Professional Documents

Culture Documents

GCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 2

Uploaded by

TOM YEEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 2

Uploaded by

TOM YEECopyright:

Available Formats

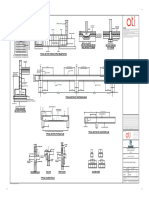

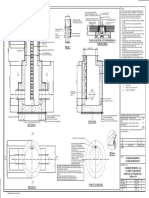

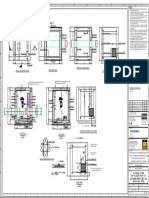

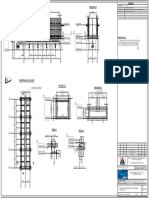

(III) INTERMEDIATE DETAIL 4.

FOUNDATION

1. HOOK & BENDING 5. COLUMN IF ADDITIONAL LINKS MAY BE

REQUIRED YOU MUST BE

WHERE COLUMNS ARE OFFSET OR CONFORMED BY DESIGNER

(I) BOTTOM DETAIL LARGE MOMENTS EXIST THESE

BARS SHOULD BE ANCHORED INTO

(I) PAD FOOTING

BENDS HOOKS FIXING DIMENSION TO BE

COMPRESSION LAP PLUS FLOOR SLAB AS SHOWN A A COMPRESSION LAP

Mark Revision Date By

r r 150 FOR FOUNDATION +75 UNLESS SPECIFIED

75 MIN.

NOMINAL FLOOR LEVEL

LEVEL TOLERANCE COVER TO STARTER COMPRESSION LAP PLUS

BARS IS SPECIFIED

Notes :

THIS DETAIL ALLOWS BARS TO 150 FOR FOUNDATION

h A h A BE EXTENDED EASILY TO GIVE FROM COLUMN FACES LEVEL TOLERANCE

FOUNDATION LEVEL SLAB OR BEAM SOFFIT

TOLERANCE

FOR MILD STEEL BARS FOR HIGH YIELD BARS A A 75 KICKER B B RC BEAM COLUMN

TOP OF FOUNDATION (150 BELOW GROUND)

75 KICKER

FOOTING LEVEL (150 BELOW GROUND)

6 8 10 12 16 20 25 32 40 d BAR SIZE (mm) d 6 8 10 12 16 20 25 32 40

30 MIN.* UNLESS SPECIFIED

* BUT AT LEAST MUST SIT

100 100 100 110 150 180 230 290 360 h HOOK ALLOWANCE h 100 100 110 140 180 220 350 450 560 ON 2 NOS OF HORIZONTAL 50 BY DESIGN - USE

REBARS A-A R10-300 (3No. MIN.)

100 100 100 100 100 100 130 160 200 n BEND ALLOWANCE n 100 100 100 100 100 110 180 230 280

SPLICE BARS ARE LOCATED 50

BY DIMENSIONS FROM FACE

12 16 20 24 32 40 50 64 80 r INTERNAL RADUIS r 18 24 30 36 48 60 100 128 160

OF LOWER COLUMN PLAN

LINKS TO STARTER BARS SHOULD BE

THESE DIMENSION ARE NOMINAL MINIMA MILD STEEL IF DIMENSION LESS THAN 175 LOCATING LINKS

MINIMUM 3 SETS

A-A

NOTES : B-B

2. MINIMUM REINFORCEMENT ANCHORAGE AND LAP LENGTHS A 75mm HIGH KICKER SHALL BE PROVIDED AT FLOOR LEVEL, PRIOR TO CASTING OF THE

SECOND CAST, KICKER SURFACE SHALL BE HACKED TO REMOVE OFF ALL LOOSE

AGGREGATES AND LAITANCE, AND SHALL BE CLEANED WITH PRESSURISED WATER JET.

MILD STEEL BAR (`R') HIGH YIELD BAR (`T')

(V) TYPICAL COLUMN ON BEAM

A.L L.L A.L L.L

(II) INTERMEDIATE DETAIL (IV) TOP DETAIL

T C T C T C T C

COMPRESSION LAP

+KITCHEN HEIGTH

NOMINAL FLOOR LEVEL COLUMN ON BEAM (COB)

Ø = DIAMETER OF BAR

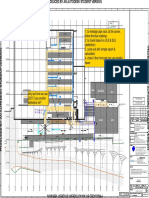

fcu = 25 N/mm² 43Ø 34Ø 60Ø 43Ø fcu = 25 N/mm² 44Ø 35Ø 62Ø 44Ø A.L = ANCHORAGE LENGTH

L.L = LAP LENGTH

T = TENSION

CONSTRUCTION JOINT

LENGTH

fcu = 30 N/mm² 39Ø 32Ø 55Ø 39Ø fcu = 30 N/mm² 40Ø 32Ø 56Ø 40Ø C = COMPRESSION

ADDITIONAL LINKS

LAP

fcu = CONCRETE STRENGTH SLAB OR BEAM SOFFIT

NOMINAL TO ENGR'S SPECIFIED RC BEAM

fcu = 35 N/mm² 36Ø 29Ø 51Ø 36Ø fcu = 35 N/mm² 38Ø 30Ø 52Ø 38Ø

FLOOR LEVEL

NOTES : WHEN LAPPING BARS ARE DIFFERENT IN DIAMETER,

THE LAP LENGTH SHALL BE BASED ON THE SMALLER TENSION LAP

DIAMETER BAR. SLAB OR (=1.4 ANCHORAGE LENGTH)

BEAM SOFFIT

ANCHORAGE

A A

R10 LINK (3 NOS. MIN.) LINK AT KNUCKLE OF CRANK

PLAN DETAIL "A" LENGTH

3. FRAMING CORNER DETAILS NO SPECIAL LINK CRANK AT BOTTOM OF LIFT

AT CRANK OFFSET-2 DIAMETERS +10%

MAX. MAX. MAX. MAX.

200 200 200 200

UNLESS OTHERWISE SHOWN IN DRAWING, REINFORCING BARS 50 MAXIMUM SLOPE 1:10

DETAILS AT CORNER FORMED BY BEAM AND COLUMN (OR WALL) ELEVATION

COMPRESSION

SHALL BE AS SHOWN BELOW: COLUMN BAR ARE

50 TO START TO LINK RUN

LAP

MINIMUM FRAMING CRITICAL POSITIONED IN LEVEL

BAR DIAMETER

ANCHORAGE ANCHORAGE RADIUS R 75mm KICKER FROM NOMINAL

(mm) STRUCTURAL FL. LEVEL

C (mm) (mm) (mm) ROOF LEVEL

L OF COLUMN OR WALL

0.25 L

32 400 1675 225

(L IS THE EFFECTIVE SPAN OF BEAM) MAIN BARS REST

ON KICKER TENSION LAP

LINK NOT REQUIRED FOR FACE BAR IF IT IS (=1.4 ANCHORAGE LENGTH)

25 300 1300 175

TOP REBARS WITHIN 150 OF RESTRAINED BAR

FRAMING ANCHORAGE

20 250 1050 140 BARS MUST BE POSITIONED

- DENOTES DIRECTION OF CRANK

TO AVOID CLASHES

12D MINIMUM

ANCHORAGE

16 200 850 115

A-A

MINIMUM

R

PLAN DETAIL "B"

12 175 700 90

NOTES : NOTES :

AT LEAST 3 LINKS SHALL BE PROVIDED AT POSITIONS OF ALL REINFORCING

10 150 525 70 BARS SPLICE. SPACING OF LINK SHALL NOT EXCEED 16 TIMES THE LINK DETAIL "A" APPLIES WHEN SLAB DEPTH IS NOT LESS THAN:

BOTTOM REBARS

DIAMETER OR 200mm (WHICHEVER IS LESS). 200 USING 20 DIA. COLUMN BARS

250 USING 25 DIA. COLUMN BARS

300 USING 32 DIA. COLUMN BARS

OTHERWISE DETAIL "B" APPLIES

PART BEAM ELEVATION

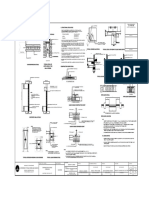

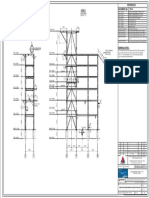

6. BEAM Principal :

(I) SPAN AND SUPPORT DETAIL

a) BEAM ELEVATION

B B C

A

GREATER OF 0.25L₁ OR 0.25L₂ GREATER OF 0.25L₁ OR 0.25L₂ GREATER OF 0.25L₁ OR 0.25L₂ GREATER OF 0.25L₁ OR 0.25L₂

GREATER OF 0.15L₂ GREATER OF 0.15L₂ GREATER OF 0.15L₂ GREATER OF 0.15L₂ NOTES :

Lc OR 0.15L₃ OR 45Ø OR 0.15L₃ OR 45Ø Lc Lc OR 0.15L₃ OR 45Ø OR 0.15L₃ OR 45Ø Lc

MIN. 3 STIRRUPS @ 30% GREATER OF AST₂ a. L IS THE COMPRESSION LAP OF REBARS.

30% AST₂

12Ø MIN. 200 MAX. CRS. AT 50 50 30% GREATER OF b. AT LEAST 3 STIRRUPS SHALL BE PROVIDED AT ALL REINFORCING BARS LAPPING

OR AST₃ 60% AST₂

AST₃

50 A REBARS LAP. AST₂ 60% AST₂ AST₂ OR AST₃ POSITION. SPACING OF STIRRUPS AT LAPPING POSITION SHALL NOT EXCEED 16

TIMES THE STIRRUPDIAMETER OR 200mm. (WHICHEVER IS LESS).

MIN.

300

Project :

STIRRUPE TO DESIGN Stirrupe to design 'CLOSER' BARS USED WITH OPEN LINKS

STIRRUPE TO DESIGN

FOR BEAM WIDTH OF 300 OR MORE

MIN.

300

BARS SPECIFIED BY DESIGNER FOR HANGER BARS TO BE 20% OF MAXIMUM

BEAM DEPTH OF 750 OR MORE SUPPORT AREA UNLESS OTHERWISE

SPECIFIED. FOR BEAMS 500 DEEP OR

12Ø MIN. 30% ASB₁ ASC₁ OR 30% GREATER OF Lc ASB₁ OR 30% GREATER

A ASB₁ ASB₁ OR ASB₂ OF ASB₁ OR ASB₃

MORE USE MINIMUM 2 T 16's

ASB₂ ASB₃

0.1L₁

B 0.15L₁ 0.15L₂ 0.15L₂ 0.15L₂

EFFECTIVE SPAN L₁ EFFECTIVE SPAN L₂ EFFECTIVE SPAN L₃

ONE SPACE SHOULD BE LEFT (75mm)

SUFFICIENT TO INSPECT POKER VIBRATOR

Drawing Title :

BEAM ELEVETION - STANDARD DETAILING REQUIREMENTS UNO.

MAIN TOP BARS PLACED

FOR SECTIONS WITH MORE THAN

ONE LAYER OF MAIN BARS SPACERS

INSIDE HANGER BARS GENERAL NOTES AND

ARE PROVIDED. DIAMETER 25 OR

MAIN BAR DIAMETER WHICHEVER IS

MISCELLANEOUS DETAIL 2

GREATER BOTTOM SUPPORT SPLICE BARS

PLACED INSIDE MAIN BARS. AREA AT

LEAST 30% OF MAXIMUM SPAN AREA.

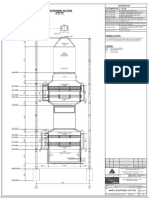

(II) BROAD SHALOW SECTION (IV) STANDARD PENETRATION DETAILS FOR BEAMS Consultants :

THE LONGITUDINAL SPACE TAKEN BY EACH SET OF LINK SHOWN IS 2 X DIA. THIS SHOULD BE CHECKED BEAMS WITH PIPE PENETRATIONS : BEAM WIDTH (mm) < 300 < 300 < 300 SPECIAL CARE SHOULD BE GIVEN TO

TO ENSURE CONGESTION DOES NOT OCCUR. 1. AS DEFINED IN THE TABLE BELOW AVOID CONGESTION OF REINFORCEMENT

2. LOCATED WITHIN THE MIDDLE THIRD DEPTH OF THE BEAM

3. LOCATED WITHIN MIDDLE 0.6 SPAN OF THE BEAM SHALL BE TRIMMED WITH ADDITIONAL REBARS AS

EXTRA BARS

(LONGITUDINAL)

2T16 x 1000 3T16 x 1500 4T16 x 1500

COVER SHOULD BE GREATER

THAN EQUIVALENT BAR SIZE ESPECIALLY AT LAPS. R GCU Consultants (Johor) Sdn Bhd

CLOSER BAR FOR OVERALL LINK SHOWN IN DETAILS. No. 12-02, Jalan Molek 1/5C, Taman Molek,

12D MIN. 75 min. 81100 Johor Bahru, Johor Darul Takzim,

CONTRACTOR SHALL SUBMIT TO THE S.O. PROPER PENETRATION COORDINATION DRAWINGS FOR ALL

8D MINIMUM PIPE PENETRATIONS THROUGH BEAMS, WHETHER WITHIN THE PERMITTED ZONE OR NOT, AND ADDITIONAL LINK (SAME DIAMETER & b) BEAMS: SPACER BAR Malaysia.

APPROVAL PRIOR CONSTRUCTION. NO.OF SETS AS LOAD AREA STIRRUP) SPARCER BARS AT 1200 CRS SHALL BE PROVIDED BETWEEN 2 LAYERS OF REINFORCING BARS. MINIMUM Tel : 07 - 350 7391 Fax : 07 - 350 7392

X 100mm CRS MAXIMUM DIAMETER OF SPACER BAR SHALL BE 25mm. OR REINFORCING BAR SIZE WHICHEVER IS GREATER.

INTERNAL LINKS SHOULD PIPE EXTERNAL DIAMETER IN mm BEAM DEPTH (H mm)

≥ 1/3h REINFORCING BAR 25mm OR GREATER REINFORCING

NOT OVER LAP 75 > = 300

≥ 1/4h BAR DIAMETER

h

50

MAXIMUM LATERAL SPACING 150 > = 600 ≥ 1/3h

. 1200mm MAX. 1200mm MAX.

OF LINK LEGS IS 0.75 x 225 > = 900 SPACER BAR EQUAL OR GREATER THAN 25mm DIAMETER

EFFECTIVE BEAM DEPTH

X 50

CENTER LINE OF SUPPORT I hereby certify that these works have been designed by me in accordance

0.6 SPAN with sound engineering practice and that I take full responsibility for the

(III) CANTILEVER BEAM ≥ 1/3h PERMITTED LENGHT FOR

(BEAM OR COLUMN)

design and proper performance of the same.

PERMITTED DEPTH FOR 0.2 SPAN RESTRICTED PENETRATIONS 0.2 SPAN

≥ 1/4h

h

AT LEAST 50% OF CANTILEVER BARS SHOULD RESTRICTED PENETRATION

c) BEAM DEEPER THAN 750mm

AT LEAST 50% OF MAXIMUM

AREA CONTINUES TO END OF

BE ANCHORED A DISTANCE OF 1.5 x ≥ 1/3h

EXTRA HORIZONTAL REBARS FOR BEAMS EQUAL AND DEEPER THAN 750mm UNLESS OTHERWISE SHOWN IN

THIS DRAWING IS COPYRIGHT

CANTILEVER UNLESS

CANTILEVER. NO REINFORCEMENT SHOULD

BE STOPPED LESS THAN 0.75 x CANTILEVER

BEAM ELEVATION DRAWINGS, EXTRA HORIZONTAL REBARS SHALL BE PROVIDED ON BOTH VERTICAL FACES OF BEAM AS

SPECIFIED OTHERWISE BY ADDITIONAL LINKS THIS DRAWING OR ANY PART OF IT SHALL NOT BE REPRODUCED IN ANY

UNLESS SPECIFIED BY DESIGNER DETAILED AND TABULATED ABOVE:

DESIGNER FORM WITHOUT THE WRITTEN PERMISSION OF THE ENGINEER.

L₂ OR 40Ø

50

SECTION X-X CONTRACTOR MUST CHECK ALL DIMENSIONS ON SITE. ANY DISCREPANCIES

BEAM WIDTH REBAR

MAX

200

(mm) EACH FACE MUST BE REPORTED IMMEDIATELY TO THE ENGINEER BEFORE PROCEEDING

R10 LINKS AT TWICE STIRRUP SPACING

Design By : Check By :

*

125 TO 225 T10 - 200

BEAM MAIN REBARS

250 TO 300 T12 - 175 HBS LKM

EXTRA HORIZONTAL REBARS

*

TENSION LAP REFER TO TABLE BESIDE FOR

25 350 TO 400 T12 - 200 CAD FILE :

MAX

FOR "U" BAR. Drawn By :

200

STIRRUP

400 TO 500 T12 - 150 MKI C-GCUJ-JJ036-SD-4000-GN-002-A

BOTTOM BARS SPECIFIED BY

DESIGNER. MINIMUM 2T16's. 550 TO 600 T16 - 200

BEAM WIDTH Date: Scale :

600 TO 750 T16 - 150 SEPT 2017 NTS

L

BEAM SECTION Drawing No :

P/GCUJ/JJ036/SD/4000/GN/002 A

Z:\1.1 PROJECT TCL\JJ036 COUNTRY GARDEN FOREST CITY\DRAWING\OUTGOING\PRELIMINARY\11 BRICK FACTORY\GENERAL NOTES (RC)\C-GCUJ-JJ036-SD-4000-GN-002-A.DWG ; 03-Oct-17 ; 12:27:25 ; PLOTTED BY : OWNER ; PLOT SCALE : 1:2

You might also like

- Plan View: SLAB Tck:150mmDocument5 pagesPlan View: SLAB Tck:150mmIsselmouNo ratings yet

- General Notes:: Drawn by Project Dhiraj Bhoir SchoolDocument1 pageGeneral Notes:: Drawn by Project Dhiraj Bhoir SchoolBhavika DabhiNo ratings yet

- Electrical Resistance Soil Corrosion Probe Test StationDocument1 pageElectrical Resistance Soil Corrosion Probe Test StationmohsenNo ratings yet

- Drainage SchemeDocument1 pageDrainage Schememohama84No ratings yet

- Floor Plan: DRY BalconyDocument1 pageFloor Plan: DRY Balconysaurabh kotechaNo ratings yet

- All Typical DWGDocument14 pagesAll Typical DWGKrishantha JayawardeneNo ratings yet

- Approval Plan 1Document1 pageApproval Plan 1Selva GaneshNo ratings yet

- S2 PalnDocument1 pageS2 PalnFrancis Lloyd MalganaNo ratings yet

- s3-11 - Tower 1 Shear Wall ElevationDocument1 pages3-11 - Tower 1 Shear Wall ElevationJason toraldeNo ratings yet

- Section Section Section: Saudi Arabian Oil CompanyDocument1 pageSection Section Section: Saudi Arabian Oil CompanyAnonymous X3PnFL6No ratings yet

- Shilp GIFT CITY PLANDocument9 pagesShilp GIFT CITY PLANnmmmNo ratings yet

- GADGopalpurROB1 3kmDocument2 pagesGADGopalpurROB1 3kmAnurag sharmaNo ratings yet

- S-003-Typical Structural Detail-1Document1 pageS-003-Typical Structural Detail-1JohnIsaacNo ratings yet

- Typical Reinforced Concrete Details and Construction Notes - 1Document1 pageTypical Reinforced Concrete Details and Construction Notes - 1Aly Arquillano JrNo ratings yet

- Base Legend Park Boundary: Existing Foot PathDocument1 pageBase Legend Park Boundary: Existing Foot PathChenkal Service CooperativeNo ratings yet

- Notes:: OPEN AT 120° 5°Document1 pageNotes:: OPEN AT 120° 5°Yazan MohammadNo ratings yet

- S. Staircase (St-02) Detail-2Document1 pageS. Staircase (St-02) Detail-2assis alihNo ratings yet

- Al Kharir - 104Document1 pageAl Kharir - 104Amro HarasisNo ratings yet

- Floor Plan Legend General Notes Abbreviations List Standard Mounting HeightsDocument1 pageFloor Plan Legend General Notes Abbreviations List Standard Mounting HeightsBu B OiNo ratings yet

- Floor Plan Legend General Notes Abbreviations List Standard Mounting HeightsDocument1 pageFloor Plan Legend General Notes Abbreviations List Standard Mounting HeightsBu B OiNo ratings yet

- Job PortfolioDocument43 pagesJob PortfolioHarleen KlairNo ratings yet

- Tam-Wbt-Sd-Sc-010 Rev-00 5TH To 15TH Floor PDFDocument1 pageTam-Wbt-Sd-Sc-010 Rev-00 5TH To 15TH Floor PDFAL TARKEEZNo ratings yet

- Notes:: Hinge DetailsDocument1 pageNotes:: Hinge DetailsYazan MohammadNo ratings yet

- General Floor Plan Notes: Existing JR Green Building To RemainDocument21 pagesGeneral Floor Plan Notes: Existing JR Green Building To RemainKEITH CHABOTNo ratings yet

- LD-1020 - Typical Dialysis CubicleDocument1 pageLD-1020 - Typical Dialysis Cubiclekarthikeyan dhanasekaranNo ratings yet

- Brickell Key Ii - A2-03 - Sections and Details - V1Document1 pageBrickell Key Ii - A2-03 - Sections and Details - V1dianaNo ratings yet

- Foundation Offset To ExcavtionDocument1 pageFoundation Offset To ExcavtionAhmed KarimNo ratings yet

- Ha4321650010f4 (Cable Routing Details)Document1 pageHa4321650010f4 (Cable Routing Details)Malik MalikNo ratings yet

- Surface Box On Field or Verges Surface Box On Paved Roads Plan ViewDocument1 pageSurface Box On Field or Verges Surface Box On Paved Roads Plan ViewAbdelmoneimNo ratings yet

- Standar Detail Penulangan 1: Standard Details For Concrete Review - 1Document2 pagesStandar Detail Penulangan 1: Standard Details For Concrete Review - 1wiyantoNo ratings yet

- GF Framing Plan PDFDocument1 pageGF Framing Plan PDFTanaya ChiplunkarNo ratings yet

- Electrical DetailsDocument1 pageElectrical Detailscherif yahyaouiNo ratings yet

- Framing Plan Terrace PDFDocument1 pageFraming Plan Terrace PDFTanaya ChiplunkarNo ratings yet

- BRG 1266 (1550x597)Document1 pageBRG 1266 (1550x597)Nilay GandhiNo ratings yet

- Site Analysis 1Document1 pageSite Analysis 1AadarshNo ratings yet

- STD 101 Rev5Document1 pageSTD 101 Rev5Adi SantosoNo ratings yet

- Confidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116Document1 pageConfidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116mirza.adeelNo ratings yet

- Drawing Set For Domestic BuildingDocument16 pagesDrawing Set For Domestic BuildingBhargav Prakash100% (1)

- Ysc Ms 769 DW 0001sht2of2 Rev BDocument1 pageYsc Ms 769 DW 0001sht2of2 Rev BbalamuralinakshatraNo ratings yet

- See Detail 1: NotesDocument1 pageSee Detail 1: NotesYazan MohammadNo ratings yet

- Notes:: 1F at SSL + 4.00mDocument1 pageNotes:: 1F at SSL + 4.00massis alihNo ratings yet

- BASEMENT 3 (LVL - 10800) : General NotesDocument1 pageBASEMENT 3 (LVL - 10800) : General NotesJagat PapaNo ratings yet

- S2 Structural NotesDocument1 pageS2 Structural NotesRaynz PatronNo ratings yet

- 03.08.16 Karama HC Plans - Revision 1-GF-RCP)Document1 page03.08.16 Karama HC Plans - Revision 1-GF-RCP)Ashiq NishmaNo ratings yet

- Schedule of Reinforcement: Section B-BDocument1 pageSchedule of Reinforcement: Section B-BSaurabh PandeyNo ratings yet

- Dn107-P01a-Qbs-Pw-7001 (Av-P01a-01)Document1 pageDn107-P01a-Qbs-Pw-7001 (Av-P01a-01)moon arainNo ratings yet

- PORTFOLIO: OFFICE WORK (20/06/2022-20/12/2022) Harleen KlairDocument34 pagesPORTFOLIO: OFFICE WORK (20/06/2022-20/12/2022) Harleen KlairHarleen KlairNo ratings yet

- Notes: Edge of Block Paved Roadway - Edge of Asphalt RoadwayDocument1 pageNotes: Edge of Block Paved Roadway - Edge of Asphalt RoadwayFiroj AlamNo ratings yet

- Reference Drawings: Saudi Arabian Oil CompanyDocument1 pageReference Drawings: Saudi Arabian Oil CompanyJohn Philip BuntalesNo ratings yet

- Ha431892003v0f1 (Cable Routing Details)Document1 pageHa431892003v0f1 (Cable Routing Details)Malik MalikNo ratings yet

- Ha431931002v0f1 (Trench & Duct Bank Details)Document1 pageHa431931002v0f1 (Trench & Duct Bank Details)Malik MalikNo ratings yet

- Proposed Garden For Nagar Palika Parishad Kumhari (C.G.) : Site Plan Key PlanDocument1 pageProposed Garden For Nagar Palika Parishad Kumhari (C.G.) : Site Plan Key PlanGaurav ReddyNo ratings yet

- Slew BearingDocument1 pageSlew BearingRTG Mechanical EnggNo ratings yet

- SRACO Window 10.10.2023Document1 pageSRACO Window 10.10.2023ShahbazNo ratings yet

- Proposed Second Storey Extension Residencial Project: Office of The Building Official D C B A C' B'Document1 pageProposed Second Storey Extension Residencial Project: Office of The Building Official D C B A C' B'JesusAntonioJugosNo ratings yet

- Elevation Section Ab: Wall 0.23M Thick DPC 0.05M Thick SunkDocument1 pageElevation Section Ab: Wall 0.23M Thick DPC 0.05M Thick SunkMarmik JavareNo ratings yet

- Lower Floor PlanDocument1 pageLower Floor PlanWilbert ReuyanNo ratings yet

- H型钢规格表Document1 pageH型钢规格表luke luckyNo ratings yet

- STD 101as Rev 4 Standard Aluminium Handrail DetailsDocument1 pageSTD 101as Rev 4 Standard Aluminium Handrail DetailsPhạm Minh HươngNo ratings yet

- Comment On Cinema Working Platform Design Calculation ReportDocument1 pageComment On Cinema Working Platform Design Calculation ReportTOM YEENo ratings yet

- Creep & Degree of ConsolDocument9 pagesCreep & Degree of ConsolTOM YEENo ratings yet

- KB1A - Plot17 - 18Document1 pageKB1A - Plot17 - 18TOM YEENo ratings yet

- 37.ON-MECH-PR-LAY-001A - GCU 20201128-ModelDocument1 page37.ON-MECH-PR-LAY-001A - GCU 20201128-ModelTOM YEENo ratings yet

- KB1A - Plot15 - 16Document1 pageKB1A - Plot15 - 16TOM YEENo ratings yet

- Design Calculation For Truck Loading StationDocument55 pagesDesign Calculation For Truck Loading StationTOM YEENo ratings yet

- ag N-Ze 1523 (En)Document1 pageag N-Ze 1523 (En)TOM YEENo ratings yet

- Calculation Sheet: Design of Splice For BeamDocument6 pagesCalculation Sheet: Design of Splice For BeamTOM YEENo ratings yet

- Comment On The Grand Staircase Shop DrawingDocument14 pagesComment On The Grand Staircase Shop DrawingTOM YEENo ratings yet

- Row-G Row-F: References Document No. TitleDocument1 pageRow-G Row-F: References Document No. TitleTOM YEENo ratings yet

- Plan at Tos El+21.785 Plan at Tos El+24.660 Plan at Tos El+28.785Document1 pagePlan at Tos El+21.785 Plan at Tos El+24.660 Plan at Tos El+28.785TOM YEENo ratings yet

- ag N-Ze 1511 (En)Document1 pageag N-Ze 1511 (En)TOM YEENo ratings yet

- Staircase Canopy Calculation ReportDocument70 pagesStaircase Canopy Calculation ReportTOM YEENo ratings yet

- PS2 PS1 PLAN AT TOS EL+21.785 PLAN AT TOS EL+24.660: References Document No. TitleDocument1 pagePS2 PS1 PLAN AT TOS EL+21.785 PLAN AT TOS EL+24.660: References Document No. TitleTOM YEENo ratings yet

- ag N-Ze 1513 (En)Document1 pageag N-Ze 1513 (En)TOM YEENo ratings yet

- ag N-Ze 1521 (En)Document1 pageag N-Ze 1521 (En)TOM YEENo ratings yet

- PLAN AT TOS EL+32.590 PLAN AT TOS EL+34.990 Platform at Tos El+40.197Document1 pagePLAN AT TOS EL+32.590 PLAN AT TOS EL+34.990 Platform at Tos El+40.197TOM YEENo ratings yet

- ag N-Ze 1516 (En)Document1 pageag N-Ze 1516 (En)TOM YEENo ratings yet

- ag N-Ze 1518 (En)Document1 pageag N-Ze 1518 (En)TOM YEENo ratings yet

- Longitudinal Section: References Document No. TitleDocument1 pageLongitudinal Section: References Document No. TitleTOM YEENo ratings yet

- Section A-A Row A Axis 4: General NotesDocument1 pageSection A-A Row A Axis 4: General NotesTOM YEENo ratings yet

- ag N-Ze 1510 (En)Document1 pageag N-Ze 1510 (En)TOM YEENo ratings yet

- ag N-Ze 1509 (En)Document1 pageag N-Ze 1509 (En)TOM YEENo ratings yet

- Iso View East Elevation Plan: References Document No. TitleDocument2 pagesIso View East Elevation Plan: References Document No. TitleTOM YEENo ratings yet

- ag N-Ze 1514 (En)Document1 pageag N-Ze 1514 (En)TOM YEENo ratings yet

- ag N-Ze 1507 (En)Document1 pageag N-Ze 1507 (En)TOM YEENo ratings yet

- ag N-Ze 1506 (En)Document1 pageag N-Ze 1506 (En)TOM YEENo ratings yet

- Sight Study - Top View Section A-A Section B-B: General NotesDocument1 pageSight Study - Top View Section A-A Section B-B: General NotesTOM YEENo ratings yet

- PLATFORM AT EL+21.570 Platform at El27.770: ReferencesDocument1 pagePLATFORM AT EL+21.570 Platform at El27.770: ReferencesTOM YEENo ratings yet

- ag N-Ze 1503 (En)Document1 pageag N-Ze 1503 (En)TOM YEENo ratings yet

- Composite Beam Bimetallic StripDocument4 pagesComposite Beam Bimetallic StripBunkun15No ratings yet

- Structural Analysis of Multi Storey Steel FramesDocument17 pagesStructural Analysis of Multi Storey Steel FramesAlem LoajnerNo ratings yet

- Pipe Support Type 3 Rev2Document68 pagesPipe Support Type 3 Rev2Romawi Stevyandi100% (1)

- Struct Nov2019Document4 pagesStruct Nov2019ryanmikeNo ratings yet

- KVH TI Folder2013Document44 pagesKVH TI Folder2013johanNo ratings yet

- Flexural Behavior of Delta and Bi-Delta Cold-Formed Steel BeamsDocument21 pagesFlexural Behavior of Delta and Bi-Delta Cold-Formed Steel BeamsGogyNo ratings yet

- BEAMANAL (Metric) CopieDocument19 pagesBEAMANAL (Metric) Copierelu59No ratings yet

- Arcelor Mittal HistarDocument32 pagesArcelor Mittal HistarAnonymous uNhWGqNzNo ratings yet

- A Simplified Two-Stage Method To Estimate The Settlement and Bending Moment of Upper Tunnel Considering The Interaction of Undercrossing Twin TunnelsDocument32 pagesA Simplified Two-Stage Method To Estimate The Settlement and Bending Moment of Upper Tunnel Considering The Interaction of Undercrossing Twin TunnelsJianfeng XueNo ratings yet

- Advanced Concrete Design ProjectDocument57 pagesAdvanced Concrete Design Projectapi-459677152No ratings yet

- Sap2000 Tutorial 2010Document92 pagesSap2000 Tutorial 2010agvelazquez100% (9)

- Shear Tab - Double Col - AISC 13th Ed - Ver1Document178 pagesShear Tab - Double Col - AISC 13th Ed - Ver1pelaoguenoNo ratings yet

- Transverse and Stresses in Beam: Loading On BeamsDocument38 pagesTransverse and Stresses in Beam: Loading On BeamsDr. BIBIN CHIDAMBARANATHANNo ratings yet

- Bridge Design CDocument46 pagesBridge Design CRefisa JiruNo ratings yet

- Reaction of Beam TestDocument10 pagesReaction of Beam TestAmyHuiNo ratings yet

- Ce8502 Structural Analysis I MCQDocument26 pagesCe8502 Structural Analysis I MCQRohan GadaveNo ratings yet

- 2.2.2-2 - DQR - SS - Cleat Angle Capacity-Rev BDocument10 pages2.2.2-2 - DQR - SS - Cleat Angle Capacity-Rev BSANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- Sobon J. A Historic American JoineryDocument56 pagesSobon J. A Historic American Joinerythierrydescamps100% (1)

- Chap-5 Framed StructuresDocument12 pagesChap-5 Framed StructurestekalignNo ratings yet

- RILEM TC 162-TDF Test and Design Methods For Steel Fibre Reinforced ConcreteDocument3 pagesRILEM TC 162-TDF Test and Design Methods For Steel Fibre Reinforced ConcreteAbdul GhaffarNo ratings yet

- Internship Report - Dusenayo Theoneste - Nur - Fas - Ce - Level 5Document39 pagesInternship Report - Dusenayo Theoneste - Nur - Fas - Ce - Level 5Théoneste Dusenayo75% (4)

- BPSC SDO Irrigation Test December 5th-1Document14 pagesBPSC SDO Irrigation Test December 5th-1Razaq Khan MandokhailNo ratings yet

- InTech-Mechanical Properties of Mems MaterialsDocument12 pagesInTech-Mechanical Properties of Mems MaterialsNico Ortega MirandaNo ratings yet

- Flanged BeamsDocument43 pagesFlanged BeamsMansa ArthurNo ratings yet

- Haunched Moment Connection AISC360-10Document5 pagesHaunched Moment Connection AISC360-10osman_sultanNo ratings yet

- Bridges - Structures and Materials, Ancient and Modern - IntechOpenDocument34 pagesBridges - Structures and Materials, Ancient and Modern - IntechOpenSerraNo ratings yet

- Direct Displacement-Based Seismic Design of StructuresDocument64 pagesDirect Displacement-Based Seismic Design of StructuresMunyaNo ratings yet

- BEAMDHDocument192 pagesBEAMDHBoaz DanilovNo ratings yet

- Web StructuralDocument4 pagesWeb StructuralFaris AsriNo ratings yet

- Process Equipment Design Materials Selection 7-02-13Document91 pagesProcess Equipment Design Materials Selection 7-02-13May TampusNo ratings yet