Professional Documents

Culture Documents

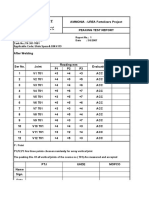

Table 4.1 WPS Qualification-Production Welding Positions Qualified by Plate, Pipe, and Box Tube Tests (See 4.3)

Table 4.1 WPS Qualification-Production Welding Positions Qualified by Plate, Pipe, and Box Tube Tests (See 4.3)

Uploaded by

Mohamed Atef0 ratings0% found this document useful (0 votes)

8 views1 pageThis document is a table that qualifies welding positions for plate, pipe, and box tube tests according to WPS standards. It shows that plug and slot welds qualify welding axes along straight lines, including along circular pipes. Circumferential pipe welds qualify for pipes 24 inches or greater in diameter. Butt joint details require qualification of the specific joint detail. Some positions are limited to prequalified details. Various connection types, like T-joints, require specific test details in the figures.

Original Description:

Original Title

Table4.1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a table that qualifies welding positions for plate, pipe, and box tube tests according to WPS standards. It shows that plug and slot welds qualify welding axes along straight lines, including along circular pipes. Circumferential pipe welds qualify for pipes 24 inches or greater in diameter. Butt joint details require qualification of the specific joint detail. Some positions are limited to prequalified details. Various connection types, like T-joints, require specific test details in the figures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views1 pageTable 4.1 WPS Qualification-Production Welding Positions Qualified by Plate, Pipe, and Box Tube Tests (See 4.3)

Table 4.1 WPS Qualification-Production Welding Positions Qualified by Plate, Pipe, and Box Tube Tests (See 4.3)

Uploaded by

Mohamed AtefThis document is a table that qualifies welding positions for plate, pipe, and box tube tests according to WPS standards. It shows that plug and slot welds qualify welding axes along straight lines, including along circular pipes. Circumferential pipe welds qualify for pipes 24 inches or greater in diameter. Butt joint details require qualification of the specific joint detail. Some positions are limited to prequalified details. Various connection types, like T-joints, require specific test details in the figures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Table 4.

1

WPS Qualification-Production Welding Positions Qualified by Plate, Pipe, and Box Tube Tests (see 4.3)

I Plug/

Slot I Qualifies Plug/Slot Welding for Only the Positions Tested

CJP-Complete Joint Penetration

PJP-Partial Joint Penetration

Notes:

I. Qualifies for a welding axis with an essentially straight line, including welding along a line parallel to the axis of circular pipe.

aP

2. Qualifies for circumferential welds in pipes equal to or greater than 24 in. [600 mm] nominal outer diameter.

3. Production butt joint details without backing or backgouging require qualification testing of the joint detail shown in Figure 4.24. P

4. Limited to prequalified joint details (see 3.12 or 3.13). 0

5. For production joints of CJP T-, Y-, and K-connections that conform to either Figure 3.8,3.9, or 3.10 and Table 3.6, use Figure 4.27 detail for testing. For other production joints, see 4.12.4. I.

6. For productionjoints of CJP T-, Y-, and K-connections that conform to Figure 3.6, and Table 3.6, use Figure 4.27 and 4.28 detail for testing, or, alternatively, test the Figure 4.27 joint and cut macroetch EI!

specimens from the comer locations shown in Figure 4.28. For other production joints, see 4.12.4.1. 0

7. For production joints of PJP T-, Y-, and K-connections that conform to Figure 3.5, use either the Figure 4.24 or Figure 4.25 detail for testing.

8. For matched box connections with comer radii less than twice the chord member thickness, see 3.12.4.1.

3

9. Fillet welds in production T-, Y-, or K-connections shall conform to Figure 3.2. WPS qualification shall conform to 4.1 1. P

You might also like

- TabbingDocument2 pagesTabbingMalcolm DiamondNo ratings yet

- Kazuha CCDocument12 pagesKazuha CCJimena Zegarra Rosado100% (1)

- Astm B139Document5 pagesAstm B139Jamil SalmanNo ratings yet

- The Practical Welding EngineerDocument154 pagesThe Practical Welding EngineerMohamed Atef0% (1)

- IEEE STD 3004.8TM-2016 Recommended Practice For Motor Protection in Indusctrial and Commercial Power SystemsDocument163 pagesIEEE STD 3004.8TM-2016 Recommended Practice For Motor Protection in Indusctrial and Commercial Power SystemsMorro DelArrabalNo ratings yet

- Technical Inquiries To API 1104Document20 pagesTechnical Inquiries To API 1104Rey Fiedacan92% (12)

- Acceptance Criteria For Weld DefectsDocument6 pagesAcceptance Criteria For Weld DefectsMohamed AtefNo ratings yet

- AWS D1.3 WPQR Guides PDFDocument2 pagesAWS D1.3 WPQR Guides PDFvladimir3oNo ratings yet

- Fitness Training Program: Program Start Date Client's Information Warm-UpDocument2 pagesFitness Training Program: Program Start Date Client's Information Warm-UpMohamed AtefNo ratings yet

- AWS D17.1 WPQR Guides PDFDocument2 pagesAWS D17.1 WPQR Guides PDFTAGUI100% (3)

- Aws d1.1 WPQR GuidesDocument3 pagesAws d1.1 WPQR GuidesDo XuanNo ratings yet

- Norma ASME A-516 SADocument7 pagesNorma ASME A-516 SASTRUCPIPE CALIDAD100% (1)

- Documentary ResearchDocument17 pagesDocumentary ResearchGlizzle MacaraegNo ratings yet

- API 1104 TestDocument5 pagesAPI 1104 Testmohsen100% (1)

- LG 43 Inch TVDocument71 pagesLG 43 Inch TVVictor Sampa100% (1)

- Barjatya Ji 1185Document3 pagesBarjatya Ji 1185Adinath InfrastructureNo ratings yet

- Anki Guide For Medical StudentsDocument6 pagesAnki Guide For Medical StudentspchamessNo ratings yet

- ASME Sec IX Groove To Fillet WeldDocument3 pagesASME Sec IX Groove To Fillet WeldAzhar Ali0% (1)

- AWS D1.1 GuidesDocument7 pagesAWS D1.1 GuidesMuhammad FakhriNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Quality Control PlanDocument4 pagesQuality Control PlanMohamed AtefNo ratings yet

- Steel Stud Assemblies For Shear Reinforcement of ConcreteDocument5 pagesSteel Stud Assemblies For Shear Reinforcement of Concretejulian ramirezNo ratings yet

- ScienceGrade11STEM LAS Earth-Science Q1Week4-5-1 PDFDocument13 pagesScienceGrade11STEM LAS Earth-Science Q1Week4-5-1 PDFMark Allen Labasan100% (3)

- Seminar Casing FailureDocument27 pagesSeminar Casing FailurehshobeyriNo ratings yet

- Procedure QualificationDocument68 pagesProcedure QualificationParvee K Nakwal100% (1)

- (OFW) Oxy-Fuel Welding (Gas WeldingOxy-Acetylene Welding)Document6 pages(OFW) Oxy-Fuel Welding (Gas WeldingOxy-Acetylene Welding)Mohamed AtefNo ratings yet

- Ship's Organizational StructureDocument8 pagesShip's Organizational StructureAmos BagaipoNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Jis G3444Document19 pagesJis G3444Tanvir HasanNo ratings yet

- Structural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesFrom EverandStructural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesRating: 3.5 out of 5 stars3.5/5 (13)

- Tajima Usb Linker User's GuideDocument35 pagesTajima Usb Linker User's GuideFermin MuñozNo ratings yet

- Brief of Variables: Smaw Gtaw Gmaw SawDocument3 pagesBrief of Variables: Smaw Gtaw Gmaw SawAdilMunirNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3)Document15 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3)Mohamed Atef100% (1)

- 4.12 Complete Joint Penetration (CJP) Groove Welds For Thbular ConnectionsDocument1 page4.12 Complete Joint Penetration (CJP) Groove Welds For Thbular ConnectionsIbrahim shaikNo ratings yet

- 3.6 Visual Examination: Part B Types of Tests, Test Methods, and Acceptance CriteriaDocument1 page3.6 Visual Examination: Part B Types of Tests, Test Methods, and Acceptance CriteriaIbrahim shaikNo ratings yet

- AWS D1.1-D1.1M-2015 - Pagina-110Document1 pageAWS D1.1-D1.1M-2015 - Pagina-110Gedalías MartínezNo ratings yet

- 4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsDocument1 page4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsIbrahim shaikNo ratings yet

- B31.3, Process Piping 1Document1 pageB31.3, Process Piping 1Jason FlowersNo ratings yet

- WPS Guides For Plug and Slot WeldsDocument4 pagesWPS Guides For Plug and Slot WeldsBrad BorgesNo ratings yet

- Modul Tambahan Kualifikasi Las (KL)Document27 pagesModul Tambahan Kualifikasi Las (KL)Nurhamsyah Susianto0% (1)

- Sec Viii D2 Art F-3Document2 pagesSec Viii D2 Art F-3Manus79No ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- Procedure For Welder QualificationDocument28 pagesProcedure For Welder Qualificationjagannath100% (1)

- Improvement of Inner Quality of Continuous Cast Round Billets by FCR Technology at Wakayama WorksDocument12 pagesImprovement of Inner Quality of Continuous Cast Round Billets by FCR Technology at Wakayama WorksSrikanth SrikantiNo ratings yet

- Preparing Tension Test Specimens For Copper Alloy Sand, Permanent Mold, Centrifugal, and Continuous CastingsDocument11 pagesPreparing Tension Test Specimens For Copper Alloy Sand, Permanent Mold, Centrifugal, and Continuous CastingsWeniton OliveiraNo ratings yet

- Codes and StandardsDocument33 pagesCodes and StandardsMohd AmaniNo ratings yet

- Figure-9 Deep-Grooved and Figure-8 Copper Trolly Wire For Industrial HaulageDocument5 pagesFigure-9 Deep-Grooved and Figure-8 Copper Trolly Wire For Industrial HaulagemahfuzNo ratings yet

- A 842 - 85 R97 Qtg0mi04nvi5nwDocument4 pagesA 842 - 85 R97 Qtg0mi04nvi5nwwahyudiNo ratings yet

- API 5L 45-th Edition: Item No SawlDocument6 pagesAPI 5L 45-th Edition: Item No SawlRob WillestoneNo ratings yet

- Preparing Tension Test Specimens For Copper Alloy Sand, Permanent Mold, Centrifugal, and Continuous CastingsDocument10 pagesPreparing Tension Test Specimens For Copper Alloy Sand, Permanent Mold, Centrifugal, and Continuous Castingspinkan25No ratings yet

- Table 302.3.4 Longitudinal Weld Joint Quality Factor, E: ASME B31.3-2018Document32 pagesTable 302.3.4 Longitudinal Weld Joint Quality Factor, E: ASME B31.3-2018GabrielNo ratings yet

- Astm B 134 B134M-08Document7 pagesAstm B 134 B134M-08Chung LeNo ratings yet

- Extracted Pages From ASME BPVC 2021 Section IX-2Document2 pagesExtracted Pages From ASME BPVC 2021 Section IX-2Roberto Carlos Arana ChumpitazNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Nickel: Standard Specification ForDocument3 pagesPressure Vessel Plates, Alloy Steel, Nickel: Standard Specification ForJerry BeanNo ratings yet

- Specification For Pressure Vessel Plates, Alloy Steel, NickelDocument4 pagesSpecification For Pressure Vessel Plates, Alloy Steel, NickelMauricio FernándezNo ratings yet

- A395x PDFDocument8 pagesA395x PDFrohit kumarNo ratings yet

- A066 Steel Screw Spikes PDFDocument3 pagesA066 Steel Screw Spikes PDFAnonymous 1GK9Hxp5YKNo ratings yet

- Visual Inspection D1-1Document1 pageVisual Inspection D1-1Malcolm DiamondNo ratings yet

- ASME InterpretationDocument4 pagesASME Interpretationhrh_pogcNo ratings yet

- End Plate ConnectionsDocument9 pagesEnd Plate ConnectionsJohn PetterNo ratings yet

- Calculation and Design of Bolted Connections: Structural Engineering Techniques Leeds Beckett UniversityDocument9 pagesCalculation and Design of Bolted Connections: Structural Engineering Techniques Leeds Beckett UniversityAhmet Selim ÇağinNo ratings yet

- Bruhn 73 C4Document28 pagesBruhn 73 C4brhNo ratings yet

- Details of Fillet Welds D15M-D15-2002 - Section - 2.1Document40 pagesDetails of Fillet Welds D15M-D15-2002 - Section - 2.1drac_dracNo ratings yet

- ASTM A.203 Rev 1997Document5 pagesASTM A.203 Rev 1997rendy simanjuntakNo ratings yet

- Norma ASTM A516-2006pdfDocument4 pagesNorma ASTM A516-2006pdfRafael DiasNo ratings yet

- SCNZ FS15Document2 pagesSCNZ FS15clam2014No ratings yet

- BOLT STRENGTH - RemovedDocument12 pagesBOLT STRENGTH - RemovedAbdul khaliquNo ratings yet

- Welder QualsDocument44 pagesWelder QualsroyalNo ratings yet

- 330 Preheating: B H R C B B RDocument2 pages330 Preheating: B H R C B B RStephen RajNo ratings yet

- Articulo 1Document8 pagesArticulo 1Daniel CoronadoNo ratings yet

- Boolean Circuit Rewiring: Bridging Logical and Physical DesignsFrom EverandBoolean Circuit Rewiring: Bridging Logical and Physical DesignsNo ratings yet

- Financial Management of Projects and Contracts Lecture 1Document37 pagesFinancial Management of Projects and Contracts Lecture 1Mohamed AtefNo ratings yet

- Third Party Inspection For Shell and Tube Heat Exchanger - ProcedureDocument11 pagesThird Party Inspection For Shell and Tube Heat Exchanger - ProcedureMohamed AtefNo ratings yet

- Financial Management Frontiers R 1Document96 pagesFinancial Management Frontiers R 1Mohamed AtefNo ratings yet

- كورس التكيبف مركز ايجى ستDocument95 pagesكورس التكيبف مركز ايجى ستMohamed AtefNo ratings yet

- PVC-DWV and ABS-DWV Pipe and Fittings: Dimensional CatalogDocument44 pagesPVC-DWV and ABS-DWV Pipe and Fittings: Dimensional CatalogMohamed AtefNo ratings yet

- SCH 40 PVC PipeDocument2 pagesSCH 40 PVC PipeMohamed AtefNo ratings yet

- Product Catalog: Marine IndustryDocument32 pagesProduct Catalog: Marine IndustryMohamed AtefNo ratings yet

- Inspection and Test Plan For Shell and Tube Heat Exchanger - Sample01Document3 pagesInspection and Test Plan For Shell and Tube Heat Exchanger - Sample01Mohamed AtefNo ratings yet

- M. J. NA: Glneerlng Data TransmiitalDocument23 pagesM. J. NA: Glneerlng Data TransmiitalMohamed AtefNo ratings yet

- Material Requisition Recieved From Pgesco Electrical: Ser. Title Document No. Rev. Date Received PGECO Transmittal NoDocument5 pagesMaterial Requisition Recieved From Pgesco Electrical: Ser. Title Document No. Rev. Date Received PGECO Transmittal NoMohamed AtefNo ratings yet

- Risk Assessment - Fixation GRP Panel Water TanksDocument9 pagesRisk Assessment - Fixation GRP Panel Water TanksMohamed AtefNo ratings yet

- Petrojet: The Petroleum Projects& Technical Consultations CoDocument14 pagesPetrojet: The Petroleum Projects& Technical Consultations CoMohamed AtefNo ratings yet

- Actual and Planned Costs of The Project CategoriesDocument3 pagesActual and Planned Costs of The Project CategoriesMohamed AtefNo ratings yet

- Approximate RT Spot Calculator For Api 650 TanksDocument2 pagesApproximate RT Spot Calculator For Api 650 TanksMohamed AtefNo ratings yet

- Calorie Amortization Schedule1Document44 pagesCalorie Amortization Schedule1Mohamed AtefNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-1)Document7 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-1)Mohamed AtefNo ratings yet

- MIG Welding - Gas Metal Arc Welding (GMAW)Document5 pagesMIG Welding - Gas Metal Arc Welding (GMAW)Mohamed AtefNo ratings yet

- How To Write A Welding Procedure Specification (WPS)Document5 pagesHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- Basics of Heat Treatment (Part-0)Document11 pagesBasics of Heat Treatment (Part-0)Mohamed AtefNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Document19 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefNo ratings yet

- NACE-Stress Corrosion Cracking (SCC)Document3 pagesNACE-Stress Corrosion Cracking (SCC)Mohamed AtefNo ratings yet

- Globe Valves - What Is A Valve (Part - 2)Document4 pagesGlobe Valves - What Is A Valve (Part - 2)Mohamed AtefNo ratings yet

- Chloride Stress Corrosion Cracking of Austenitic Stainless SteelDocument6 pagesChloride Stress Corrosion Cracking of Austenitic Stainless SteelMohamed AtefNo ratings yet

- ABM 11 - Org&Mgt Module 2Document40 pagesABM 11 - Org&Mgt Module 2carl fuerzasNo ratings yet

- LIST Egam3s 2019Document92 pagesLIST Egam3s 2019Muhammad ZulvindadaniNo ratings yet

- 4 Using Gaussian Elimination: Column Space, Nullspace, Rank, Nullity, Linear Independence, Inverse MatrixDocument14 pages4 Using Gaussian Elimination: Column Space, Nullspace, Rank, Nullity, Linear Independence, Inverse Matrixmcs mNo ratings yet

- Computing Fundamentals: Dr. Muhammad Yousaf HamzaDocument62 pagesComputing Fundamentals: Dr. Muhammad Yousaf HamzaAr rehmanNo ratings yet

- New Coleccion Harmony DJ AcademyDocument6 pagesNew Coleccion Harmony DJ AcademyvictoredjNo ratings yet

- Basic Concept - : Goods and Services Tax MCQDocument103 pagesBasic Concept - : Goods and Services Tax MCQBighnesh Prasad SahooNo ratings yet

- Descriptions: PEG-4000 Is A Water-Soluble, Waxy Solid That Is Used Extensively in The Several Industries Such AsDocument1 pageDescriptions: PEG-4000 Is A Water-Soluble, Waxy Solid That Is Used Extensively in The Several Industries Such AsKeremNo ratings yet

- SS Corrosion SlidesDocument36 pagesSS Corrosion SlidesNathanianNo ratings yet

- (Dekningsbidrag) : (Inntekter) (Variable Kostnader) (Faste Betalbare Kostnader) (Avskrivninger)Document5 pages(Dekningsbidrag) : (Inntekter) (Variable Kostnader) (Faste Betalbare Kostnader) (Avskrivninger)umarbutt99No ratings yet

- Carlos Soubrier, P.Eng.: Materials Engineer, Materials Performance and Corrosion ControlDocument6 pagesCarlos Soubrier, P.Eng.: Materials Engineer, Materials Performance and Corrosion Controlpravin awalkondeNo ratings yet

- Dwnload Full Database Systems A Practical Approach To Design Implementation and Management 6th Edition Connolly Solutions Manual PDFDocument36 pagesDwnload Full Database Systems A Practical Approach To Design Implementation and Management 6th Edition Connolly Solutions Manual PDFtabetha363100% (16)

- Module 3Document36 pagesModule 3Lorena Pingul50% (2)

- Đề Thi Thử Thptqg Môn Tiếng AnhDocument11 pagesĐề Thi Thử Thptqg Môn Tiếng AnhnguyenngocquynhchiNo ratings yet

- Dissertation Questionnaire Cover Letter ExampleDocument8 pagesDissertation Questionnaire Cover Letter ExamplePayToDoPaperKansasCity100% (1)

- Eternal Distribution BookDocument107 pagesEternal Distribution BookShappan Abd AllhaNo ratings yet

- Work and JobsDocument17 pagesWork and JobsCrows and CrownNo ratings yet

- Chapter 2 Opportunity Seeking, Screening and SeizingDocument73 pagesChapter 2 Opportunity Seeking, Screening and SeizingMjhane Herrera BattungNo ratings yet

- Sous Vide Time and Temperature Guide - ChefStepsDocument9 pagesSous Vide Time and Temperature Guide - ChefStepssalzedofranciscoNo ratings yet

- Lifting Operations Onboard ShipDocument3 pagesLifting Operations Onboard ShipGiorgi KandelakiNo ratings yet

- RxNorm's Drug Interface Terminology Supports InteroperabilityDocument4 pagesRxNorm's Drug Interface Terminology Supports InteroperabilityimomedicalNo ratings yet

- Organizational Resilience Cranfieldresearch ExecutivesummaryDocument12 pagesOrganizational Resilience Cranfieldresearch ExecutivesummaryAhmar HayatNo ratings yet