Professional Documents

Culture Documents

AD 348 - Bolt Resistance Tables in The Eurocode Blue Book

Uploaded by

symon ellimac0 ratings0% found this document useful (0 votes)

50 views1 pageAD 348 - Bolt resistance tables in the Eurocode Blue Book

Original Title

AD 348 - Bolt resistance tables in the Eurocode Blue Book

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAD 348 - Bolt resistance tables in the Eurocode Blue Book

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

50 views1 pageAD 348 - Bolt Resistance Tables in The Eurocode Blue Book

Uploaded by

symon ellimacAD 348 - Bolt resistance tables in the Eurocode Blue Book

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Codes & Standards

New and Revised Codes & Standards

(from BSI Updates July 2010)

BS EN PUBLICATIONS NEW WORK STARTED DRAFT BRITISH STANDARDS FOR

PUBLIC COMMENT

BS EN ISO 14344:2010 BS 7371-8 (Revision)

Welding consumables. Procurement of filler Coatings on metal fasteners. Specifications for 10/30219617 DC

materials and fluxes sherardized coatings BS EN ISO 898-1 AMD1 Mechanical properties of

Supersedes BS EN ISO 14344:2005 Will supersede BS 7371-8:1998 fasteners made of carbon steel and alloy steel.

Bolts, screws and studs with specified property

classes. Coarse thread and fine pitch thread

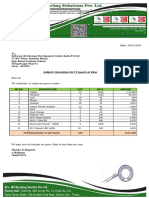

Advisory Desk

AD 348

Bolt resistance tables in the Eurocode Blue Book

This AD Note provides clarification of resistance values given in SCI p2 = 2e2 = 2 × 25 = 50 mm

publication P363 Steel building design: Design data (the Eurocode Blue Book). For this bolt arrangement:

The publication covers Class 4.6, 8.8 and 10.9 bolts, including non-

e p1 1 f 32 45 . 5 1 800

preloaded and preloaded hexagon head bolts and countersunk bolts. α b = min 1 ; − ; ub ; 1. 0 = min ; − ; ; 1 . 0 = 0 . 593

3 d 0 3 d 0 4 fu 3 × 18 3 × 18 4 410

Resistances for preloaded bolts include values for serviceability limit state

and ultimate limit state. The calculation of resistances is described in the e p 25 50

k 1 = min 2.8 2 − 1. 7 ; 1. 4 2 − 1. 7 ; 2.5 = min 2. 8 − 1. 7 ; 1. 4 − 1.7 ; 2. 5 = 2.189

explanatory notes, Section 11.1 of the publication. d0 d0 18 18

For Class 4.6 non-preloaded bolts, two tables of resistances are provided;

For a ply thickness of 10 mm in S275:

for Class 8.8 and 10.9 non-preloaded bolts, three tables are provided.

For each bolt class, the first table gives tension resistance, shear k 1α b fu dt 2 .189 × 0.593 × 410 × 16 × 10

F b, Rd = = = 68 .1 kN

resistance and minimum thickness to avoid punching shear, all determined γ M2 1.25 × 10 3

in accordance with Table 3.4 of BS EN 1993-1-8. Although the punching This is the value tabulated in P363.

shear resistance needs to be verified, this is not a common mode of failure

If the resistance calculation were carried out using the tabulated values of

in practical situations. The publication provides the minimum thickness

e1 = 35 mm and p1 = 50 mm, then the resistance would increase to 74.4 kN.

required to ensure punching shear does not occur. Note that the dimensions

of preloaded and non-preloaded bolts are different and therefore, for the same The third table, for bolt classes 8.8 and 10.9, gives bearing resistances for

bolt size, the minimum thickness to prevent punching shear differs for the two increased values of e1, e2, p1 and p2, which give higher bearing resistance. As

types of bolts. for the second table, values have been chosen according to an exact multiple

The second table gives bearing resistances for various ply thicknesses. of bolt or hole diameter and then rounded up to the nearest 5 mm. Resistances

The bearing resistance depends on the bolt arrangement, defined by e1, e2, have been calculated based on the exact values, not the rounded values. The

p1 and p2. The end distance e1 has been taken as twice the bolt diameter and calculation has been based on the following values of e1, e2, p1 and p2:

resistances have been calculated for these values of e1. However, the values e2 = 1.5d0

of e1 printed in the tables have been rounded up to the nearest 5 mm. The e1 = 3d

edge distance e2 has been chosen to match common practice; values rounded

p1 = 3.75d0

to 5 mm have been chosen. The values of pitch, p1 and p2, have been chosen

such that resistance values based on them are not more critical than those p2 = 3d0

based on e1 (the ‘exact’ value rather than the rounded value) and e2, and they The third table is not given for class 4.6 bolts because increasing the bolt

also have been rounded up to the nearest 5 mm. Examples of values in the spacing only has a modest effect. For an increased bearing resistance, a

second table are illustrated as follows: higher bolt class is recommended.

Page C-303, Table 2, Class 8.8, M16 bolts:

Contact: Edurne Nunez Moreno

e2 = 25 mm

Tel: 01344 636525

e1 = 2d = 2×16 = 32 mm, which is tabulated as 35 mm Email: advisory@steel-sci.com

e1 1 32 1

p1 = 3d 0 + = 3 × 18 + = 45.5 mm, which is tabulated as 50 mm

3d 0 4 3 × 18 4

38 NSC September 2010

You might also like

- Calculate Anchorage Lap Lengths EC2Document8 pagesCalculate Anchorage Lap Lengths EC2Giurcanas Andrei100% (2)

- Design of Connections: Fig 4.1: Typical Connections: (A) Beam To Column (B) Beam To BeamDocument16 pagesDesign of Connections: Fig 4.1: Typical Connections: (A) Beam To Column (B) Beam To BeamMuriungi RicharsNo ratings yet

- Hes B008-03 Hexagon NutsDocument5 pagesHes B008-03 Hexagon NutsPreetam KumarNo ratings yet

- SDM Chapter E - 0708Document6 pagesSDM Chapter E - 0708Janice FernandezNo ratings yet

- Blue Book' Tables For Bolts, Welds and Webs: TechnicalDocument3 pagesBlue Book' Tables For Bolts, Welds and Webs: TechnicalsteNo ratings yet

- Beam Design & Detailing (Simply Supported)Document58 pagesBeam Design & Detailing (Simply Supported)dixn__100% (8)

- Nota Design Using Ec2 2Document119 pagesNota Design Using Ec2 2mon100% (1)

- Design of Anchorage Length EC2Document4 pagesDesign of Anchorage Length EC2ECC100% (2)

- ECSC Stainless Steel Bolted Joint DesignDocument6 pagesECSC Stainless Steel Bolted Joint Designcollins unankaNo ratings yet

- Rebar TableDocument4 pagesRebar TableyadavniranjanNo ratings yet

- How To Design Concrete Structures Using Eurocode 2 - (3) SlabsDocument8 pagesHow To Design Concrete Structures Using Eurocode 2 - (3) Slabsbobbytirona566100% (1)

- 11 Continuous BeamsDocument55 pages11 Continuous BeamsMelinda GordonNo ratings yet

- Examples Bolted ConnectionsDocument16 pagesExamples Bolted Connectionsaisha nakato100% (2)

- En 1993-1-8Document69 pagesEn 1993-1-8atiNo ratings yet

- Lecture 4-2-2 - Design of Compression Members NewDocument47 pagesLecture 4-2-2 - Design of Compression Members NewHarold Jackson MtyanaNo ratings yet

- Rectangular beam design procedureDocument11 pagesRectangular beam design procedureshada aidaNo ratings yet

- Structural Connection Design Example: For Class 4.6 Bolts For Class 4.6 Bolts For 20 Diameter of BoltDocument7 pagesStructural Connection Design Example: For Class 4.6 Bolts For Class 4.6 Bolts For 20 Diameter of BoltremedanNo ratings yet

- Introduction-Design-Guide 2Document16 pagesIntroduction-Design-Guide 2Sutha100% (1)

- Blue Book' Tables For Bolts, Welds and Webs: TechnicalDocument3 pagesBlue Book' Tables For Bolts, Welds and Webs: TechnicalJacob GrechNo ratings yet

- CE 308-Design of Steel Structures: Analysis of Tension MembersDocument5 pagesCE 308-Design of Steel Structures: Analysis of Tension MembersAli BahuNo ratings yet

- Design of Connetiomn Chankara AryaDocument21 pagesDesign of Connetiomn Chankara AryaMohamed AbdNo ratings yet

- Chapter 2 Tension MembersDocument8 pagesChapter 2 Tension MembersGamtesa EjetaNo ratings yet

- 0 1 Reinforced Concrete EC2 Definitions and Details p1-5Document6 pages0 1 Reinforced Concrete EC2 Definitions and Details p1-5VijayNo ratings yet

- BoltsDocument5 pagesBoltsdan BeaulandaNo ratings yet

- Chapter-2 Design For Tension MemberDocument14 pagesChapter-2 Design For Tension Memberzakai zakiNo ratings yet

- NCCI PN 001a - Stud StrengthDocument7 pagesNCCI PN 001a - Stud StrengthravisbadryNo ratings yet

- Steel Connection DesignDocument16 pagesSteel Connection DesignHazza JumaaNo ratings yet

- CE302 MECHANICS OF MATERIALS Chapter 2 - Tutorial ProblemsDocument7 pagesCE302 MECHANICS OF MATERIALS Chapter 2 - Tutorial ProblemsAhmet Tüken100% (1)

- Connection - Bolt 2022Document80 pagesConnection - Bolt 2022LUGHANO NGAJILONo ratings yet

- Lecture 6 - Design of RC SlabsDocument21 pagesLecture 6 - Design of RC SlabsTuan Jalai100% (1)

- Extracts From Ec3 For Students 2012Document6 pagesExtracts From Ec3 For Students 2012Alexandru MarincuNo ratings yet

- Welded Connections DesignDocument35 pagesWelded Connections DesignBelkacem AchourNo ratings yet

- Design of End Plate Joints Made With Preloaded Bolts Subject To Coincident Shear and TensionDocument1 pageDesign of End Plate Joints Made With Preloaded Bolts Subject To Coincident Shear and TensionAnonymous 37PvyXCNo ratings yet

- Slabs: Designing To Eurocode 2Document8 pagesSlabs: Designing To Eurocode 2way2saleemNo ratings yet

- AD 399 - Design of Partial Penetration Butt Welds in Accordance With BS EN 1993-1-8Document1 pageAD 399 - Design of Partial Penetration Butt Welds in Accordance With BS EN 1993-1-8symon ellimacNo ratings yet

- Calculation and Design of Bolted Connections: Structural Engineering Techniques Leeds Beckett UniversityDocument9 pagesCalculation and Design of Bolted Connections: Structural Engineering Techniques Leeds Beckett UniversityAhmet Selim ÇağinNo ratings yet

- Din 11851 Edited VersionDocument22 pagesDin 11851 Edited VersionSenthilKumarShanmughamNo ratings yet

- Substructure - Beam Design (Example)Document31 pagesSubstructure - Beam Design (Example)Arghya Pal100% (1)

- Analyses On Reinforced Concrete Cross SectionsDocument35 pagesAnalyses On Reinforced Concrete Cross SectionsnavaleriNo ratings yet

- Initial Sizing of Fin Plate ConnectionsDocument8 pagesInitial Sizing of Fin Plate ConnectionsBobaru Marius100% (1)

- Design Calculations: Sheet 1 of 12Document12 pagesDesign Calculations: Sheet 1 of 12Shawkat Ali Khan100% (1)

- RC Detailing To Eurocode 2Document39 pagesRC Detailing To Eurocode 2Sandipan DharNo ratings yet

- Watertank GSDocument38 pagesWatertank GSSushobhit ChoudharyNo ratings yet

- B17 RC Detailing To EC2Document69 pagesB17 RC Detailing To EC2Mahmoud Moustafa Elnegihi100% (1)

- 3.5 Strength Calculations: Tension Is A Force That Stretches Something. Compression Is A Force That SqueezesDocument4 pages3.5 Strength Calculations: Tension Is A Force That Stretches Something. Compression Is A Force That SqueezesAlfermae CaongNo ratings yet

- Design and Analysis of Simple ConnectionsDocument88 pagesDesign and Analysis of Simple ConnectionsSabih Hashim Alzuhairy100% (1)

- Tying Resistance of A Fin Plate ConnectionDocument9 pagesTying Resistance of A Fin Plate ConnectionSam Samoura0% (1)

- Toaz - Info Merge PRDocument81 pagesToaz - Info Merge PRMildred CanopinNo ratings yet

- Pin Bush Coupling DesignDocument15 pagesPin Bush Coupling Designyogwani79No ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Design Actions During Concreting For Beams and Decking in Composite FloorsDocument2 pagesDesign Actions During Concreting For Beams and Decking in Composite FloorsMosab Abdelhalim Abdelkarim MakkiNo ratings yet

- Web Resistance To Transverse Loads According To BS EN 1993-1-5Document1 pageWeb Resistance To Transverse Loads According To BS EN 1993-1-5witwatersrandNo ratings yet

- AD 435 - Beams Supporting Precast Planks - Checks in The Temporary Condition, November 2019Document1 pageAD 435 - Beams Supporting Precast Planks - Checks in The Temporary Condition, November 2019symon ellimacNo ratings yet

- AD 430 - Wind Load On Unclad Frames, May 2019Document1 pageAD 430 - Wind Load On Unclad Frames, May 2019symon ellimac100% (1)

- AD 379 - Tying Resistances of Full Depth End PlatesDocument1 pageAD 379 - Tying Resistances of Full Depth End Platessymon ellimacNo ratings yet

- AD 439 - Transverse Reinforcement in Composite Beams, April 2020Document2 pagesAD 439 - Transverse Reinforcement in Composite Beams, April 2020symon ellimacNo ratings yet

- AD 424 - Shear Stud Length, November 2018Document1 pageAD 424 - Shear Stud Length, November 2018symon ellimacNo ratings yet

- AD 447 - Openings in Composite Slabs, July 2020Document1 pageAD 447 - Openings in Composite Slabs, July 2020symon ellimacNo ratings yet

- AD 428 - Draft Guidance - Lateral and Torsional Vibration of Half-Through Truss Footbridges, March 2019Document1 pageAD 428 - Draft Guidance - Lateral and Torsional Vibration of Half-Through Truss Footbridges, March 2019symon ellimacNo ratings yet

- AD 429 - Slip Factors For Alkali-Zinc Silicate Paint, April 2019Document1 pageAD 429 - Slip Factors For Alkali-Zinc Silicate Paint, April 2019symon ellimacNo ratings yet

- AD 434 - Validity Rules For Hollow Section Joints, October 2019Document1 pageAD 434 - Validity Rules For Hollow Section Joints, October 2019symon ellimacNo ratings yet

- SCI AD 423 Reduction in Bending Resistance Due To High ShearDocument1 pageSCI AD 423 Reduction in Bending Resistance Due To High Sheartun20000No ratings yet

- AD 422 - Punching Shear Check F - JOURNAL - NSC - ADDocument1 pageAD 422 - Punching Shear Check F - JOURNAL - NSC - ADsymon ellimacNo ratings yet

- AD 422 - Punching Shear Check F - JOURNAL - NSC - ADDocument1 pageAD 422 - Punching Shear Check F - JOURNAL - NSC - ADsymon ellimacNo ratings yet

- AD 453 - Accumulated Deviations in Erected Steelwork, November 2020Document1 pageAD 453 - Accumulated Deviations in Erected Steelwork, November 2020symon ellimacNo ratings yet

- AD 431 - Column Web Panel Strengthening, June 2019Document1 pageAD 431 - Column Web Panel Strengthening, June 2019symon ellimacNo ratings yet

- AD 448 - Support To Profiled Steel Decking, September 2020Document1 pageAD 448 - Support To Profiled Steel Decking, September 2020symon ellimacNo ratings yet

- AD 433 - Dynamic Modulus of Concrete For Floor Vibration Analysis, September 2019Document1 pageAD 433 - Dynamic Modulus of Concrete For Floor Vibration Analysis, September 2019symon ellimacNo ratings yet

- AD 438 - Non-Slip Connections To BS 5950, March 2020Document1 pageAD 438 - Non-Slip Connections To BS 5950, March 2020symon ellimacNo ratings yet

- AD 450 - Resistance of Composite Slabs To Concentrated Loads, October 2020Document1 pageAD 450 - Resistance of Composite Slabs To Concentrated Loads, October 2020symon ellimacNo ratings yet

- New and Revised Codes & Standards: From BSI Updates May 2020Document1 pageNew and Revised Codes & Standards: From BSI Updates May 2020KemoHNo ratings yet

- New and Revised Codes & Standards: AD 425: AD 426Document1 pageNew and Revised Codes & Standards: AD 425: AD 426symon ellimacNo ratings yet

- AD 440 - Fire Design of External Steelwork, May 2020Document1 pageAD 440 - Fire Design of External Steelwork, May 2020symon ellimacNo ratings yet

- Ad 432Document1 pageAd 432Victor OmotoriogunNo ratings yet

- AD 437 - Curtailment of Transverse Bar Reinforcement in Composite Beams With Steel Decking Designed Using Eurocodes, February 2020Document1 pageAD 437 - Curtailment of Transverse Bar Reinforcement in Composite Beams With Steel Decking Designed Using Eurocodes, February 2020symon ellimacNo ratings yet

- AD 436 - Section Classification of A Flat Plate, January 2020Document1 pageAD 436 - Section Classification of A Flat Plate, January 2020symon ellimacNo ratings yet

- New and Revised Codes & Standards: AD 425: AD 426Document1 pageNew and Revised Codes & Standards: AD 425: AD 426symon ellimacNo ratings yet

- AD 427 - Typographical Error in P419, February 2019Document1 pageAD 427 - Typographical Error in P419, February 2019symon ellimacNo ratings yet

- AD 416 - Artificially Reducing The Effective Width of Slab To Satisfy Shear Connection Requirements, March 2018Document1 pageAD 416 - Artificially Reducing The Effective Width of Slab To Satisfy Shear Connection Requirements, March 2018symon ellimacNo ratings yet

- Spring Boot & Micro Services Course ContentDocument4 pagesSpring Boot & Micro Services Course ContentRamakrishna PradhanNo ratings yet

- Analysis The Effect of Environmental Conditions On Abs Grade A Steel and Bki Grade A Steel Coating On The Resistance Test of Impact CoatingDocument15 pagesAnalysis The Effect of Environmental Conditions On Abs Grade A Steel and Bki Grade A Steel Coating On The Resistance Test of Impact Coatingary rizkiNo ratings yet

- PCGamer MAY2013Document99 pagesPCGamer MAY2013Wilson CrunchNo ratings yet

- Isee Nses2023 BrochureDocument12 pagesIsee Nses2023 BrochurehksachinNo ratings yet

- Article Review 1Document24 pagesArticle Review 1limap5No ratings yet

- Sunny Brochure 16 Pages 23102018 PDFDocument8 pagesSunny Brochure 16 Pages 23102018 PDFSunilNo ratings yet

- Asme Sec Viii D1 Nma App RDocument2 pagesAsme Sec Viii D1 Nma App RADRIAN100% (2)

- 3BUA000135R5001 DCI ConfigDocument34 pages3BUA000135R5001 DCI ConfigCristi CrseNo ratings yet

- CV - Linkedin 3Document5 pagesCV - Linkedin 3Samir ChaudharyNo ratings yet

- Retinopathy Report 2023Document83 pagesRetinopathy Report 2023Hydra ANINo ratings yet

- Microcontroller To Sensor Interfacing TechniquesDocument13 pagesMicrocontroller To Sensor Interfacing TechniquesSantosh Martha100% (1)

- NTU-FTA DeckDocument10 pagesNTU-FTA DeckSanjaya RegaliazNo ratings yet

- Simplify and Automate Connectivity To AWS With Prisma SD-WANDocument4 pagesSimplify and Automate Connectivity To AWS With Prisma SD-WANAishwarya PradhanNo ratings yet

- BDT 135 e-ticket booked for Adhora Ruma's journey from BBSETU_E to DHAKA on SUNDARBAN_EXPRESSDocument1 pageBDT 135 e-ticket booked for Adhora Ruma's journey from BBSETU_E to DHAKA on SUNDARBAN_EXPRESSMS.sumonNo ratings yet

- P65-18-XDHHW2-M: Quadruple Broadband AntennaDocument2 pagesP65-18-XDHHW2-M: Quadruple Broadband Antennazeeshanriaz1077No ratings yet

- Reading Innovation Via ProFuturo SolutionDocument7 pagesReading Innovation Via ProFuturo SolutionMa Cristina ServandoNo ratings yet

- Digital Marketing Agency AhmedabadDocument24 pagesDigital Marketing Agency AhmedabadDhavalNo ratings yet

- Estimation and Budget FormatDocument8 pagesEstimation and Budget Formatlinga2014No ratings yet

- Datasheet Uni M QNB NS enDocument2 pagesDatasheet Uni M QNB NS enLinh dươngNo ratings yet

- Bus ID No.: E-1347: Passenger InformationDocument1 pageBus ID No.: E-1347: Passenger InformationVignesh KumarNo ratings yet

- Chapter 1. Defining and Collecting Data Triệu Vi GửiDocument43 pagesChapter 1. Defining and Collecting Data Triệu Vi GửiDang Thuy Trang (K17 QN)No ratings yet

- Bike TN02 BK 4721 RC Book Honda UnicornDocument1 pageBike TN02 BK 4721 RC Book Honda UnicornvinothNo ratings yet

- Smart BeltDocument9 pagesSmart BeltDavid SfkaNo ratings yet

- Mares Nemo Dive Computer ManualDocument77 pagesMares Nemo Dive Computer Manualjohn@moron.it100% (1)

- Essar Steel PlantDocument62 pagesEssar Steel PlantKrishnadev C.SNo ratings yet

- AGIP GREASE SM 2 Molybdenum GreaseDocument1 pageAGIP GREASE SM 2 Molybdenum GreaseranjanguptNo ratings yet

- Blank Letterhead..... PDF - 20240120 - 143356 - 0000Document1 pageBlank Letterhead..... PDF - 20240120 - 143356 - 0000jrsrecyclingltdNo ratings yet

- Catálogo EIXO ZFDocument27 pagesCatálogo EIXO ZFOdirley JonesNo ratings yet

- LOGIQ Book Cart Instructions Quick Card - English - UM - 2399122-100 - 000Document2 pagesLOGIQ Book Cart Instructions Quick Card - English - UM - 2399122-100 - 000Dody Setyo AnggoroNo ratings yet

- MFL Floormap - How To Scan and Get DataDocument18 pagesMFL Floormap - How To Scan and Get DataNguyen PhucNo ratings yet