Professional Documents

Culture Documents

1 PDF

1 PDF

Uploaded by

Rohit Shrestha0 ratings0% found this document useful (0 votes)

11 views2 pagesOriginal Title

1 (47).pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views2 pages1 PDF

1 PDF

Uploaded by

Rohit ShresthaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Heating and Ventilating Systems 41

Figure 3-8. Oil Burner

An improperly adjusted burner, a blocked exhaust stack, the

blower or dampers set incorrectly, or any condition which results

in a negative pressure in the boiler room, can cause a high fuel-

to-air condition. A negative pressure in the boiler room can be the

result of one or a combination of conditions such as an exhaust

fan creating a negative pressure in the boiler room, a restricted

combustion air louver into the boiler room, or even adverse wind

conditions.

High air-to-fuel ratios also reduce boiler efficiency. If too

much air is brought in (excess air), the hot gases are diluted too

much and move too fast through the tubes before proper heat

transfer can occur. High air volumes are typically caused by im-

proper blower or damper settings.

ELECTRIC BOILERS

Electric boilers produce heat by electricity and operate at up

to 16,000 volts. Electric boilers are typically compact, clean and

42 HVAC Fundamentals

quiet. They have replaceable heating elements, either electrode or

resistance-coil. With the electrode type boiler, the heat is gener-

ated by electric current flowing from one electrode to another

electrode through the boiler water. Resistance-coil electric boilers

have the electricity flowing through a coiled conductor similar to

an electric space heater. Resistance created by the coiled conduc-

tor generates heat. Resistance-coil electric boilers are not as com-

mon as electrode electric boilers.

Electric boilers are an alternative to oil or gas boilers where

these boilers are restricted by emission regulation and in areas

where the cost of electric power is minimal. Electric boilers can be

fire tube or water tube and supply low or high pressure steam or

hot water. Sizes range from 9 kW to 3,375 kW output, which is

30,717 Btuh to 11,518,875 Btuh (1 kW = 3413 Btuh).

HEAT AND FLUID FLOW CALCULATIONS

FOR HEATING SYSTEM

Looking at the heating system, Figure 3-9, calculate gpm of

water flow if the heating coil load is 243,810 Btuh and TD is 20°F

(200°F EWT - 180°F LWT).

Btuh = gpm × 500 × TD

Where:

Btuh = Btu per hour

gpm = volume of water flow, gallons per minute

500 = constant

60 min/hr × 8.33 lb/gal × 1 Btu/lb/°F

TD = temperature difference of the water entering (EWT)

and leaving (LWT) the coil. ∆T may be used substituted for TD.

Then:

gpm = Btuh ÷ (500 × TD)

gpm = 243,810 ÷ (500 × 20)

You might also like

- FurnacesDocument22 pagesFurnacesaipshitaNo ratings yet

- Waste Heat RecoveryDocument11 pagesWaste Heat RecoveryKashifKhan100% (1)

- Laing Electric Heater-CirculatorDocument20 pagesLaing Electric Heater-Circulatorkamilawehbe100% (1)

- Capstone RehearsalDocument14 pagesCapstone RehearsalRaakesh RajanNo ratings yet

- Amulya Gaikwada ProjectDocument34 pagesAmulya Gaikwada ProjectHarikrishna NethaNo ratings yet

- Water Tube BoilersDocument8 pagesWater Tube Boilershafidhrahadiyan2No ratings yet

- Boilers and Boiler Control Systems (Energy Engineering)Document22 pagesBoilers and Boiler Control Systems (Energy Engineering)Obayomi KennyNo ratings yet

- Steam BoilerDocument7 pagesSteam BoilerVishnu VardhanNo ratings yet

- Air Cooling SystemDocument12 pagesAir Cooling SystemMai DangNo ratings yet

- Chapter 1 Steam GenerationDocument18 pagesChapter 1 Steam GenerationfaranimohamedNo ratings yet

- Water Tube BoilerDocument8 pagesWater Tube Boilersandeep kumarNo ratings yet

- Understand Boiler Performance CharacteristicsDocument5 pagesUnderstand Boiler Performance CharacteristicsdeerajksNo ratings yet

- Power Plant FamiliarisationDocument110 pagesPower Plant FamiliarisationmrdipakwaghNo ratings yet

- Tugas Util (Boiler)Document4 pagesTugas Util (Boiler)AkhmadSumarnoNo ratings yet

- Thermal Power PlantDocument11 pagesThermal Power PlantAnand Kalani100% (1)

- Thermal Power PlantDocument35 pagesThermal Power PlantAngelaa DassNo ratings yet

- 8 Steam Power PlantsDocument57 pages8 Steam Power PlantsSaif Younus100% (1)

- Chapter - IIIDocument20 pagesChapter - IIIRajeshNo ratings yet

- Power PlantDocument4 pagesPower PlantNumair AshrafNo ratings yet

- Electric Geyser (Electrical Water Heater)Document15 pagesElectric Geyser (Electrical Water Heater)vipinkathpalNo ratings yet

- Hydronic SystemsDocument5 pagesHydronic SystemsValentinNo ratings yet

- Unit - I Steam Power PlantsDocument32 pagesUnit - I Steam Power Plantsrsankarganesh MECH-HICET100% (1)

- Ground Source Heating and CoolingDocument25 pagesGround Source Heating and CoolingAnuj Reddy100% (1)

- Thermal Power Plant Layout and OperationDocument8 pagesThermal Power Plant Layout and OperationRAJENDRA TELVEKARNo ratings yet

- Presentation On KSTPSDocument28 pagesPresentation On KSTPSatul mishra100% (1)

- Boiler Q ADocument26 pagesBoiler Q AGnanaSekar100% (1)

- EEC 122 CompleteDocument34 pagesEEC 122 CompleteAdeniji OlusegunNo ratings yet

- Basic Civil and Mechanical Engineering Unit III Classification of Power PlantsDocument21 pagesBasic Civil and Mechanical Engineering Unit III Classification of Power PlantsSiman NapstervkkNo ratings yet

- Basics of Thermal Power PlantDocument35 pagesBasics of Thermal Power PlantMansoor Chowdhury100% (1)

- Mechanical Engineering Project - Thermal Power Plant Study - WWW - Amie.nbcafe - inDocument24 pagesMechanical Engineering Project - Thermal Power Plant Study - WWW - Amie.nbcafe - inbtdoss72100% (1)

- Cooling Tower PDFDocument30 pagesCooling Tower PDFcynaidu100% (1)

- Firetube Heaters: FIG. 8-31 Convection HeaterDocument7 pagesFiretube Heaters: FIG. 8-31 Convection Heatery149487No ratings yet

- Boiler Operation & Maintenance: Study GuideDocument24 pagesBoiler Operation & Maintenance: Study GuidedadangkoeNo ratings yet

- Lecture 8: Steam Generators: Fig. 8.1: A Shell Boiler With An EconomizerDocument6 pagesLecture 8: Steam Generators: Fig. 8.1: A Shell Boiler With An EconomizerIjazzzAliNo ratings yet

- Exhaust Temperature: Steam Turbine Cycles and Cycle Design OptimizationDocument12 pagesExhaust Temperature: Steam Turbine Cycles and Cycle Design OptimizationMuh AmmadNo ratings yet

- Geothermal Energy: EE153/B12 Atienza, Jannela Pontanares, Sergio Rostata, ErwinDocument26 pagesGeothermal Energy: EE153/B12 Atienza, Jannela Pontanares, Sergio Rostata, ErwinChanning TatumNo ratings yet

- CHAPTER 1 STEAM GENERATION (Complete Slide)Document25 pagesCHAPTER 1 STEAM GENERATION (Complete Slide)nisasoberiNo ratings yet

- SIREreport 118ee0297Document13 pagesSIREreport 118ee0297Bhabani sankar KishanNo ratings yet

- Lecture 3 - Coal Power PlantsaDocument48 pagesLecture 3 - Coal Power PlantsaGomolemo BaarxxNo ratings yet

- Lecture 4-Combustion and Boilers PDFDocument39 pagesLecture 4-Combustion and Boilers PDFjuan maganNo ratings yet

- Unit-I Power PlantsDocument22 pagesUnit-I Power Plantsamsk24_24No ratings yet

- Boiler Definition & TypesDocument17 pagesBoiler Definition & TypesDevidutta PandaNo ratings yet

- Superheated SteamDocument19 pagesSuperheated SteamSAKDA MAPRADITKUL100% (1)

- Waste HeatDocument6 pagesWaste HeatHassan MehrizNo ratings yet

- Boiler Temperature ControllerDocument6 pagesBoiler Temperature ControllerAlokNo ratings yet

- Chapter Three: Steam Generators 3.1 DefinitionDocument43 pagesChapter Three: Steam Generators 3.1 DefinitionHeber Farid Fabrica Quispe100% (1)

- Ppe Pit Obando's PartDocument8 pagesPpe Pit Obando's PartJane PondulanNo ratings yet

- Gas Turbine Power PlantDocument15 pagesGas Turbine Power Plantrahul100% (2)

- Thermal Power Plant: Shubham Thakur 13BME8149 5MEL3 Mechanical EngineeringDocument34 pagesThermal Power Plant: Shubham Thakur 13BME8149 5MEL3 Mechanical EngineeringMos MohNo ratings yet

- Water-Tube Boilers - International Site For Spirax SarcoDocument7 pagesWater-Tube Boilers - International Site For Spirax SarcotahirNo ratings yet

- Different Refrigeration systems-AKMDocument23 pagesDifferent Refrigeration systems-AKMRafia RizwanaNo ratings yet

- Geothermal "Earth Energy" By: Faheem Haider HaidryDocument37 pagesGeothermal "Earth Energy" By: Faheem Haider HaidryFaheem HaiderNo ratings yet

- Steam Drum Systems As Well As Once-Through Steam Generators (OTSG) SystemsDocument8 pagesSteam Drum Systems As Well As Once-Through Steam Generators (OTSG) SystemsGobardhana swainNo ratings yet

- BodyDocument69 pagesBodyRoi Benedict BuenaNo ratings yet

- Thermal Power Plant Lay OutDocument8 pagesThermal Power Plant Lay OutSaheli ChoudhuriNo ratings yet

- Assignment: Cogeneration and Waste Heat Recovery SystemsDocument8 pagesAssignment: Cogeneration and Waste Heat Recovery Systemsd_raj187No ratings yet

- Lec 3 BoilerDocument20 pagesLec 3 BoilerRajiv SharmaNo ratings yet

- Combined Gas and Steam: (COGAS) Plant. Multiple Stage Turbine or Steam Cycles Are AlsoDocument12 pagesCombined Gas and Steam: (COGAS) Plant. Multiple Stage Turbine or Steam Cycles Are AlsoRobinsyahNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningFrom EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningRating: 5 out of 5 stars5/5 (2)

- Heating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerDocument2 pagesHeating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerrohitNo ratings yet

- Heating and Ventilating Systems 33Document2 pagesHeating and Ventilating Systems 33rohitNo ratings yet

- 1 PDFDocument2 pages1 PDFrohitNo ratings yet

- Figure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamDocument2 pagesFigure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamrohitNo ratings yet

- Heating and Ventilating Systems 25Document2 pagesHeating and Ventilating Systems 25rohitNo ratings yet

- Heating and Ventilating Systems 27Document2 pagesHeating and Ventilating Systems 27rohitNo ratings yet

- Air Conditioning Systems 57Document2 pagesAir Conditioning Systems 57rohitNo ratings yet

- Heating and Ventilating Systems 29: Figure 3-2. Steam BoilerDocument2 pagesHeating and Ventilating Systems 29: Figure 3-2. Steam BoilerrohitNo ratings yet

- Heating and Ventilating Systems 35Document2 pagesHeating and Ventilating Systems 35rohitNo ratings yet

- Figure 4-4. Air-to-Water AC SystemDocument2 pagesFigure 4-4. Air-to-Water AC SystemrohitNo ratings yet

- Air Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)Document2 pagesAir Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)rohitNo ratings yet

- Figure 4-.2 Air Conditioning System ExampleDocument2 pagesFigure 4-.2 Air Conditioning System ExamplerohitNo ratings yet

- Air Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemDocument2 pagesAir Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemrohitNo ratings yet

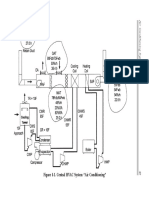

- Figure 4-1. Central HVAC System "Air Conditioning"Document2 pagesFigure 4-1. Central HVAC System "Air Conditioning"rohitNo ratings yet

- Btuh GPM ×: Heat Flow 23Document2 pagesBtuh GPM ×: Heat Flow 23rohitNo ratings yet

- This Page Intentionally Left BlankDocument2 pagesThis Page Intentionally Left BlankrohitNo ratings yet

- Air Conditioning Systems 55Document2 pagesAir Conditioning Systems 55rohitNo ratings yet

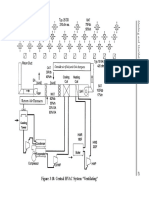

- Figure 3-10. Central HVAC System "Ventilating"Document2 pagesFigure 3-10. Central HVAC System "Ventilating"rohitNo ratings yet

- Air Conditioning Systems 51Document2 pagesAir Conditioning Systems 51rohitNo ratings yet

- Air Conditioning Systems 47Document2 pagesAir Conditioning Systems 47rohitNo ratings yet

- Heating and Ventilating Systems 43: MAT (%OA ×Document2 pagesHeating and Ventilating Systems 43: MAT (%OA ×rohitNo ratings yet

- Heat Flow 19Document2 pagesHeat Flow 19rohitNo ratings yet

- HVAC Systems 1Document2 pagesHVAC Systems 1rohitNo ratings yet

- HVAC Systems 13: VentilatingDocument2 pagesHVAC Systems 13: VentilatingrohitNo ratings yet

- This Page Intentionally Left BlankDocument2 pagesThis Page Intentionally Left BlankrohitNo ratings yet

- Heat Flow 15Document2 pagesHeat Flow 15rohitNo ratings yet

- Latent HeatDocument2 pagesLatent HeatrohitNo ratings yet

- Air Volume: HVAC Systems 11Document2 pagesAir Volume: HVAC Systems 11rohitNo ratings yet

- Heat Flow 17: ConductionDocument2 pagesHeat Flow 17: ConductionrohitNo ratings yet

- HVAC Systems 9Document2 pagesHVAC Systems 9rohitNo ratings yet

- The Plenitude: A CompanionDocument85 pagesThe Plenitude: A CompanionThe MIT Press97% (36)

- DELICT Lecture NotesDocument21 pagesDELICT Lecture Notesngozi_vinel88% (8)

- ESEM 5554 Reflection 4Document3 pagesESEM 5554 Reflection 4nitiyahsegarNo ratings yet

- Effective Presentation BoardDocument25 pagesEffective Presentation BoardJerica Tamayo100% (1)

- Students List Semester 1 2021-2022 Update 250821Document21 pagesStudents List Semester 1 2021-2022 Update 250821Haniff NazimuddinNo ratings yet

- Meditation IndexDocument1 pageMeditation IndexEdwin CondonNo ratings yet

- Cme2100 Quick Manual English v.3.0 0Document59 pagesCme2100 Quick Manual English v.3.0 0mgugiNo ratings yet

- Required Books For Pharm-DDocument18 pagesRequired Books For Pharm-DNaveed AkhterNo ratings yet

- FINAL Assignment For TENTATIVE BALE ZONE 24 1Document55 pagesFINAL Assignment For TENTATIVE BALE ZONE 24 1Abdulnasir AbdulmelikeNo ratings yet

- Enhanced - Research Summary-Recto - Visitacion-Baybay City DivisionDocument22 pagesEnhanced - Research Summary-Recto - Visitacion-Baybay City DivisionVISITACION RECTONo ratings yet

- The Great 01 (2) - TraitorAIZENDocument520 pagesThe Great 01 (2) - TraitorAIZENGiga GigaNo ratings yet

- Sadhana Prakash - Hinduism in Practice .Its Not A Stupid Religion ! Try For Your Self !!!!Document4 pagesSadhana Prakash - Hinduism in Practice .Its Not A Stupid Religion ! Try For Your Self !!!!VabOMNo ratings yet

- Factories and Works Act 15:04 RGN 264: Building, Structural and Excavation WorkDocument19 pagesFactories and Works Act 15:04 RGN 264: Building, Structural and Excavation WorkCourageNo ratings yet

- Nikah NammaDocument4 pagesNikah NammaM.ASIM IQBAL KIANI100% (2)

- Virtual Tour of The Presidential Car MuseumDocument1 pageVirtual Tour of The Presidential Car MuseumRod Stephen SobrevillaNo ratings yet

- 2 Pie 20-21Document32 pages2 Pie 20-21akshat guptaNo ratings yet

- DLL - Mathematics 5 - Q4 - W3Document7 pagesDLL - Mathematics 5 - Q4 - W3Beverly Amora SeradaNo ratings yet

- 6 - Johnson, K - Geotechnical Investigations For Dredging Projects PDFDocument16 pages6 - Johnson, K - Geotechnical Investigations For Dredging Projects PDFAhmed GadNo ratings yet

- Midlife Crisis - Signs, Causes, and Coping TipsDocument13 pagesMidlife Crisis - Signs, Causes, and Coping TipsMonyesmaNo ratings yet

- Cryptography With CertificatesDocument5 pagesCryptography With CertificatesramtulsipurNo ratings yet

- 【Haug-1984】Computer Aided Analysis and Optimization of Mechanical System Dynamics PDFDocument718 pages【Haug-1984】Computer Aided Analysis and Optimization of Mechanical System Dynamics PDFAlfoilNo ratings yet

- 30 Day Classical Arabic CourseDocument31 pages30 Day Classical Arabic CourseAhmed ChNo ratings yet

- Scrotal Disease - 2Document47 pagesScrotal Disease - 2Hillary BushnellNo ratings yet

- Welcome To Tangible User Interfaces - Theory and Practice of Tangible User InterfacesDocument2 pagesWelcome To Tangible User Interfaces - Theory and Practice of Tangible User InterfacesMauricio ValenciaNo ratings yet

- Gran Armada de 1588Document5 pagesGran Armada de 1588samuraijack7No ratings yet

- Problems On Sole PropritersDocument10 pagesProblems On Sole PropritersMouly ChopraNo ratings yet

- Φ630 Cantilever frame Single-twist Cabling MachineDocument3 pagesΦ630 Cantilever frame Single-twist Cabling Machinetees220510No ratings yet

- Lesson Plan ReadingDocument5 pagesLesson Plan ReadingAzreena RahimNo ratings yet

- Wanted A Chaperon 1Document23 pagesWanted A Chaperon 1jeffersonsabater61No ratings yet