Professional Documents

Culture Documents

Field Ramba Workover Daily Report

Uploaded by

Bayu Eko Ariesta0 ratings0% found this document useful (0 votes)

13 views2 pagesThe daily rig report summarizes activities from November 26-27, 2020 for Well BN-122. Operations included running and setting a 7" packer, wireline work to install downhole gauges, solvent stimulation, and pulling out the work string. Rain halted operations on the 26th. On the 27th, the work string was pulled and a kill string run in to secure the well. Preparations began to install an ESP pump. The ESP and generator arrived on location. Future plans include BOP changes and starting the ESP.

Original Description:

daily report rig

Original Title

Form laporan

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe daily rig report summarizes activities from November 26-27, 2020 for Well BN-122. Operations included running and setting a 7" packer, wireline work to install downhole gauges, solvent stimulation, and pulling out the work string. Rain halted operations on the 26th. On the 27th, the work string was pulled and a kill string run in to secure the well. Preparations began to install an ESP pump. The ESP and generator arrived on location. Future plans include BOP changes and starting the ESP.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views2 pagesField Ramba Workover Daily Report

Uploaded by

Bayu Eko AriestaThe daily rig report summarizes activities from November 26-27, 2020 for Well BN-122. Operations included running and setting a 7" packer, wireline work to install downhole gauges, solvent stimulation, and pulling out the work string. Rain halted operations on the 26th. On the 27th, the work string was pulled and a kill string run in to secure the well. Preparations began to install an ESP pump. The ESP and generator arrived on location. Future plans include BOP changes and starting the ESP.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

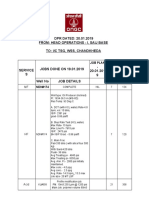

Field Ramba

PERTAMINA EP ASSET 1 FIELD RAMBA

WORK OVER & WELL SERVICE DEPARTEMENT

DAILY REPORT RIG SERVICE

RIG : S/R # 02 JOB DAY : H-5 day

PRESENT STATUS : DATE : 26/11/2020

Loc. Condition : gelap

Well : BN-122

Weather : Hujan

TD :

Open Perforate : EOT :

PBTD : CSG Size :

PKR/RET/RBP

Running :

HOURS RIG OPERATION ACTIVITIES

FROM TO TOTAL

06.00 07.00 Hand over, cek suhu tubuh dan tensi darah.

Pjsm w/topik : lanjut masuk rangkaian 7" packer single grip samapai 1185 m + set

packer dan job wire line masuk SBHP + stimulasi solvent oleh Halliburton

07.00 08.30 Lanjut masuk rangkaian 7" Packer dari kedalaman 575 m sampai ke dalaman

1185.91 m dengan : 66 jts 2.7/8 tbg, Total : 126 jts 2.7/8" tbg.

Set EOT @ 1185.91 m, Set packer @ 1175.59 m w/12000 klbs compress

08.30 09.00 Isi lobang w/13 Bbls AF lobang penuh test packer 300 Psi baik dan bertahan selama 15 menit

Masuk rangkaian 7" packer sambil visual check dan tally semua tbg

V.truck AT 529 isi 70 bbls AF ke dalam mud tank dan hisap 20 bbls crude oil di dalam mud tank.

09.00 11.00 R/U wire line masuk & cabut GC 1.90" sampai @ 1184 m.

Masuk EMR set @ 1184 m dan mulai rendam pkl 10.00 wib, selama 1 jam.

Crew training bersama HSSE coach tentang BHL + BST tentang Life Saving Rules.

11.00 13.30 Cabut rangkaian bertahap EMR dari 1184 m sampai permukaan sesuai program + R/D unit wire

line 100%.

13.30 14.00 Pjsm bersama PE + Crew Hallco dan crew rig dengan topik prosedur job stimulasi solvent

14.00 15.00 Pasang line Hallco ke string + test line Hallco low 500 psi dan High 4000 psi, selama 10 menit -

baik.

- Mix KCL brien w/ 60 bbls ( KCL + fresh water + losurf 259)

- Fill up string 2.3 bbls KCL brine, total 18.8 bbls KCL brine

Injectivity test :

0.6 bpm tekanan 50 psi

0.7 bpm tekanan 100 psi

1 bpm tekanan 200 psi

1.5 bpm tekanan 360 psi

2 bpm tekanan 700 psi - 1040 psi.

15.00 18.00 Mix and pump 36 bbl Xylen Solvent (Xylen + solvent + Diesel + musol)

0.6 bpm - 0.8 bpm, 8 psi - 497 psi.

Displace well dgn 31 bbls KCL brine :

1 bpm - 1.3 bpm, 529 psi turun 465 psi.

18.00 19.00 Soaking Solvent selama 1 jam. THP dan CHP 0 psi. Berlanjut.

18.00 19.00 Hand over , cek suhu tubuh dan tensi darah.

Pjsm w/topik : Cabut rangkaian 7" Packer single grip & soaking solvent.

19.00 20.30 Check + ablas tekanan line Hallco - ok. R/D line Hallco & aksesoris.

Unset Packer. Ok.Observasi sumur 15 menit. Well static.

20.30 22.30 R/U Circulating head, pompa 21 bbls AF, sumur return.

Lanjut sirkulasi 1 cycle , pressure 20 - 30 psi , 1.6 bpm, Partial losses 77 bbls. Total losses 107 bbl

22.30 23.00 Flow check visual sumur 30 menit. aman.

23.00 24.00 Turun hujan deras di lokasi BN.122. (Unsafe condition).

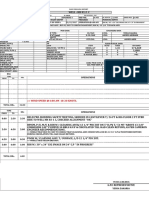

Status Pagi , 27/11/2020

00.00 04.30 Cabut rangkaian 7" Packer single grip secara berlahan & isi lobang sumur dengan AF setiap cabut

10 jts tbg , dari kedalaman 1185.91 m sampai ke permukaan, dengan 125 jts 2.⅞" tbg + 7" Packer

single grip + 1 jts 2.⅞" tbg tail pipe. Total : 126 jts 2.⅞" tbg.

04.30 05.00 Masuk rangkaian kill string 5jt, 2-7/8" tbg dan R/U circulating head. amankan

sumur.

05.00 06.00 Persiapan Masuk rangkaian pompa ESP Novomet.

Note :

- Peralatan ESP Novomet tiba di lokasi BN-122, jam 04.00 dini hari, Move out 80%, Genset

estimasi tiba di BN-122 jam 22.00 wib.

Next Plant

- Bongkar 7-1/16" x 3K double ram BOP + Pasang 7-1/16" x 3K Annular BOP

- Masuk rangkaian pompa ESP. Set Pump intake @1161 m , Set EOT @1176.65 m.

- Bongkar 7-1/16" x 3K Annular BOP + Pasang ESP flange & wellhead

- Pengukuran Static Fluid Level.

- Start up ESP dengan frekuensi 40 Hz.

- Monitor well produksi. & assesment sumur berikut nya.

- Rig Move

REPORT BY : : Pengawas M.Edi Agus/Feisal VERIFIED BY :

: Toolpusher Supriyansyah/Jhon k M. AJI WIBOWO ( Assistant Manager )

: DRILLER Gerry Aprinhu/Juliono KUKUH GM (Supv )

OPR COST : TOTAL OPR COST : TO DAY

RIG COST : TOTAL OPR COST : YESTERDAY

AFE / COST CENTRE : TOTAL ACCUM COST : TO DATE

You might also like

- ASTM C 219 Standard Terminology Relating To Hydraulic CementDocument3 pagesASTM C 219 Standard Terminology Relating To Hydraulic CementRyan LasacaNo ratings yet

- Chikyu DAILY MORNING REPORT Provides Drilling DetailsDocument4 pagesChikyu DAILY MORNING REPORT Provides Drilling DetailsInes NaserNo ratings yet

- Dwor#14 - Cosl-225 - Titi A-16 - 11 Jan 2024Document1 pageDwor#14 - Cosl-225 - Titi A-16 - 11 Jan 2024Surya FandanaNo ratings yet

- PDO Wells Operations Summary ReportDocument30 pagesPDO Wells Operations Summary ReportShraddhanand MoreNo ratings yet

- DPR DATED: 20.01.2019 From: Head Operations - I, Saij Base To: I/C TSG, WSS, ChandkhedaDocument13 pagesDPR DATED: 20.01.2019 From: Head Operations - I, Saij Base To: I/C TSG, WSS, ChandkhedaCTU DPRNo ratings yet

- Daily Drilling Operations SummaryDocument3 pagesDaily Drilling Operations SummaryDheeraj KapoorNo ratings yet

- DOR ABH 033 04 210 Rig2 20190628Document4 pagesDOR ABH 033 04 210 Rig2 20190628Dheeraj KapoorNo ratings yet

- Mom 509Document7 pagesMom 509Julinus PrioNo ratings yet

- GAME PLAN RTTS RBP Wellhead WorkDocument1 pageGAME PLAN RTTS RBP Wellhead WorkMohamed AbozeimaNo ratings yet

- DAILY DRILLING REPORT FOR WELL HH 83/1 BDocument1 pageDAILY DRILLING REPORT FOR WELL HH 83/1 BMahmoud Ahmed Ali AbdelrazikNo ratings yet

- DSQ PD HistoryDocument22 pagesDSQ PD Historyeng20072007No ratings yet

- Pooh W/ Fb-2 Plug Finish Productio Line Connection, Start Esp & Put The Well On ProductionDocument1 pagePooh W/ Fb-2 Plug Finish Productio Line Connection, Start Esp & Put The Well On ProductionMahmoud Ahmed Ali AbdelrazikNo ratings yet

- DAILY DRILLING REPORT FOR WELL HH 83/1 ADocument1 pageDAILY DRILLING REPORT FOR WELL HH 83/1 AMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Mdata Miano-26: 660256622Document14 pagesMdata Miano-26: 660256622Yaqoob IbrahimNo ratings yet

- DDR WellsDocument15 pagesDDR WellsShraddhanand MoreNo ratings yet

- Casing Data Bit Data Mud Data: Hours RemarksDocument8 pagesCasing Data Bit Data Mud Data: Hours RemarksdiegoNo ratings yet

- SLB COSL 223 Morning Report 12-Jul-2020) REV.01Document2 pagesSLB COSL 223 Morning Report 12-Jul-2020) REV.01Jusman Van SitohangNo ratings yet

- Activity: AZIM (Deg)Document1 pageActivity: AZIM (Deg)Naisee KilLNo ratings yet

- Logbook Ctu 07 (Arif SB 2023) - 1Document240 pagesLogbook Ctu 07 (Arif SB 2023) - 1Arief Setia budiNo ratings yet

- SLB COSL 223 Morning Report 11-Jul-2020) REV.01Document2 pagesSLB COSL 223 Morning Report 11-Jul-2020) REV.01Jusman Van Sitohang100% (1)

- Cepu Fract. ProjectDocument1 pageCepu Fract. Projectsari susantiNo ratings yet

- Laporan Operasional BM JS 04-01-2024 Shift 1DDocument2 pagesLaporan Operasional BM JS 04-01-2024 Shift 1DLuthfi PrayogiNo ratings yet

- Daily Morning Report No.92 (C0002N) - 131214Document1 pageDaily Morning Report No.92 (C0002N) - 131214Ines NaserNo ratings yet

- Boiler Observations & RecommendationsDocument16 pagesBoiler Observations & RecommendationsParthosarothy K MukherjiNo ratings yet

- Evening Report 17-2-2018Document1 pageEvening Report 17-2-2018Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- 2022 - Feb 22 - Darlipalli U2 TG Barring Gear Stalling and High Vibration IssueDocument27 pages2022 - Feb 22 - Darlipalli U2 TG Barring Gear Stalling and High Vibration Issueanil peralaNo ratings yet

- H-6DEL - Report - DOF - 2017.07.21 Coriendo TR de 20Document9 pagesH-6DEL - Report - DOF - 2017.07.21 Coriendo TR de 20PAZCOSL3 MEJIANo ratings yet

- Daily Activity Report EAC-001Document14 pagesDaily Activity Report EAC-001Ibrahim AjiNo ratings yet

- Lab Report Plug (3705-3700m) r66 MurmanskyaDocument1 pageLab Report Plug (3705-3700m) r66 MurmanskyaThế Dũng NguyễnNo ratings yet

- Lab Report Plug (3705-3700m) r66 MurmanskyaDocument1 pageLab Report Plug (3705-3700m) r66 MurmanskyaThế Dũng NguyễnNo ratings yet

- Well ControlDocument2 pagesWell ControlAli Ahmed PathanNo ratings yet

- HOOGLY MATERIAL STATUSDocument5 pagesHOOGLY MATERIAL STATUSPravin KumarNo ratings yet

- HSD-4X DDR Oct 03 18Document2 pagesHSD-4X DDR Oct 03 18Hưng Lê TrungNo ratings yet

- DAILY DRILLING REPORT FOR WELL HH 83/1 CDocument1 pageDAILY DRILLING REPORT FOR WELL HH 83/1 CMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Crushing Circuit Residence TimesDocument6 pagesCrushing Circuit Residence TimesJulio Wacas BangguiyaoNo ratings yet

- Petronas Carigali Sdn. BHD.: Objective Programme (Routine Wireline)Document2 pagesPetronas Carigali Sdn. BHD.: Objective Programme (Routine Wireline)Rick Raynold ClaudiusNo ratings yet

- End of Well Summary of Karjisan-04: ObjectiveDocument3 pagesEnd of Well Summary of Karjisan-04: ObjectiveSahil BalistiNo ratings yet

- InductionDocument13 pagesInductionVigneshNo ratings yet

- 112 DMR ARK-19 DSTDocument2 pages112 DMR ARK-19 DSTB fattahiNo ratings yet

- RAB PE20Tx1set Amo, 60HP (1) Cetakan 50kg (400 Balok 16 Can) + Ice Storage 50TDocument3 pagesRAB PE20Tx1set Amo, 60HP (1) Cetakan 50kg (400 Balok 16 Can) + Ice Storage 50THidayat SyamsiNo ratings yet

- 10 Dec 2019Document2 pages10 Dec 2019Chukwuma Emmanuel OnwufujuNo ratings yet

- Annex 6.2. BRS-19 Bis - Operations Summary Report (Open Wells)Document63 pagesAnnex 6.2. BRS-19 Bis - Operations Summary Report (Open Wells)mann_974No ratings yet

- Evening Report 9-1-2018Document1 pageEvening Report 9-1-2018Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- Exercise 4 AnswersDocument12 pagesExercise 4 AnswersadeelsnNo ratings yet

- Py51a06h DDR 19 17mar05Document2 pagesPy51a06h DDR 19 17mar05Cleevh MabialaNo ratings yet

- PT Pertamina EP Drilling & Workover Daily ReportDocument6 pagesPT Pertamina EP Drilling & Workover Daily ReportArreva7474No ratings yet

- EP Wells Operations Summary ReportDocument13 pagesEP Wells Operations Summary ReportShraddhanand MoreNo ratings yet

- A-21 Field Copy ReportDocument15 pagesA-21 Field Copy Reportحسن الجازويNo ratings yet

- Pru - Oseil-29 - 40 Aft - March 19, 2020Document2 pagesPru - Oseil-29 - 40 Aft - March 19, 2020Abang GaffiNo ratings yet

- EP Wells Operations Summary ReportDocument7 pagesEP Wells Operations Summary ReportShraddhanand MoreNo ratings yet

- QT No.0817 FRANMAN (UWS)Document1 pageQT No.0817 FRANMAN (UWS)Idwan IskandarNo ratings yet

- Shutdown Report July 10Document21 pagesShutdown Report July 10sakthiwab4No ratings yet

- Electrical Safety Pre-Survey QuestionnaireDocument2 pagesElectrical Safety Pre-Survey QuestionnaireAbdul WahabNo ratings yet

- Well Control Exercise 4Document12 pagesWell Control Exercise 4adeelsnNo ratings yet

- NBR-575 Operation Game Plan HRDH-1201 Running 4 '' Completion Nov 18, 2014 To: RM/NTP, DR, Ad, Me, Baker Eng, Franks. Al-Mansori S/LDocument2 pagesNBR-575 Operation Game Plan HRDH-1201 Running 4 '' Completion Nov 18, 2014 To: RM/NTP, DR, Ad, Me, Baker Eng, Franks. Al-Mansori S/LMohamed Abozeima100% (1)

- Py51a06h DDR 04 02mar05Document3 pagesPy51a06h DDR 04 02mar05Cleevh MabialaNo ratings yet

- Lean Water PeriodDocument15 pagesLean Water PeriodChirag SoratekarNo ratings yet

- Monthly Bankers Report Oct-19Document12 pagesMonthly Bankers Report Oct-19biranchi satapathyNo ratings yet

- Invoice Acs # 18 TDH Dan Rof - Maret - 2021Document101 pagesInvoice Acs # 18 TDH Dan Rof - Maret - 2021Rafi RaziqNo ratings yet

- NTPC/SMPP Operation Department REV:0.00 Area-Tg TDBFP Isolation & Normalization Procedure UNIT-1/2 Date: 27.07.2010Document5 pagesNTPC/SMPP Operation Department REV:0.00 Area-Tg TDBFP Isolation & Normalization Procedure UNIT-1/2 Date: 27.07.2010Balaji AllupatiNo ratings yet

- Redox SystemDocument21 pagesRedox SystemDesy KriswintariNo ratings yet

- Experimental 2 Cylinder Horizontal Valveless Steam Engine. (B 30Mmxs 30Mm) General Arrangement, Notes and Bill of MaterialDocument3 pagesExperimental 2 Cylinder Horizontal Valveless Steam Engine. (B 30Mmxs 30Mm) General Arrangement, Notes and Bill of MaterialOscar OsornoNo ratings yet

- United States Patent: (10) Patent N0.: Anciaux Et Al. (45) Date of PatentDocument8 pagesUnited States Patent: (10) Patent N0.: Anciaux Et Al. (45) Date of PatentHabib Maulana YasmintoNo ratings yet

- Unit 6: Ionic & Covalent Compounds, Lewis Structures: Chapter 5 & 6Document38 pagesUnit 6: Ionic & Covalent Compounds, Lewis Structures: Chapter 5 & 6chanNo ratings yet

- Sustainable Alternative For Food Packaging: Chitosan Biopolymer-A ReviewDocument11 pagesSustainable Alternative For Food Packaging: Chitosan Biopolymer-A ReviewIeqa HaziqahNo ratings yet

- HL Paper3Document23 pagesHL Paper3dilemNo ratings yet

- Surfactant Precipitation in Aqueous Solutions Containing MixturesDocument9 pagesSurfactant Precipitation in Aqueous Solutions Containing MixturesSanjay singhNo ratings yet

- NGL RECOVERY PROCESSESDocument5 pagesNGL RECOVERY PROCESSESsatishchemengNo ratings yet

- Effects of Temperature On Enzyme ActivityDocument6 pagesEffects of Temperature On Enzyme Activityapi-340424437No ratings yet

- ColaLubes - General OverviewDocument3 pagesColaLubes - General OverviewmndmattNo ratings yet

- Viscosity of Polyvinyl Alcohol SolutionsDocument6 pagesViscosity of Polyvinyl Alcohol SolutionsidownloadbooksforstuNo ratings yet

- Proper Fluid Selection Maintenance For Heat Transfer TNTCFLUIDS PDFDocument12 pagesProper Fluid Selection Maintenance For Heat Transfer TNTCFLUIDS PDFAnonymous bHh1L1No ratings yet

- Environmental studies on microbial degradation of oil hydrocarbonsDocument18 pagesEnvironmental studies on microbial degradation of oil hydrocarbonsAgung Raden MangkubumiNo ratings yet

- Export Pesticide Residue CurrentMRLDocument24 pagesExport Pesticide Residue CurrentMRLING.PUICON2981No ratings yet

- Water Sample Testing ProjectDocument35 pagesWater Sample Testing ProjectVishakha PatelNo ratings yet

- Soil Survey Field and USAgriculturalDocument487 pagesSoil Survey Field and USAgriculturalMohamed El BaghdadiNo ratings yet

- GT HER 2023 - ApprovedDocument21 pagesGT HER 2023 - ApprovedAkmanezy AbdullahNo ratings yet

- Fomblin PFPE Lubricants - EN 220535 PDFDocument4 pagesFomblin PFPE Lubricants - EN 220535 PDFHermanNo ratings yet

- Emesol 50/100 Material Safety Data SheetDocument2 pagesEmesol 50/100 Material Safety Data SheetBharat ChatrathNo ratings yet

- Molecular Rearrangements: Pinacol and Baeyer-VilligerDocument22 pagesMolecular Rearrangements: Pinacol and Baeyer-VilligerVipul Newaskar100% (1)

- Removal of CD (II) and PB (II) From Aqueous Solution by Modified Attapulgite ClayDocument15 pagesRemoval of CD (II) and PB (II) From Aqueous Solution by Modified Attapulgite ClaySyarifahNo ratings yet

- Epoxy Composites ApplicationDocument37 pagesEpoxy Composites ApplicationMohammed SalmanNo ratings yet

- 03 Specification PDFDocument8 pages03 Specification PDFSihamaSihamNo ratings yet

- Elingham DiagramDocument3 pagesElingham DiagramAnant MadhavNo ratings yet

- 860 Moldable Polymer GasketingDocument2 pages860 Moldable Polymer GasketingprajanegaraNo ratings yet

- CBQ Carbon and Its CompoundsDocument6 pagesCBQ Carbon and Its CompoundsSairam KrishNo ratings yet

- Characterization of Antioxidants Extracted From Thai Riceberry BranDocument10 pagesCharacterization of Antioxidants Extracted From Thai Riceberry BranYoravika dwiwibanggaNo ratings yet

- ASTM A563 - Portland BoltDocument5 pagesASTM A563 - Portland BoltamrNo ratings yet

- R FR B1Document39 pagesR FR B1risnasilvi13No ratings yet