Manual (in course of preparation)

Notes:

. 2 T..1 -‘I.-’

You might also like

- 2.4.2 Electronic Module (E Module) CAN InterfaceDocument2 pages2.4.2 Electronic Module (E Module) CAN InterfaceThylaneNo ratings yet

- Schematic125 170Document4 pagesSchematic125 170agus haryono100% (1)

- T05-06 Fault+Codes+1381+and+20101 (20140115)Document2 pagesT05-06 Fault+Codes+1381+and+20101 (20140115)Nick Cayanan100% (1)

- PowerWizard Control SystemDocument54 pagesPowerWizard Control SystemErissonNo ratings yet

- Monitor System PW200 220-7Document26 pagesMonitor System PW200 220-7Teknik Makina100% (1)

- Power Start PS0500 - Series Controls: C 8 D5 / C 11 D5 Series GensetsDocument35 pagesPower Start PS0500 - Series Controls: C 8 D5 / C 11 D5 Series GensetsJoshika R67% (3)

- Battery Chargers LEHX7055-03Document2 pagesBattery Chargers LEHX7055-03dfheardNo ratings yet

- UMC Universal Motor Control and Protection ABB 2005Document14 pagesUMC Universal Motor Control and Protection ABB 2005Edwin QuispeNo ratings yet

- Mics Modys Manual EnuDocument11 pagesMics Modys Manual EnuRicardo Barajas GuerreroNo ratings yet

- Feature List (175, 220, 250)Document5 pagesFeature List (175, 220, 250)Saad ZiaNo ratings yet

- Esquema Elétrico Case 6130Document40 pagesEsquema Elétrico Case 6130Everton RicardiNo ratings yet

- AA05050 - Modificacion Del Procedimiento de Los Embragues de DireccionDocument9 pagesAA05050 - Modificacion Del Procedimiento de Los Embragues de DireccionJose A. Basanta H.No ratings yet

- PCC3100 Overview Incl ParallelDocument40 pagesPCC3100 Overview Incl ParallelRODRIGO_RALONo ratings yet

- 18BT-9U LM211 Stall RotorDocument3 pages18BT-9U LM211 Stall RotorJet acostaNo ratings yet

- Kea 091 NSTRDocument7 pagesKea 091 NSTRamin shirkhaniNo ratings yet

- Retrieving Fault Codes Fault Code Display: A B CD E A CDocument19 pagesRetrieving Fault Codes Fault Code Display: A B CD E A CPabloMatiasC100% (2)

- Service Manual For Dynamove Vector Ii: KonecranesDocument20 pagesService Manual For Dynamove Vector Ii: KonecranesDante Williams100% (2)

- SIEMENS-7SA522 Setting CalculationDocument20 pagesSIEMENS-7SA522 Setting Calculationnaran19794735No ratings yet

- T935 Inclinometer: DC-Operated, Gravity-ReferencedDocument4 pagesT935 Inclinometer: DC-Operated, Gravity-ReferencedNicolasSuchNo ratings yet

- D01418en AutorreparableDocument5 pagesD01418en AutorreparableSubiNo ratings yet

- CodesDocument3 pagesCodesإطار كيسيNo ratings yet

- TecoDocument94 pagesTecoNgọc ÁnhNo ratings yet

- Basic Parameter Setting Needs To Be Done To Run Two Servo and One Spindle - For 0i-FDocument6 pagesBasic Parameter Setting Needs To Be Done To Run Two Servo and One Spindle - For 0i-FAdvance CNC TechnologiesNo ratings yet

- Deutz Application - ENDocument10 pagesDeutz Application - ENWilliam AvellanedaNo ratings yet

- Y290 WML 209.PDF Rexton SsangyongDocument6 pagesY290 WML 209.PDF Rexton SsangyongVelasquez JavierNo ratings yet

- Ba, Ia MDPS System PDFDocument19 pagesBa, Ia MDPS System PDFNhật ĐặngNo ratings yet

- M2-BHM CódigosDocument8 pagesM2-BHM CódigosdedaluxsalvajeNo ratings yet

- U Esr31Document6 pagesU Esr31erhan erenNo ratings yet

- Fuji Frn3.7e1s-2j (204-217) PDFDocument14 pagesFuji Frn3.7e1s-2j (204-217) PDFMadison MadisonNo ratings yet

- User/proqrammer Manual: CORY200 DaldossDocument12 pagesUser/proqrammer Manual: CORY200 DaldossDANIEL REYESNo ratings yet

- User/proqrammer Manual: CORY200 DaldossDocument12 pagesUser/proqrammer Manual: CORY200 DaldossDANIEL REYESNo ratings yet

- Trobleshoting PDFDocument59 pagesTrobleshoting PDFJose Figueroa67% (3)

- 900EFR-BL-U Earth Fault Relay: FeaturesDocument2 pages900EFR-BL-U Earth Fault Relay: FeatureschinnathambijNo ratings yet

- Cid Mid FmiDocument11 pagesCid Mid FmiLuis Enrique Castro Manzaneda100% (1)

- HD785-7 SEN01274-15 Shop Manual-804-1004Document201 pagesHD785-7 SEN01274-15 Shop Manual-804-1004Muhammad RizqiNo ratings yet

- MCT 10 Set-Up Software Project - Untitled Tuesday, May 21, 2019Document9 pagesMCT 10 Set-Up Software Project - Untitled Tuesday, May 21, 2019SERVICIO TECNICONo ratings yet

- Service and Diagnostics 611ADocument11 pagesService and Diagnostics 611ARubens MartinsNo ratings yet

- Extrait Doc Variateur GBDocument7 pagesExtrait Doc Variateur GBErick Fernando Chavez VargasNo ratings yet

- Technical 6SN1118 TroubleshootingDocument4 pagesTechnical 6SN1118 TroubleshootingJoaoNo ratings yet

- 432zx ErrorCodesDocument28 pages432zx ErrorCodesmushfiq66100% (4)

- Engine Fault Codes: CumminsDocument20 pagesEngine Fault Codes: CumminsCarlosNo ratings yet

- Ivr Caracteristicas y BeneficiosDocument21 pagesIvr Caracteristicas y Beneficiosjulio cesar0% (1)

- Manual and Remote Start Unit With Key Switch, 72x72 DIN SizeDocument9 pagesManual and Remote Start Unit With Key Switch, 72x72 DIN SizeRaja Bilal LatifNo ratings yet

- Eges4202 DTCDocument7 pagesEges4202 DTCeng_hamada_4uNo ratings yet

- FFD Dpig 315 S2Document32 pagesFFD Dpig 315 S2Javier Santana GarcíaNo ratings yet

- MID163-FL-FE-Edicion 1Document20 pagesMID163-FL-FE-Edicion 1Elifio Cortes MazaNo ratings yet

- Em I Pii (08)Document16 pagesEm I Pii (08)M ONo ratings yet

- Trane PDFDocument145 pagesTrane PDFvampiro_yiyo0% (1)

- LM1815 Adaptive Variable Reluctance Sensor Amplifier: Features DescriptionDocument18 pagesLM1815 Adaptive Variable Reluctance Sensor Amplifier: Features DescriptiondangthutqmNo ratings yet

- Inclination Sensor: Inc-M2M090Abiakg/UsDocument5 pagesInclination Sensor: Inc-M2M090Abiakg/UsAmol KaleNo ratings yet

- Safe - Run Starters: Reliable. Flexible. LowcostDocument4 pagesSafe - Run Starters: Reliable. Flexible. LowcostGokula Krishnan CNo ratings yet

- En 3rb2283-4aa1Document6 pagesEn 3rb2283-4aa1Adetunji TaiwoNo ratings yet

- DTC Troubleshooting: Before You Troubleshoot, Review The General Troubleshooting InformationDocument32 pagesDTC Troubleshooting: Before You Troubleshoot, Review The General Troubleshooting InformationpaniyaNo ratings yet

- Renr8131 02Document16 pagesRenr8131 02David ShawNo ratings yet

- Inovance Err Trouble Shooting GuideDocument23 pagesInovance Err Trouble Shooting GuideSohag Walle UllahNo ratings yet

- KG934V1 21-25Document5 pagesKG934V1 21-25Niten GuptaNo ratings yet

- Lider Yangın Alarm ListDocument7 pagesLider Yangın Alarm Listfratk8093No ratings yet

- KUBOTA Tractor Fault Codes DTCDocument20 pagesKUBOTA Tractor Fault Codes DTCRubenNo ratings yet

- Codigos de Fallas Komatsu WA900-3E0Document8 pagesCodigos de Fallas Komatsu WA900-3E0Jose A. Basanta H.No ratings yet

- Electricity and Magnetism 8.02x, Mit, UsaDocument540 pagesElectricity and Magnetism 8.02x, Mit, UsaRahul JaiswalNo ratings yet

- Eca Lab ManualDocument158 pagesEca Lab ManualRamarao Gude50% (2)

- Fully Integrated LDO Linear Voltage RegulatorDocument15 pagesFully Integrated LDO Linear Voltage RegulatorAram ShishmanyanNo ratings yet

- Book 4Document197 pagesBook 4fgdfgdfNo ratings yet

- SM Smg935uDocument119 pagesSM Smg935uHAITHM MURSHEDNo ratings yet

- High Sidegated RiverDocument4 pagesHigh Sidegated RiverJulien de TotoNo ratings yet

- User Manual: Ultra-Di Di20Document12 pagesUser Manual: Ultra-Di Di20joaoNo ratings yet

- PF520 - User ManualDocument244 pagesPF520 - User ManualJonatan Zayas ValdezNo ratings yet

- DC Machine61 74Document3 pagesDC Machine61 74Charina PinlacNo ratings yet

- Pa2 Class 6 GKDocument5 pagesPa2 Class 6 GKRavi DeshwalNo ratings yet

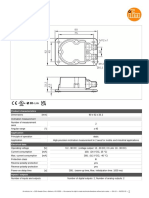

- F20C20A/F20C30A/F20C40A/F20C50A/F20C60ADocument2 pagesF20C20A/F20C30A/F20C40A/F20C50A/F20C60AAnonymous XQ97FmjNo ratings yet

- Week 11 - Module 9 Sequential Logic CircuitsDocument12 pagesWeek 11 - Module 9 Sequential Logic CircuitsBen GwenNo ratings yet

- Proteus Tutorial - Light Emitting Diode (LED) and Bar Graph DisplayDocument7 pagesProteus Tutorial - Light Emitting Diode (LED) and Bar Graph DisplayGebBerheNo ratings yet

- AozDocument16 pagesAozAndreNo ratings yet

- JVC Gr-Df470us PartDocument19 pagesJVC Gr-Df470us Partsonny_boy35_51147747No ratings yet

- ESD Protection: Labour StandardsDocument7 pagesESD Protection: Labour StandardsAKISNo ratings yet

- 4 (DC Ohmmeter)Document14 pages4 (DC Ohmmeter)Mohd Hafizat Ahmad ZikriNo ratings yet

- Good (ELEC6089) Power Cable Insulation DesignDocument22 pagesGood (ELEC6089) Power Cable Insulation DesignvahrmNo ratings yet

- 3S MTDocument9 pages3S MTThomas GarzaNo ratings yet

- Difference Between Analog & Digital Multimeter AND Capacitor & SupercapacitorDocument11 pagesDifference Between Analog & Digital Multimeter AND Capacitor & SupercapacitorYonas AberaNo ratings yet

- Control Ningbo NBSL Nsfc01-01 Control System (4sw)Document14 pagesControl Ningbo NBSL Nsfc01-01 Control System (4sw)Winderson Macauran89% (18)

- Mode of Arc Extinction Mode of Arc Extinction: High Resistance Arc Interruption High Resistance Arc InterruptionDocument9 pagesMode of Arc Extinction Mode of Arc Extinction: High Resistance Arc Interruption High Resistance Arc Interruptionwan anisNo ratings yet

- Akron ThesisDocument153 pagesAkron Thesisthirumalai22No ratings yet

- OMD6068 Case Analysis - Call Drop ISSUE1.1Document75 pagesOMD6068 Case Analysis - Call Drop ISSUE1.1Quốc Minh NguyễnNo ratings yet

- Preventa XPS - XPSAK351144PDocument4 pagesPreventa XPS - XPSAK351144PTiago da Silva PereiraNo ratings yet

- 1 Electrical RegulationsDocument37 pages1 Electrical RegulationsGraezelNo ratings yet

- A Novel: Battery Charger Random Sound Sources Air PressureDocument30 pagesA Novel: Battery Charger Random Sound Sources Air PressureSNEHA LIZ PAULNo ratings yet

- Printer Circuit Board RelaysDocument23 pagesPrinter Circuit Board Relaysphyo7799No ratings yet

- List of IEC Standards Wikipedia, The FRDocument5 pagesList of IEC Standards Wikipedia, The FRSrikant RanjanNo ratings yet